Zr-Cu-based amorphous alloy compound electrode material and preparation method thereof

A composite electrode and amorphous alloy technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of difficult control of composite electrode reaction parameters, inability to observe the deposition process, and long hydrothermal method time, etc., to achieve Electrochemical deposition is convenient, the synthesis path is optimized, and the effect of heating is not required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

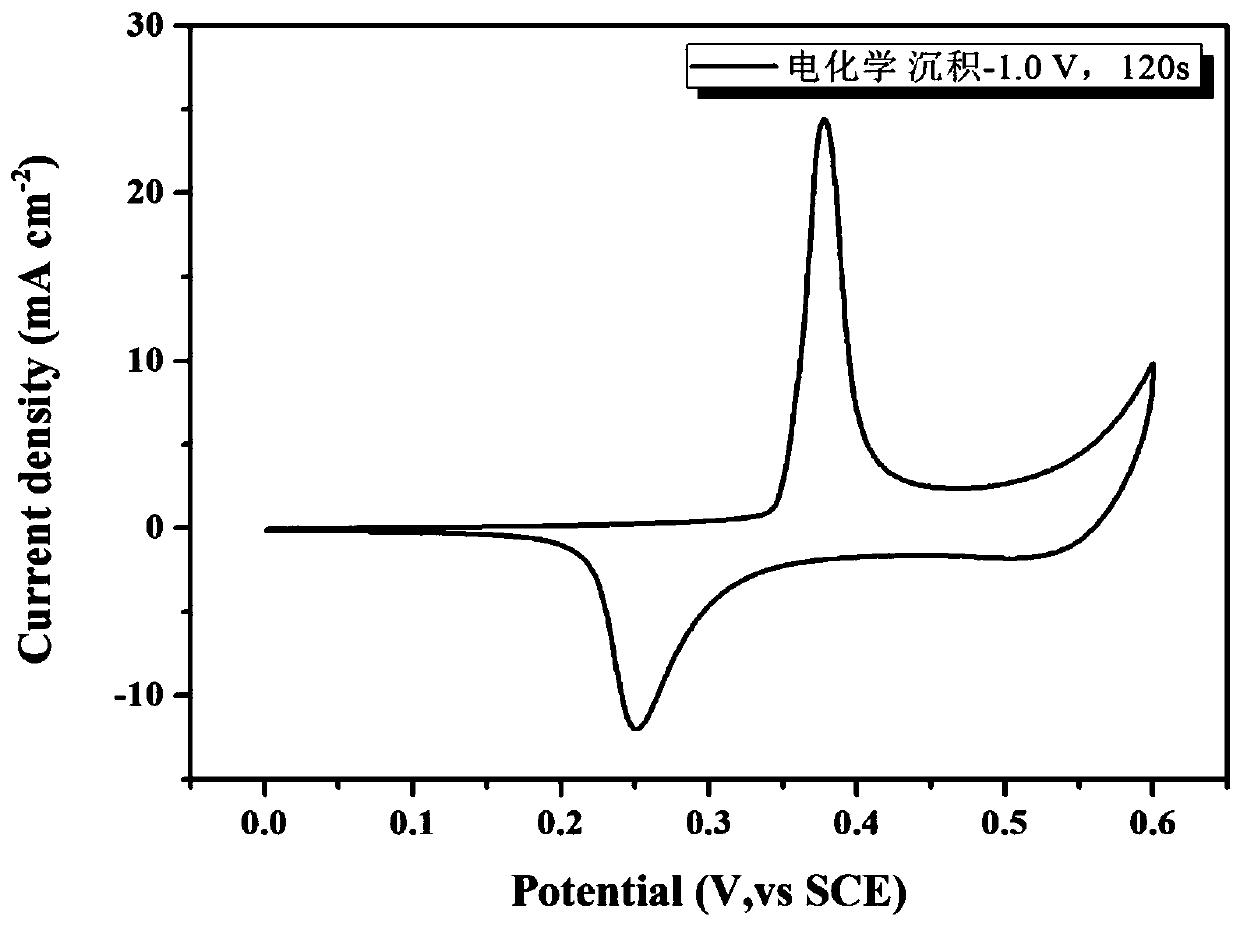

Embodiment 1

[0037] The zirconium rods and copper rods with a purity of 99.99% are polished off the surface oxide layer and cleaned with ethanol ultrasonically, according to the alloy composition Zr 50 Cu 50 The atomic ratio of Zr element and Cu element (Zr: 50at.%, Cu: 50at.%) accurately weighed a total of about 10g, put it into a vacuum non-consumable arc melting furnace, and melt it in an argon atmosphere , the arc temperature of each smelting is about 2500 ℃, and the smelting time is 5 minutes, and the next smelting will be carried out after the furnace is cooled and turned over. Melting 5 times until the alloy is evenly mixed to obtain a master alloy ingot.

