Method for preparing di-(N-methyl phthalimide) ether

A technology of methylphthalimide and nitrophthalimide, which is applied in the field of organic matter preparation, can solve the problems of difficult wastewater treatment, difficulty in wide application, rising environmental protection costs, etc., and achieve environmental protection The effect of less pollution, lower production cost, and higher product yield

Inactive Publication Date: 2010-12-01

NORTHWEST A & F UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There is also a method of composite catalyst mixed with gas phase white carbon black, carbonate and phase transfer catalyst, but it is difficult to widely apply in industry to filter the catalyst in a polar aprotic solvent with high viscosity

In addition, in the presence of a binary inorganic catalyst sodium nitrite and potassium fluoride and a third-dimensional phase transfer catalyst tetrabutylammonium bromide, a white condensation reaction is carried out to prepare bis (N-methylphthalimide) ether, However, this method brings a large amount of inorganic salts into the water, making it difficult to treat the wastewater and causing an increase in environmental protection costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

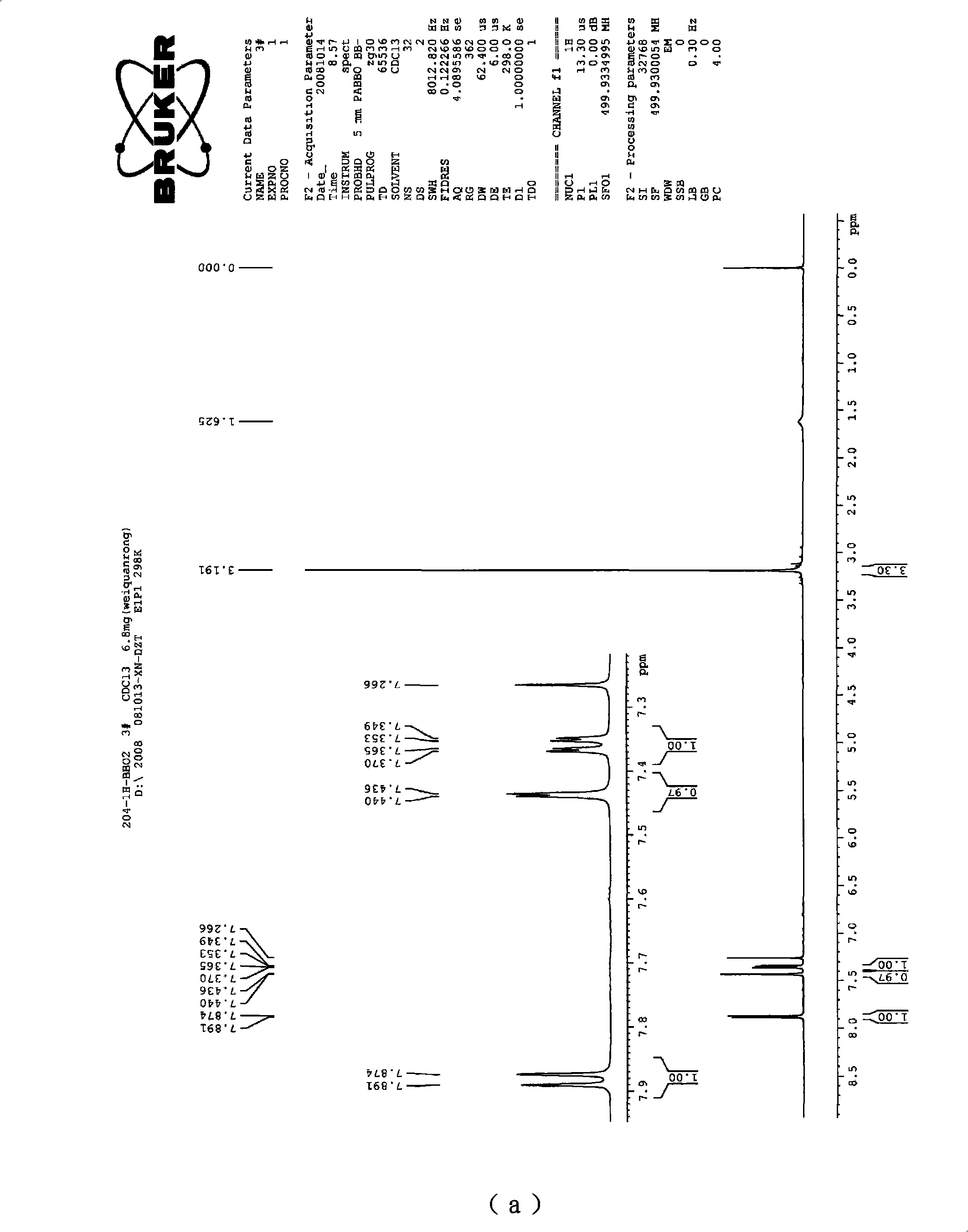

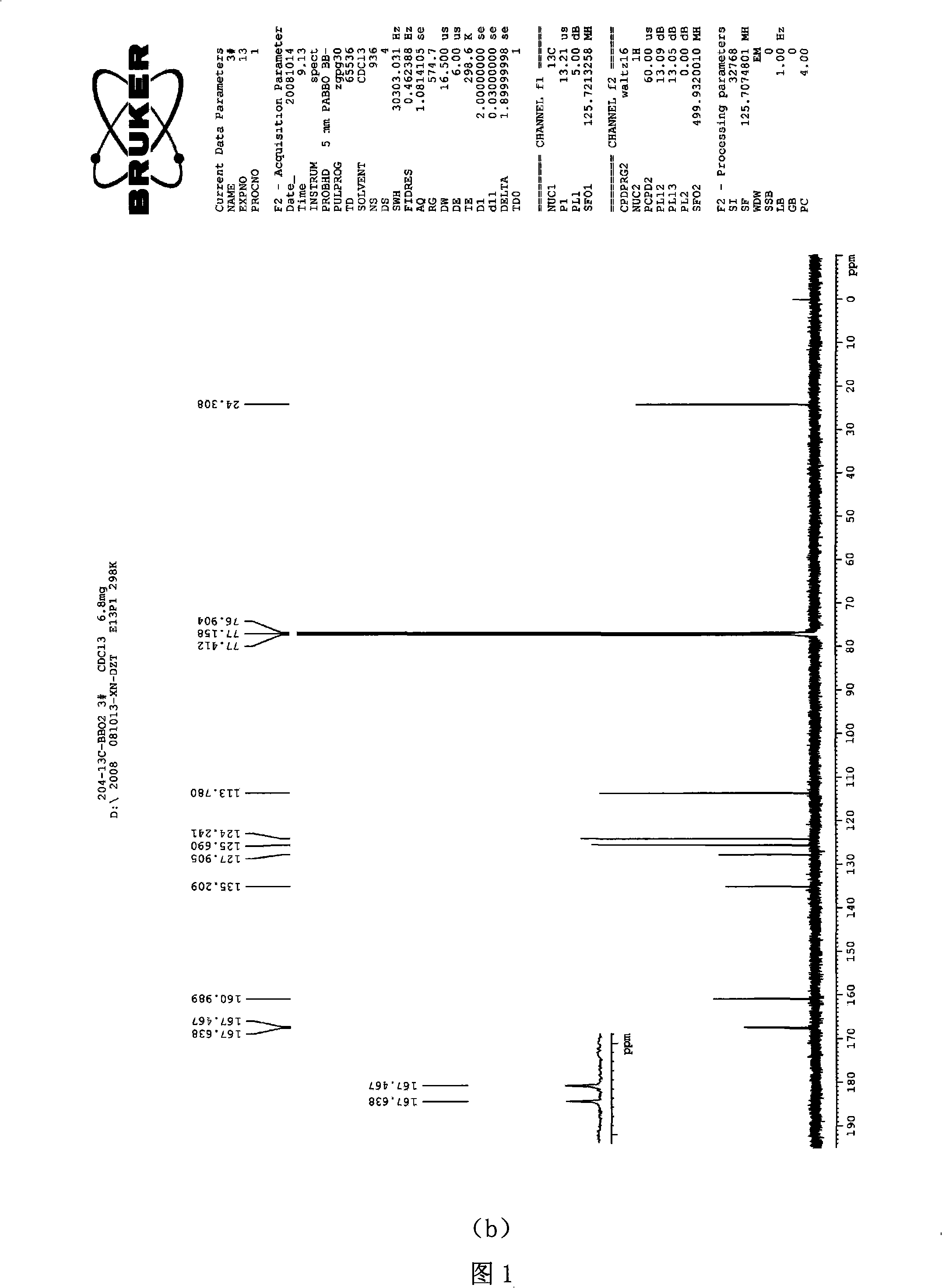

The invention discloses a method for preparing di-(N-methyl phthalimide) ether. The method comprises the following steps: firstly, one or two types of non-polar solvents and one kind of polar non-protonic solvent are mixed, the non-polar solvents are steamed out, then the mixed solvent reaches a certain proportion, N-methyl-4-nitryl phthalimide carries out self