Use of carbon/carbon, carbon/ceramic composite material as brake lining, method and apparatus for making same

A ceramic composite material, brake pad technology, applied in the direction of brakes, brake parts, mechanical equipment, etc., can solve the problems of long densification process and time, affecting the personal safety of vehicles, wasting energy and time, etc., to shorten the construction period, The effect of short process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

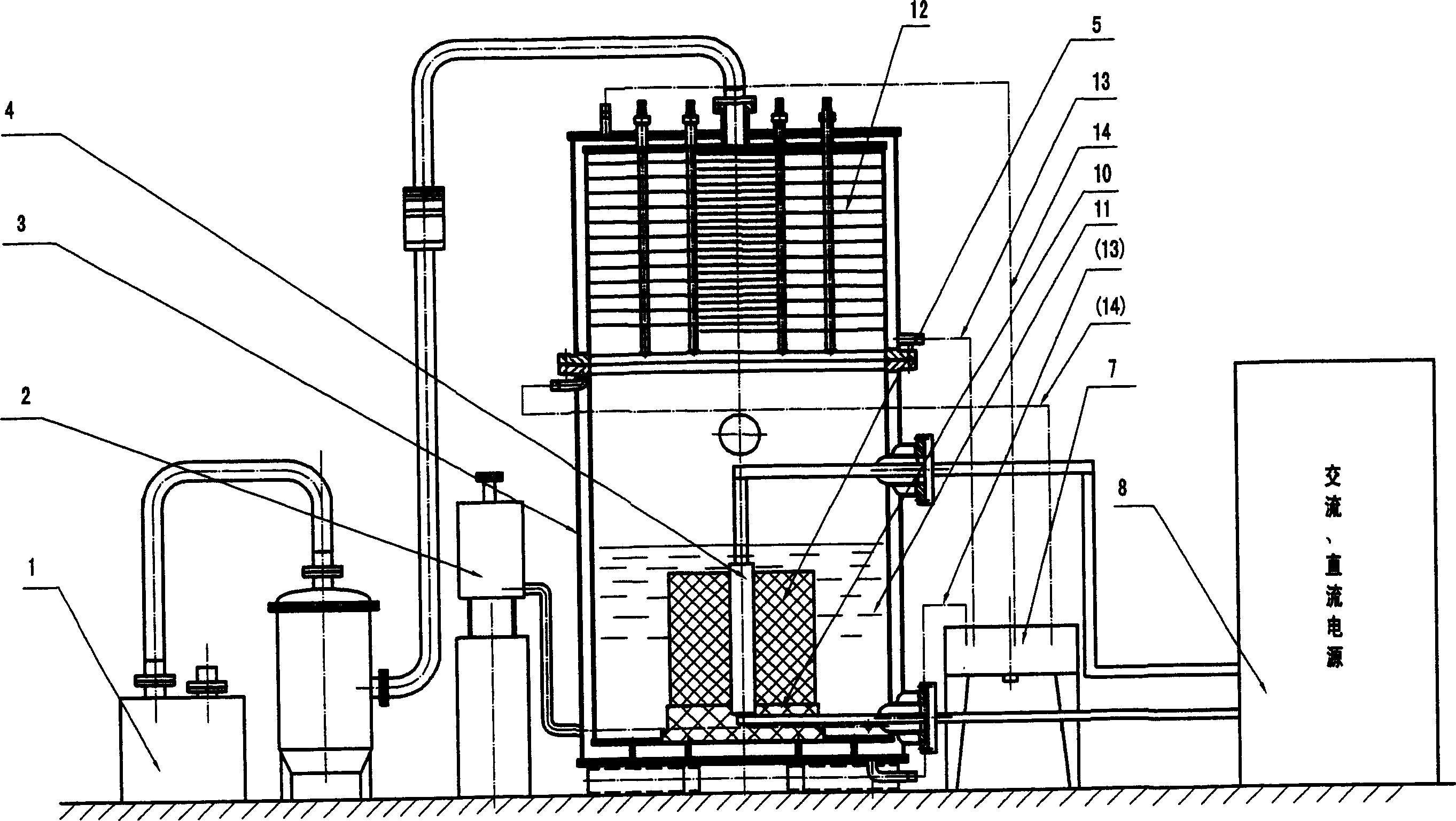

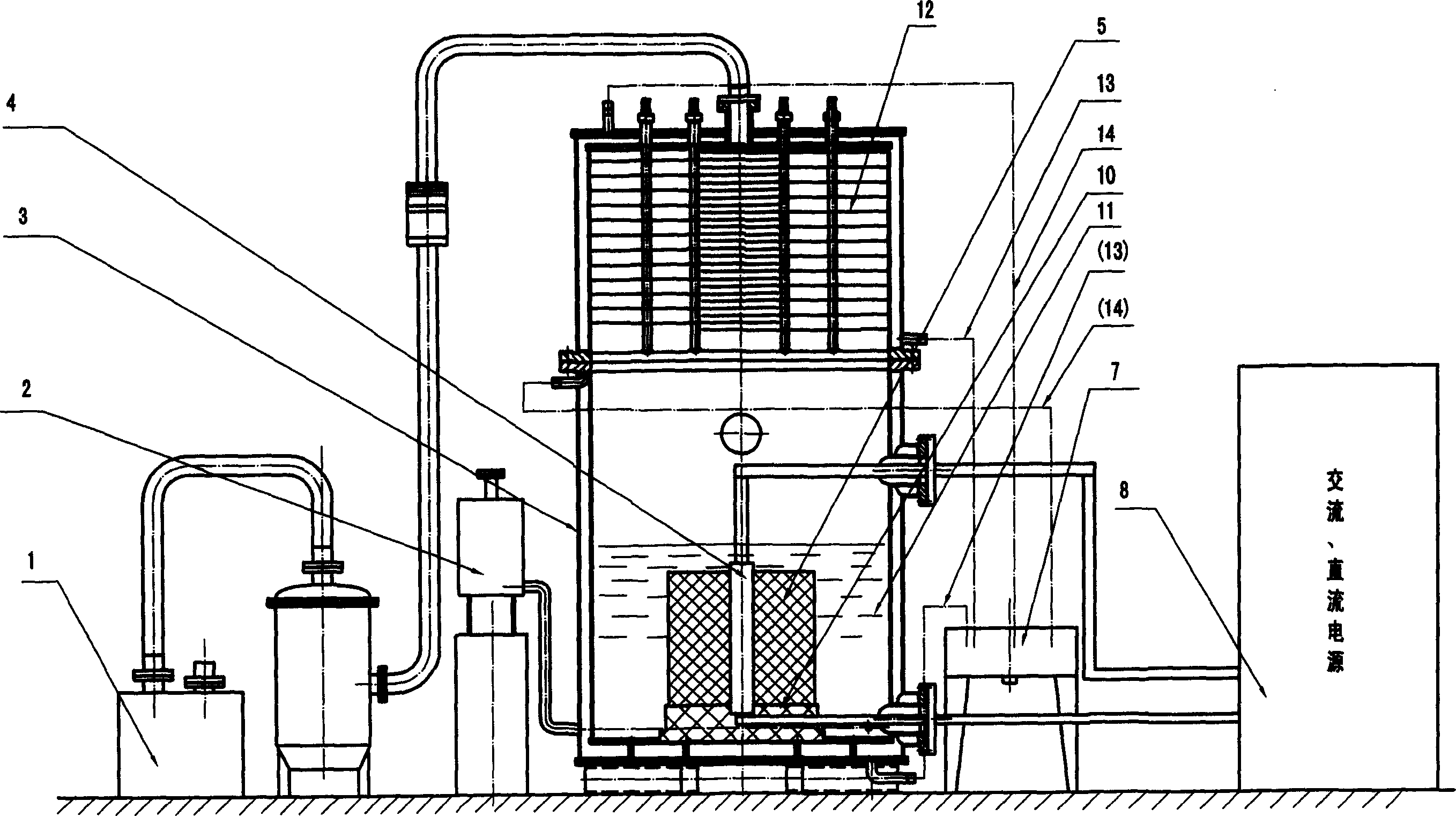

[0032] The attached drawing shows an embodiment of the invention

[0033] The content of the present invention will be further explained below in conjunction with the accompanying drawings

