Patents

Literature

146 results about "Gel free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gel-free buffer tube with adhesively coupled optical element

Owner:DRAKA COMTEQ BV

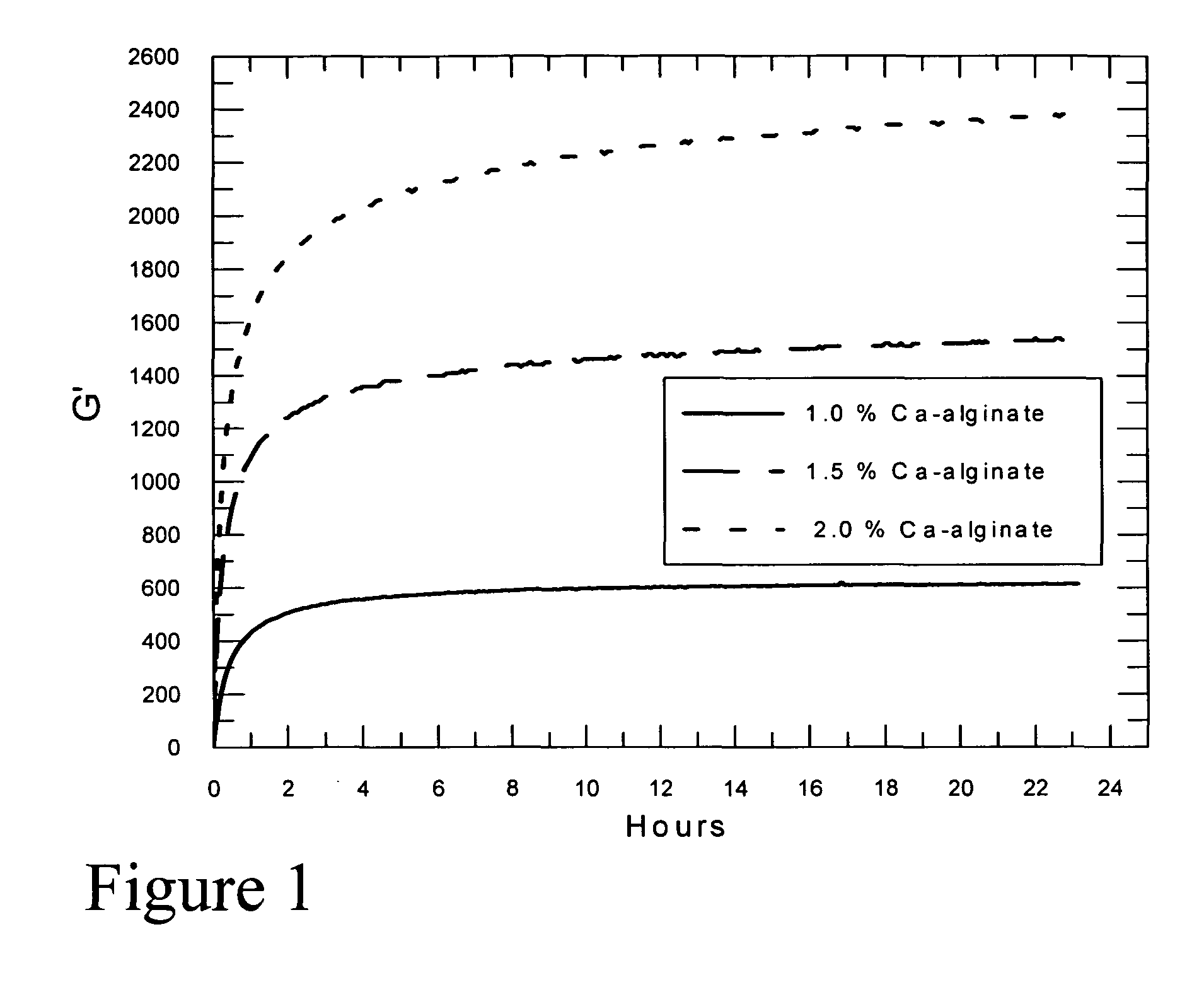

Self-gelling alginate systems and uses thereof

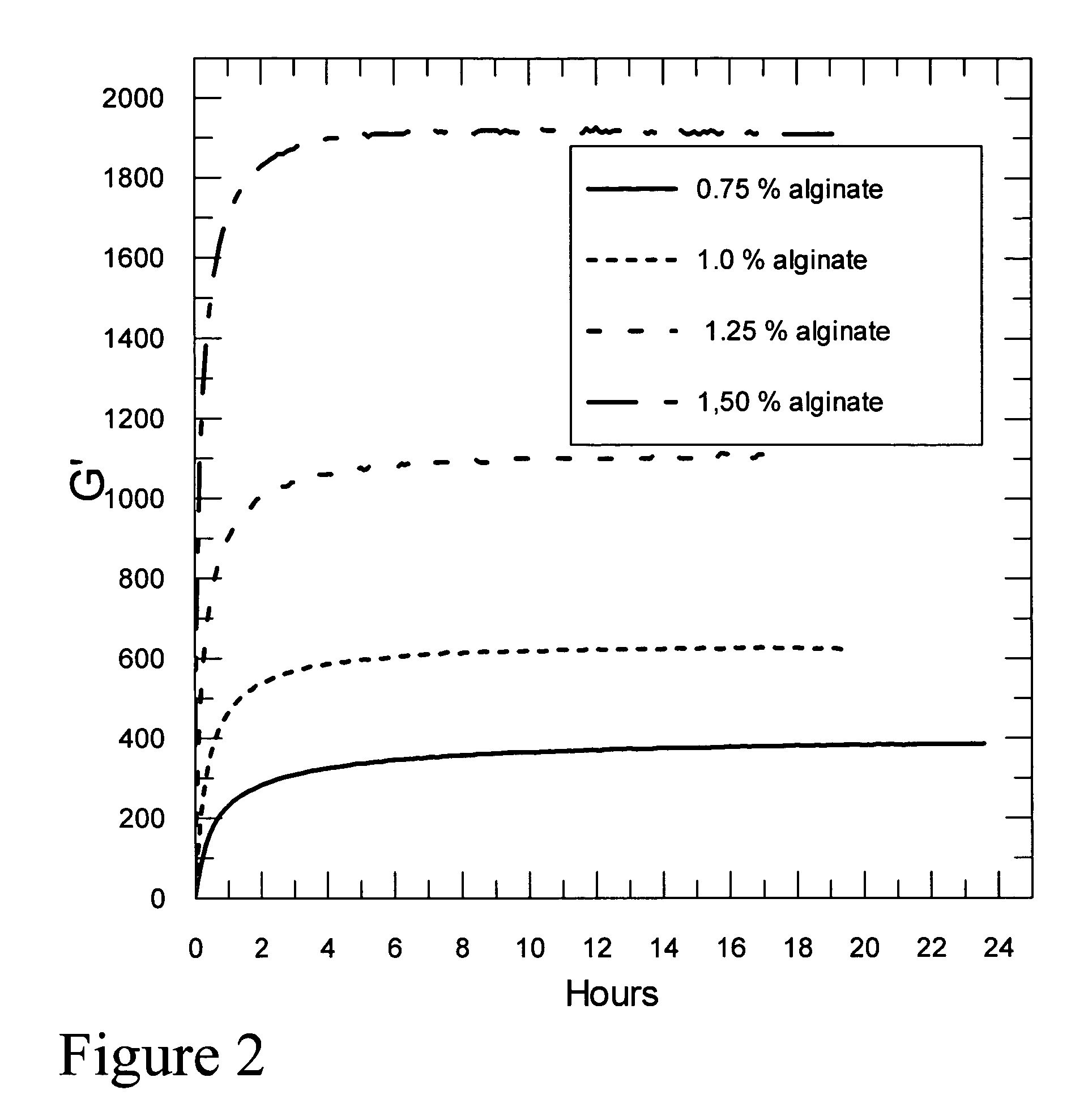

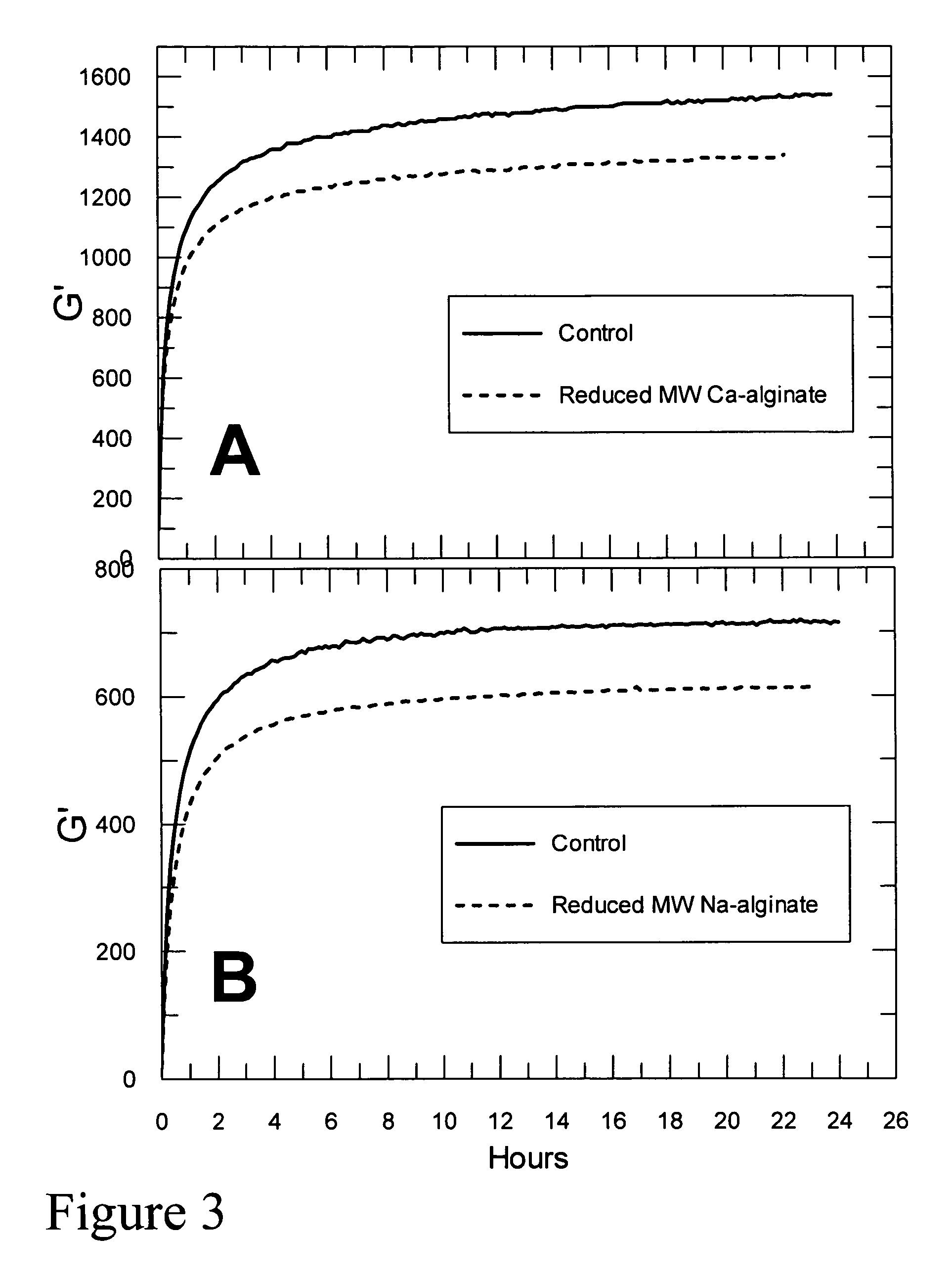

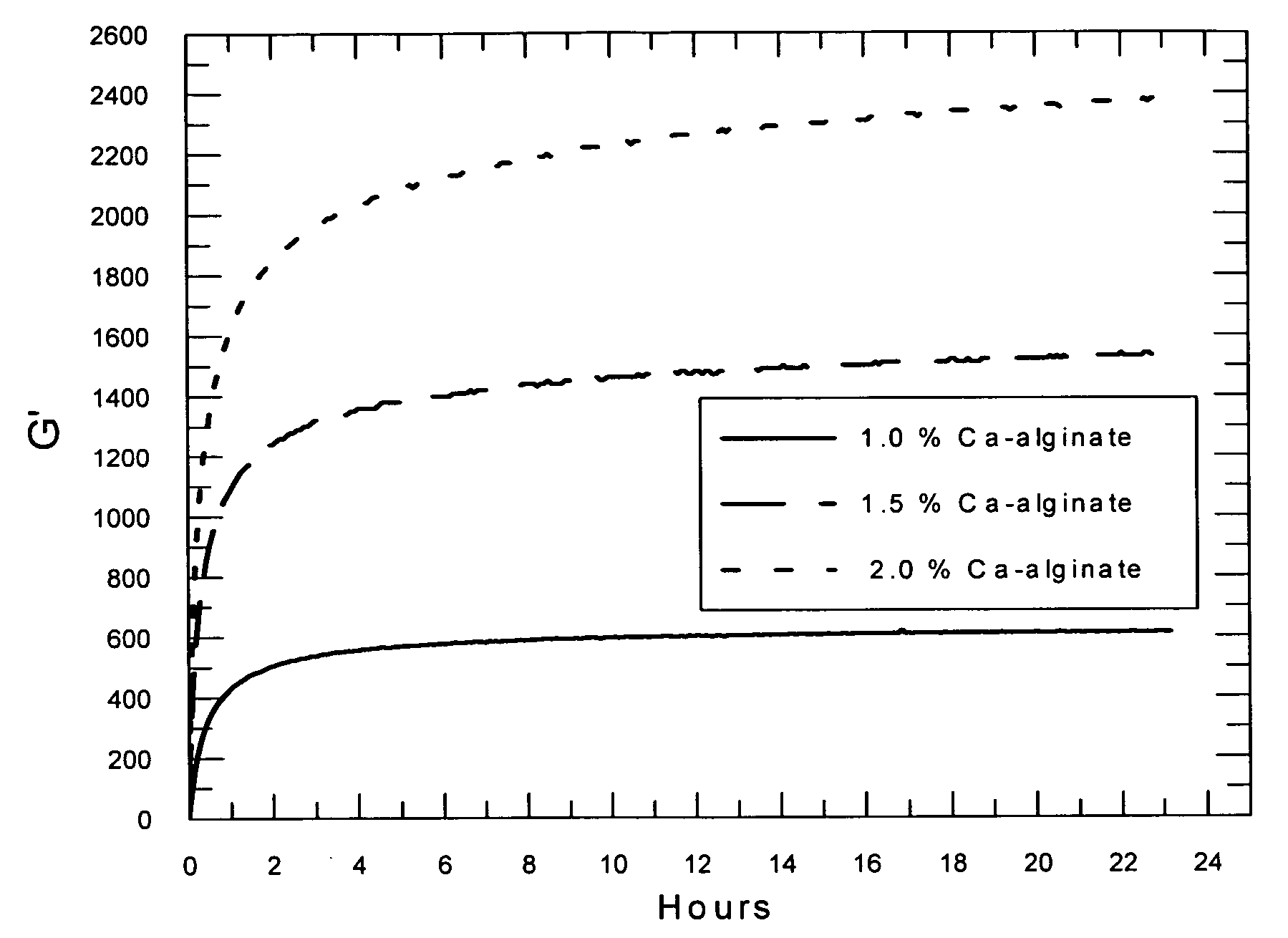

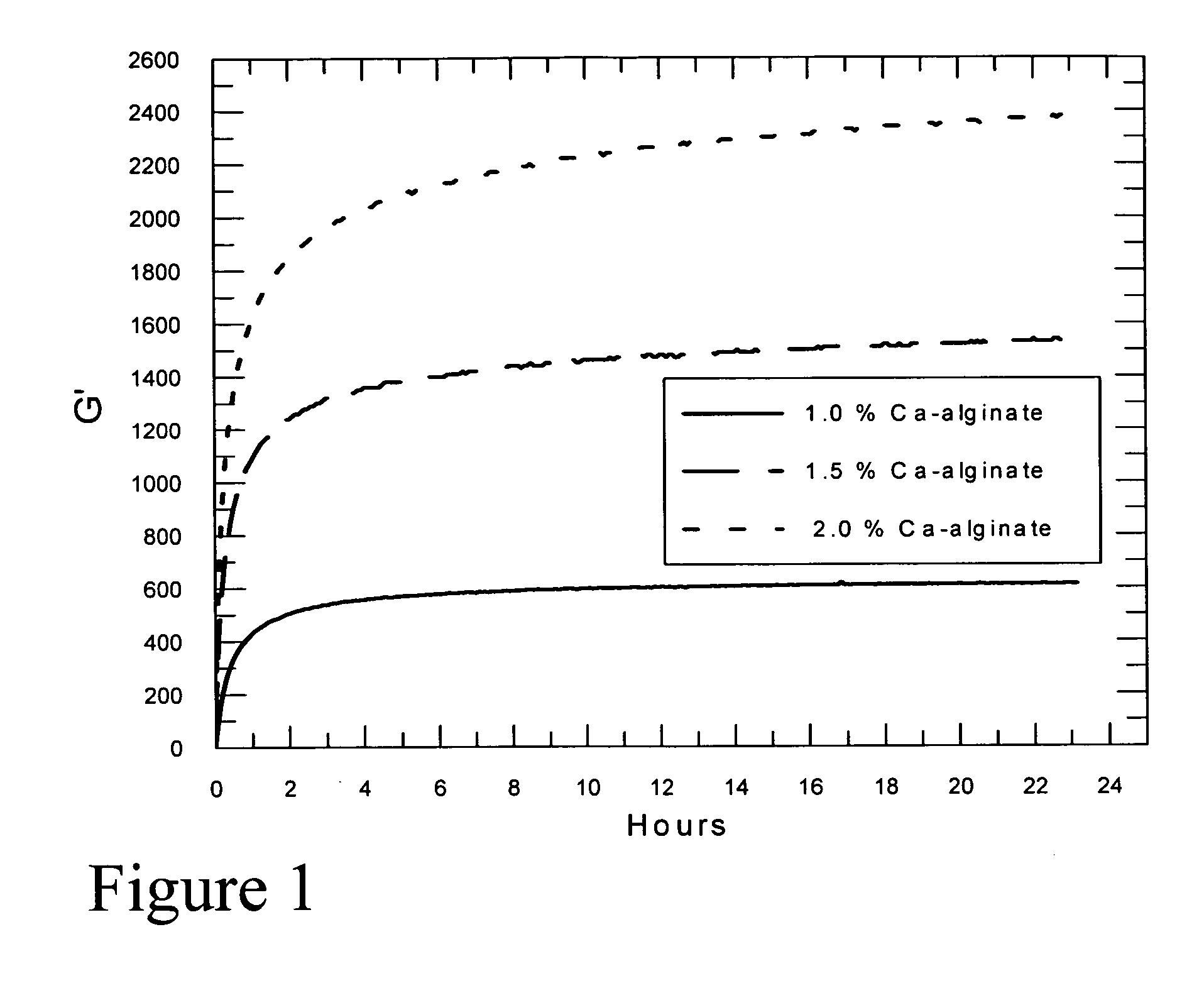

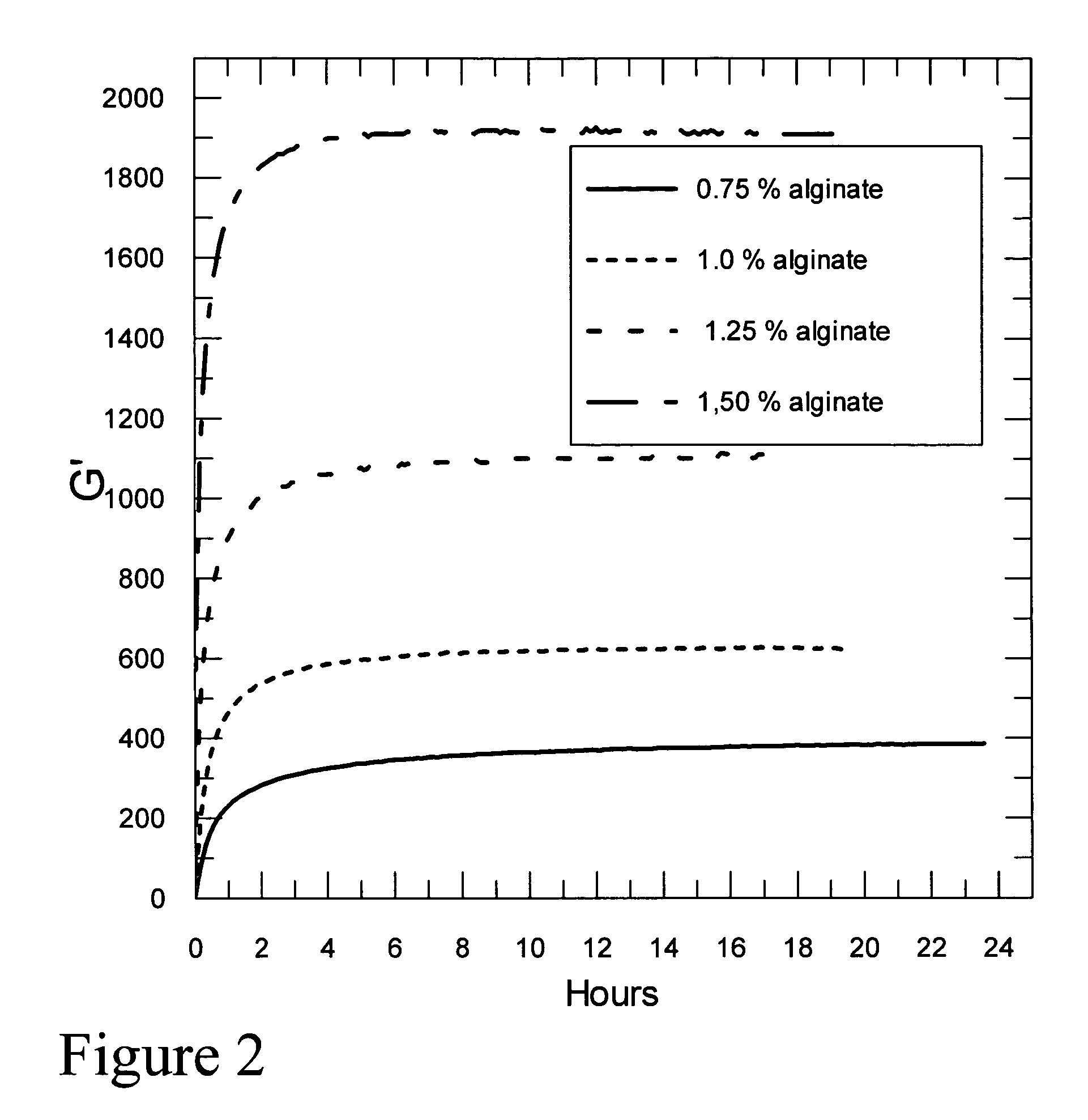

Kits and compositions for producing an alginate gel are disclosed. The kits and compositions comprise soluble alginate and insoluble alginate / gelling ion particles. Methods for dispensing a self-gelling alginate dispersion are disclosed. The methods comprise forming a dispersion of insoluble alginate / gelling ion particles in a solution containing soluble alginate, and dispensing the dispersion whereby the dispersion forms an alginate gel matrix. The methods may include dispensing the dispersion into the body of an individual. An alginate gel having a thickness of greater than 5 mm and a homogenous alginate matrix network and homogenous alginate gels free of one or more of: sulfates citrates, phosphates, lactatates, EDTA or lipids are disclosed. Implantable devices comprising a homogenous alginate gel coating are disclosed. Methods of improving the viability of pancreatic islets, or other cellular aggregates or tissue, following isolation and during storage and transport are disclosed.

Owner:FMC BIOPOLYMER AS

Self-gelling alginate systems and uses thereof

ActiveUS20060159823A1Improve survivabilityBiocideOrganic active ingredientsLipid formationCITRATE ESTER

Kits and compositions for producing an alginate gel are disclosed. The kits and compositions comprise soluble alginate and insoluble alginate / gelling ion particles. Methods for dispensing a self-gelling alginate dispersion are disclosed. The methods comprise forming a dispersion of insoluble alginate / gelling ion particles in a solution containing soluble alginate, and dispensing the dispersion whereby the dispersion forms an alginate gel matrix. The methods may include dispensing the dispersion into the body of an individual. An alginate gel having a thickness of greater than 5 mm and a homogenous alginate matrix network and homogenous alginate gels free of one or more of: sulfates citrates, phosphates, lactatates, EDTA or lipids are disclosed. Implantable devices comprising a homogenous alginate gel coating are disclosed. Methods of improving the viability of pancreatic islets, or other cellular aggregates or tissue, following isolation and during storage and transport are disclosed.

