Method for rapid depositing barium tungstate micron film at low-temperature

A barium tungstate, fast technology, applied in chemical instruments and methods, solution from liquid solvent at room temperature, single crystal growth, etc., can solve the problems of destroying the original shape of the film, affecting the luminescence characteristics of the film, and affecting the application of the film. To achieve the effect of shortening the film deposition time, avoiding a large number of nucleation and precipitation, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

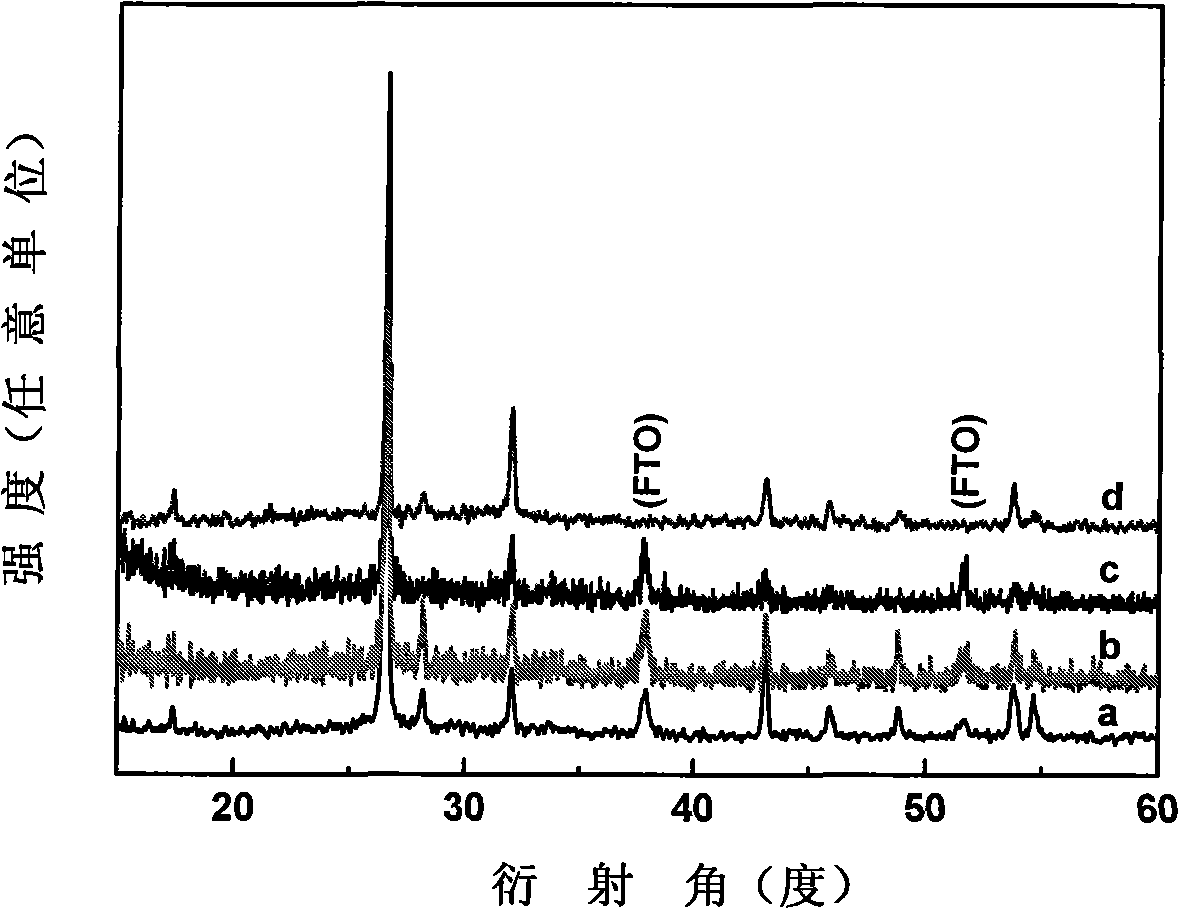

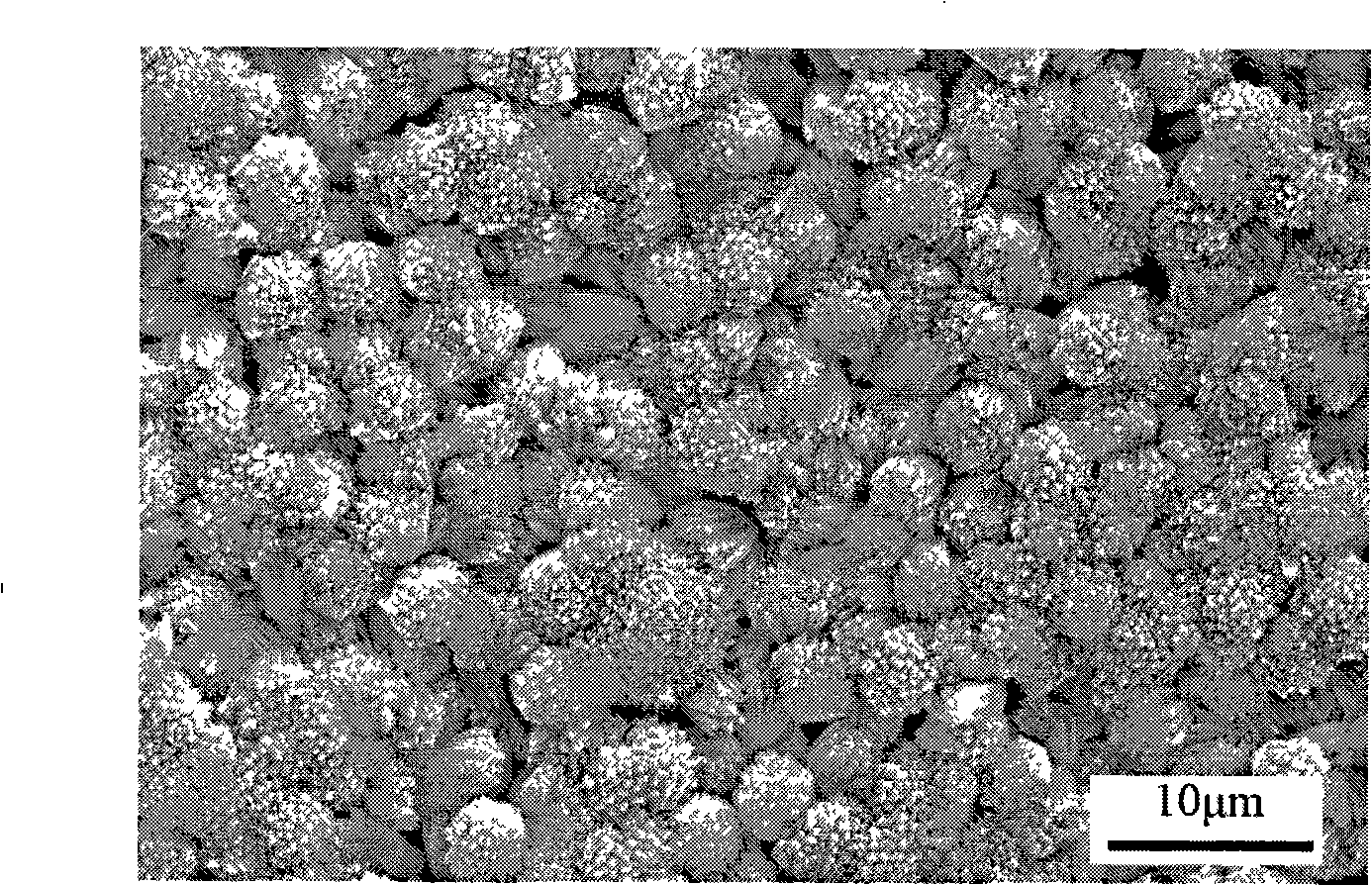

Embodiment 1

[0024] 1) Clean the FTO glass successively with toluene, acetone, and ethanol in an ultrasonic cleaner for 15 minutes, rinse it with deionized water, soak it in ethanol, and store it for later use;

[0025] 2) Dissolve 0.03mol of complexing agent EDTA-2Na in 60ml of deionized water, stir and dissolve, then add 0.03molBa(NO 3 ) 2 ·6H 2 O, keep stirring to obtain clear and transparent solution A1;

[0026] 3) Add 10mol / L NaOH solution and 30% HNO to solution A1 3 solution, adjusting the pH value of solution A1 to 8 to obtain solution B1;

