Method for removing formaldehyde and methanol from carboxylic ester containing material and application

A carboxylate and logistics technology, applied in the field of separation technology, can solve the problems of difficult separation, easy polymerization, high energy consumption for formaldehyde recycling and utilization, and achieve the effects of high economy, simple process and high industrial application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

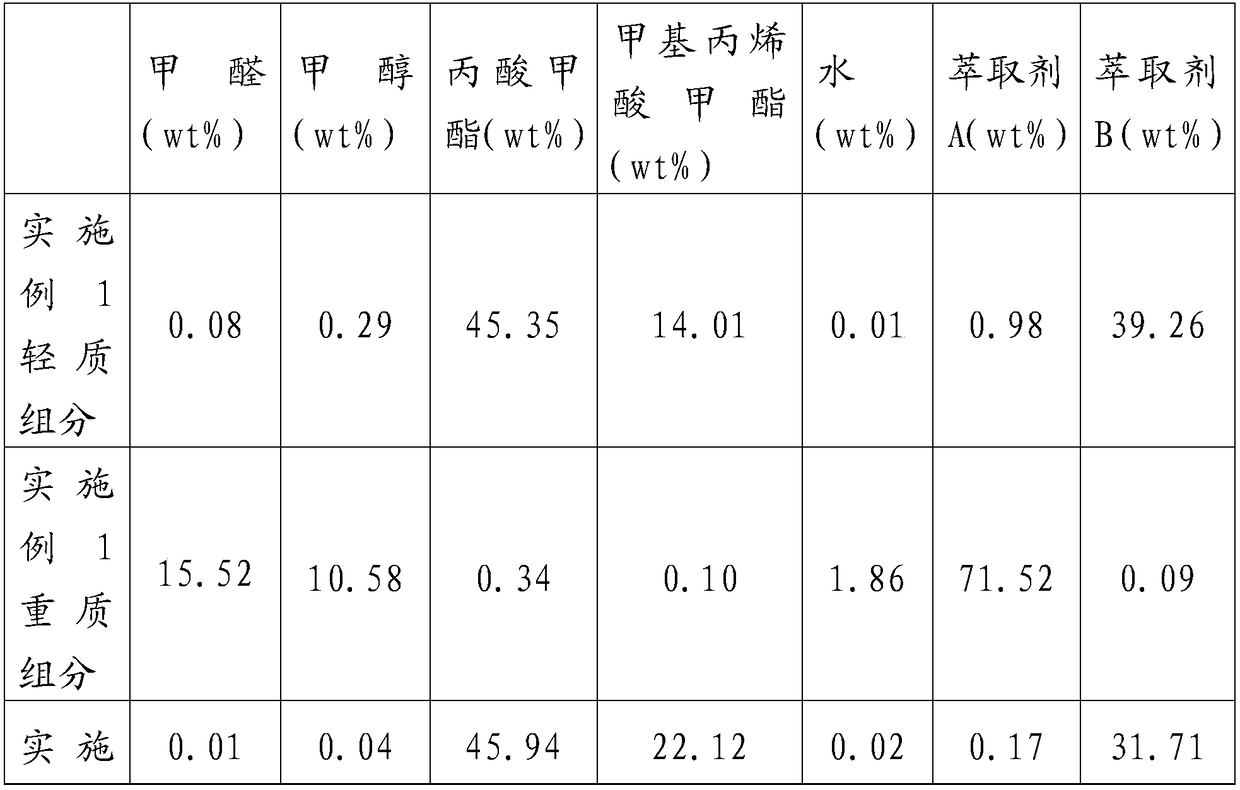

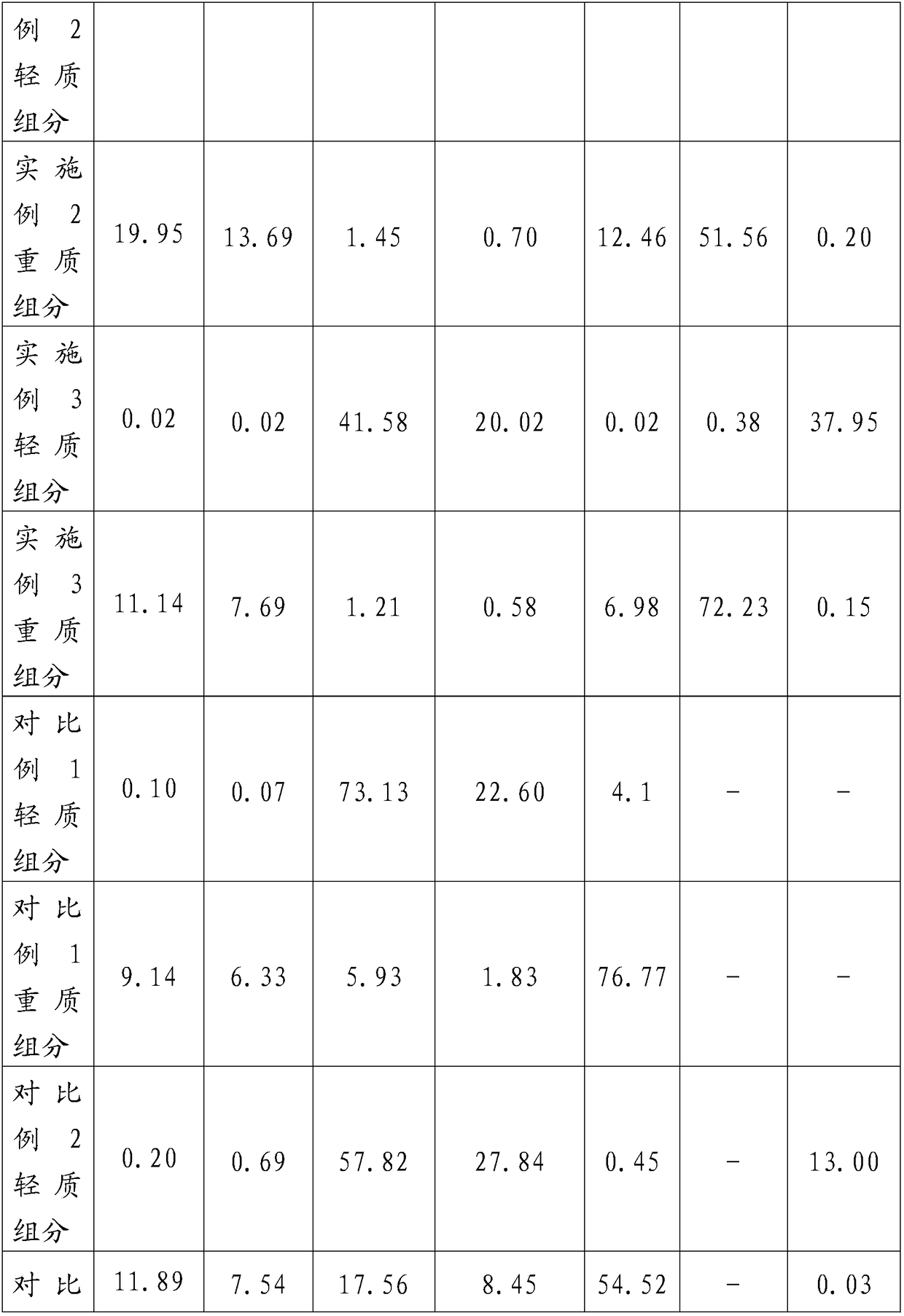

Embodiment 1

[0061] In this embodiment, the extractant A is dimethyl sulfoxide, and the extractant B is cyclohexane, ε A = 48.9, ε B = 2.02.

[0062] Through the aldol condensation reaction of methyl propionate and formaldehyde, stream 1 containing carboxylic acid esters was obtained. After testing, the composition of stream 1 containing carboxylic acid esters was: 8.66 wt% formaldehyde, 38.80 wt% methanol, and 45.73 methyl propionate. wt%, methyl methacrylate (abbreviated as MMA) 5.77 wt%, water 1.04 wt%.

[0063] (1) The stream 1 containing carboxylic acid ester is subjected to pre-rectification treatment to remove part of methanol as an azeotrope of methanol and methyl propionate. The operating conditions of the rectification tower are atmospheric pressure, 25°C operating temperature, 20 theoretical plates, stream 1 containing carboxylic acid ester is fed into the eighth plate, and the top temperature of the rectification tower is 62.5°C. The temperature is 75°C, the reflux ratio is 1, the ...

Embodiment 2

[0067] In this embodiment, the extractant A is dimethyl sulfoxide, and the extractant B is cyclohexane, ε A = 48.9, ε B = 2.02.

