Vertical, multi-pipe and external heating type manganese dioxide reduction roaster

A technology of external heating and manganese dioxide, which is applied in the field of industrial smelting, can solve the problems of small cooling capacity constraints, increased roasting output, and no adjustable space, so as to increase the cooling contact area, increase cooling capacity, and improve product quality. Quantitative and qualitative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

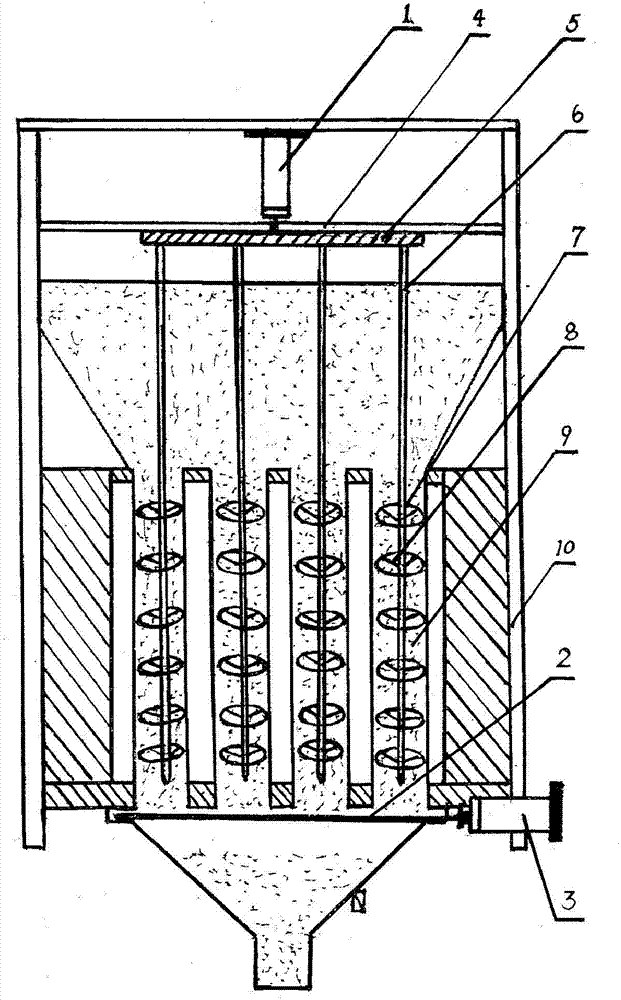

[0016] refer to figure 1 , a vertical multi-tube external heating manganese dioxide reduction roaster, the roaster includes a vertical furnace body 10 and 16 roasting tubes 9 installed in the furnace body, a set of hydraulic pressure is installed in the vertical furnace body 10 Multi-ring push rod roasting tube sintered lag dredger, which consists of a hydraulic system, 16 heat-resistant stainless steel push rods with multiple scraping rings and a fixed bracket. The hydraulic system includes the hydraulic pump and the cylinder plunger 1 driven by the hydraulic pump. The cylinder plunger 1 is installed on the fixed support 4; the cylinder plunger 1 is connected to and drives the movable support 5, and 16 heat-resistant stainless steel push rods 6 are installed on the movable support 5 , 16 push rods are respectively inserted into corresponding 16 roasting tubes 9; a plurality of scraper rings 7 are fixedly installed on the push rods 6, and the scraper rings 7 are circular, and ...