[0027] 4) To 0.03mol Na 2 WO 4 2H 2 Add 20ml of deionized water to O, stir until completely dissolved, then add it to solution B1, add deionized water to 100ml, and stir for 1 minute to obtain a clear and transparent solution C1, and move the C1 solution to a jar;

[0028] 5) Rinse the pre-treated substrate with deionized water, put it into solution C1, and make it float on the surface of the solution, cover the jar, and put it into a h...

Embodiment 2

[0031] 1) Clean the FTO glass successively with toluene, acetone, and ethanol in an ultrasonic cleaner for 15 minutes, rinse it with deionized water, soak it in ethanol and store it for later use;

[0032] 2) Dissolve 0.02mol of complexing agent EDTA-2Na in 60ml of deionized water, stir and dissolve, then add 0.02molBa(NO 3 ) 2 ·6H 2 0, continuous stirring obtains clear and transparent solution A2;

[0033] 3) Add 10mol / L NaOH solution and 30% HNO to solution A2 3 solution, adjust the pH value of solution A2 to 8 to obtain solution B2;

[0034] 4) To 0.02mol Na 2 WO 4 2H 2 Add 20ml of deionized water to O, stir until completely dissolved, then add it to solution B2, add deionized water to 100ml, and stir for 1 minute to obtain a clear and transparent solution C2, and move the C2 solution to a jar;

[0035] 5) Rinse the pre-treated substrate with deionized water, put it into solution C2, and make it float on the surface of the solution, cover the jar, and put it into a h...

