Method for preparing nano platinum/ruthenium modified titanium dioxide nanotube electrode by utilizing pulse electrodeposition

A pulse electrodeposition, titanium dioxide technology, applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of low current density, hydrogen evolution reaction, etc., achieve improved electrocatalytic performance, high resistance to CO poisoning, and reduce use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

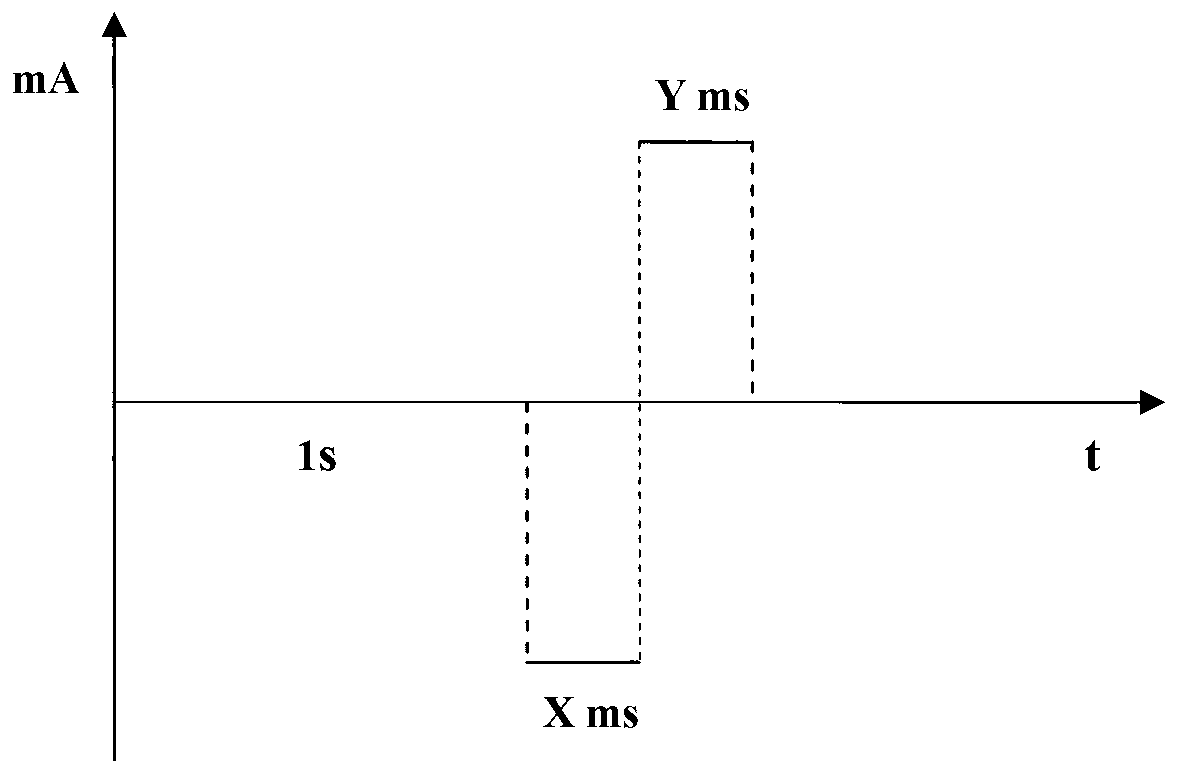

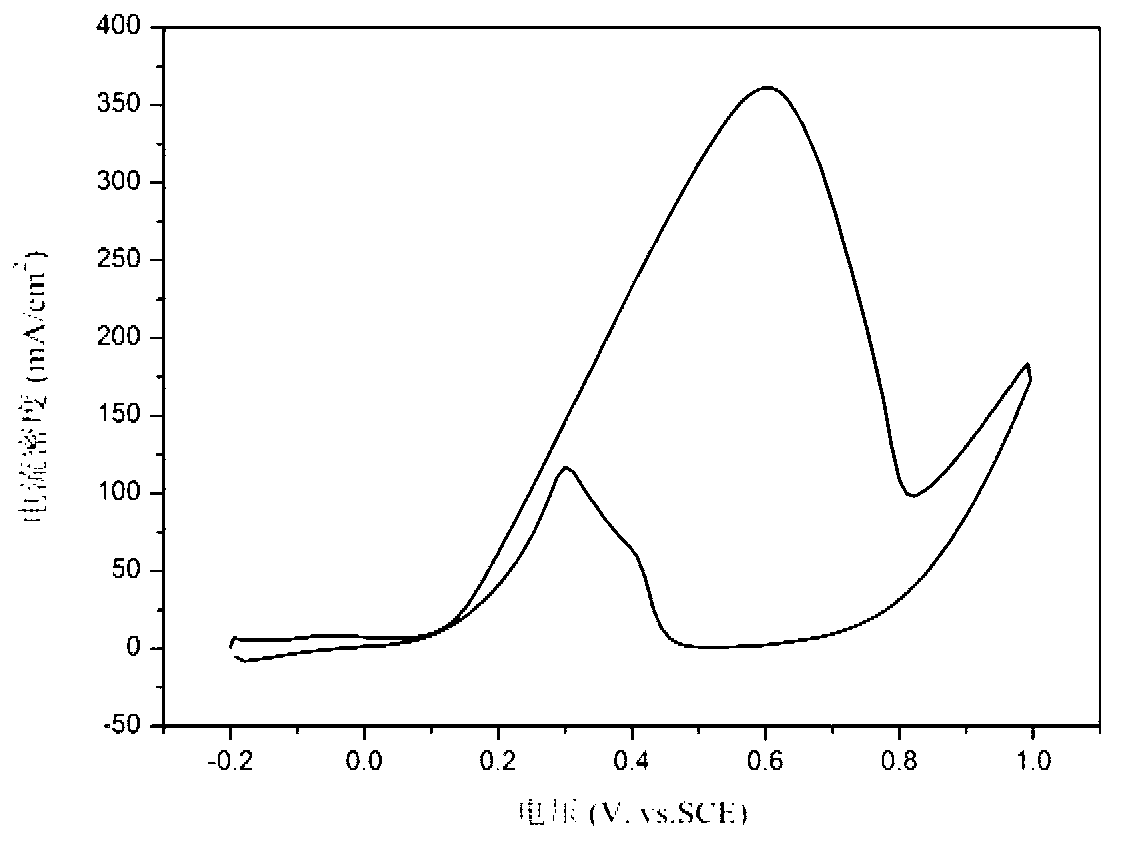

[0027] Example 1. After surface treatment of 1cm*1cm TA1 titanium sheet (surface treatment is to polish the titanium sheet on sandpaper, use acetone ultrasonic cleaning to remove surface oil, then put it into alcohol for ultrasonic cleaning, and then rinse it with distilled water. Make an electrode after drying. The following examples are the same) put in a solution containing 1g / L NH 4 HF 2 , 50g / L H 2 The ethylene glycol solution of O was subjected to anodic oxidation at a constant voltage of 60V and a temperature of 10°C for 1h, with constant mechanical stirring during the period. Prepared TiO 2 The nanotubes were heat treated at 500°C for 2 hours and cooled with the furnace. TiO after high temperature heat treatment 2 The nanotubes were placed in a mixed aqueous solution containing 4.0mM chloroplatinic acid, 4.0mM ruthenium trichloride and 0.5M sulfuric acid, and the cathode and anode pulse current densities were -250mA / cm and 250mA / cm respectively. 2 , the cathode pu...