Embodiment 2

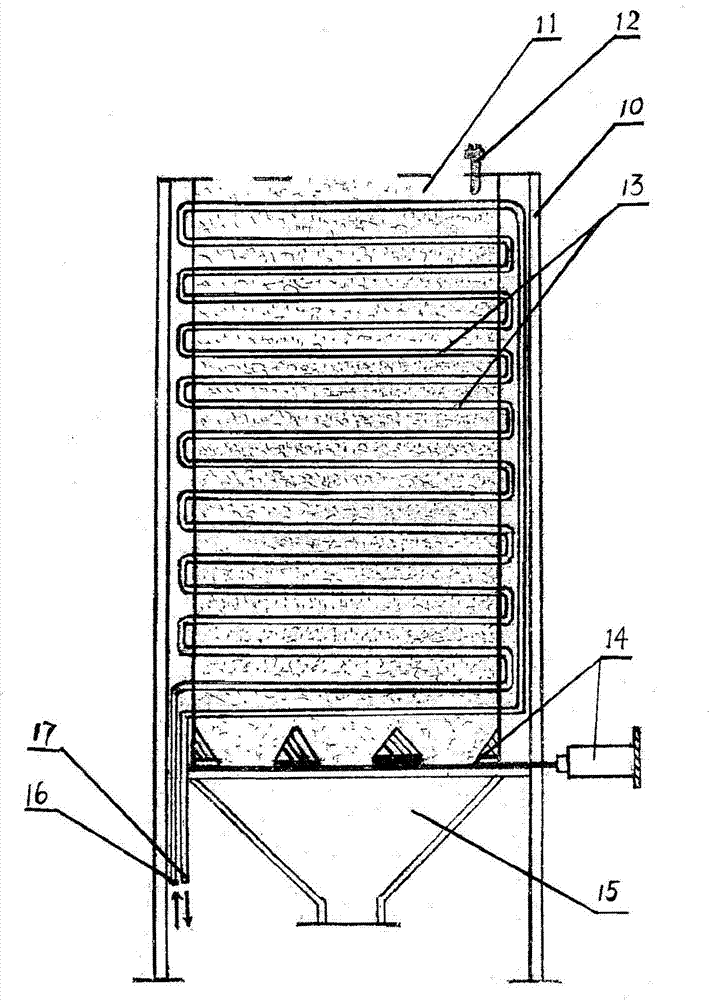

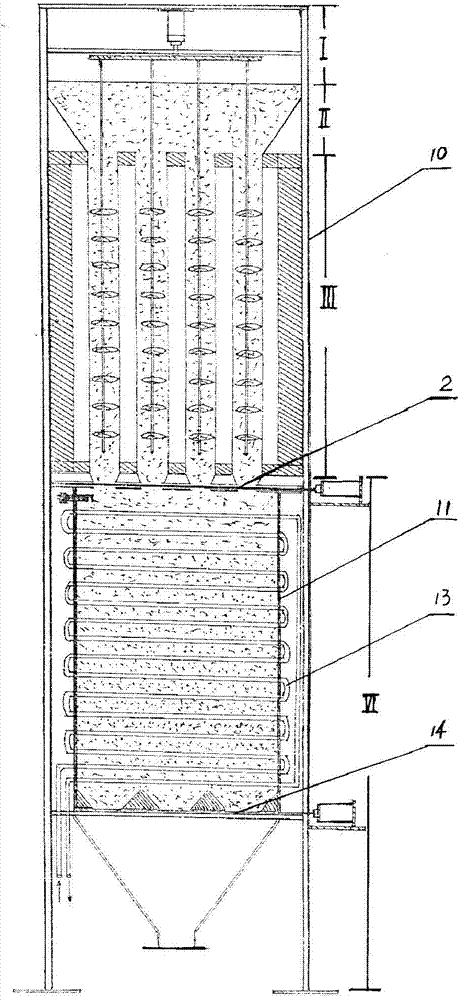

[0019] Referring to Figure 2, image 3 , a vertical multi-tube external heating manganese dioxide reduction roasting furnace, including a vertical furnace body, the furnace body is composed of four parts: a dredger, a silo, a roasting section, and a cooler. From top to bottom, the upper part of the furnace body is the dredger I, the silo II, and the roasting section III. The dredger I is a hydraulic multi-ring push rod roasting tube sintering lag dredger, which is installed on the top of the roaster, and consists of a set of double-column hydraulic system, 16 heat-resistant stainless steel push rods with multiple scraping rings fixed and fixed Support and movable friendly frame are combined, and concrete structure is with embodiment 1. Silo II is a conical closed container made of iron, with a feeding port on the upper part and an open opening on the lower part, which is connected to the roasting calciner III, and stores the roasted material to supply the roasting tube for ca...

Embodiment 3

[0022] A vertical multi-tube external heating manganese dioxide reduction roasting furnace, comprising a vertical furnace body and a plurality of roasting tubes installed in the furnace body, a push rod is installed in the roasting tube, and the push rod is fixedly installed There are multiple scraping rings, which make intermittent motions of up and down reciprocating with a fixed stroke in the roasting tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com