Medical sodium alginate gel microsphere and preparation method and application thereof

A technology of sodium alginate and gel microspheres is applied in the directions of non-active ingredients medical preparations, pharmaceutical formulations, endocrine system diseases, etc., to achieve the effects of improving chemical stability, controlling sustained release, and improving molecular cross-linking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

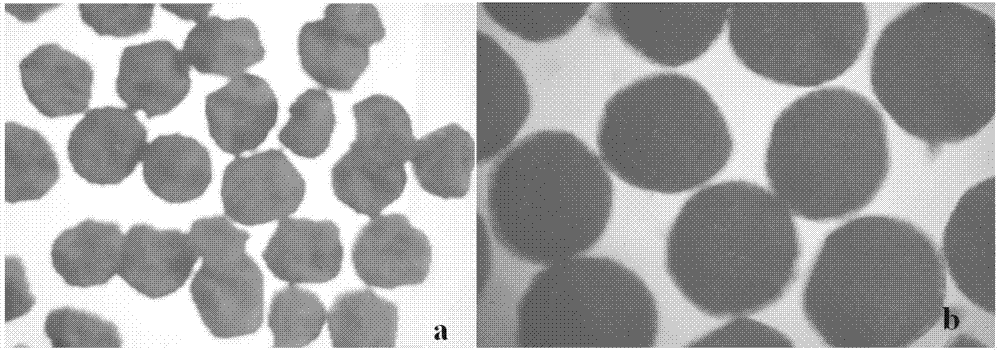

Embodiment 1

[0032] 1. Preparation of gel microspheres containing rifabutin-calcium alginate-aminomethylbenzoic acid. The preparation method comprises the following steps:

[0033] (1) After passing the rifabutin powder through a 160-mesh sieve, weigh 4 g for later use.

[0034] (2) 1.5 g of sodium alginate was weighed and dissolved in 100 mL of distilled water to obtain a sodium alginate solution with a concentration of 1.5 wt%.

[0035] (3) Weigh 2 g of 4-aminomethylbenzoic acid, add it into 200 mL of distilled water, and stir at room temperature to obtain a 4-aminomethylbenzoic acid solution with a concentration of 1%.

[0036] (4) Weigh 8 g of anhydrous calcium chloride, add it into 400 mL of distilled water, and stir at room temperature to obtain a calcium chloride solution with a concentration of 2%.

[0037] (5) 200 mL of the 4-aminomethylbenzoic acid solution obtained in step (3) was mixed in equal volumes with 200 mL of the calcium chloride solution obtained in step (4), and stir...

Embodiment 2

[0053] The preparation of paclitaxel-loaded sodium alginate gel microspheres comprises the following steps:

[0054] (1) After passing the paclitaxel powder through a 160-mesh sieve, weigh 2 g.

[0055] (2) Weigh 2 g of sodium alginate and dissolve it in 100 mL of distilled water to obtain a sodium alginate solution with a concentration of 2.0 wt%.

[0056] (3) Weigh 1 g of 4-aminomethylbenzoic acid, add it into 200 mL of distilled water, and stir at room temperature to obtain a 4-aminomethylbenzoic acid solution with a concentration of 0.5%.

[0057] (4) Weigh 6 g of anhydrous calcium chloride, add it into 400 mL of distilled water, and stir at room temperature to obtain a calcium chloride solution with a concentration of 1.5%.

[0058] (5) Mix 200 mL of the 4-aminomethylbenzoic acid solution obtained in step (3) with 200 mL of the calcium chloride solution obtained in step (4) in equal volumes, and stir at room temperature to obtain a composite coagulation solution.

[005...

Embodiment 3

[0062] The preparation of sodium alginate gel microspheres loaded with 17β-estradiol comprises the following steps:

[0063] (1) After passing the 17β-estradiol powder through a 160-mesh sieve, weigh 1 g.

[0064] (2) Weigh 2 g of sodium alginate and dissolve it in 100 mL of distilled water to obtain a sodium alginate solution with a concentration of 2.0 wt%.

[0065] (3) Weigh 1 g of 4-aminomethylbenzoic acid, add it into 200 mL of distilled water, and stir at room temperature to obtain a 4-aminomethylbenzoic acid solution with a concentration of 0.5%.

[0066] (4) Weigh 8 g of anhydrous calcium chloride, add it into 400 mL of distilled water, and stir at room temperature to obtain a calcium chloride solution with a concentration of 2%.

[0067] (5) 200 mL of the 4-aminomethylbenzoic acid solution obtained in step (3) was mixed with 200 mL of the calcium chloride solution obtained in step (4) in equal volumes, and stirred at room temperature to obtain a composite coagulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com