Owner:FMC BIOPOLYMER AS

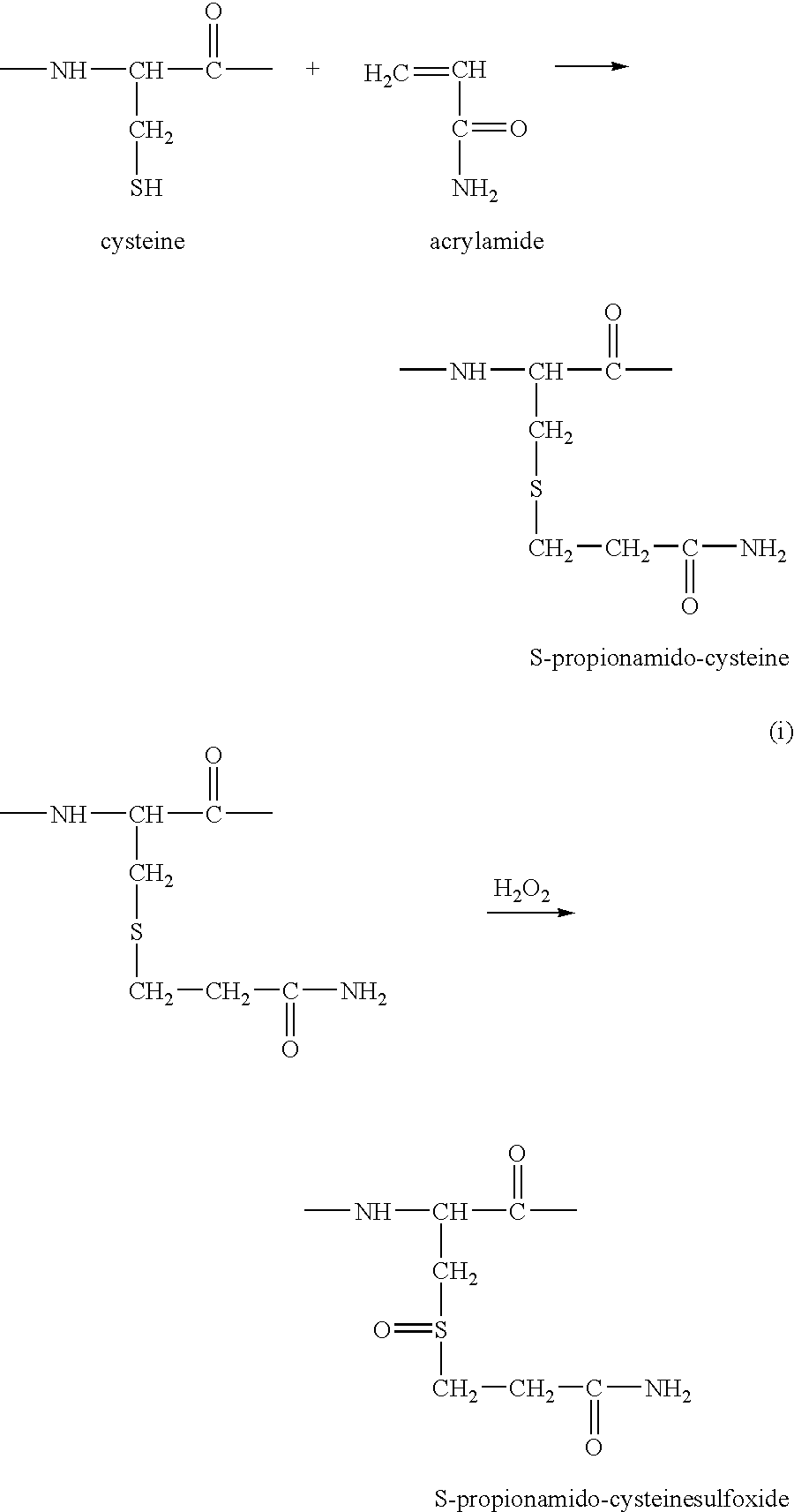

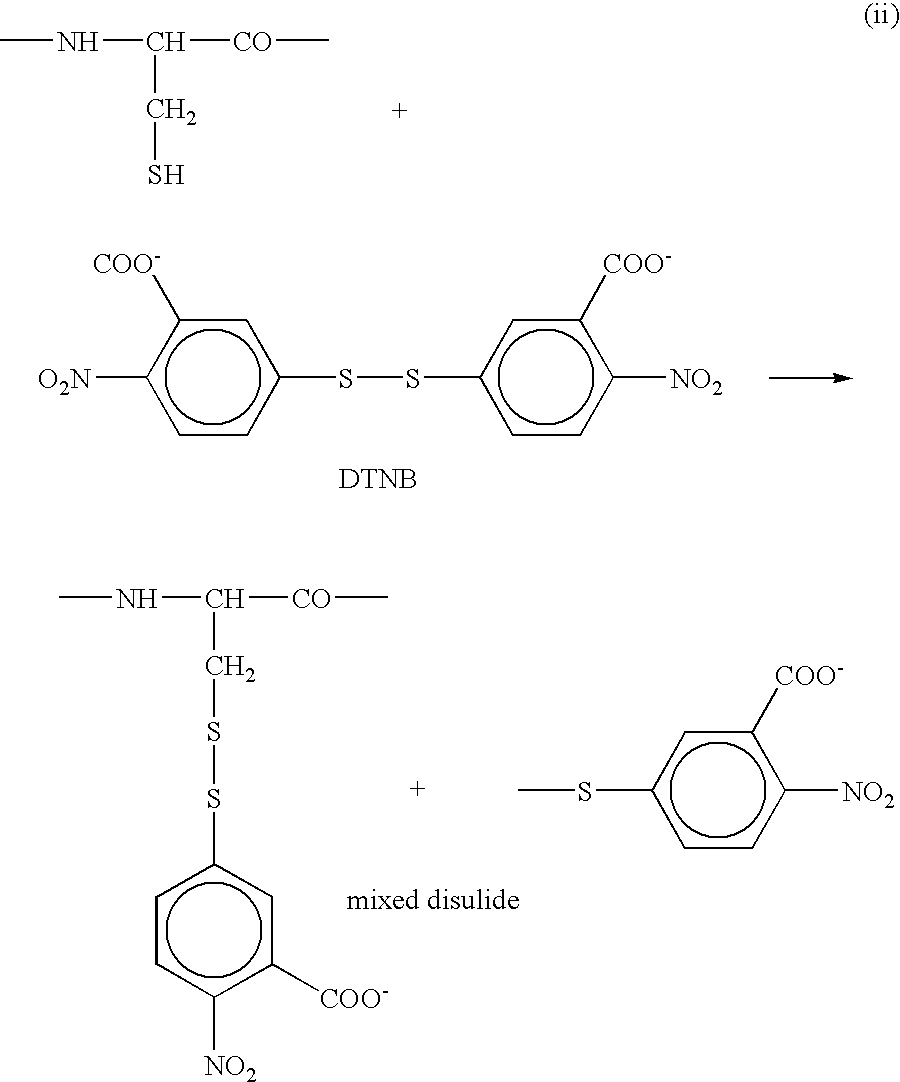

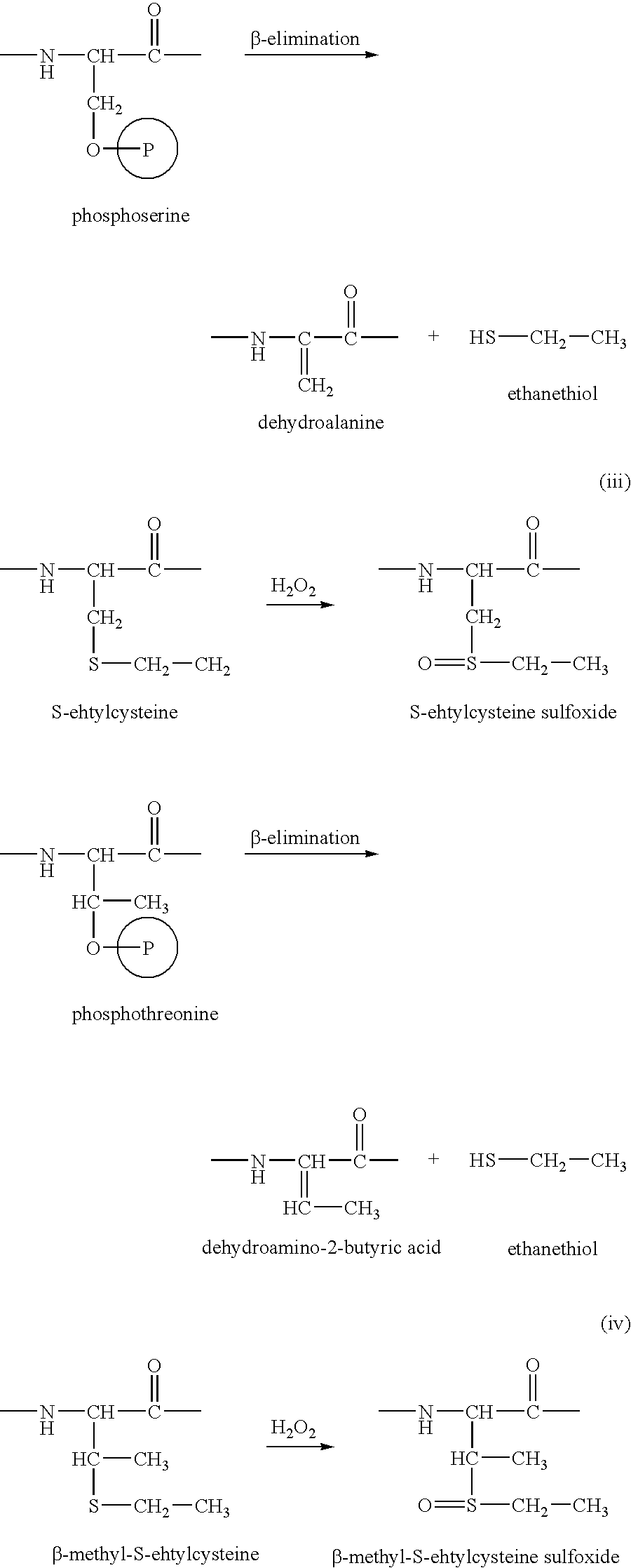

Methods and apparatus for gel-free qualitative and quantitative proteome analysis, and uses therefore

InactiveUS6908740B2Bioreactor/fermenter combinationsBiological substance pretreatmentsEnzymeProteome

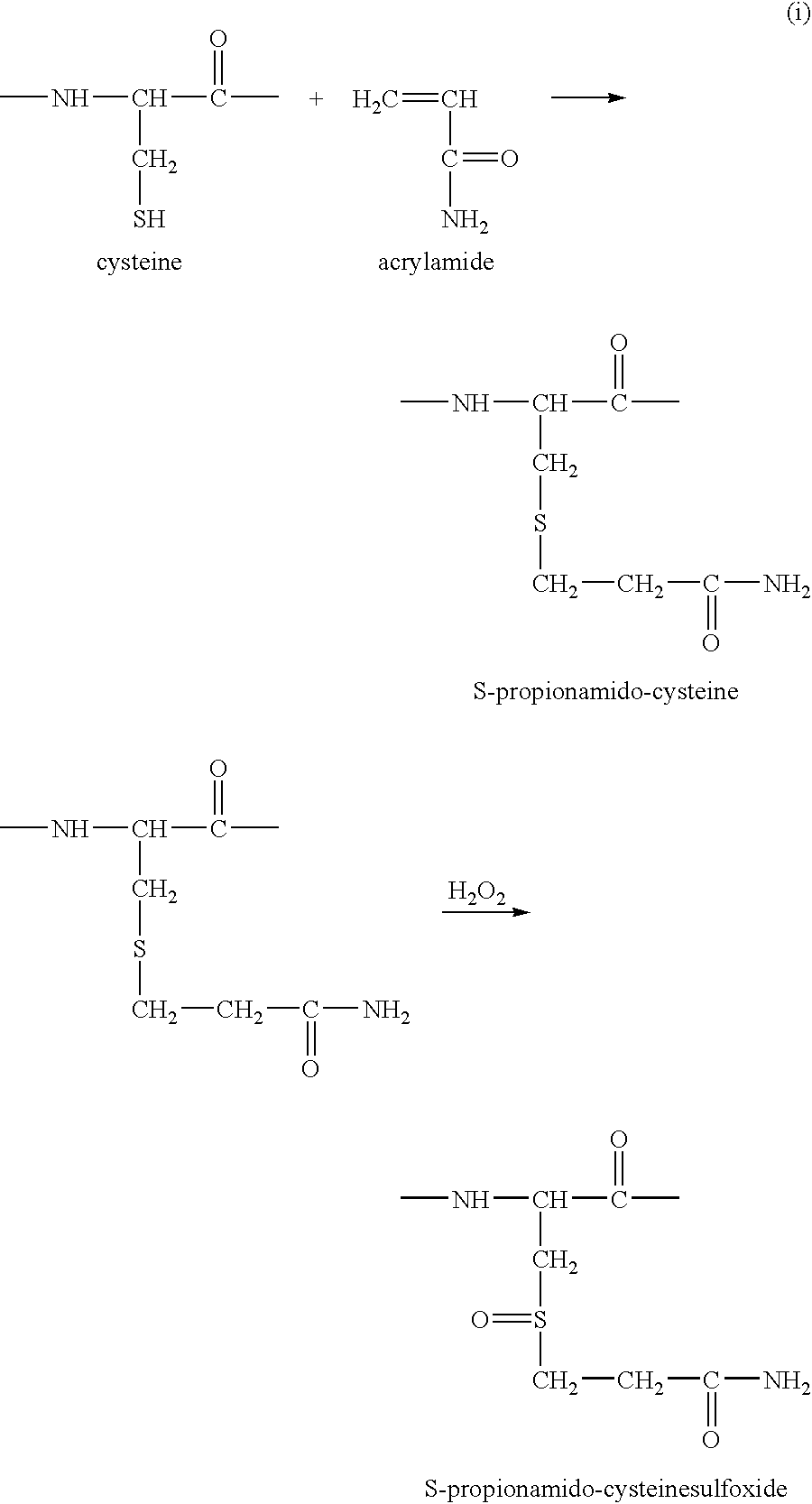

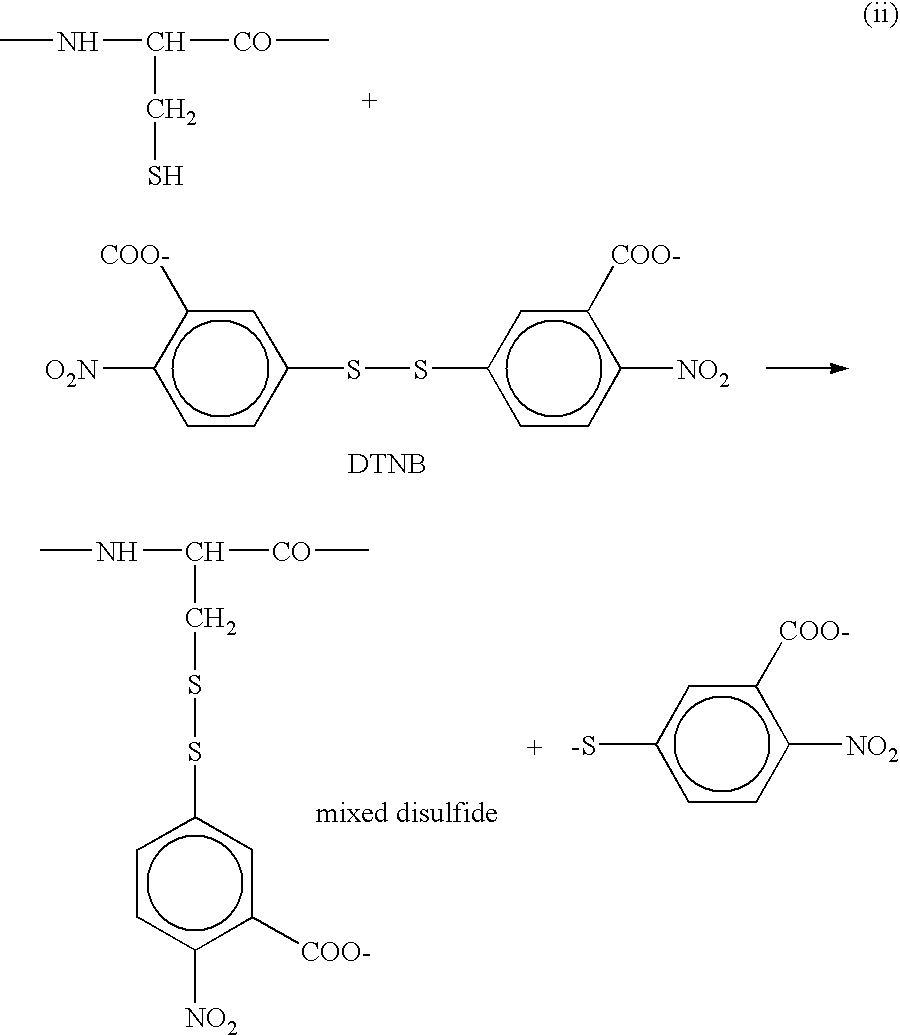

Methods and apparatus for qualitative and quantitative proteome analysis are provided. The methods and apparatus allow for the isolation of a subset of peptides out of complex mixtures of peptides. The isolation is based on a specific chemical and / or enzymatic alteration of one or more types of peptides. This alteration modifies the biophysical, chemical or any other biochemical property of the affected types of peptides (e.g., net electrical charge and / or hydrophobicity) in such way that the altered peptides can be separated from the unaltered peptides.

