Method of manufacturing connector with ejection forming technique

A technology of injection molding and manufacturing method, which is applied in the field of connector manufacturing of injection molding technology, can solve the problems of efficiency, low output, high cost, easy bending and breaking of terminals, etc., and achieves low raw material cost, time saving and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

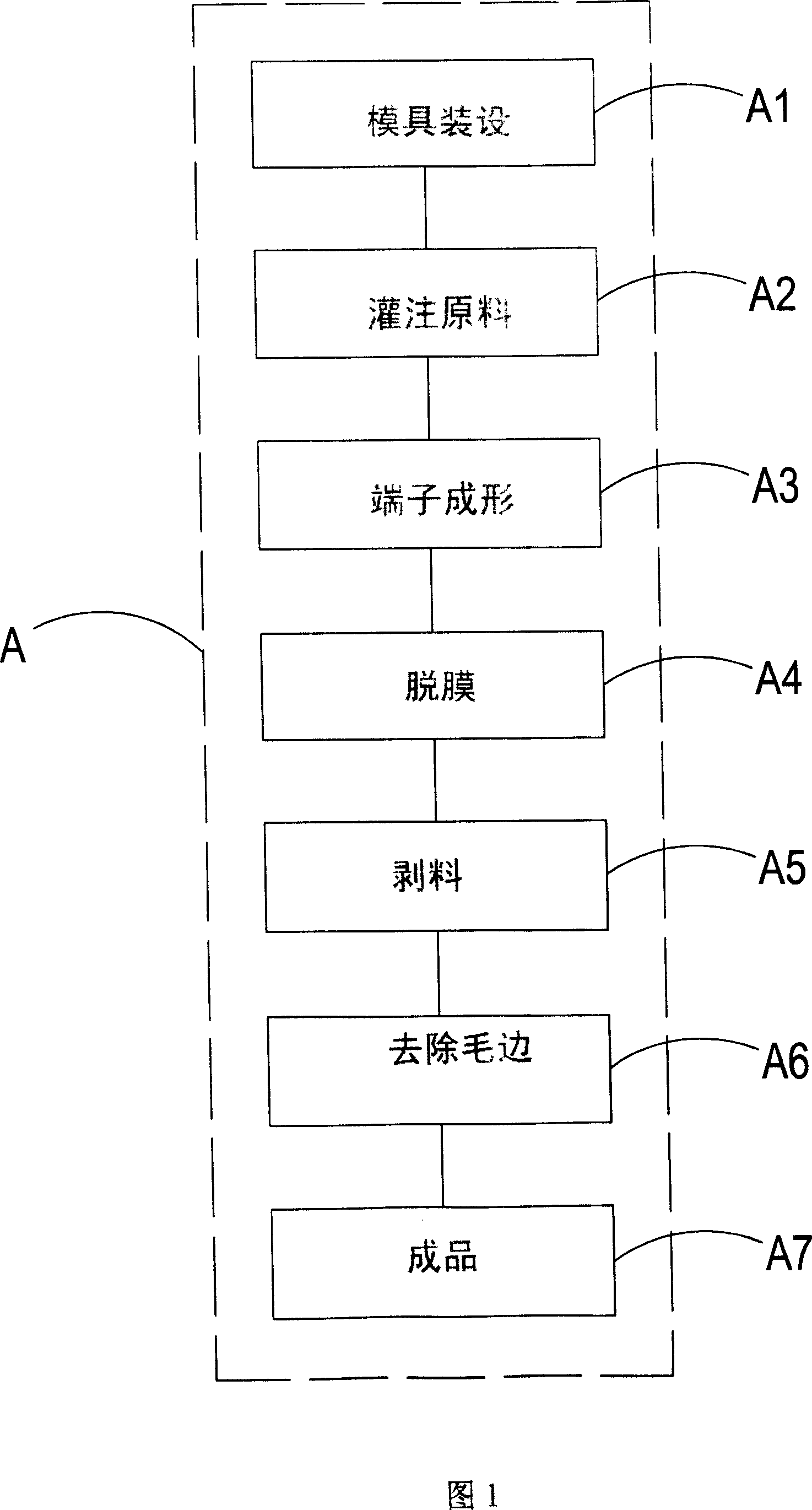

[0008] As shown in Figure 1, the terminal forming process A of the present invention includes mold installation A1, installing the casting plate on the machine, and pouring raw material A2 into the casting plate to form the terminal A3, and after the terminal forming A3 Then it is a semi-finished product, and then the semi-finished product is stripped A4 on the casting template, and the terminal is stripped A5 after stripping A4, and after stripping A5, the side edge of the semi-finished product has burrs, and the burr A6 is removed by a grinding machine. After removing the burr A6, it becomes the finished product A7. Moreover, the raw material A2 is made of zinc alloy, and the raw material cost of the zinc alloy is low and the hardness is high, so that the manufacturing cost can be saved, and the hardness of the terminal can be improved. The terminal is bent and broken due to external force.

