Recycled concrete and preparation method thereof

A technology of recycled concrete and recycled coarse aggregate, applied in the field of concrete, can solve the problems of uneven dispersion of polypropylene fibers, achieve the effects of enhancing strength, improving cross-linking and dispersion, and enhancing cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

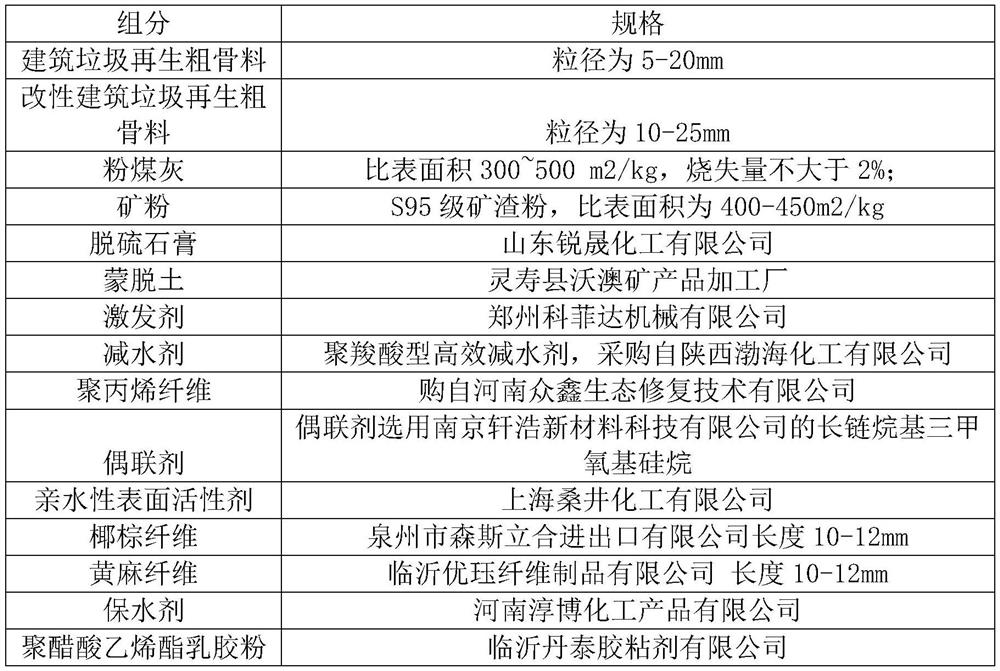

Method used

Image

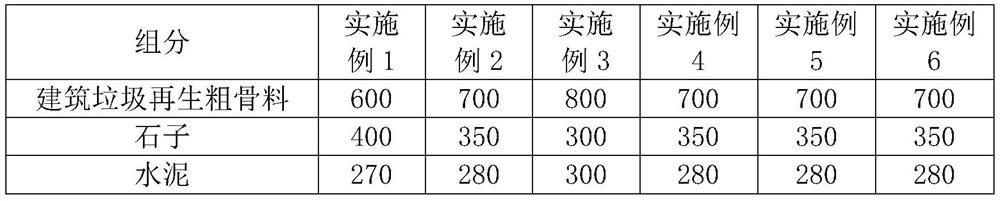

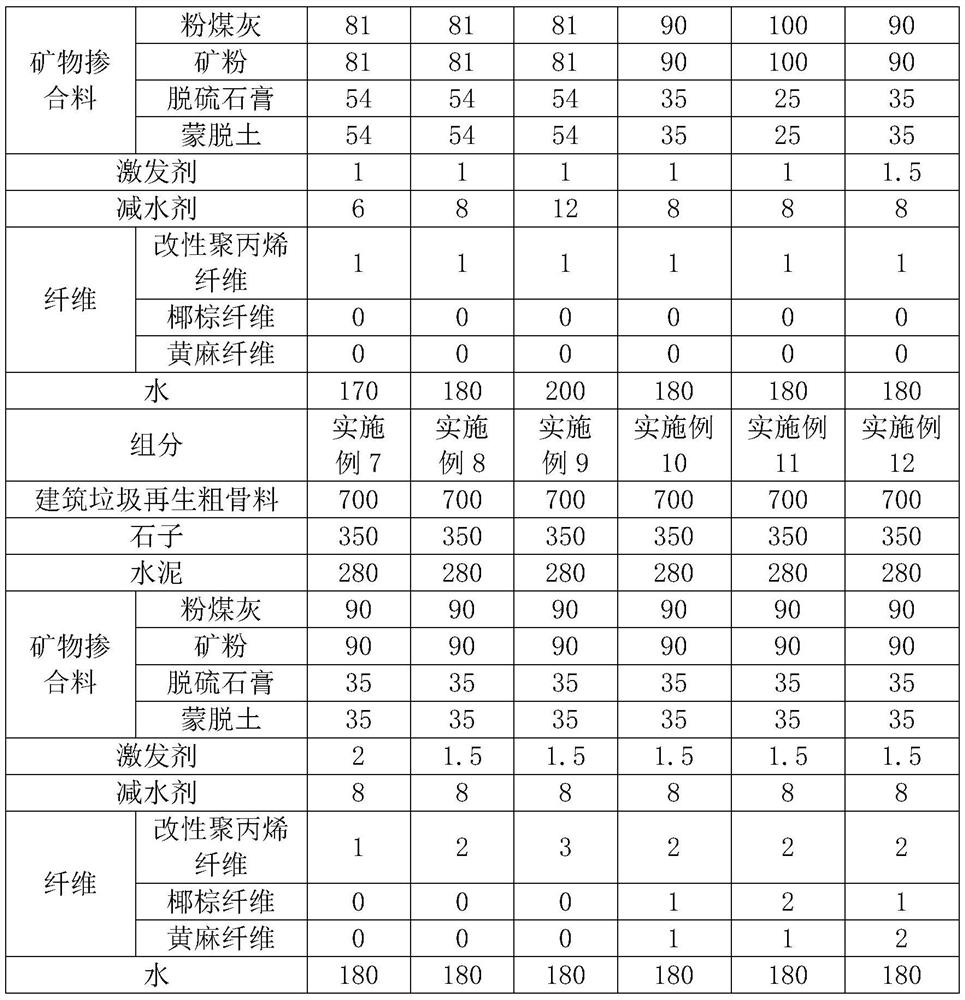

Examples

preparation example 1

[0052] Mix 1 kg of polypropylene fiber with 0.1 kg of oxidant, soak for 1 hour and wash to obtain the first product, add the first product to the coating solution and mix to obtain modified polypropylene fiber.

[0053] The oxidizing agent consists of 0.004kg of K 2 Cr 2 o 7 , 0.007kg of water, 0.088kg of concentrated H 2 SO 4 composition.

[0054] The coating solution consists of 1 kg of silane coupling agent, 0.2 kg of hydrophilic surfactant, 1 kg of calcium sulfoaluminate and 0.2 kg of carbon black.

preparation example 2

[0056] Mix 2 kg of polypropylene fiber with 0.15 kg of oxidizing agent, soak for 1.5 h and wash to obtain the first product, add the first product to the coating solution and mix to obtain modified polypropylene fiber.

[0057] The oxidant consists of 0.009kg of K 2 Cr 2 o 7 , 0.0012kg of water, 0.129kg of concentrated H 2 SO 4 composition.

[0058] The coating solution consists of 1.3kg of acetate coupling agent, 0.3kg of hydrophilic surfactant, 1.2kg of calcium sulfoaluminate and 0.3kg of carbon black.

preparation example 3

[0060] Mix 3 kg of polypropylene fiber with 0.2 kg of oxidizing agent, soak for 2 hours and wash to obtain the first product, add the first product to the coating liquid and mix to obtain modified polypropylene fiber.

[0061] The oxidant consists of 0.014kg of K 2 Cr 2 o 7 , 0.0017kg of water, 0.169kg of concentrated H 2 SO 4 composition.

[0062] The coating solution consists of 1.5kg of silane coupling agent, 0.5kg of hydrophilic surfactant, 1.5kg of calcium sulfoaluminate and 0.5kg of carbon black.

[0063] Preparation of Modified Construction Waste Regenerated Coarse Aggregate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com