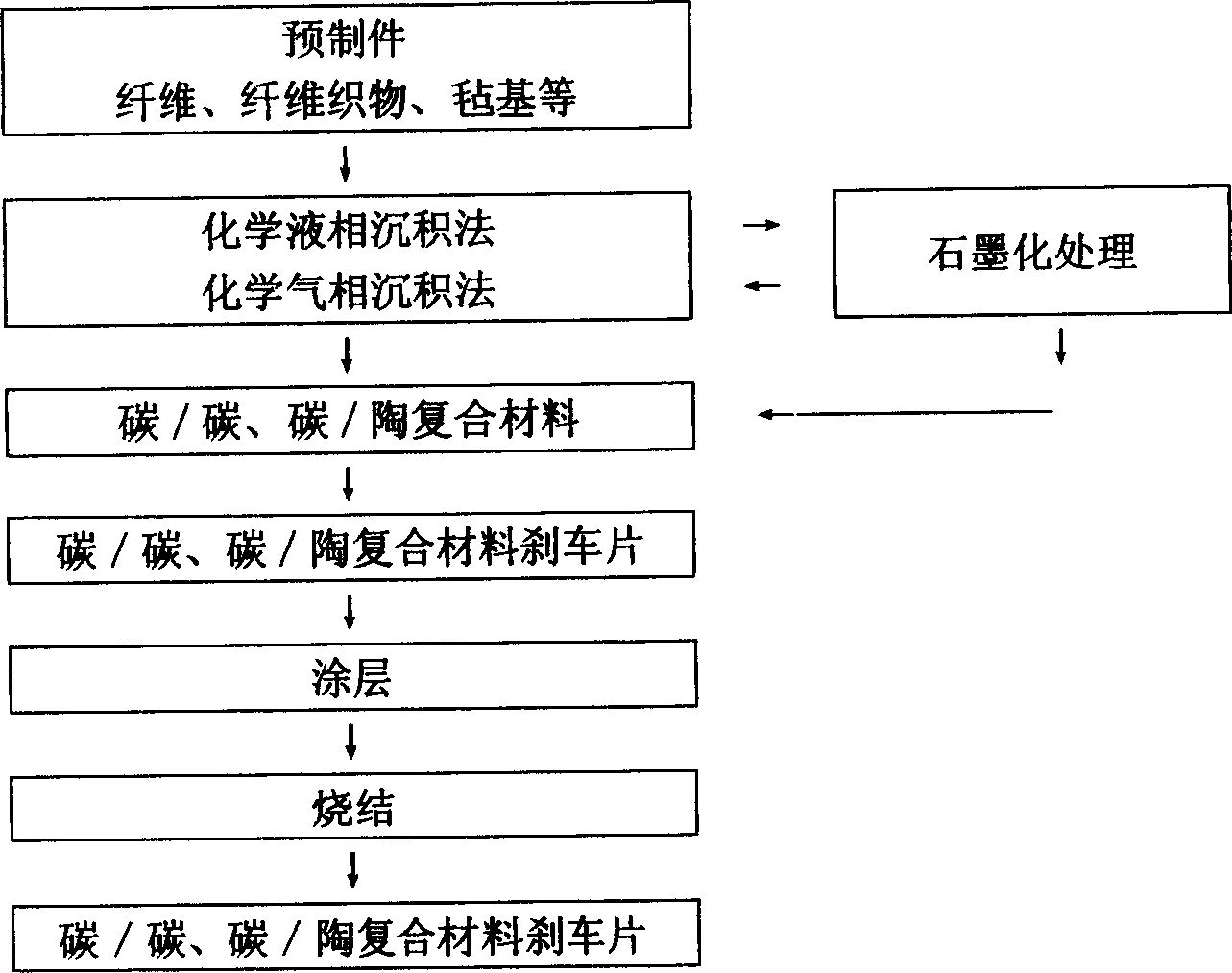

[0034] Reference attached figure 1 , Carbon / carbon and carbon / ceramic composite materials are used as the preparation method of brake pad application, including the following steps in sequence:

[0035] I. Making preforms for brake pads, the preforms mainly include fibers, fiber fabrics, and felt bases;

[0036] II. Put the prepared brake pad preforms into the chemical liquid deposition device for producing composite brake pads for chemical liquid deposition, and the chemical liquid deposition temperature is at least 850°C or above; or chemical vapor phase Deposition method, the chemical vapor deposition temperature is at least 800℃ or above;

[0037] III. Send the deposited preform products to the graphitization furnace for treatment, and the graphitization temperature is at least 2000°C or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com