Method for preparing base paper of facing paper from plant fibers

A technology of plant fiber and veneer paper, which is applied in the direction of fiber raw material, fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, etc., which can solve the problems of inability to curl, limit the scope of application, and have health and safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

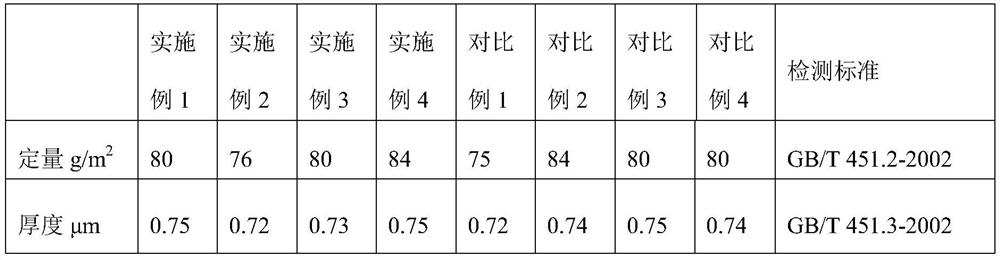

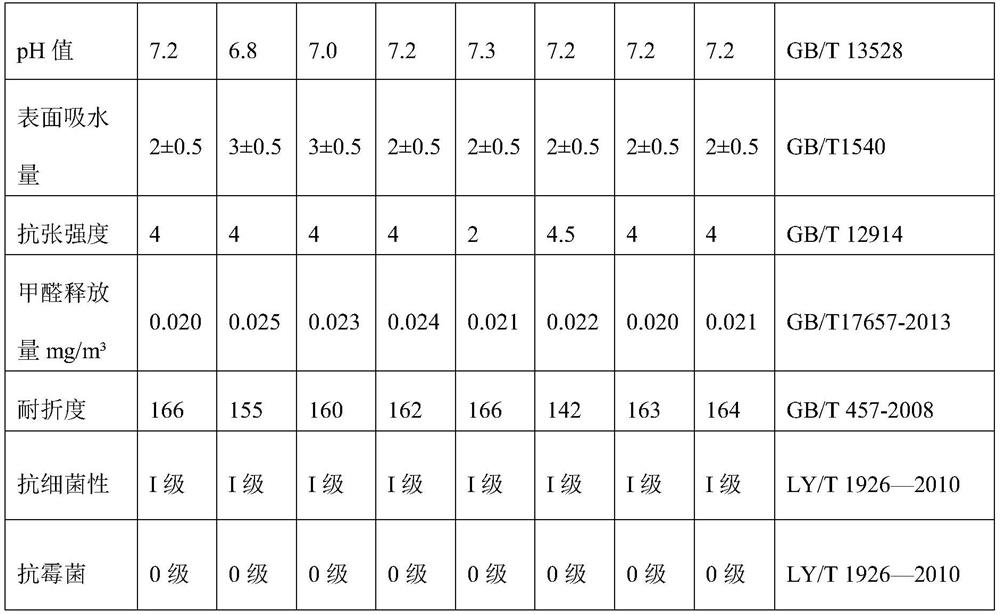

Examples

Embodiment 1

[0029] Prepare raw material plant fiber, inorganic fiber, sepiolite, EVA resin and modifier; the preparation method of modifier is: add pulping black liquor to sodium dodecylbenzene sulfonate, stir for 20-30 minutes, and then Add sodium silicate, silver-loaded zeolite powder and powdered activated carbon, and continue stirring for 30-40 minutes to make a modifier;

[0030] Plant fibers are crop straw, poplar, bagasse, pulp or forestry processing residues;

[0031] Inorganic fiber is glass fiber and ore powder;

[0032] According to the mass percentage of raw materials, plant fiber accounts for 60%, glass fiber accounts for 10%, ore powder accounts for 10%, sepiolite accounts for 5%, EVA resin accounts for 5%, and modifier accounts for 10%;

[0033] Stir the plant fiber with water, then add inorganic fiber, sepiolite, EVA resin and modifier, and stir evenly to obtain a mixed material; the amount of water added is 1:5 according to the mass ratio of plant fiber to water;

[003...

Embodiment 2

[0037] Method is with embodiment 1, and difference is:

[0038] (1) Inorganic fiber is ore powder; plant fiber is crop straw, poplar, bagasse, pulp or forestry processing residue;

[0039] (2) plant fiber accounts for 65% by mass percentage in the raw material, ore powder accounts for 15%, sepiolite accounts for 10%, EVA resin accounts for 5%, modifier accounts for 5%;

[0040] (3) The addition of water is 1: 10 by the mass ratio of plant fiber and water;

[0041] (4) The pressure of pressing and dehydration is 400KN / m; the temperature of drying and dehydration is 120°C.

Embodiment 3

[0043] Method is with embodiment 1, and difference is:

[0044] (1) Inorganic fibers are glass fibers; plant fibers are crop straw, poplar, bagasse, pulp or forestry processing residues;

[0045] (1) plant fiber accounts for 70% by mass percentage in the raw material, glass fiber accounts for 10%, sepiolite accounts for 5%, EVA resin accounts for 5%, modifier accounts for 15%;

[0046] (2) the addition of water is 1: 8 by the mass ratio of plant fiber and water;

[0047] (3) The pressure of pressing and dehydration is 450KN / m; the temperature of drying and dehydration is 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com