condensation reaction under the catalysis of one or two catalysts and normal pressure in the mixed solvent, heating and reflowing are conducted for 2 to 8 hours, and then the solvent is recovered, water is added, product is precipitatedafter cooling, and finally, tawny di-(N-methyl phthalimide) ether is obtained after filtering, washing and drying, the yield rate is 68 to 85 percent, and the melting point is 272.6 to 273 DEG C. Thecatalyst is organic acid salt and carbonate of organic acid salt of alkali metals and alkali-earth metals.

Description

The preparation method of bis-(N-methylphthalimide) ether technical field The invention relates to a preparation of organic matter, in particular to a preparation method of bis-(N-methylphthalimide) ether. Background technique Bis(N-methylphthalimide) ether is a fine organic product with high added value. ) is the most important intermediate. Monoether anhydride is one of the important monomers of new special engineering plastics polyimide, polyetherimide, polyesterimide, polyamideimide, polymaleimide, polyaramide and other high temperature resistant resins . It can also be used as a cross-linking agent for synthetic polymer materials such as high-performance heat-resistant epoxy resin and polyurethane. Monoether anhydride polyimide has outstanding mechanical properties, electrical properties, and radiation resistance, and can be used for a long time in the range of 180 ° C to 230 ° C. Due to the introduction of flexible ether bonds in the polyimide main chain structur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07D209/48B01J31/04B01J27/232

Inventor 杜振亭于洪瑞

Owner NORTHWEST A & F UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com