Method for electrophoretic deposition of rare-earth lanthanum oxide film on aluminium alloy surface

An oxide film, electrophoretic deposition technology, applied in electrophoretic plating, electrolytic coatings, coatings, etc., can solve the problems of long time required, impractical, complex solution formulation, etc., to achieve high stability, simple process, deposition short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

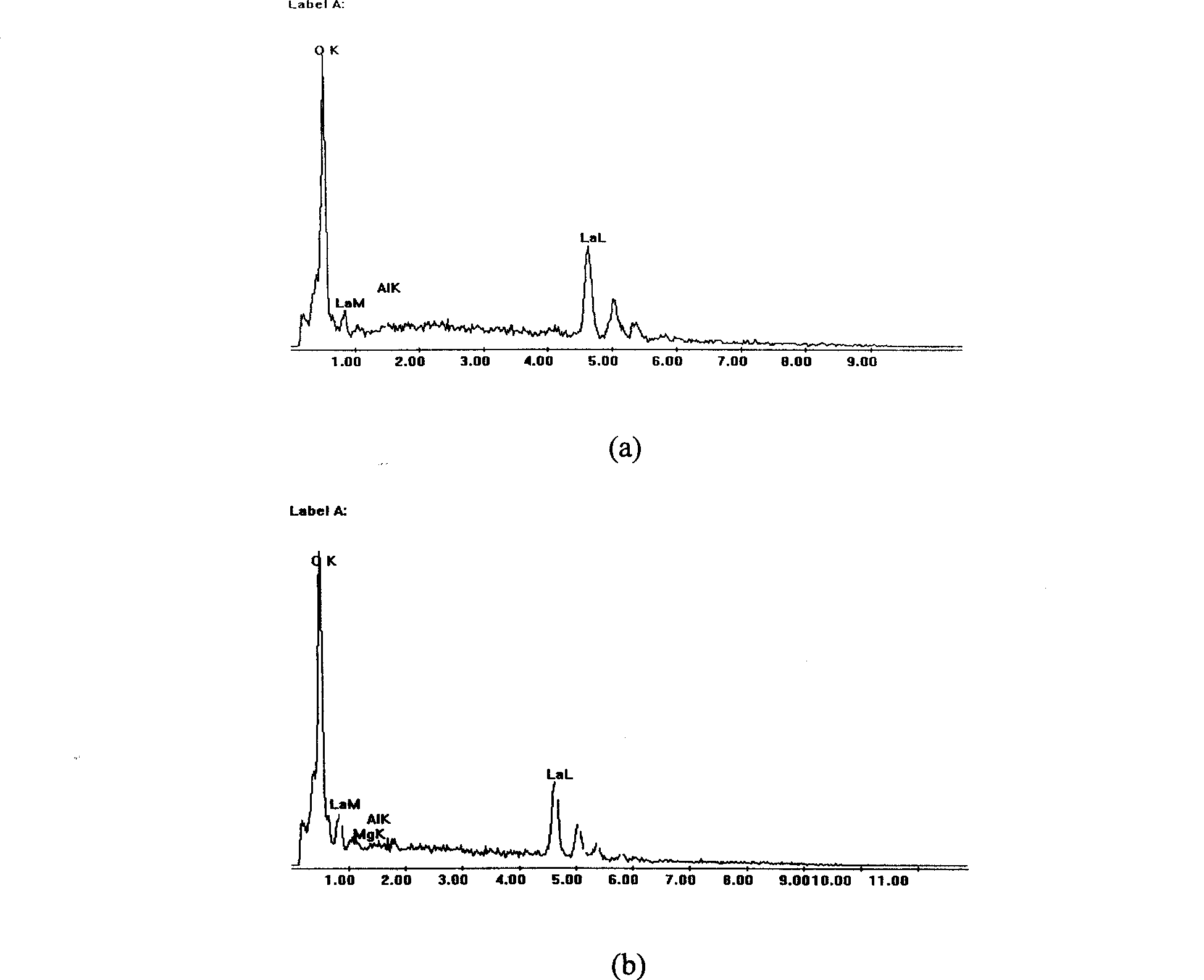

[0018] Example 1 Using optimized process parameters, AA5083 and AA6061 were subjected to surface electrophoretic deposition of La oxide film treatment. AA5083 and AA6061 aluminum alloys were all processed according to the steps described in the summary of the invention, and La(NO 3 ) 3 The concentration of ethanol solution is 0.1mol / L, the applied potential is 12V, and the deposition time is 40s to form a rare earth film. Then, under a nitrogen atmosphere, the temperature is controlled at 280° C., and the La oxide film is formed by baking for 30 minutes. The formed rare earth film has smooth surface, compact structure and good corrosion resistance. A large number of intermetallic compound phases can be observed on the surface of polished AA5083 aluminum alloy and AA6061 aluminum alloy, and these phases are often the preferential corrosion sites.

[0019] attached figure 1 with figure 2 It is a typical surface morphology diagram of AA5083 and AA6061 aluminum alloy samples ...

Embodiment 2

[0021] Embodiment 2 Use other process parameters to carry out surface electrophoretic deposition La oxide film treatment on AA5083 and AA6061. AA5083 and AA6061 aluminum alloys are all processed according to the steps described in the summary of the invention, and La(NO 3 ) 3 The concentration of ethanol solution is 0.1mol / L, the applied potential is 6V, and the deposition time is 120s to form a rare earth film. Then, under a nitrogen atmosphere, the temperature is controlled at 280° C., and the La oxide film is formed by baking for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com