example 2

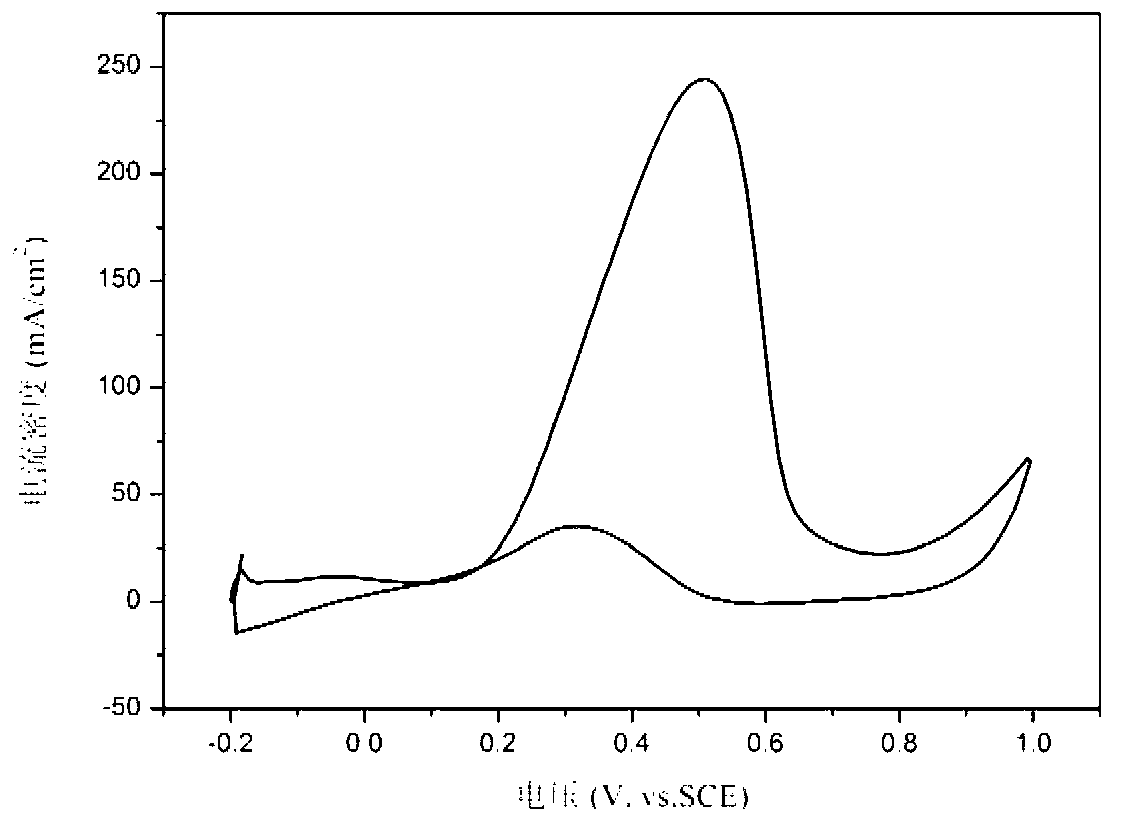

[0028] Example 2. After surface treatment of 1cm*1cm TA1 titanium sheet (surface treatment is to polish the titanium sheet on sandpaper, use acetone ultrasonic cleaning to remove surface oil, then put it in alcohol for ultrasonic cleaning, and then rinse it with distilled water. Make an electrode after drying. The following examples are all the same) put in 3g / L NH 4 HF 2 , 100g / L H 2 The ethylene glycol solution of O was anodized at a constant voltage of 30V and a temperature of 20°C for 4h, with constant mechanical stirring. Prepared TiO 2 The nanotubes were heat treated at 450°C for 4 hours and cooled with the furnace. TiO after high temperature heat treatment 2 The nanotubes were placed in a mixed aqueous solution containing 4.0mM chloroplatinic acid, 1.0mM ruthenium trichloride, and 0.5M sulfuric acid, and the pulse current densities of the cathode and anode were -350mA / cm and 350mA / cm respectively. 2 , the on-time of cathode and anode pulses is 2ms, the off-time is ...

example 3

[0029] Example 3. After surface treatment of 1cm*1cm TA1 titanium sheet (surface treatment is to polish the titanium sheet on sandpaper, use acetone ultrasonic cleaning to remove surface oil, then put it into alcohol for ultrasonic cleaning, and then rinse it with distilled water. Make an electrode after drying. The following examples are all the same) put in 5g / L NH 4 HF 2 , 200g / L H 2 The ethylene glycol solution of O was subjected to anodic oxidation at a constant voltage of 10V and a temperature of 30°C for 6h, with constant mechanical stirring during the period. Prepared TiO 2 The nanotubes were heat treated at 350°C for 4 hours and cooled with the furnace. TiO after high temperature heat treatment 2 The nanotubes were placed in a mixed aqueous solution containing 1.0mM chloroplatinic acid, 0.5mM ruthenium trichloride, and 0.5M sulfuric acid, and the pulse current densities of the cathode and anode were -350mA / cm and 350mA / cm respectively. 2 , the cathode and anode p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com