Corrosion-resistant cable material and preparation method thereof

A cable material and corrosion-resistant technology, applied in the field of corrosion-resistant cable material and its preparation, can solve the problem of high cost, achieve the effects of good strength and toughness, promote rapid and uniform dispersion, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

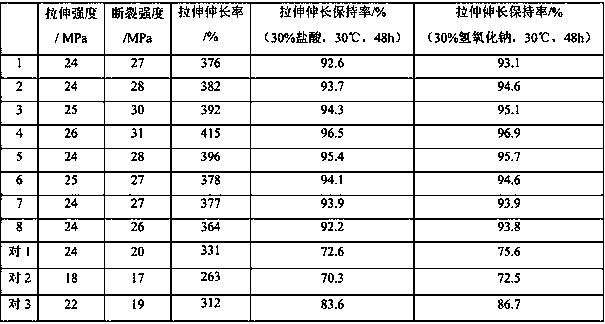

Examples

Embodiment 1

[0024] A corrosion-resistant cable material, made of the following raw materials in parts by weight:

[0025] 30 parts of fluorosilicone rubber, 15 parts of EPDM rubber, 18 parts of ethylene-vinyl acetate copolymer, 6 parts of glass fiber, 10 parts of flame retardant, 4 parts of anti-aging agent, 12 parts of softener, 1 part of antioxidant, 3 parts of plasticizer and 2 parts of crosslinking agent.

[0026] The flame retardant is antimony trioxide.

[0027] Described antioxidant is OD.

[0028] Described softening agent is simethicone.

[0029] Described antioxidant is antioxidant 1010.

[0030] Described plasticizer is dioctyl terephthalate.

[0031] The cross-linking agent is dicumyl peroxide.

[0032] The preparation method of above-mentioned corrosion-resistant cable material, comprises the following steps:

[0033] (1) Put fluorosilicone rubber, EPDM rubber and ethylene-vinyl acetate copolymer in a twin-screw extruder for blending and granulation;

[0034] (2) Put t...

Embodiment 2

[0037] A corrosion-resistant cable material, made of the following raw materials in parts by weight:

[0038] 32 parts of fluorosilicone rubber, 16 parts of EPDM rubber, 19 parts of ethylene-vinyl acetate copolymer, 7 parts of glass fiber, 12 parts of flame retardant, 4 parts of anti-aging agent, 13 parts of softener, 1.2 parts of antioxidant, 4 parts of plasticizer and 2 parts of crosslinking agent.

[0039] Described flame retardant is magnesium hydroxide.

[0040] Described antioxidant is MB.

[0041] Described softening agent is hydroxyl silicone oil.

[0042] Described antioxidant is antioxidant 618.

[0043] Described plasticizer is dioctyl phthalate.

[0044] The cross-linking agent is benzoyl peroxide.

[0045] The preparation method of above-mentioned corrosion-resistant cable material, comprises the following steps:

[0046] (1) Put fluorosilicone rubber, EPDM rubber and ethylene-vinyl acetate copolymer in a twin-screw extruder for blending and granulation;

...

Embodiment 3

[0050] A corrosion-resistant cable material, made of the following raw materials in parts by weight:

[0051]35 parts of fluorosilicone rubber, 18 parts of EPDM rubber, 20 parts of ethylene-vinyl acetate copolymer, 8 parts of glass fiber, 14 parts of flame retardant, 5 parts of anti-aging agent, 15 parts of softener, 1.8 parts of antioxidant, 4.3 parts of plasticizer and 3 parts of crosslinking agent.

[0052] The flame retardant is aluminum oxide.

[0053] Described antioxidant is 4010NA.

[0054] Described softening agent is simethicone.

[0055] Described antioxidant is antioxidant 300.

[0056] Described plasticizer is di-isooctyl phthalate.

[0057] The crosslinking agent is 2,5-dimethyl-2,5-di(t-butylperoxy)hexane.

[0058] The preparation method of above-mentioned corrosion-resistant cable material, comprises the following steps:

[0059] (1) Put fluorosilicone rubber, EPDM rubber and ethylene-vinyl acetate copolymer in a twin-screw extruder for blending and granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com