Method of continuously manufacturing a product panel and system and method of detecting the front edge of a film

A manufacturing method and front-end technology, applied in the direction of layered products, chemical instruments and methods, optics, etc., can solve the problems of inability to apply continuous manufacturing of product panels, difficulty in obtaining high bonding accuracy, etc., and achieve shortened and increased moving distances. The effect of improving the number of manufactures and bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]

[0042] The present invention will be described in detail below with reference to the accompanying drawings.

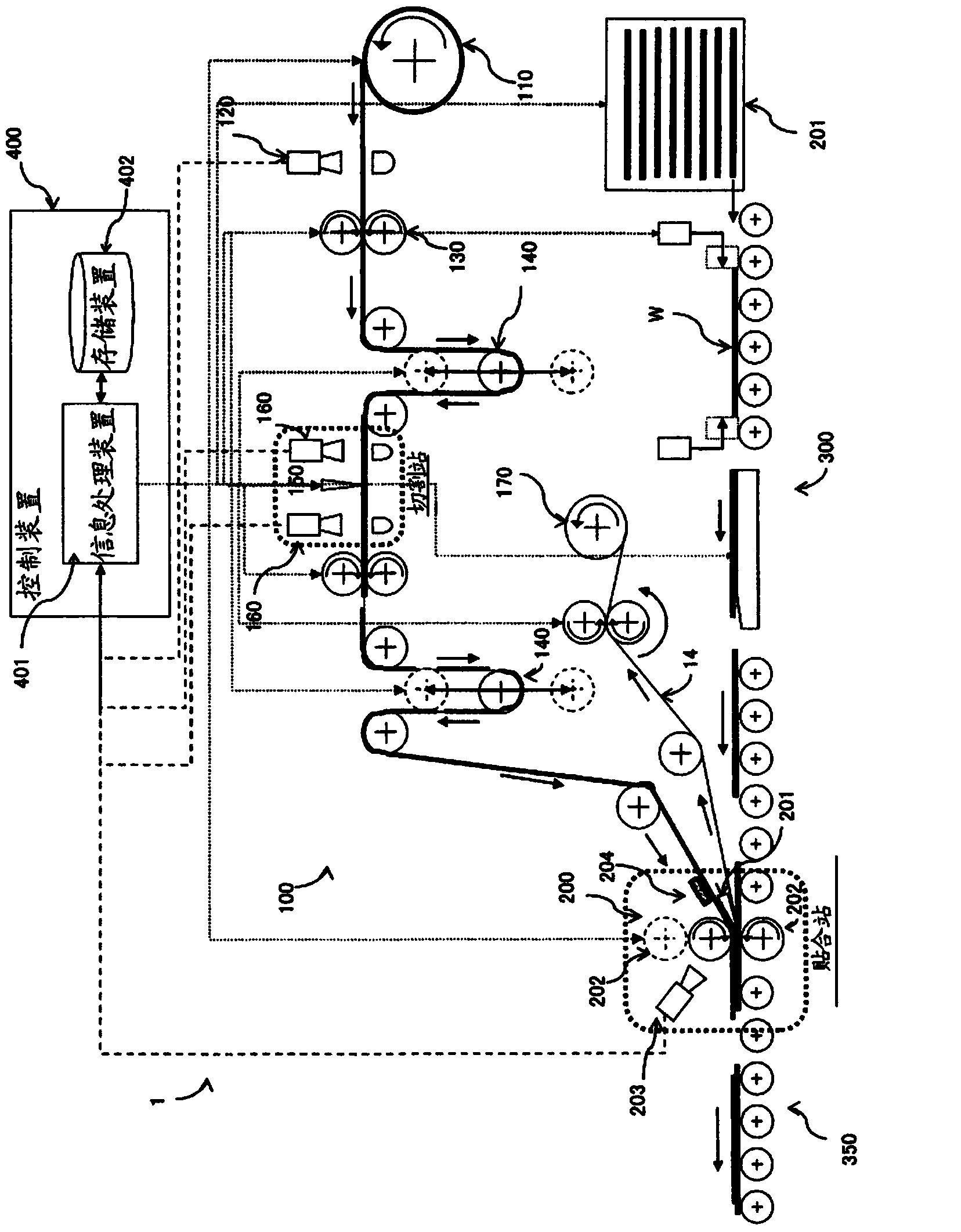

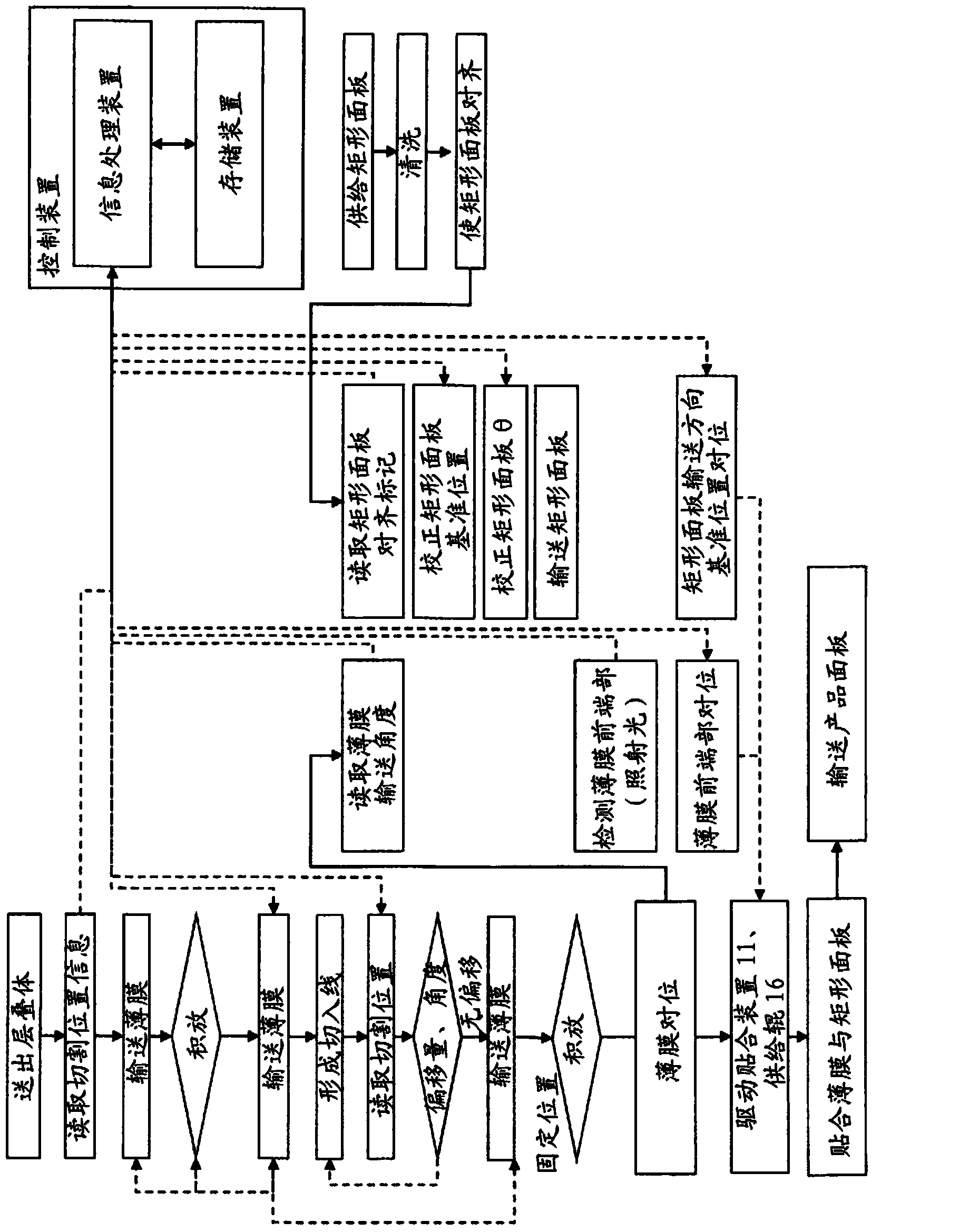

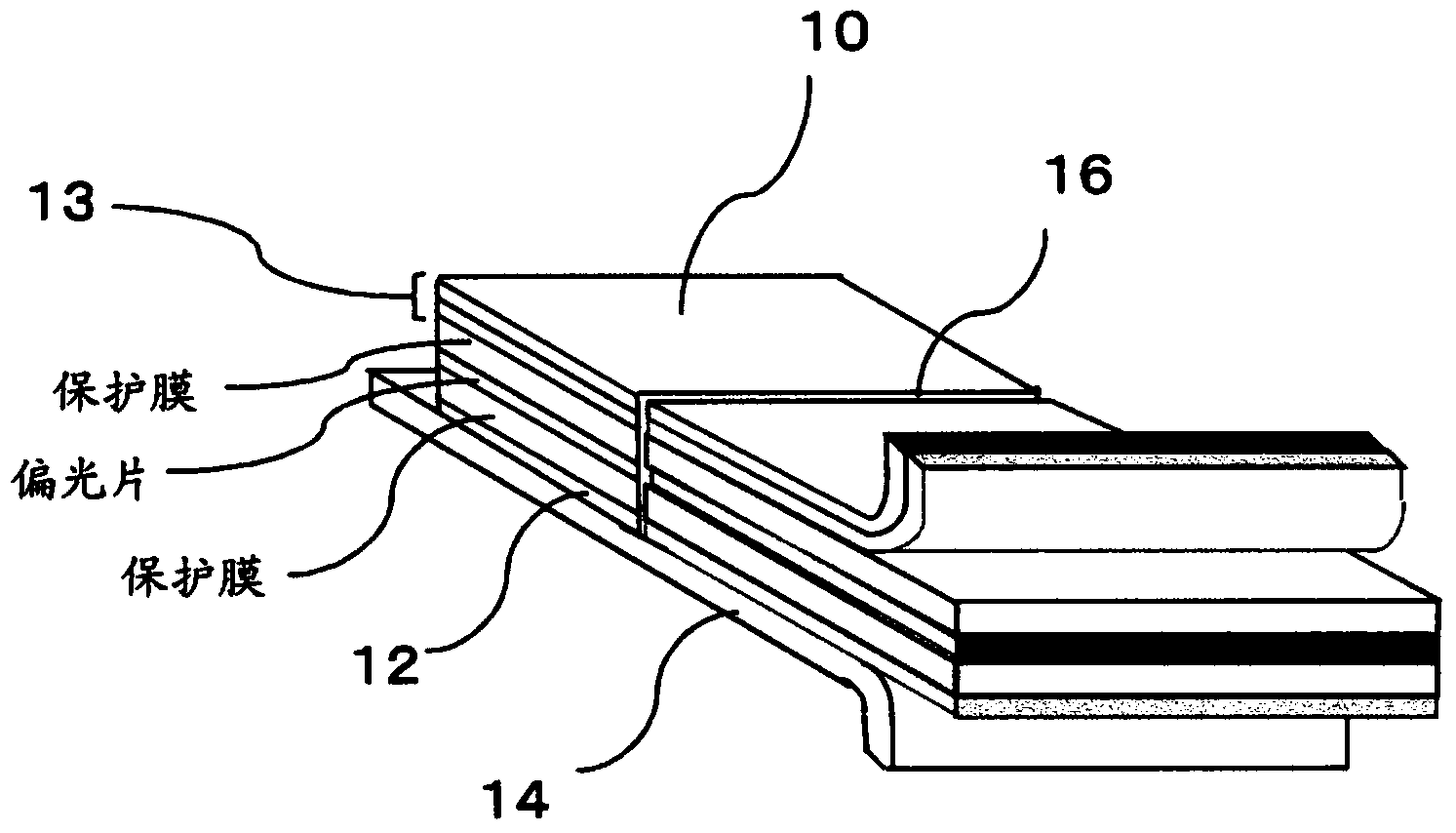

[0043] figure 1 is a schematic diagram of a device for realizing the continuous manufacturing method of the product panel of the present invention, figure 2 It is a process flowchart of the continuous manufacturing method of this invention. figure 1 The shown continuous manufacturing device 1 includes the image 3 The shown sheet-shaped polarizing film 10 is transported to the film conveying device 100 of the laminating station, the laminating device 200 is used to bond the sheet-shaped polarizing film 10 to the rectangular panel W, and the rectangular panel conveying device is used to transport the rectangular panel W to the laminating position The device 300 and the control device 400 for controlling the overall operations of the film conveying device 100 , the laminating device 200 and the rectangular panel conveying device 300 . The sheet-shaped pola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com