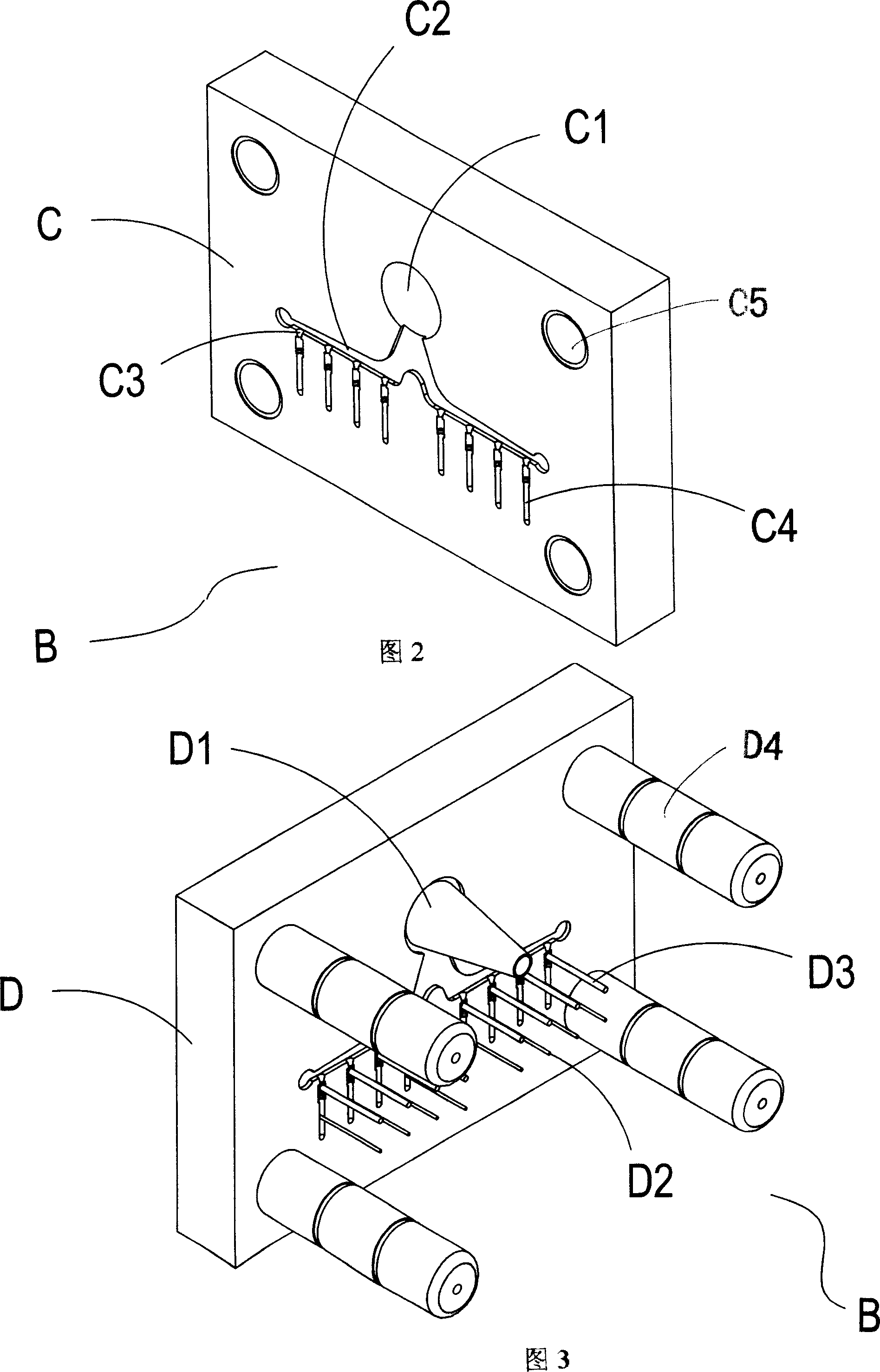

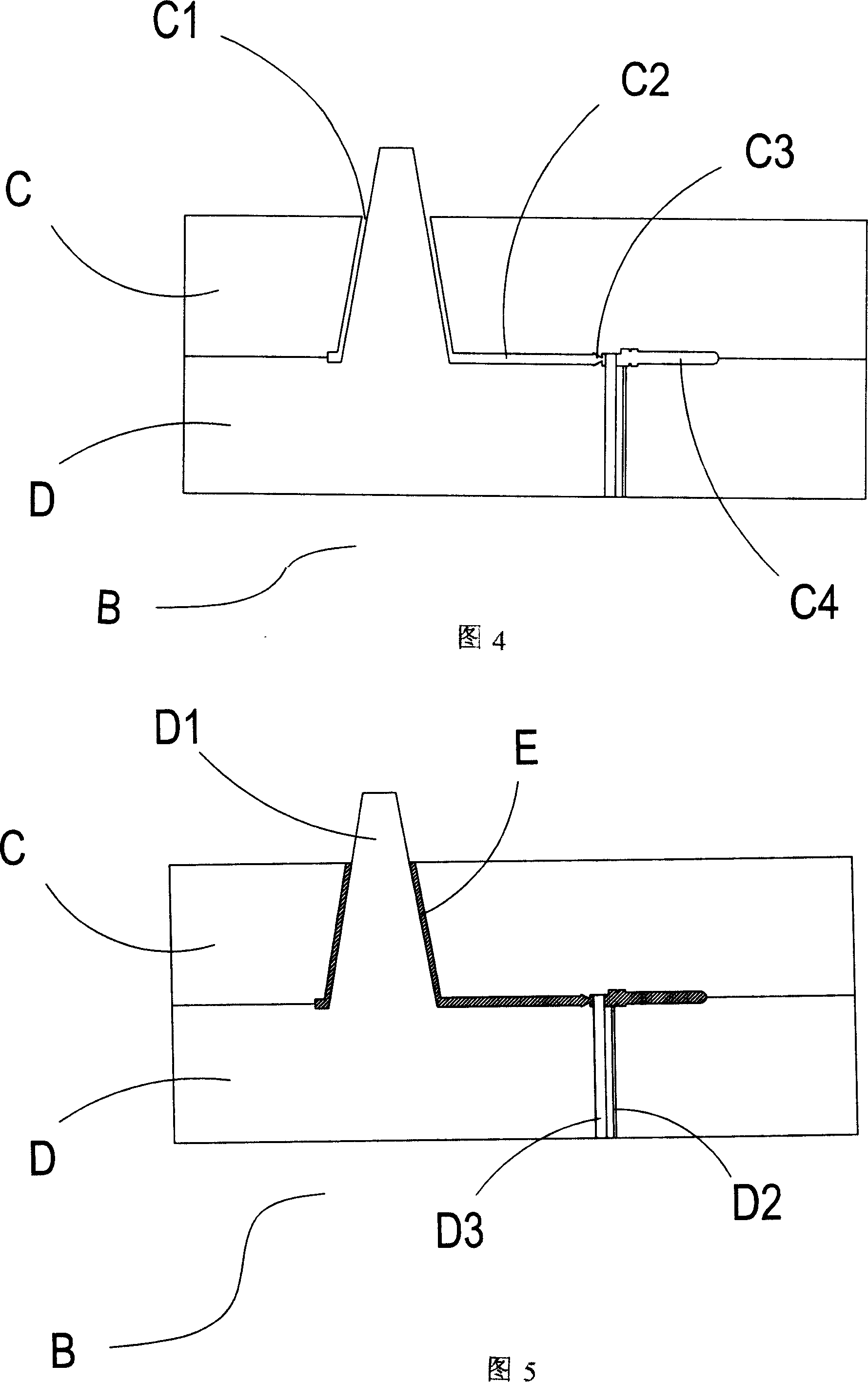

[0009] As shown in accompanying drawings 2 to 9, when in use, its casting formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com