Dust collection device for vibration bed mixed flow dryer

A technology of dust removal device and dryer, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc. It can solve the problems of restricting the hot air passing capacity of the dryer, excessive dust in the workplace, and poor air outlet of the dryer. Achieve the effect of low total investment and operation and maintenance costs, convenient maintenance and management, and guaranteed drying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

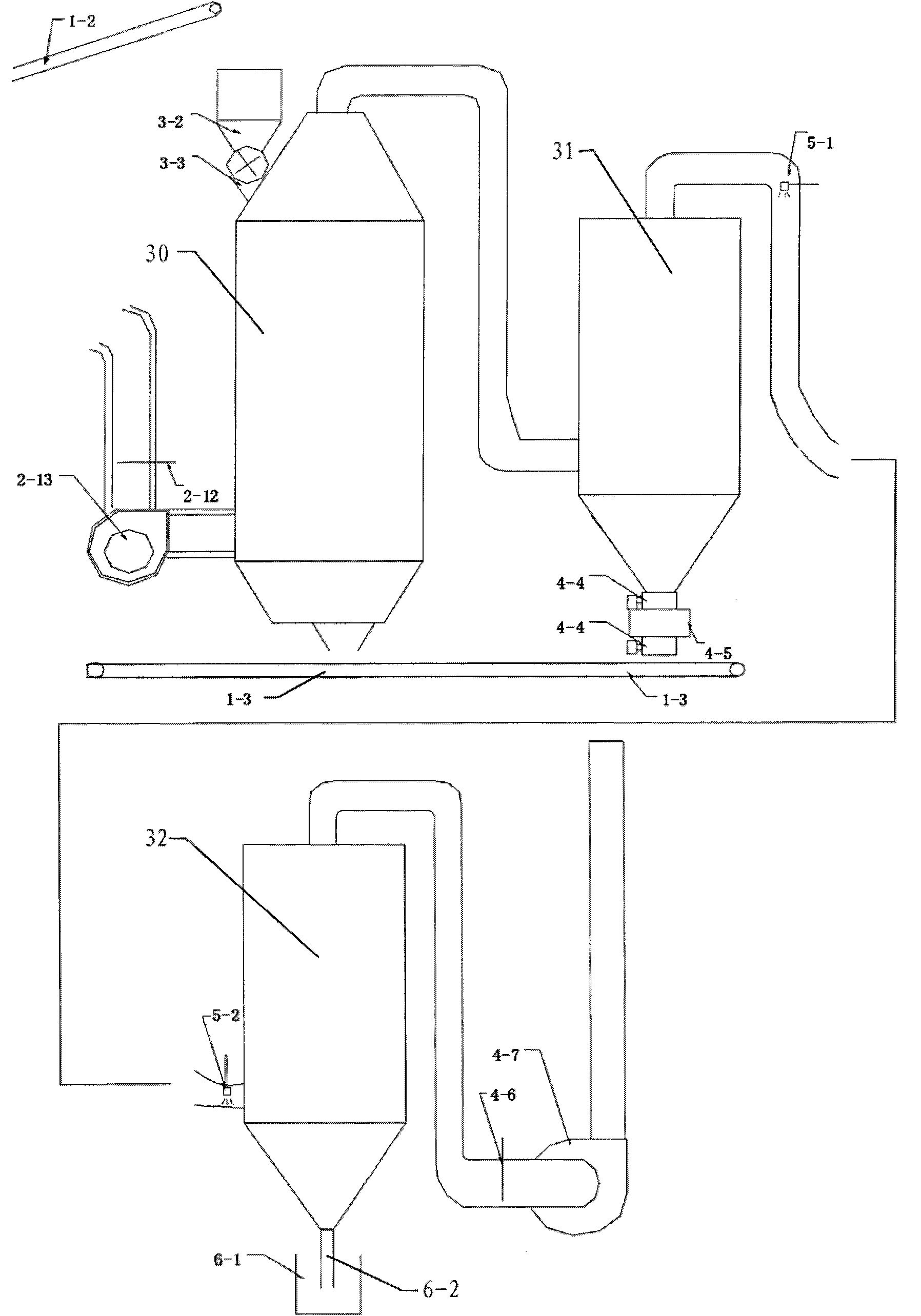

[0030] see image 3 , which shows a preferred embodiment of the dust removal device of a vibrating bed mixed-flow dryer of the present invention, including a dryer 30 and at least one cyclone dust removal chamber 31 and a secondary cyclone dust removal chamber connected in sequence with the dryer 30 through pipelines 32. A steam humidifier 5-1 is provided in the outlet pipe at the top of the primary cyclone chamber 31, and a sprayer 5-2 is provided at the entrance of the secondary cyclone chamber 32. The steam humidifier 5-1 of the present invention and the sprayer 5-2 can be the same steam humidification spray equipment, or different steam humidification equipment and spray equipment, which is obvious to those of ordinary skill in the art. understandable. In addition, if image 3 As shown, preferably at the bottom of the secondary cyclone dust removal chamber 32, a coal slime water discharge pipe 6-2 is provided. The dust removal device of the vibrating bed mixed flow drye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com