Multi-layer product support for vapor deposition, and chemical vapor deposition reaction chamber

A technology of chemical vapor deposition and multi-layer products, which is applied in the direction of gaseous chemical plating, coating, metal material coating technology, etc., can solve the problems of increased output, low production efficiency, high production cost, etc., and achieve production efficiency and cost savings The effect of improving and improving production efficiency, reducing trouble and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

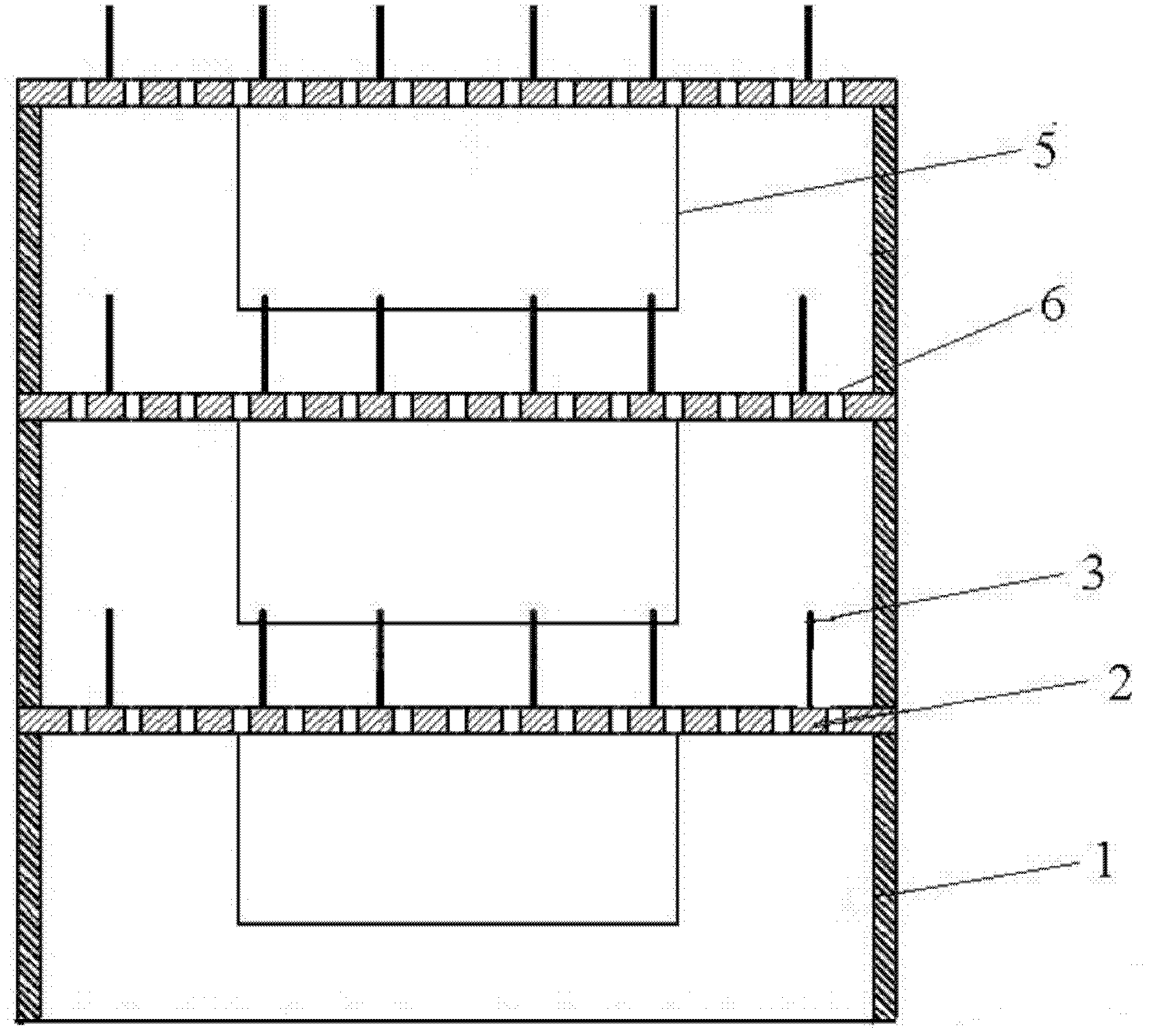

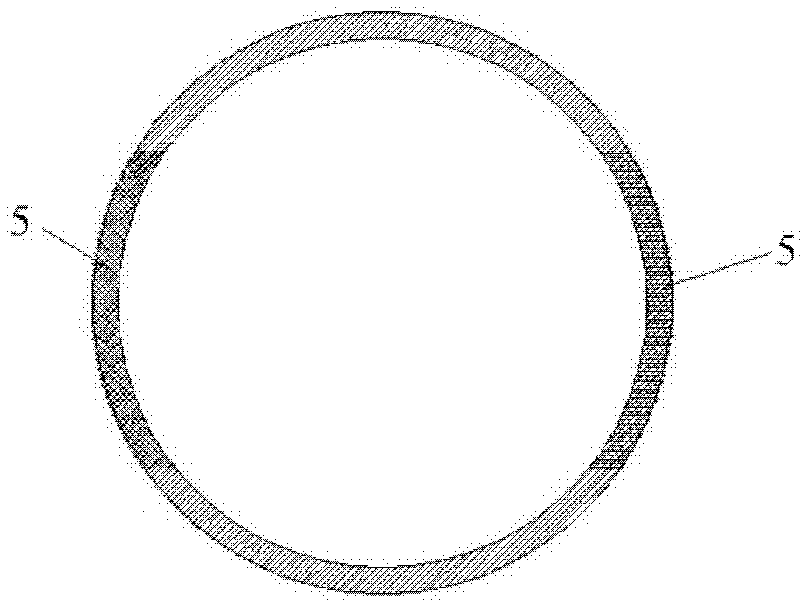

[0038] A multi-layer product support for chemical vapor deposition, with a structure such as figure 1 , figure 2 As shown, it includes a unit layer composed of a circular sleeve 1, an air distribution disc 2 and a pole 3; the structure of the unit layer is that the air distribution disc 2 is placed on the circular sleeve 1, and the outer diameter of the circular sleeve 1 is the same as the The gas discs 2 have the same diameter. The support rod 3 is fixed upright on the air distribution plate 2, and the circular sleeve 1 of another unit layer is placed on the air distribution plate 2 of one unit layer, and a total of 3 unit layers are arranged layer by layer; wherein, the circular sleeve The upper part of the wall of cylinder 1 is symmetrically provided with two rectangular notches 5 as gas circulation channels; the support rod is a tungsten needle, and the bottom end of the tungsten needle is fixed in the concave hole on the gas distribution plate. The substrate on which t...

Embodiment 2

[0042] A chemical vapor deposition multilayer product support, as described in Example 1, the difference is that there are 4 unit layers; wherein, the upper part of the wall of the circular sleeve 1 is symmetrically provided with two arc-shaped notches as A gas circulation channel; the tungsten needles fixed on the gas distribution plate are supported by 4 tungsten needles per substrate. The circular sleeve is made of graphite, with a wall thickness of 8 mm, and the height is 25 mm from the top of the substrate to the gas distribution plate of another unit layer after the tungsten needle is fixed on the gas distribution plate to support the substrate.

