Controlled degradation magnesium alloy coating bracket and preparation thereof

A magnesium alloy and coating technology, applied in metal material coating process, cleaning method using liquid, coating and other directions, can solve problems such as delaying the degradation of magnesium alloy materials, and achieve improved stability, delayed corrosion, and reduced degradation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

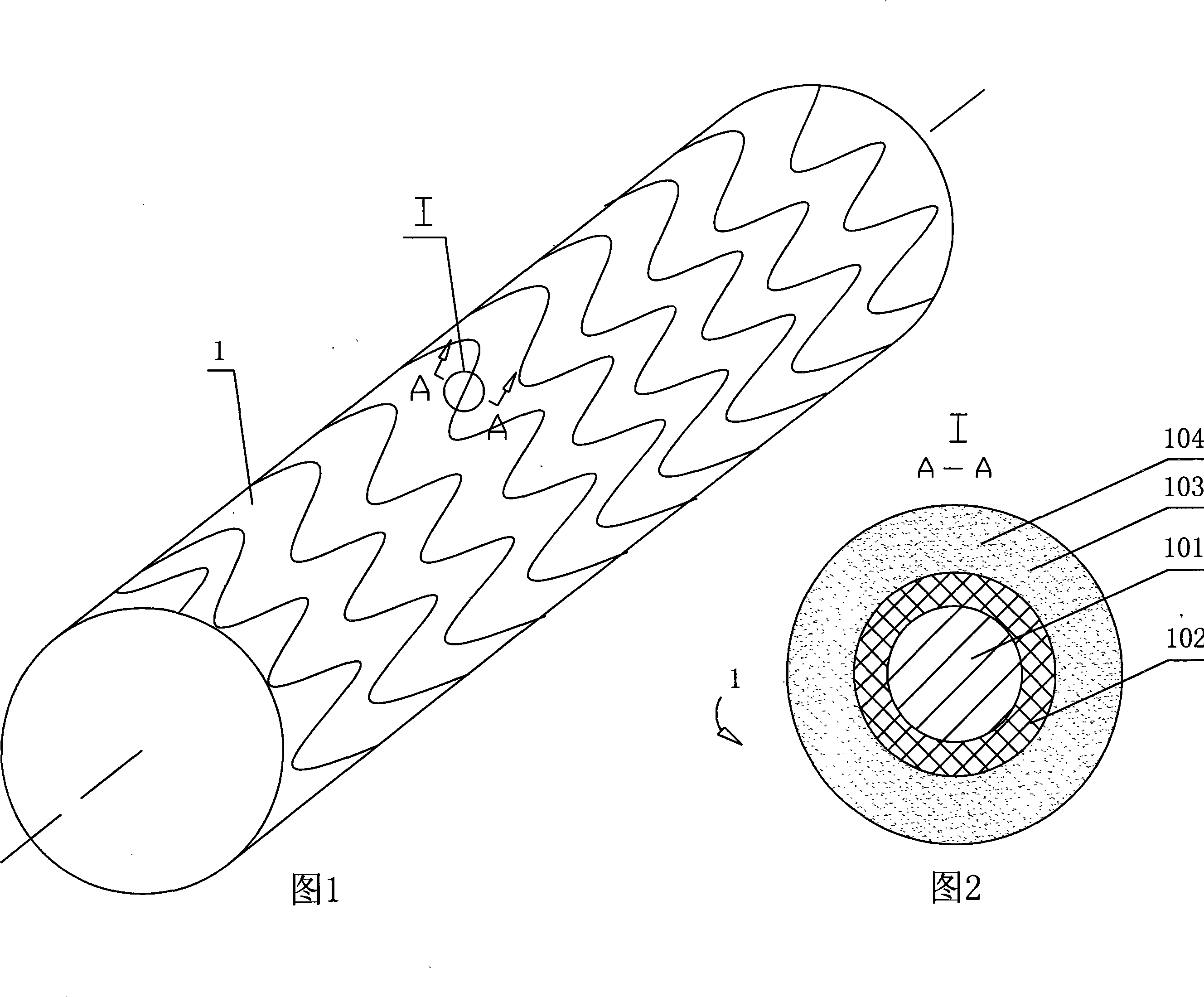

[0064] High-purity magnesium is selected and polished, and then laser-engraved into vascular stents;

[0065] ①Surface cleaning: cleaning the surface of the bracket body 101 with an ultrasonic frequency of 100khz, including: 1) cleaning with a medical ethanol solvent with a concentration of 75% for 5 minutes; 2) cleaning with an analytically pure acetone solution with a concentration of 99.5% for 5 minutes; 3 ) cleaning with deionized water for 5 minutes; placing the cleaned bracket body 101 in a vacuum dryer to dry;

[0066] ②Surface anticorrosion treatment: immerse the bracket body 101 in a solution of potassium dichromate 15g / L, nitric acid 15g / L, and sodium chloride 1.0g / L, and oxidize it at 80°C for 1 minute, and an oxide film can be formed on the surface;

[0067] ③ Preparation of degradable polymer film drug-loaded coating; put the antiseptic-treated stent 1 into 1.0 mg / mL polylactic acid (PLA) solution and soak for 15 minutes, and put it on Feige TGL-16G centrifuge at ...

Embodiment 2

[0070] AZ91B magnesium alloy is selected and polished, and then laser-engraved into vascular stents;

[0071] ①Surface cleaning: cleaning the surface of the bracket body 101 with an ultrasonic frequency of 28khz, including: 1) cleaning with a medical ethanol solvent with a concentration of 75% for 10 minutes; 2) cleaning with acetone analytically pure solution with a concentration of 99.5% for 10 minutes; 3 ) cleaning with deionized water for 10 minutes; placing the cleaned bracket body 101 in a vacuum dryer to dry;

[0072] ②Surface anticorrosion treatment: Anodize the cleaned stent body 101, and install the same stent body 101 on the two electrodes. The composition of the bath solution for anodic oxidation treatment is: potassium permanganate 15g / L, trisodium phosphate 15g / L, Potassium Fluoride 25g / L, Potassium Hydroxide 65g / L, Aluminum Hydroxide 15g / L, at 30°C, oxidize for 15 minutes, and the current density is 3A / dm 2 , the AC voltage is 60V, and an oxide film can be for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com