Nanometer granule reinforced metal-based amorphous composite material and preparation method thereof

A technology of amorphous composite materials, nanoparticles, applied in the field of science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

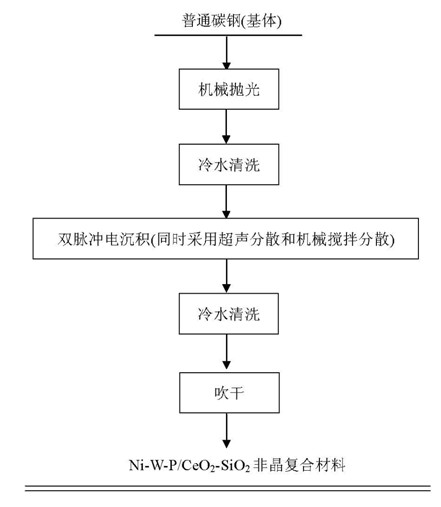

[0031] Example 1: see figure 1 , the specific preparation steps of the preparation method of the present nanoparticle-reinforced metal matrix amorphous composite material are as follows:

[0032] (1) Use the electrolytic nickel plate as the anode material of the electrodeposition process, clean it with water, then immerse it in the electrolyte, and connect it with the anode wire of the double pulse power supply;

[0033] (2) Ordinary carbon steel is used as the cathode (substrate) material of the electrodeposition process, which is mechanically polished and cleaned with water, then immersed in the electrolyte, and connected with the cathode wire of the double pulse power supply.

[0034] (3) Turn on the ultrasonic and mechanical stirring and dispersing device and the double-pulse power supply, electrodeposit 1.5 under the double-pulse parameters, take it out, clean it with water and dry it, and get Ni-W-P / CeO on the surface of ordinary carbon steel 2 -SiO 2 Amorphous comp...

Embodiment 2

[0039] Example 2: see figure 1 , the specific preparation steps of the preparation method of the present nanoparticle-reinforced metal matrix amorphous composite material are as follows:

[0040] (1) Use the electrolytic nickel plate as the anode material of the electrodeposition process, clean it with water, then immerse it in the electrolyte, and connect it with the anode wire of the double pulse power supply.

[0041] (2) Ordinary carbon steel is used as the cathode material of the electrodeposition process, which is mechanically polished and cleaned with water, then immersed in the electrolyte, and connected with the cathode wire of the double pulse power supply.

[0042] (3) Turn on the ultrasonic and mechanical stirring and dispersing device and the double-pulse power supply, electrodeposit for 3 hours under the double-pulse parameters, take it out, clean it with cold water and dry it, and get Ni-W-P / CeO on the surface of ordinary carbon steel 2 -SiO 2 Amorphous com...

Embodiment 3

[0047] Example 3: see figure 1 , the specific preparation steps of the preparation method of the present nanoparticle-reinforced metal matrix amorphous composite material are as follows:

[0048] (1) Use the electrolytic nickel plate as the anode material of the electrodeposition process, clean it with water, then immerse it in the electrolyte, and connect it with the anode wire of the double pulse power supply.

[0049] (2) Ordinary carbon steel is used as the cathode material of the electrodeposition process, which is mechanically polished and cleaned with water, then immersed in the electrolyte, and connected with the cathode wire of the double pulse power supply.

[0050] (3) Turn on the ultrasonic and mechanical stirring and dispersing device and the double-pulse power supply, electrodeposit for 6 hours under the double-pulse parameters, take it out, clean it with cold water and dry it, and get Ni-W-P / CeO on the surface of ordinary carbon steel 2 -SiO 2 Amorphous com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com