Vertical type carbonization device capable of automatically cleaning tar for carbon fiber production

A technology of automatic removal and carbonization device, applied in the direction of chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of incomplete protection of products, affecting normal production, and burning and hardening strength of carbon fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

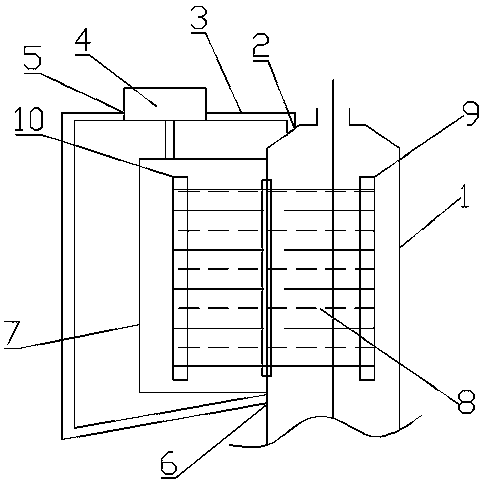

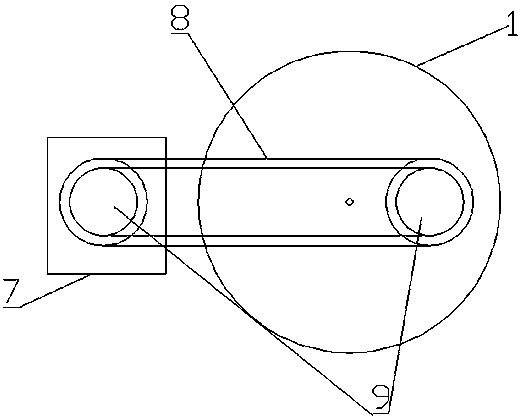

[0011] Vertical carbonization device for automatic removal of tar for carbon fiber production. It heats the tar gas outlet 2 set on the upper part of the inner chamber 1, and is connected to one end of the gas tar recovery pipeline 3 in a through-type connection. The other end of the gas recovery pipeline 3 is connected to the ultrasonic gas tar purification equipment. 4 The air inlet is through-connected, one end of the air supply pipeline is connected through the air outlet 5 of the tar purification equipment 4, and the other end of the air supply pipeline is connected through the air inlet 6 of the heating inner chamber; one side of the heating inner chamber 1 is provided with a heating chamber 7 , the heating inner chamber 1 is provided with a traction roller 9, and the heating chamber 7 is provided with a driven roller 10, and the adsorption belt 8 has a crawler structure with the traction roller 9 and the driven roller 10 as two ends, and the adsorption belt 8 passes throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com