Owner:MYCARTIS

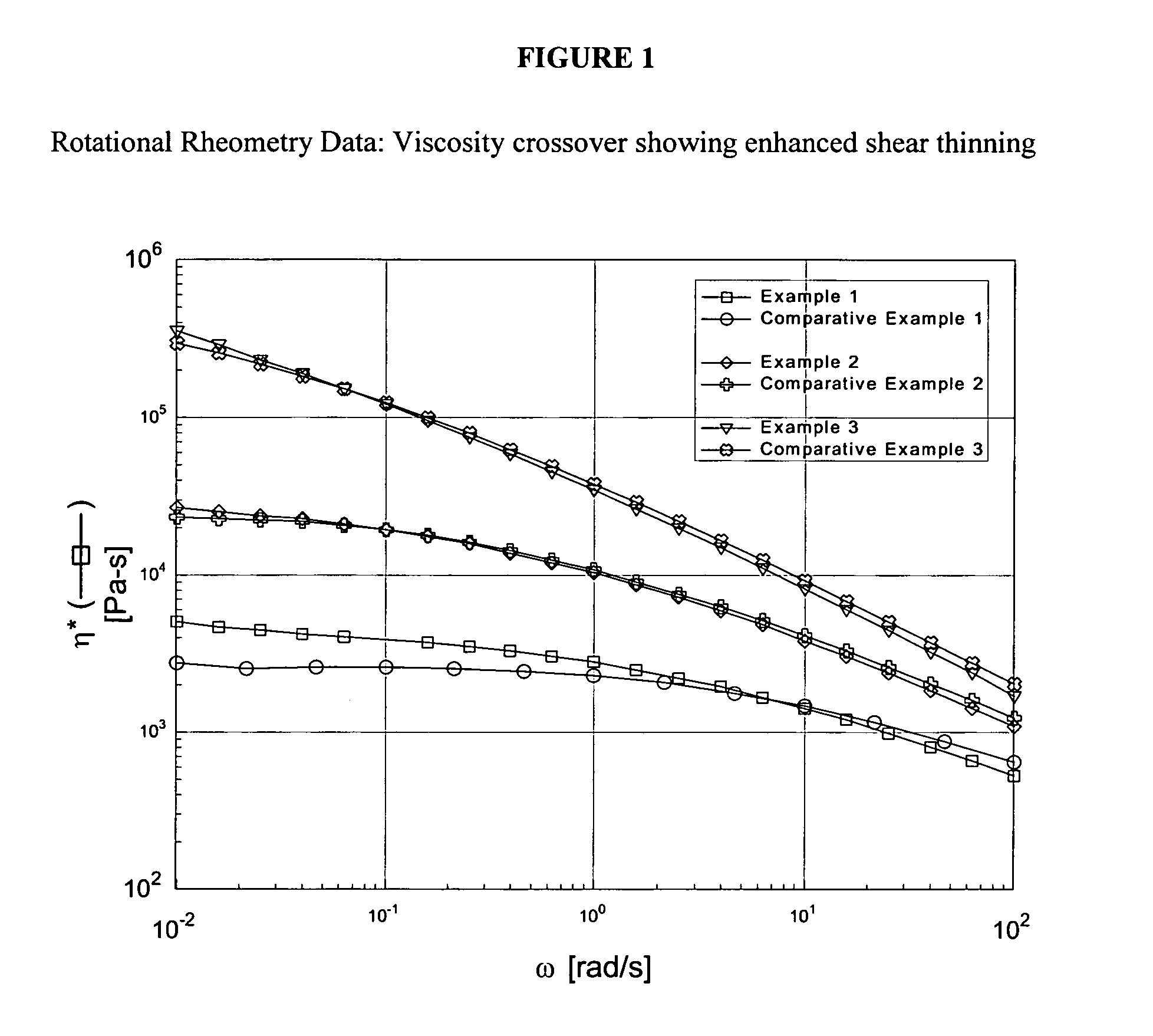

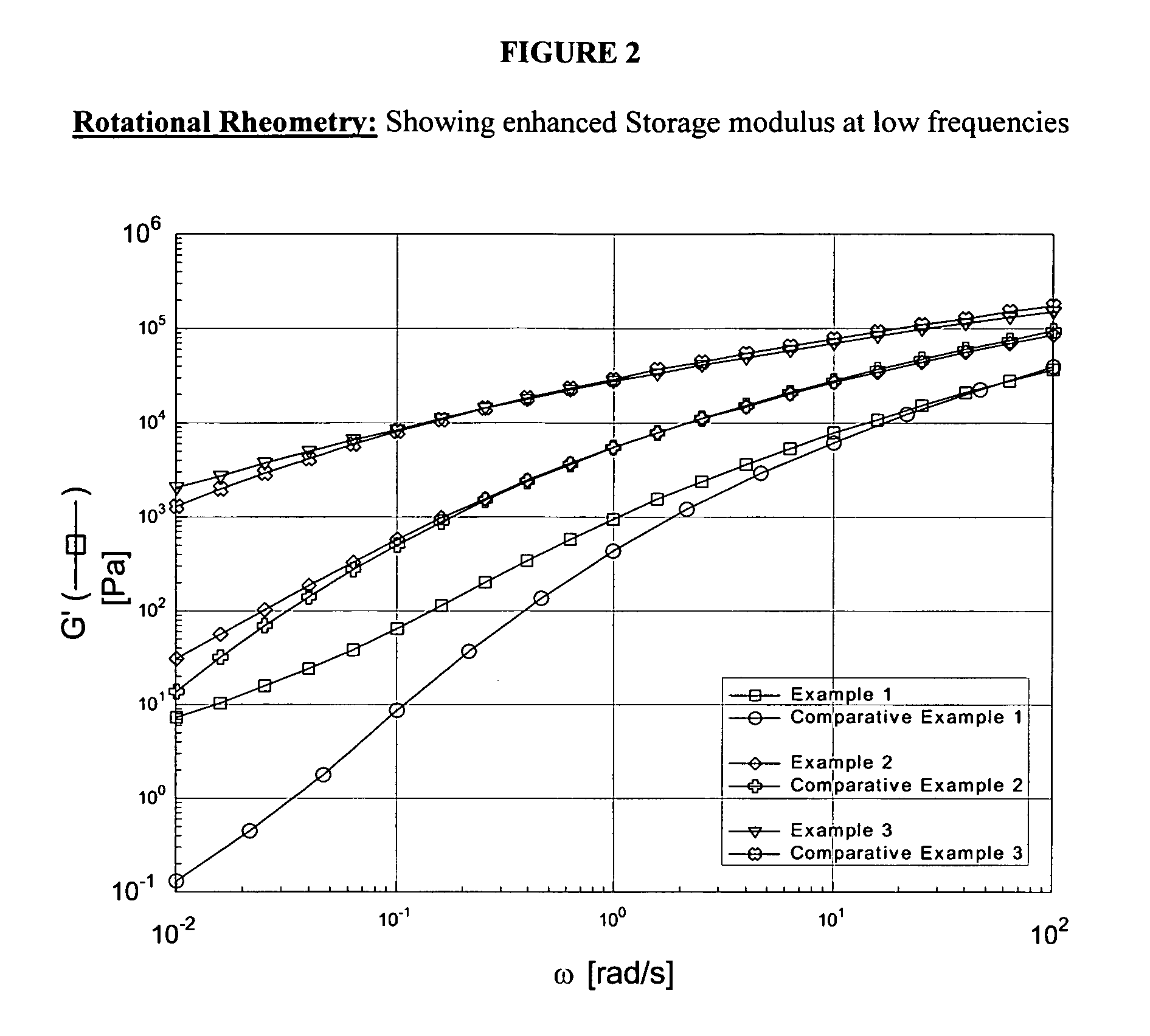

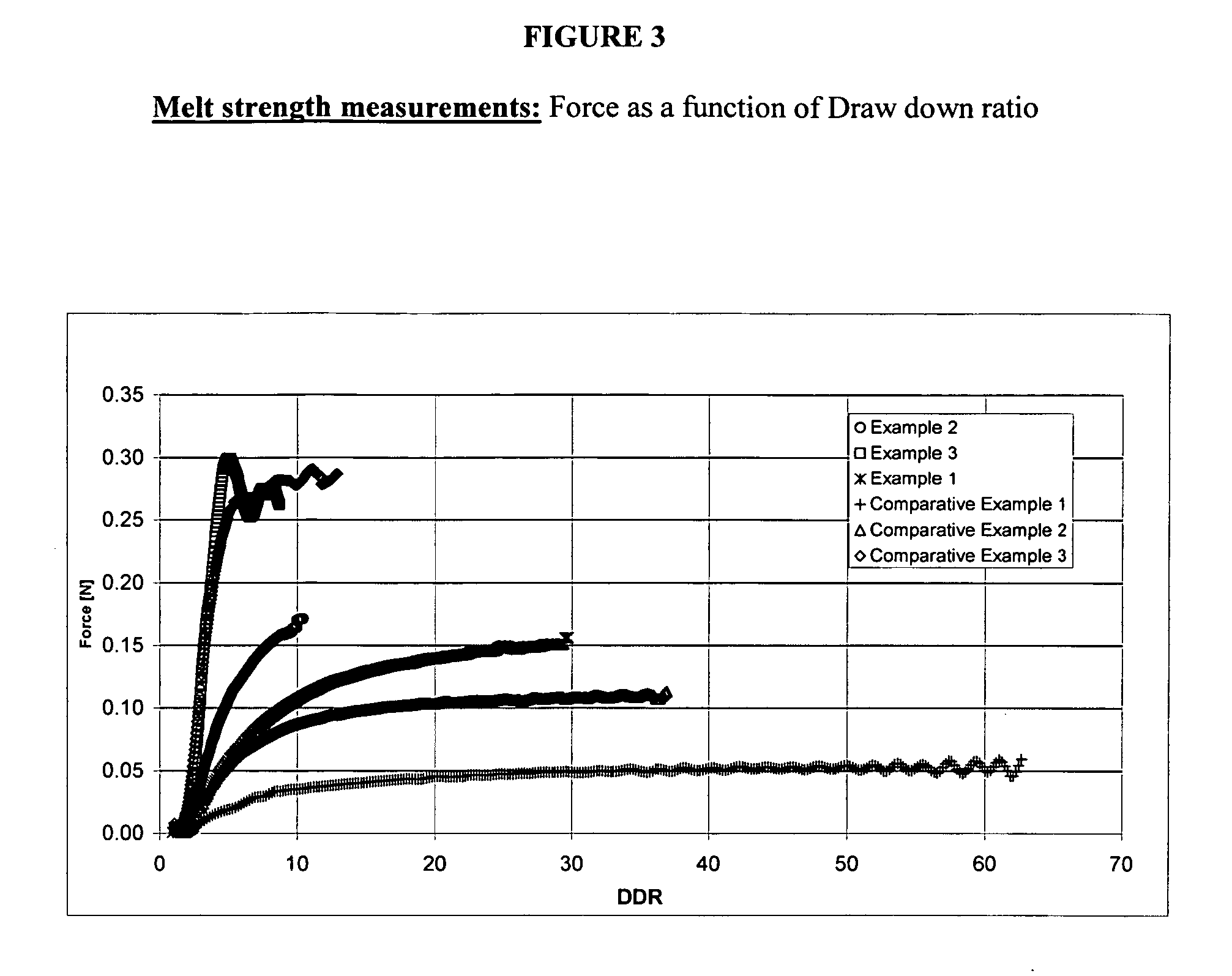

Polypropylene material with high bath strength and preparation method

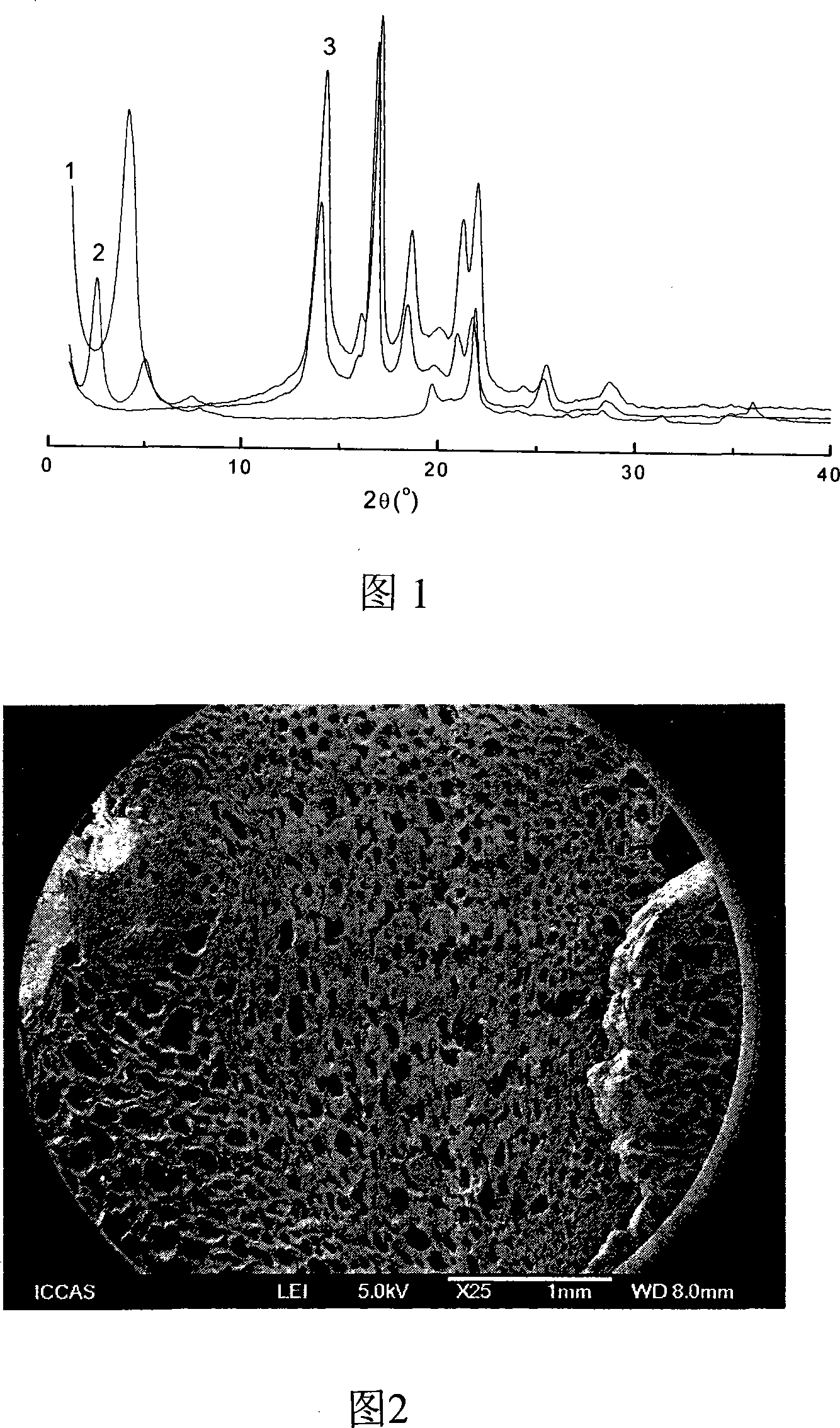

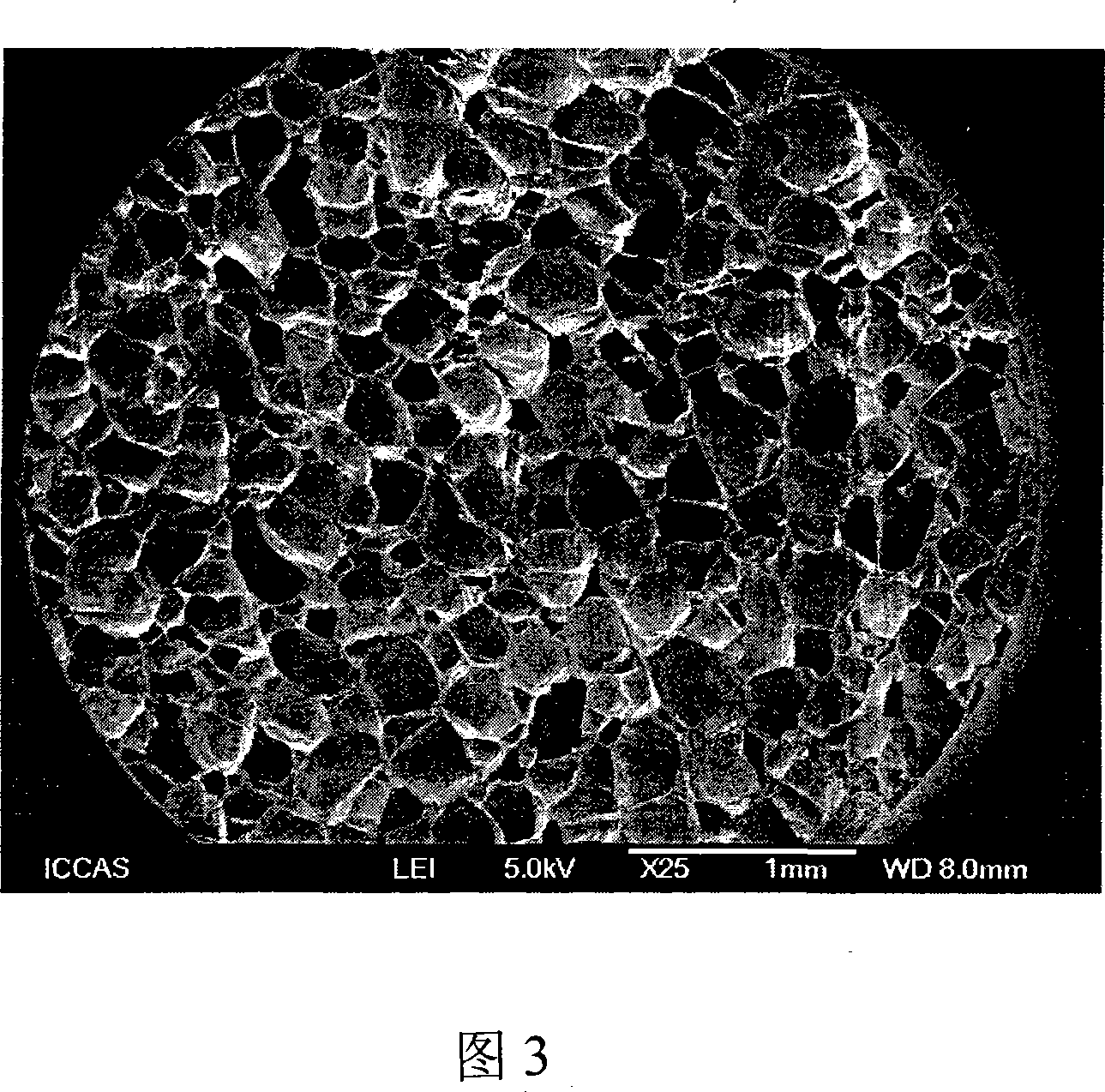

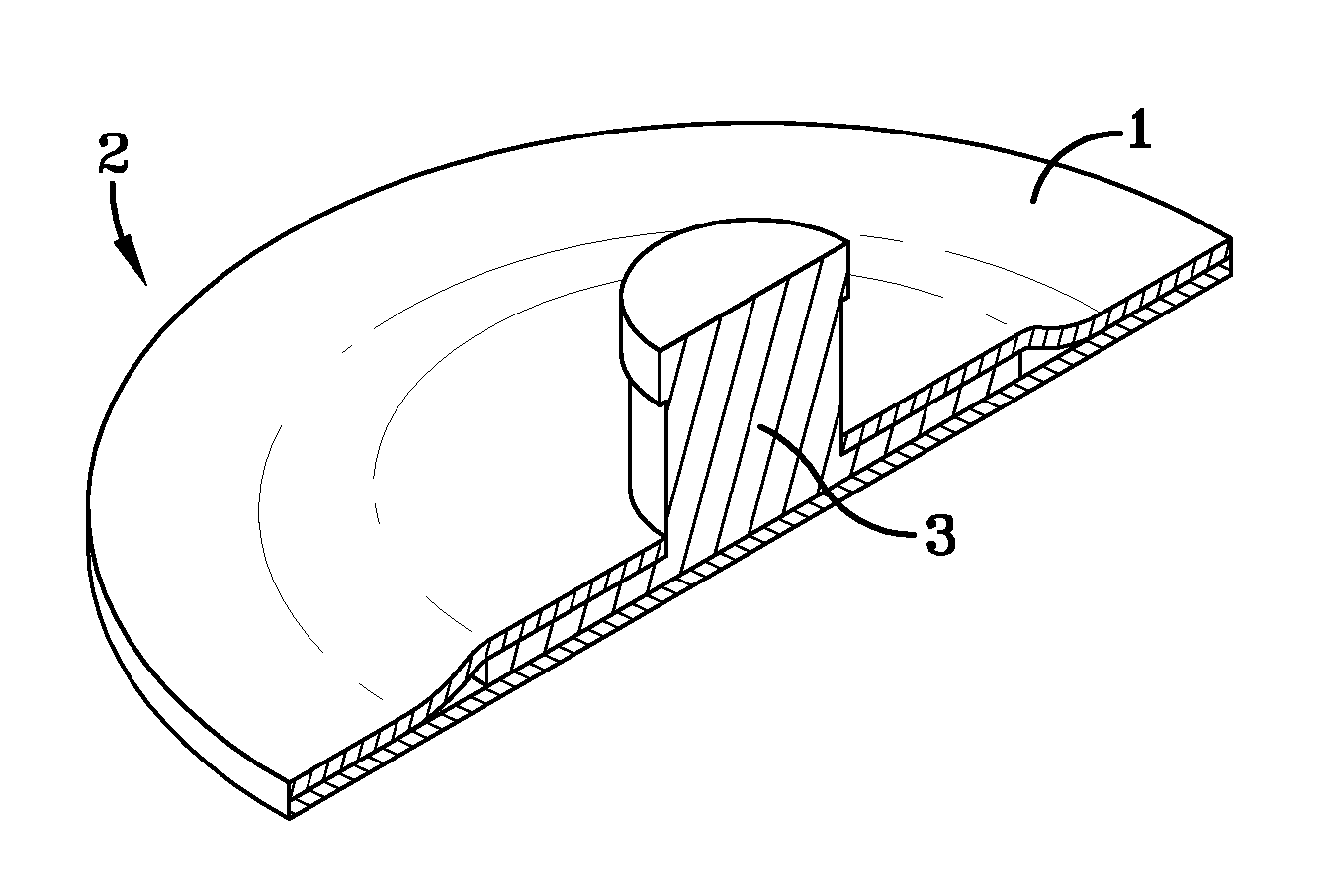

This invention relates to a method for preparing propylene material with high melt strength. The propylene material is composed of: propylene 100 parts, organic peroxide initiator 0.002-4 parts, multifunctional monomer 0.005-5 parts, branching promoter 0.001-4 parts, and organic clay 0.1-10 parts. The dispersion degree of organic clay is 10-100 nm. The method comprises: uniformly mixing propylene, organic peroxide initiator, multifunctional monomer, branching promoter and organic clay, adding into a twin-screw extruder, melting, extruding and granulating with temperature, rotation speed and feeding rate controlled to obtain gel-free propylene material with high melt strength. During the in-situ intercalation process, organic clay is dispersed in the polymer matrix on nanoscale. Uniformly dispersed organic clay can control the formation of branching structure, and improve the melt strength and mechanical properties of the propylene material. The propylene material is suitable for extrusion foaming and other thermal molding processes.

