Preparation method of mixed-material glue-free composite material based on high-frequency waves

A composite material, high-frequency technology, applied in the direction of manufacturing tools, wood processing appliances, wood veneer bonding, etc., can solve the problems of high defect rate, open glue, endanger human health and other problems, achieve high toughness, high strength, formaldehyde and The effect of low xylene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0046] Embodiment 1-8 provides 8 kinds of preparation methods based on high-frequency mixed materials and glue-free composite materials, and these 8 kinds of composite materials are composed of at least two pieces with a density of no more than 0.7kg / m 3 The planks are formed by high-frequency heating and pressing, and a degenerated connection layer is formed between adjacent planks. The preparation method includes the following steps:

[0047] a. Pretreatment: Treat the plank to a moisture content of 8%-18% and a thickness of no more than 10cm to obtain a pretreated plank;

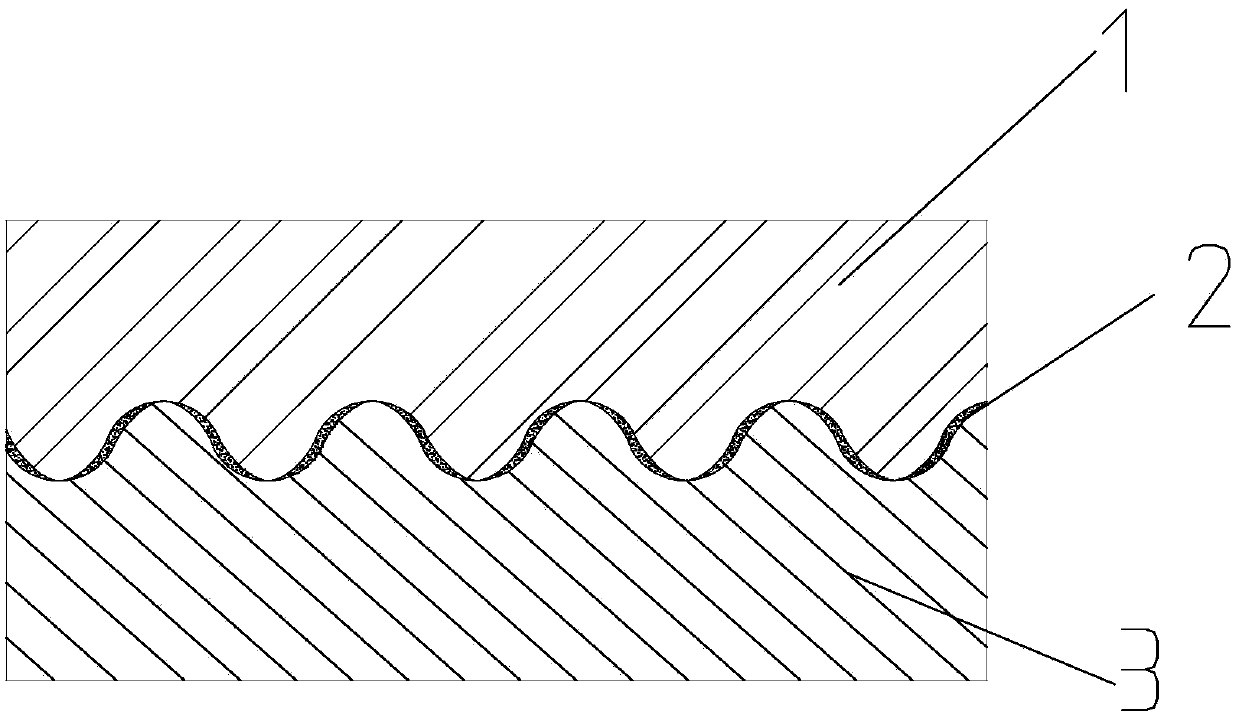

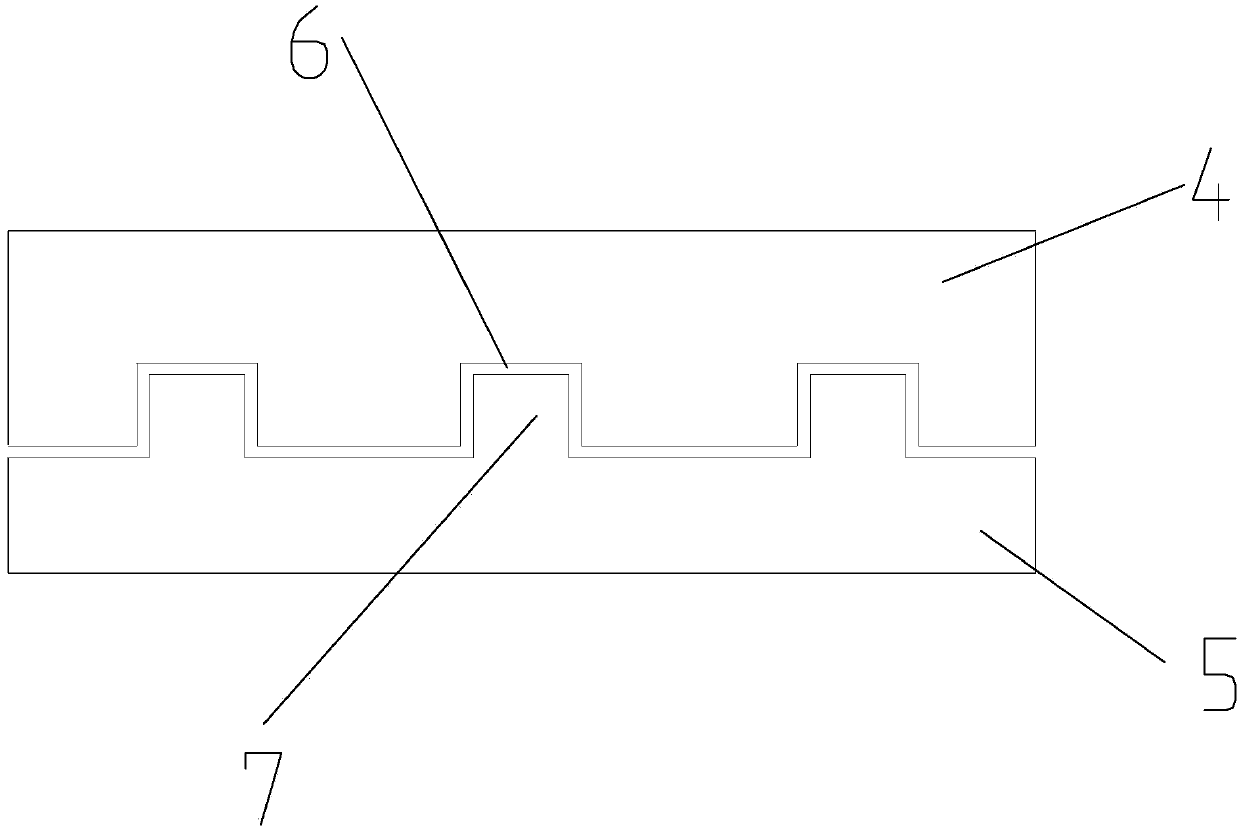

[0048] b. Lamination treatment: Take 2 or more pretreated wood boards and place them in layers according to at least one direction of force to make laminated wood boards. The direction of force includes the direction of direct pressure and the direction of indirect pressure;

[0049] c. Heating and pressure treatment: heat the degraded connection layer of laminated wood boards until the temperature of the...

Embodiment 9-11

[0069] Embodiment 9-11 is based on each parameter in the method for embodiment 5, difference is:

[0070] The number of planks is 5, and the thickness of each plank is the same, and is 8cm. The curing treatment in step d is heated by high-frequency waves. For N parts, measure the average moisture content Q of each part, assume that the temperature of the board when high-frequency heating is used in the curing process is T, and the heating time is t, then Q, T and t meet the following conditions:

[0071] When 8%≤Q≤10%, then 180℃≤T≤185℃, 1min≤t<2min;

[0072] When 10%

[0073] When 12%

[0074] When 14%

[0075] In the stacking process of step b: 5 pretreated wood boards are stacked according to the direction of indirect force to form a laminated wood board, and the densities of the adjacent first pretreated wood board and the second pretreated wood board are res...

Embodiment 12

[0083] This embodiment provides a preparation method based on high-frequency mixed materials and glue-free composite materials, which specifically includes the following steps:

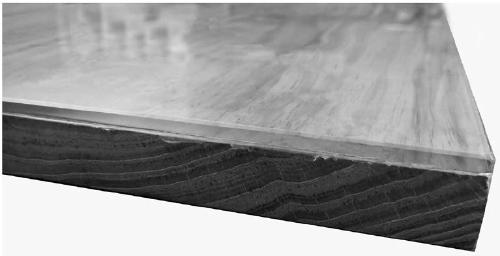

[0084] The board has a density of 0.55kg / m 3 , the thickness of the glass plate is 1.5cm, and the composite material is mainly prepared by the following steps:

[0085] a. Pretreatment: Treat the plank to a moisture content of 10% and a thickness of 8 cm to obtain a pretreated plank;

[0086] b. Lamination treatment: Take 2 pre-treated wooden boards and place them in layers according to the direction of force, and place the glass plate between the two wooden boards to obtain a laminated wooden board;

[0087] c. Heating and pressure treatment: heat the degraded connection layer of the laminated wood boards to a temperature of 90° C., keep the heat for 5 minutes, and then perform pressure treatment according to the preset compression ratio (preset compression ratio P=35%);

[0088] d. Curing treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com