High-temperature composting process of wheat straw

A wheat straw, high-temperature heap technology is applied in the fields of organic fertilizer, organic fertilizer preparation, biological organic part treatment, etc. The effect of material uniformity and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

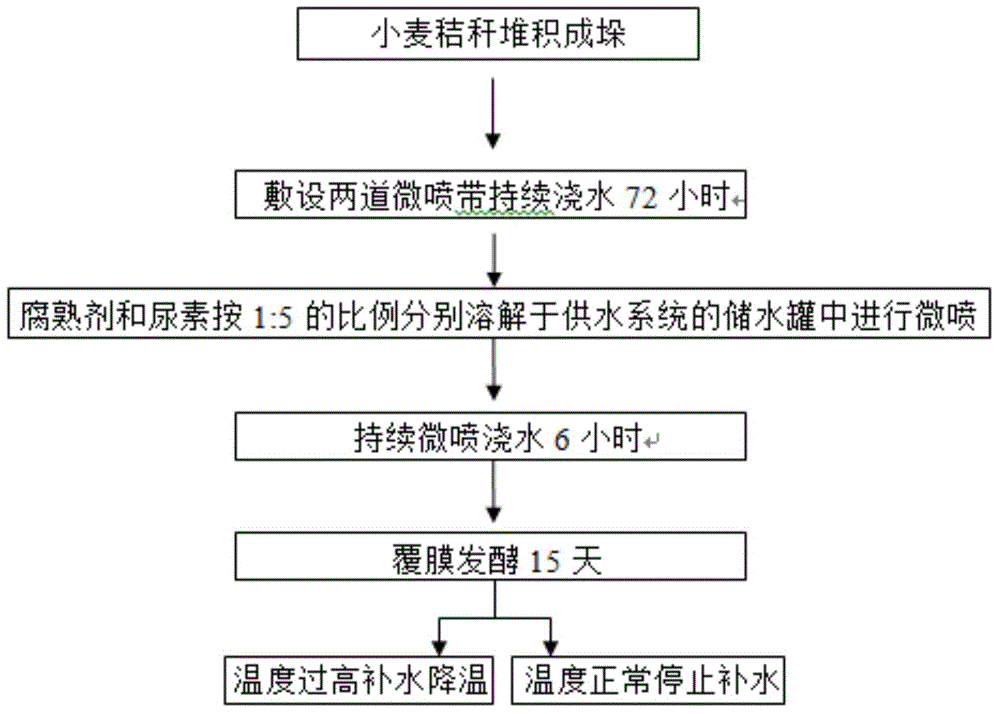

[0016] Combine below figure 1 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0017] A high-temperature composting process of wheat straw, comprising the following steps:

[0018] (1) use the grass catcher to pile up the wheat straw into a long pile; in a preferred embodiment, the long pile is 60m long, 4m wide, and 2m high, and the specific specifications can be piled up according to the actual situation on the spot;

[0019] (2) Lay two micro-spray belts on the wheat straw heap, the distance between the two micro-spray belts is 1m, utilize the full-automatic water supply system to carry out micro-spray by the micro-spray belt, the micro-spray belt and the full-automatic water supply system Connected, when the water pressure is insufficient, the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com