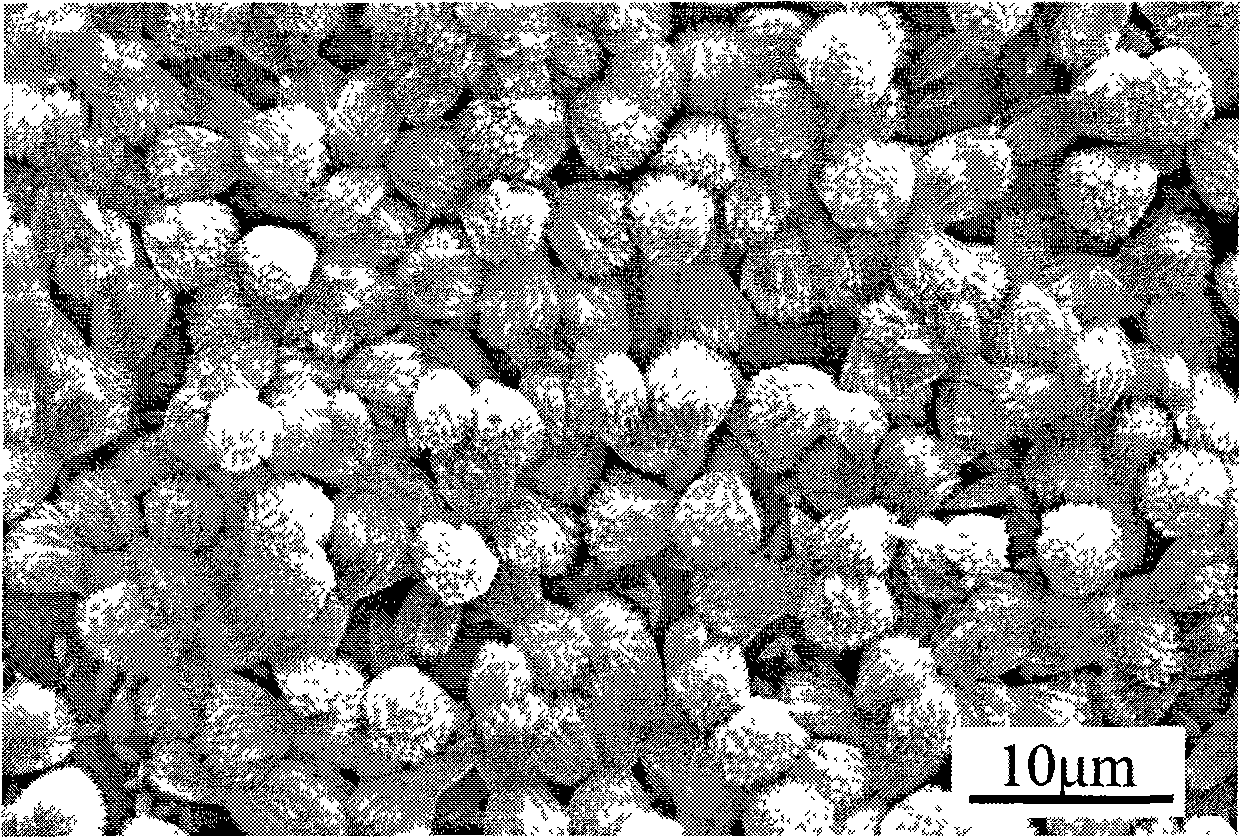

Embodiment 3

[0038]1) Clean the FTO glass successively with toluene, acetone, and ethanol in an ultrasonic cleaner for 15 minutes, rinse it with deionized water, soak it in ethanol, and store it for later use;

[0039] 2) Dissolve 0.01mol of complexing agent EDTA-2Na in 60ml of deionized water, stir and dissolve, then add 0.01molBa(NO 3 ) 2 ·6H 2 O, continuous stirring obtains clear and transparent solution A3;

[0040] 3) Add 10mol / L NaOH solution and 30% HNO to solution A3 3 solution, adjust the pH value of solution A3 to 13 to obtain solution B3;

[0041] 4) To 0.01mol Na 2 WO 4 2H 2 Add 20ml of deionized water to O, stir until completely dissolved, then add it to solution B3, add deionized water to 100ml, and stir for 1 minute to obtain a clear and transparent solution C3, and move the C3 solution to a jar;

[0042] 5) Rinse the pre-treated substrate with deionized water, put it into solution C3, and make it float on the surface of the solution, cover the jar, and put it into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com