Owner:河北福恩特电气设备集团有限公司

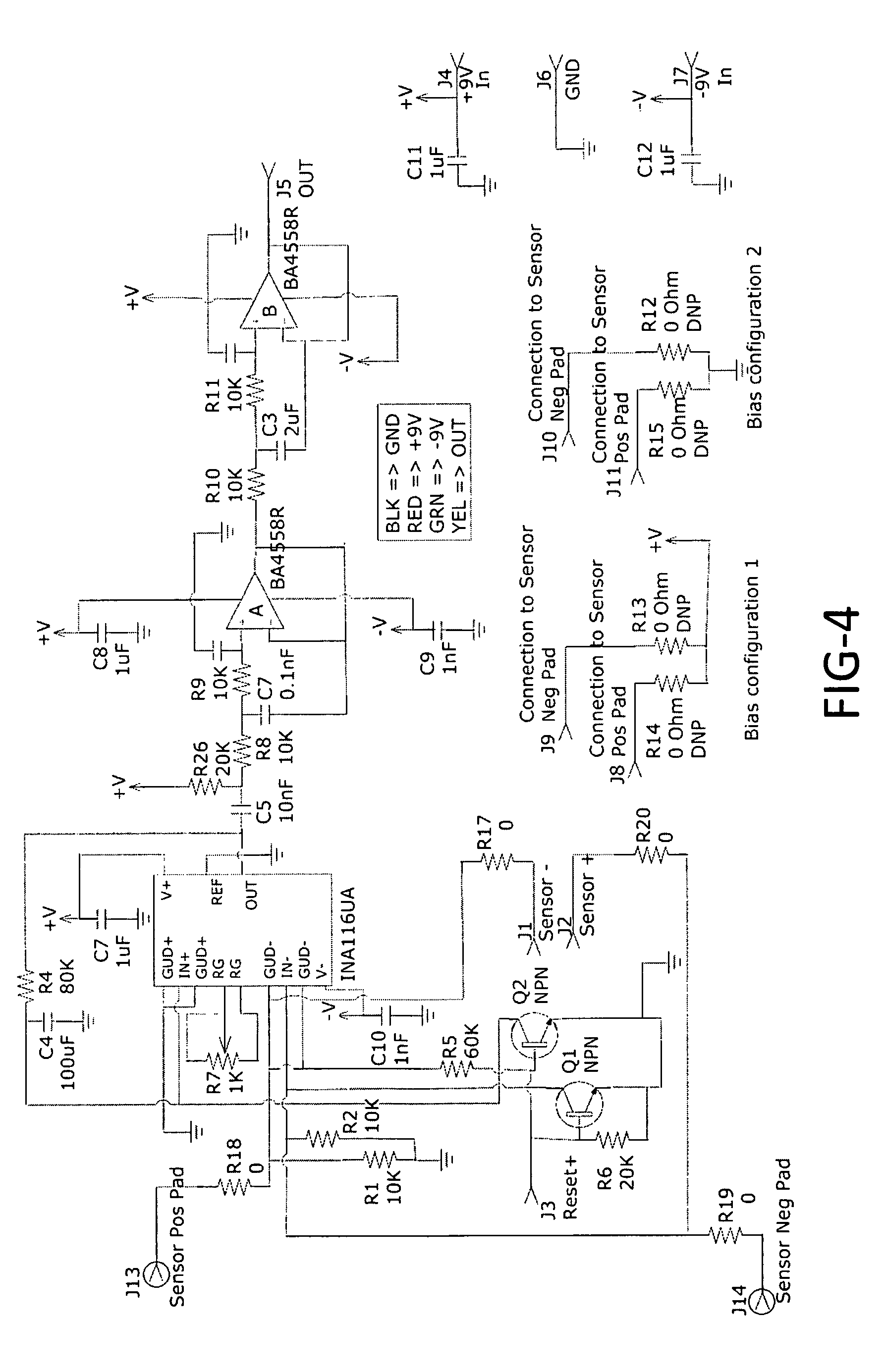

Polymer nano-composites as dry sensor material for biosignal sensing

A multifunctional polymer nano-composite sensor system for detecting various biosignals like ECG and other kinds of signals for sensing strain, temperature and moisture has been disclosed. This sensor system includes (1) a polymer nano-composite sensor material that is flexible, elastic, soft, and conductive, (2) a sensor material fabricated into a desired shape or form, and (3) a signal capturing interface for collecting, transmitting and processing the signals. This sensor system can easily be integrated into a user environment for various user-transparent sensing applications. The present invention more specifically reveals a multi-functional nano-composite sensor for detecting biologically generated electrical signals which is comprised of a polymeric composition having an electrically conductive wire embedded therein, wherein the polymeric composition has a dispersion phase and a dispersed phase, wherein the dispersion phase is comprised of a thermoplastic polymer or a thermoset polymer, wherein the dispersed phase includes an electrically conductive filler, wherein the polymeric composition is gel-free, and wherein the electrically conductive wire is adapted for conveying an electrical signal to a signal processing device. The present invention further discloses a polymeric composition which is comprised of a thermoplastic polyurethane, a styrenic polymer, and at least one electrically conductive filler wherein the styrenic polymer is present in the composition at a level which is within the range of 10 weight percent to 50 weight percent and wherein the electrically conductive filler is present at a level which is within the range of 0.5 weight percent to 40 weight percent, based on the total weight of the polymeric composition.

Owner:CLEVELAND MEDICAL POLYMERS

Branched fluoropolymers

ActiveUS20070106010A1Fibre treatmentMonocomponent halogenated hydrocarbon artificial filamentPersulfateFluoropolymer

The invention relates to the preparation of branched fluoropolymers having long chain branches and little or no gels, by a process involving polymerization at high temperatures using persulfates and optionally multifunctional initiators. The invention also relates to gel-free, branched polymers with strain hardening produced by the process.

Owner:ARKEMA INC

Non-adhesive polyethylene protective film and preparation method thereof

ActiveCN102152568AImprove mechanical propertiesIncrease viscosityFilm/foil adhesivesSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a non-adhesive polyethylene protective film and a preparation method thereof. The non-adhesive polyethylene protective film comprises a base film layer, an intermediate layer and a self-adhesive layer, wherein the base film layer comprises the following components in percentage by weight: 25 percent to 60 percent of low-density polyethylene, 40 percent of 75 percent of linear low-density polyethylene and 1 percent to 10 percent of metallocene linear low-density polyethylene. The intermediate layer comprises the following components in percentage by weight: 30 percent to 60 percent of low-density polyethylene, 40 percent to 70 percent of linear low-density polyethylene and 10 percent to 30 percent of ethylene-vinylacetate copolymer. The self-adhesive layer comprises the following components in percentage by weight: 5 percent to 15 percent of low-density polyethylene, 5 percent to 20 percent of linear low-density polyethylene and 80 percent to 90 percent of polyacrylate hot-melt pressure sensitive adhesive master batch. The non-adhesive polyethylene protective film has the advantages of high viscous force, no adhesive residue, good mechanical property, high transparency and the like. The defects of the existing polyethylene film can be overcome.