[0068] Through the aldol condensation reaction of methyl propionate and formaldehyde, stream 2 containing carboxylic acid ester is obtained. After testing, the composition of stream 2 containing carboxylic acid ester is: formaldehyde 5.07% by weight, methanol 22.1% by weight, and methyl propionate 52% by weight %, methyl methacrylate 17.65wt%, water 3.18wt%.

[0069] (1) The stream 2 containing carboxylic acid esters is subjected to pre-rectification treatment, and part of the methanol is removed in the form of an azeotrope of methanol and methyl propionate. The operating conditions of the rectification column are normal pressure and 25 ℃, the number of theoretical plates is 20 plates, the feed position of stream 1 is at the tenth plate, the top temperature is 62.5℃, the bottom temperature is 75℃, the reflux ratio is 0.7, the feed flow rate is 1.51kg / h, ...

Embodiment 3

[0073] The pre-rectified stream 2 containing carboxylic acid esters in Example 2 was input from the middle of the extraction tower at a mass flow rate of 1 kg / h; at the same time, dimethyl sulfoxide was discharged from the top of the extraction tower at a mass flow rate of 0.5 kg / h. Into the tower, the cyclohexane is fed into the tower internal stream from the bottom of the extraction tower at a mass flow of 0.5kg / h. The cyclohexane and dimethyl sulfoxide are in countercurrent contact in the tower and are extracted step by step. Finally, 1.2 kg / h of light components were obtained from the upper section of the extraction tower, and 0.38 kg / h of heavy components were obtained from the lower section of the extraction tower. The operating pressure of the extraction tower is normal pressure, the operating temperature is 25°C, and the theoretical number of stages is 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com