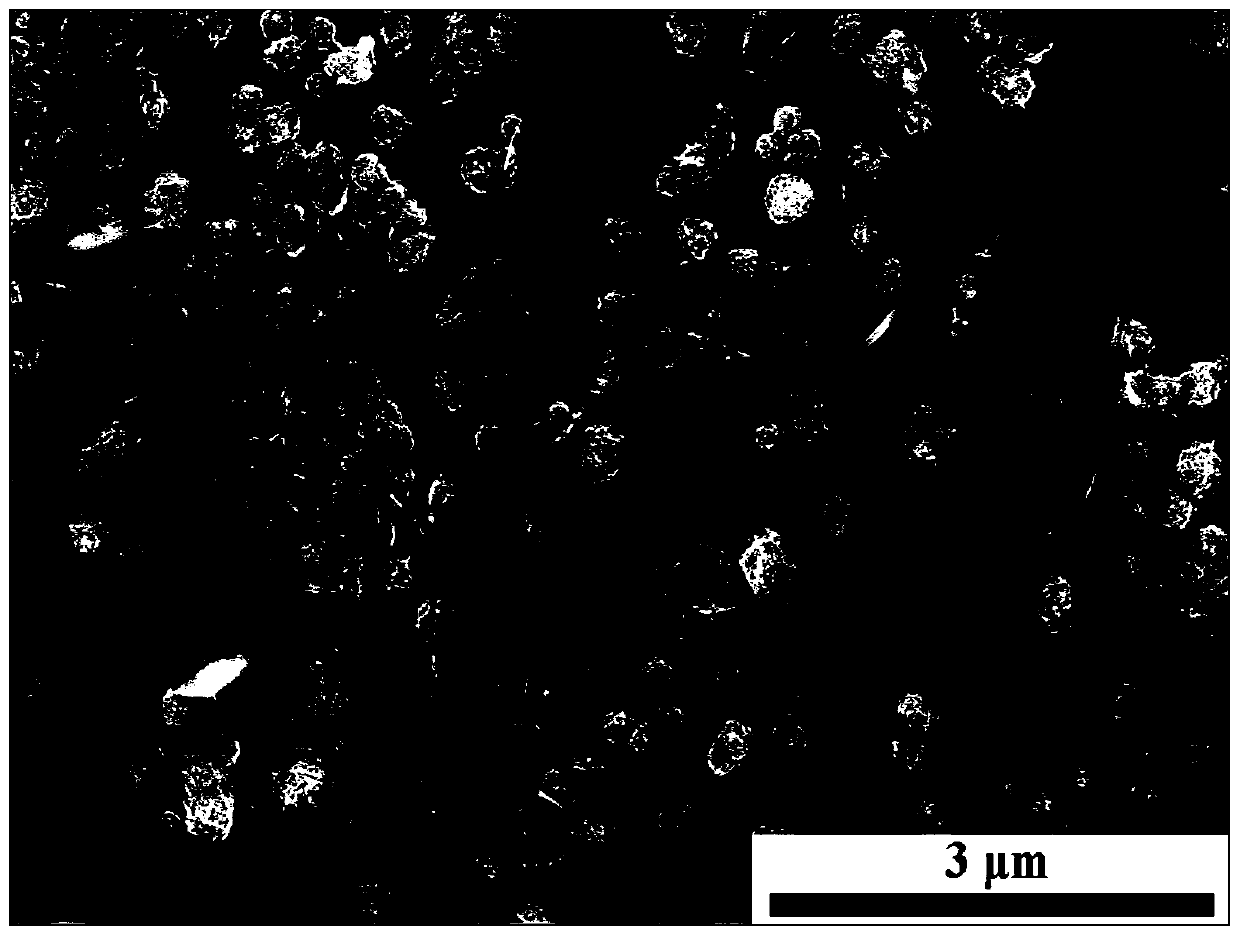

[0038] Take about 3g of the master alloy and place it in a quartz tube with an opening of about 1mm at the bottom, and pump a high vacuum to 3×10 in a quenching strip machine. -3 Argon is filled after Pa, and the master alloy is melted by induction heating (induction current 20A) in an argon atmosphere, and the melt is sprayed ...

Embodiment 2

[0049] The preparation of nanoporous copper is the same as in Example 1, except that the electrochemical deposition time is changed to 60s to prepare the nickel hydroxide / nanoporous copper composite material, and other steps are the same as in Example 1.

[0050] The specific capacitance of the composite supercapacitor prepared in this example is 450.4 F / g.

Embodiment 3

[0052] The preparation of nanoporous copper is the same as in Example 1, except that the electrochemical deposition time is changed to 90s to prepare the nickel hydroxide / nanoporous copper composite material, and the rest of the steps are the same as in Example 1.

[0053] The specific capacitance of the composite supercapacitor prepared in this example is 584.1 F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com