Owner:无锡达美新材料有限公司

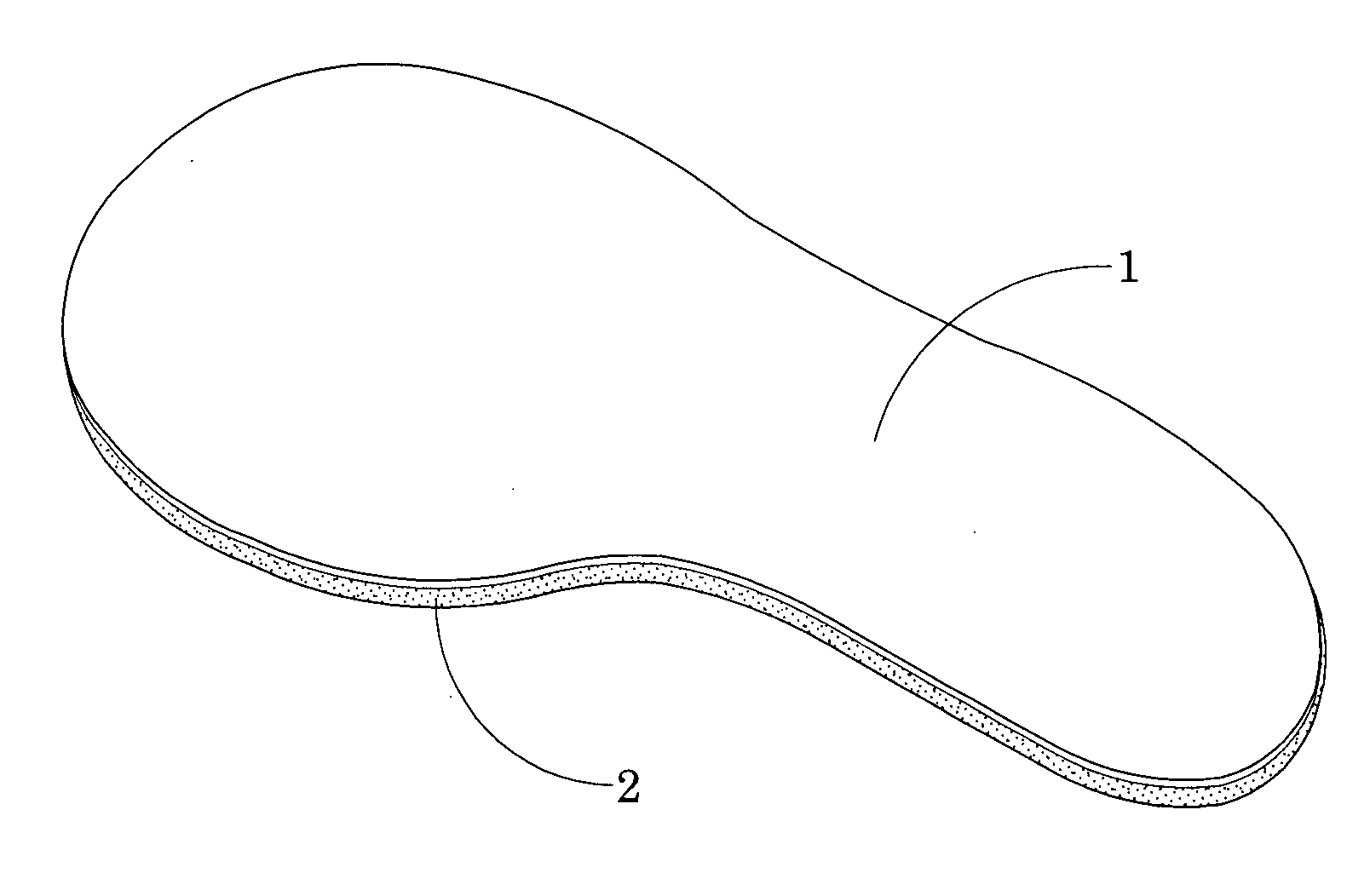

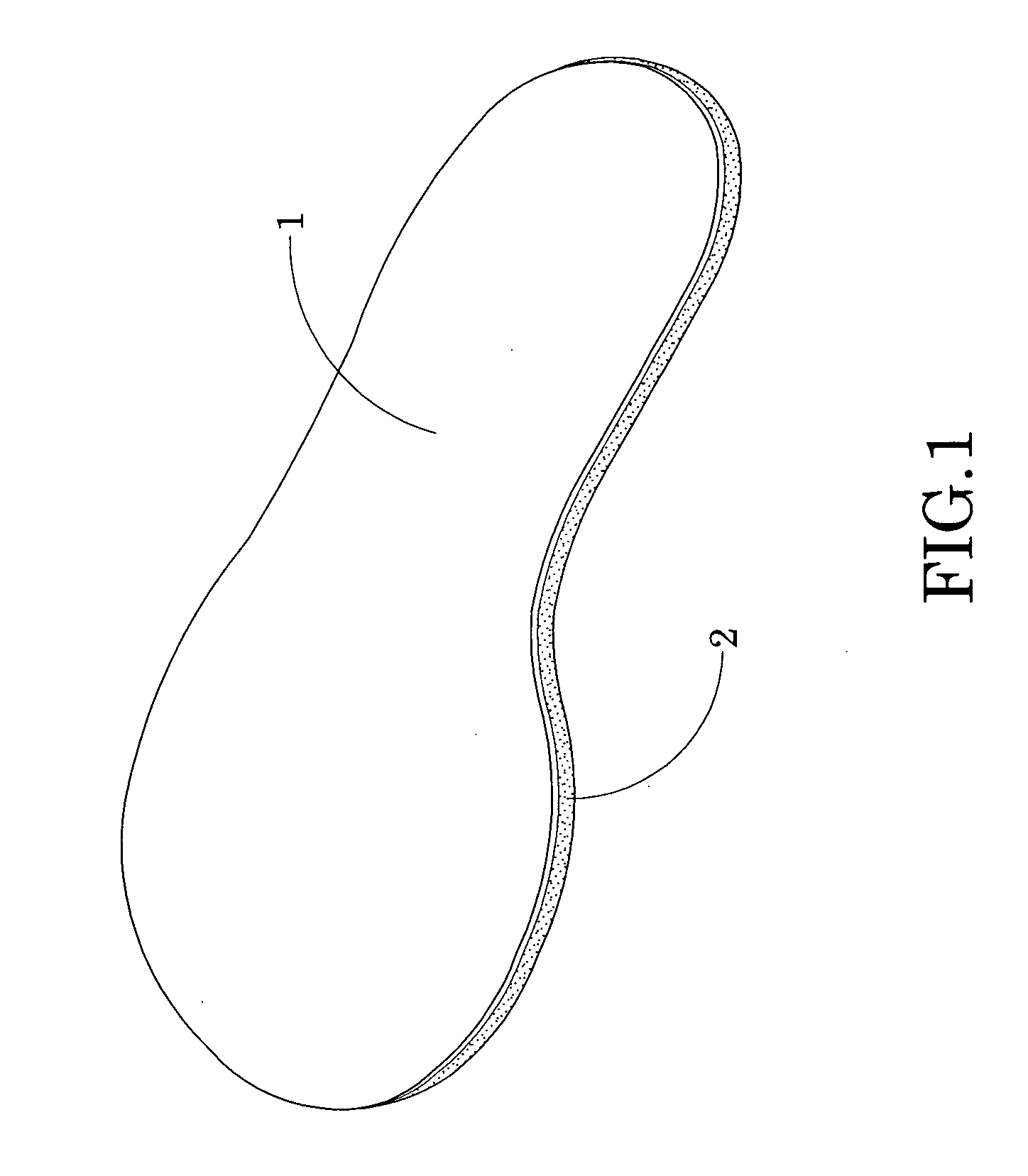

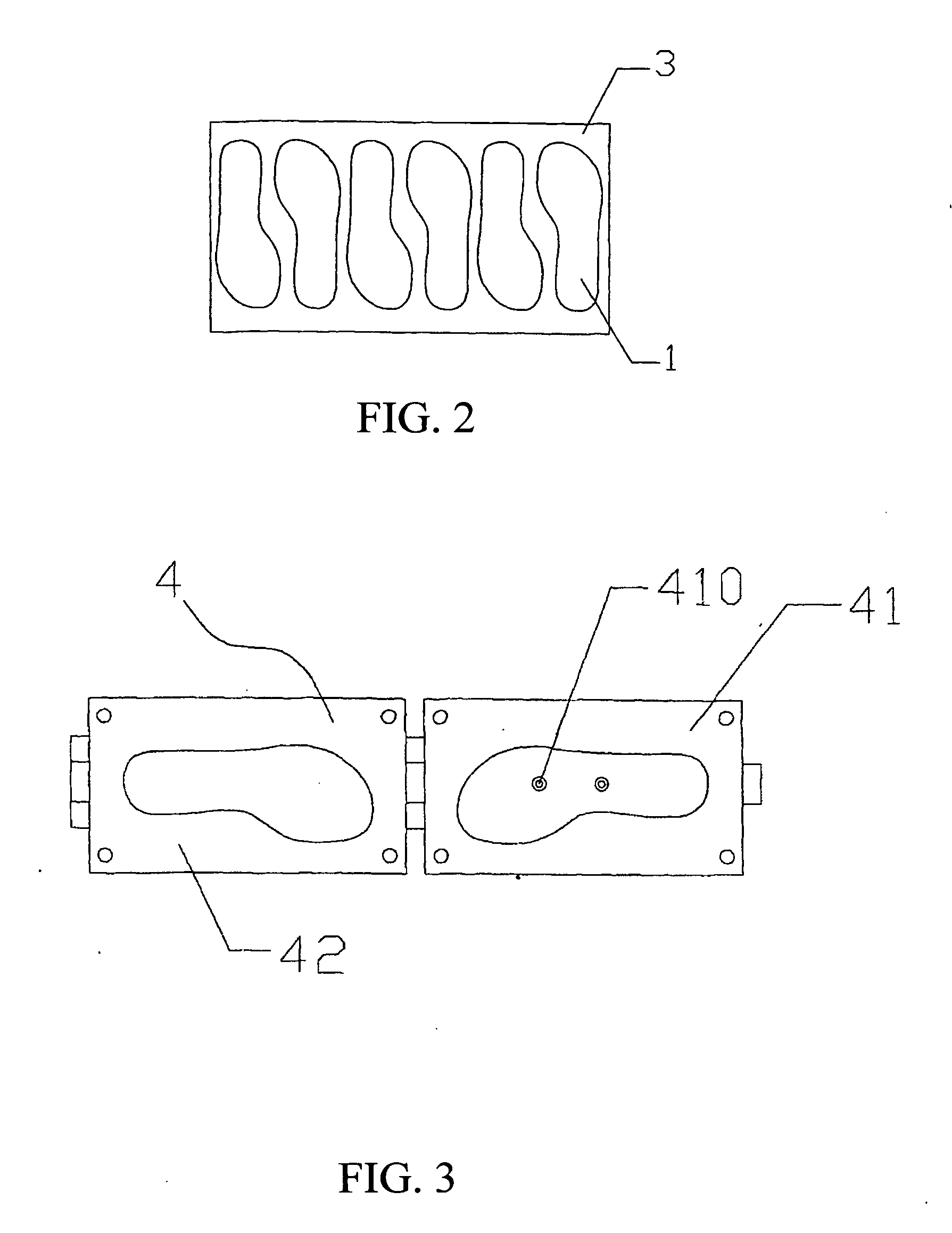

Non-peelabel insole and manufacturing method

InactiveUS20110072686A1Increased durabilitySimple manufacturing processSolesInsolesSecondary layerElectrical and Electronics engineering

An insole of the present invention includes a first layer, and a second layer integrally and continuously formed with the first layer. The second layer is mold-injected on the first layer to bond the second layer with the first layer, so as to form the stable bonding therebetween for securely and integrally bonding the first and second layers in a glue-less manner.

Owner:JIANGSU GAOSHIDA ELECTRIC TOOL CO LTD

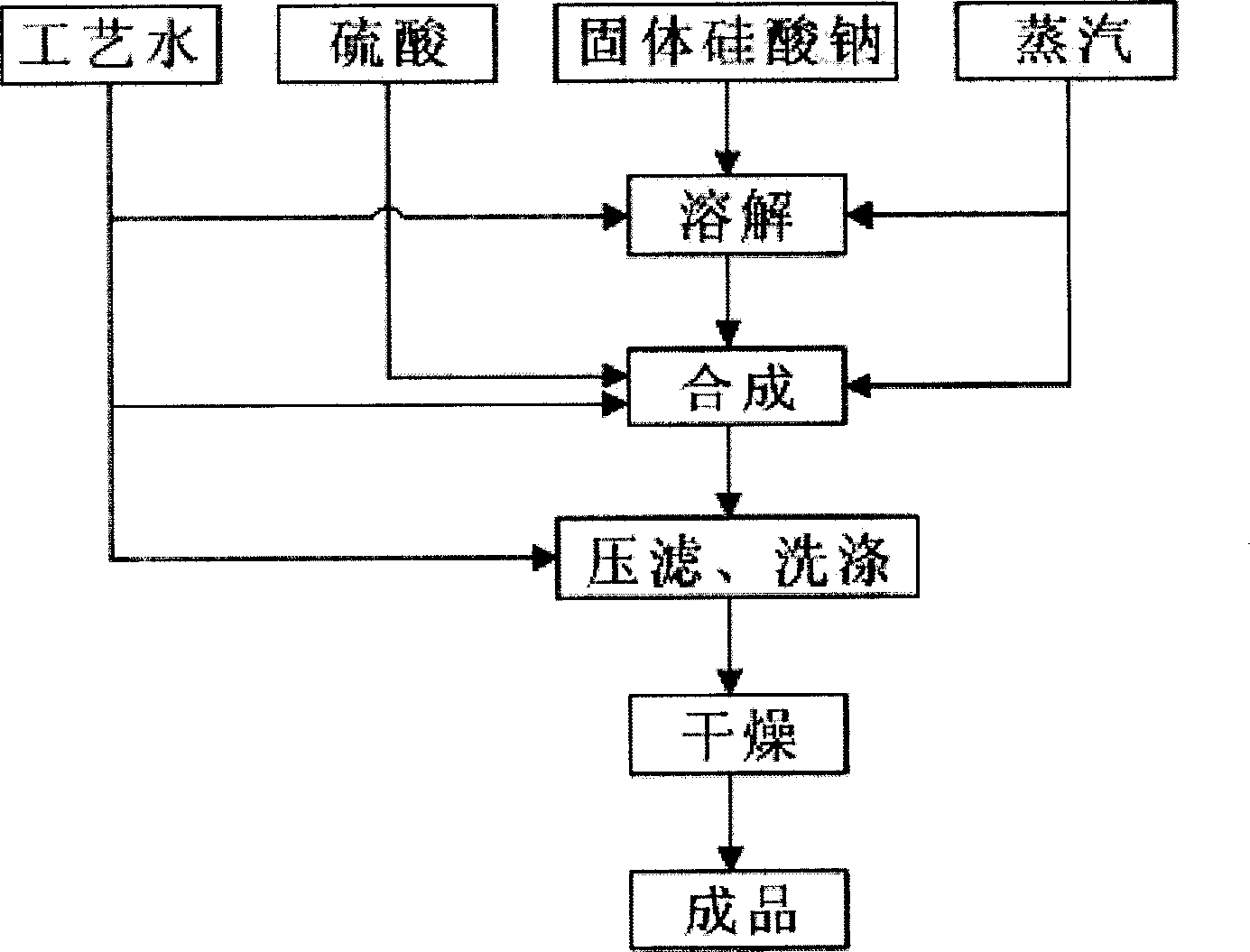

High dispersion gel-free white carbon black and its preparing method

InactiveCN1899961AGood dispersionMethod to save energy and reduce consumptionSilicaNanotechnologySpray drying

The present invention discloses a kind of high dispersion gel-free white carbon black, which contains SiO2 over 99 wt%, and has specific surface area of 320-380 sq m / g and particle diameter smaller than 11 nm. The present invention also discloses the preparation process of the high dispersion gel-free white carbon black, and the preparation process is one direct process including dissolving, synthesis, filtering and spray drying. The preparation process has low production cost.

Owner:周玉芳 +3

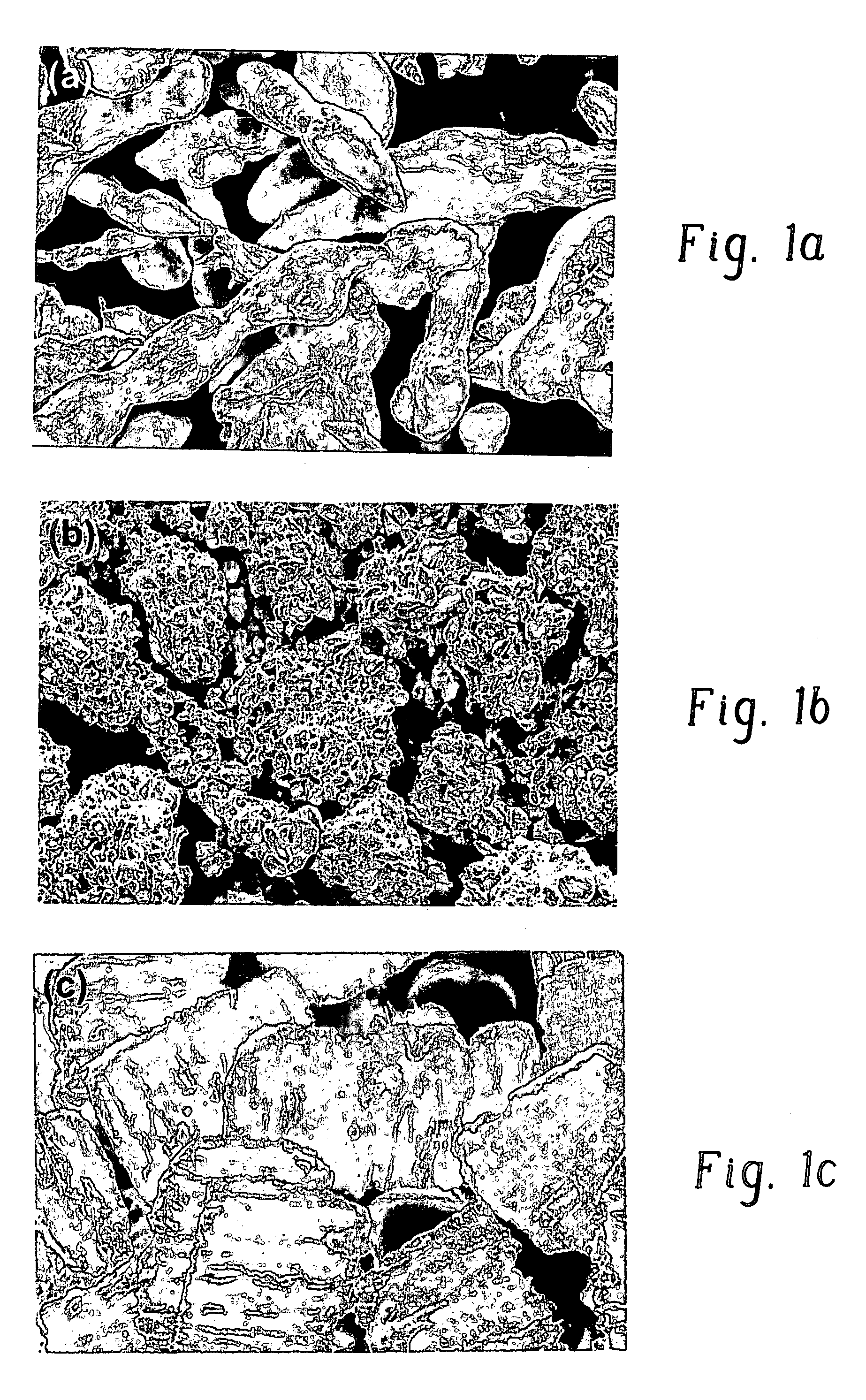

Preparation of acrylic hot-melt pressure-sensitive adhesives from aqueous disperse systems

A process for preparing hot-melt pressure-sensitive adhesives from aqueous dispersions based on polyacrylate, and pressure-sensitively adhesive articles produced therefrom, which comprises producing highly concentrated aqueous dispersions with polymer contents between 68% by weight and 87% by weight of gel-free, molecularly-dispersely meltable polymer particles with an at least bimodal size distribution in size ranges between 0.5 μm and 1000 μm Ø.

Owner:TESA SE

Epoxidation method of gel-free double bond-contained polymer

Owner:XIAMEN UNIV

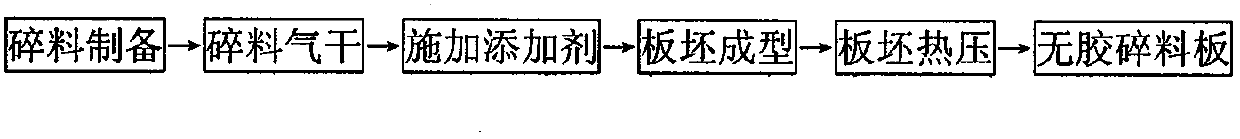

Environment-friendly glue free particle board and preparation method thereof

The invention discloses an environment-friendly glue free particle board and a preparation method thereof, and belongs to artificial boards prepared by using natural-occurring substances. The environment-friendly glue free particle board is prepared by comprising the following steps: adding water with cane sugar, citric acid and acetic acid to prepare uniform compound additive, weighting the particles, uniformly spraying the compound additive on the surfaces of the particles, then paving the particles uniformly sprayed with the compound additive into a slab, prepressing, and then sending the pre-pressed slab into a thermocompressor to be hot pressed and formed. The raw material used in the invention is pure natural substance non-toxic to the safety of the human body; the integrated physical and mechanical properties of the board made by the compound additive recipe used in the invention is best; the acetic acid used in the invention has functions of bacteriostasis and mildew proofing; through the addition of certain acetic acid, the physical and mechanical properties of the board can be improved; meanwhile the durability can be improved. The physical and mechanical properties of the particle board are good; no free formaldehyde is released; the particle board can be taken as furniture, indoor decorating, packing and the like to use; the preparation method is simple and convenient; the common particle board production line is not needed to be changed to produce.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Methods and apparatus for gel-free qualitative and quantitative proteome analysis, and uses therefore

InactiveUS20050196823A1Component separationMicrobiological testing/measurementBiophysical chemistryCompound (substance)

Methods and apparatus for qualitative and quantitative proteome analysis are provided. The methods and apparatus allow for the isolation of a subset of peptides out of complex mixtures of peptides. The isolation is based on a specific chemical and / or enzymatic alteration of one or more types of peptides. This alteration modifies the biophysical, chemical or any other biochemical property of the affected types of peptides (e.g., net electrical charge and / or hydrophobicity) in such way that the altered peptides can be separated from the unaltered peptides.