Embodiment 3

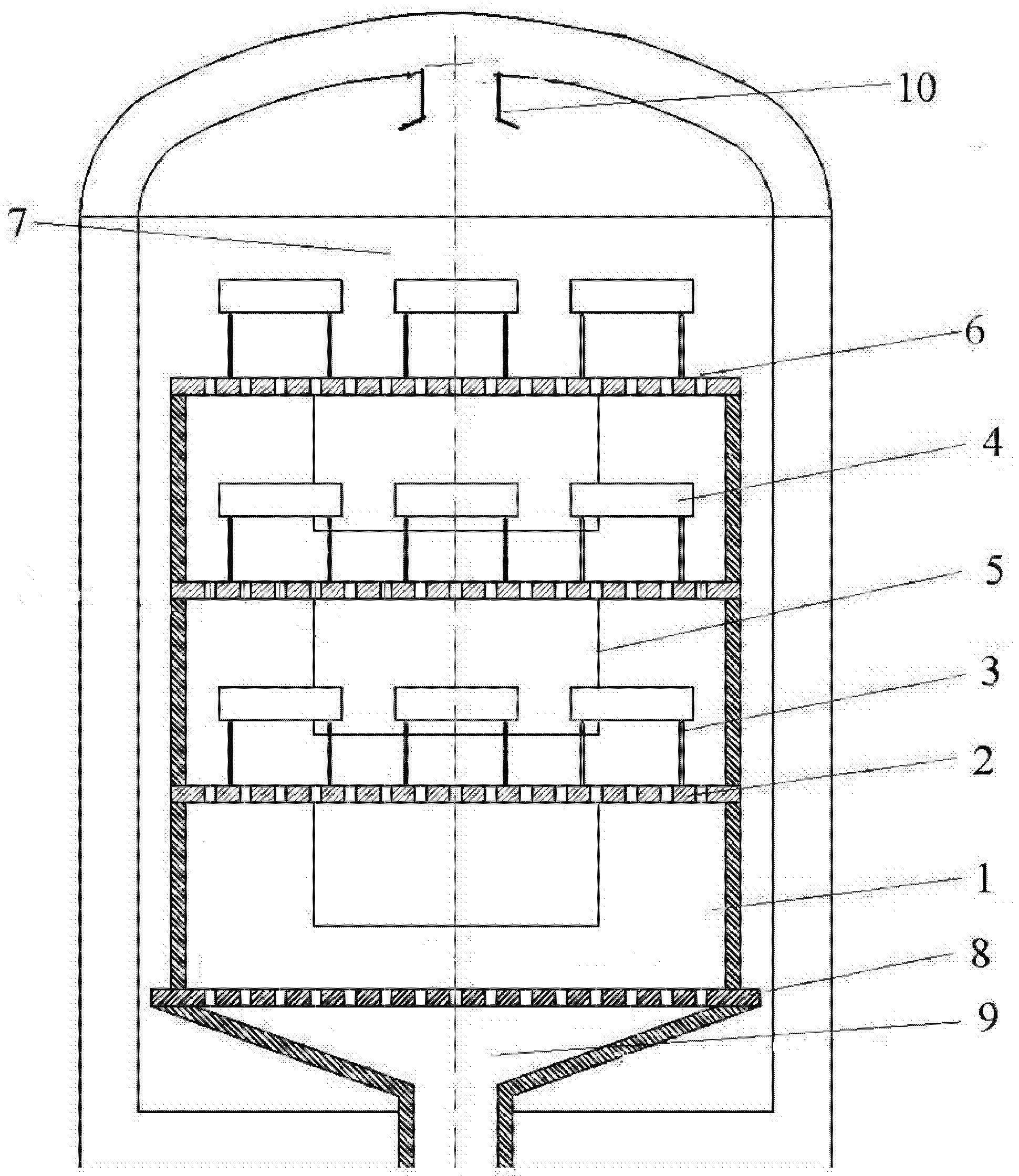

[0044] A chemical vapor deposition reaction chamber, comprising a reaction chamber cavity 7 and the multilayer product support described in Embodiment 1, the multilayer product support is placed on the gas distribution plate 8 on the air inlet 9 in the chamber Above, the gas inlet 9 is located at the bottom of the reaction chamber, and the gas outlet 10 is located at the top of the reaction chamber relative to the gas inlet 9 . It is used as a chemical vapor deposition equipment with a vacuum degree of 200-5000 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com