Owner:PRONOTA NV

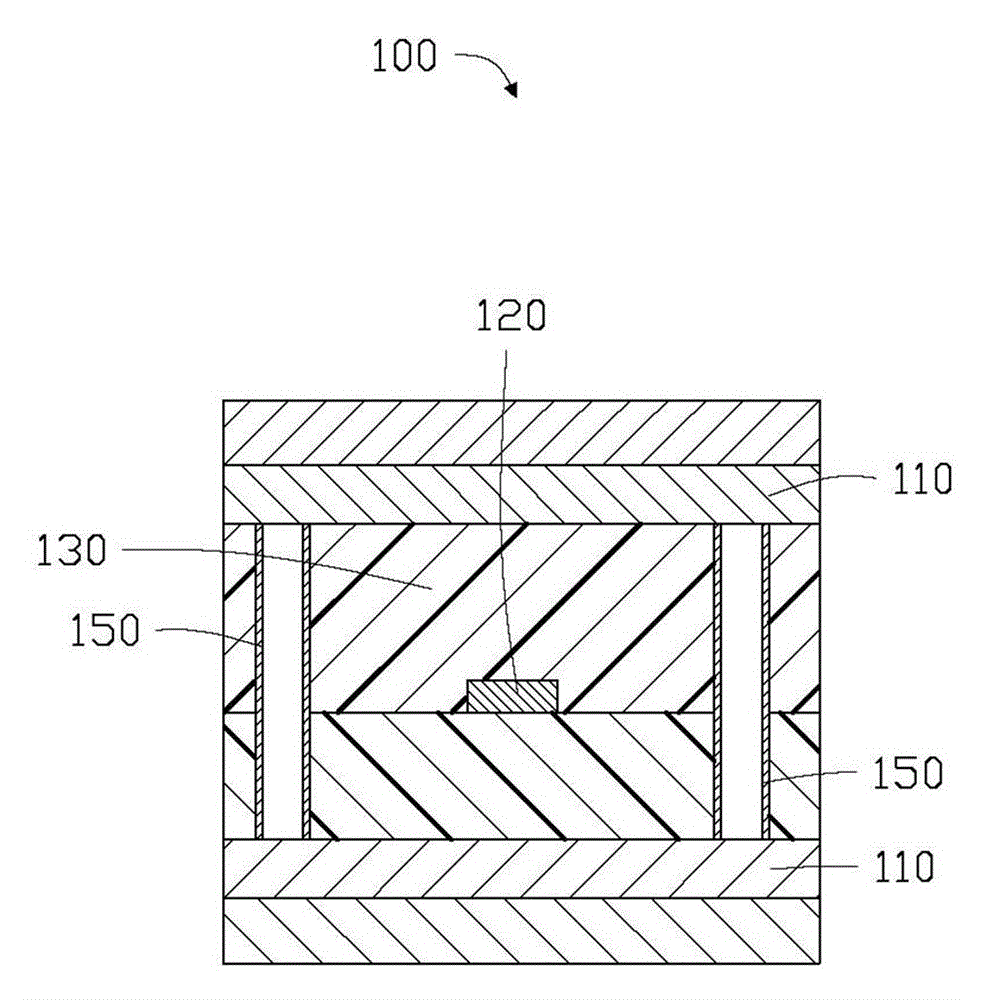

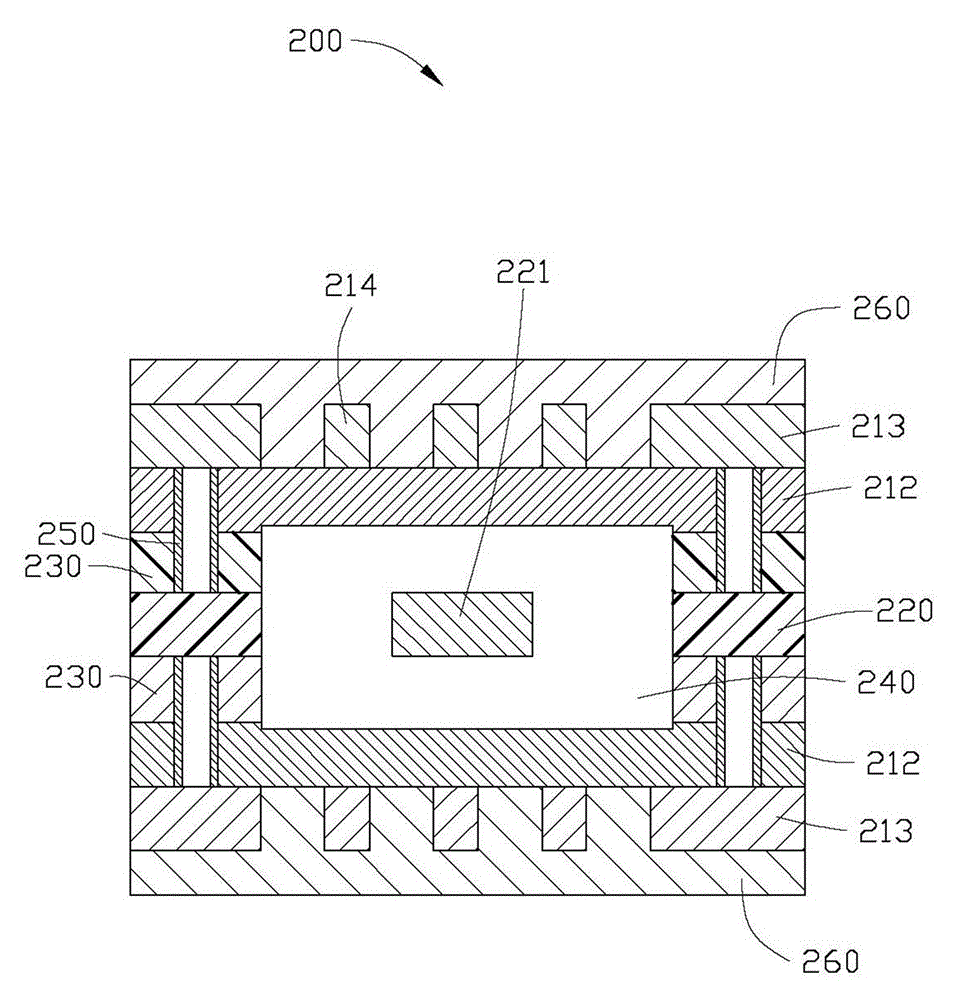

Flexible circuit board and manufacturing method thereof

ActiveCN106332434AReduce lossImprove transmission qualityCross-talk/noise/interference reductionPrinted circuit aspectsFlexible circuitsColloid

The invention relates to a flexible circuit board, which comprises a plurality of copper clad substrates, a line pattern, a plurality of bonding colloids corresponding to the plurality of copper clad substrates, and a plurality of conductive holes; each copper clad substrate is provided with an insulating base material and an outer-layer line; the line pattern comprises a linear signal line, two ground lines and two hollow areas; the two ground lines are arranged at two sides of the linear signal line and are parallel to each other; the plurality of copper clad substrates are located at two reverse sides of the line pattern; each bonding colloid is stacked between the line pattern and the corresponding copper clad substrate; a gel-free slot is formed in each bonding colloid; the slots of the plurality of bonding colloids and the two hollow areas form an air dielectric layer to coat the linear signal line; the slot of each bonding colloid is aligned at the linear signal line; and the linear signal line is spaced from the plurality of bonding colloids to form a suspended state. The plurality of conductive holes are electrically connected with the plurality of outer-layer lines and the two ground lines. The invention further relates to a manufacturing method of the flexible circuit board.

Owner:AVARY HLDG (SHENZHEN) CO LTD +2

Preparation of acrylic hot-melt pressure-sensitive adhesives from aqueous disperse systems

InactiveUS20010034394A1High film strengthReduce intensityFilm/foil adhesivesPaper coatingPolymer scienceHot melt

A process for preparing hot-melt pressure-sensitive adhesives from aqueous dispersions based on polyacrylate, and pressure-sensitively adhesive articles produced therefrom, which comprises producing highly concentrated aqueous dispersions with polymer contents between 68% by weight and 87% by weight of gel-free, molecularly-dispersely meltable polymer particles with an at least bimodal size distribution in size ranges between 0.5 mum and 1000 mum .

Owner:TESA SE

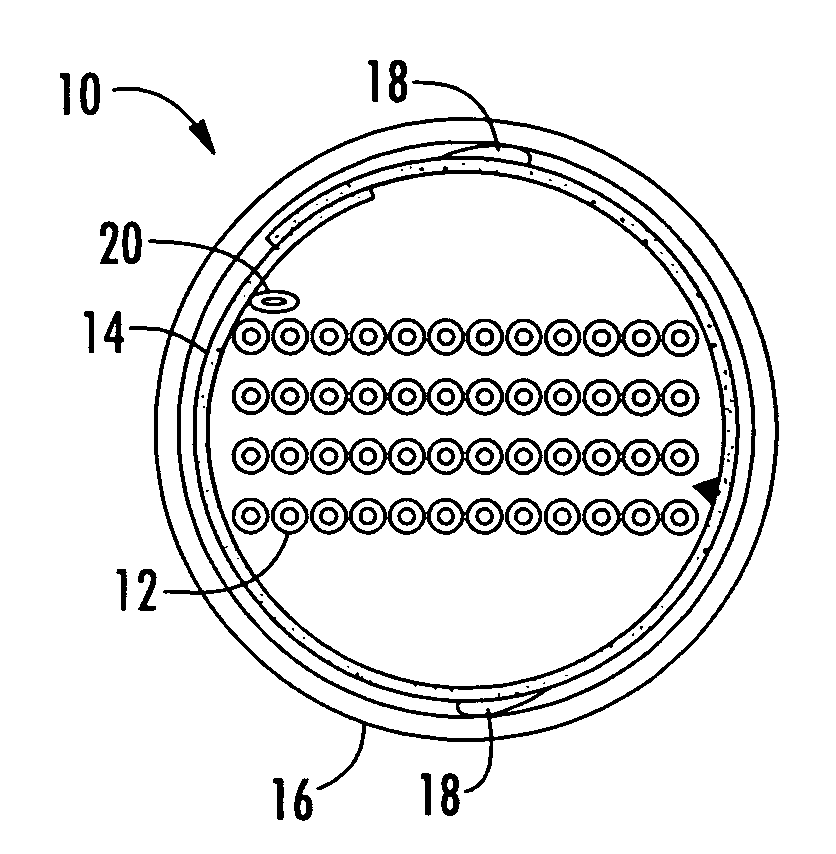

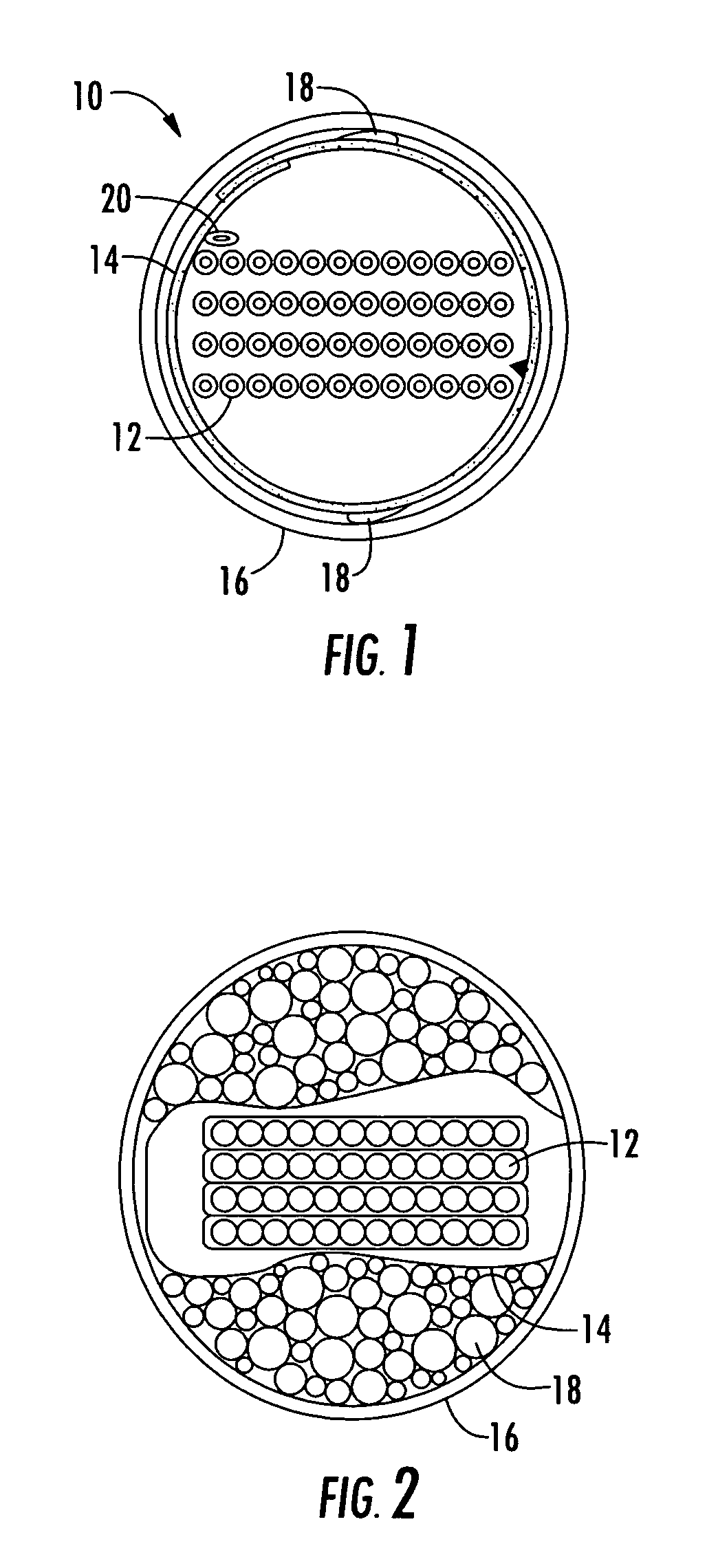

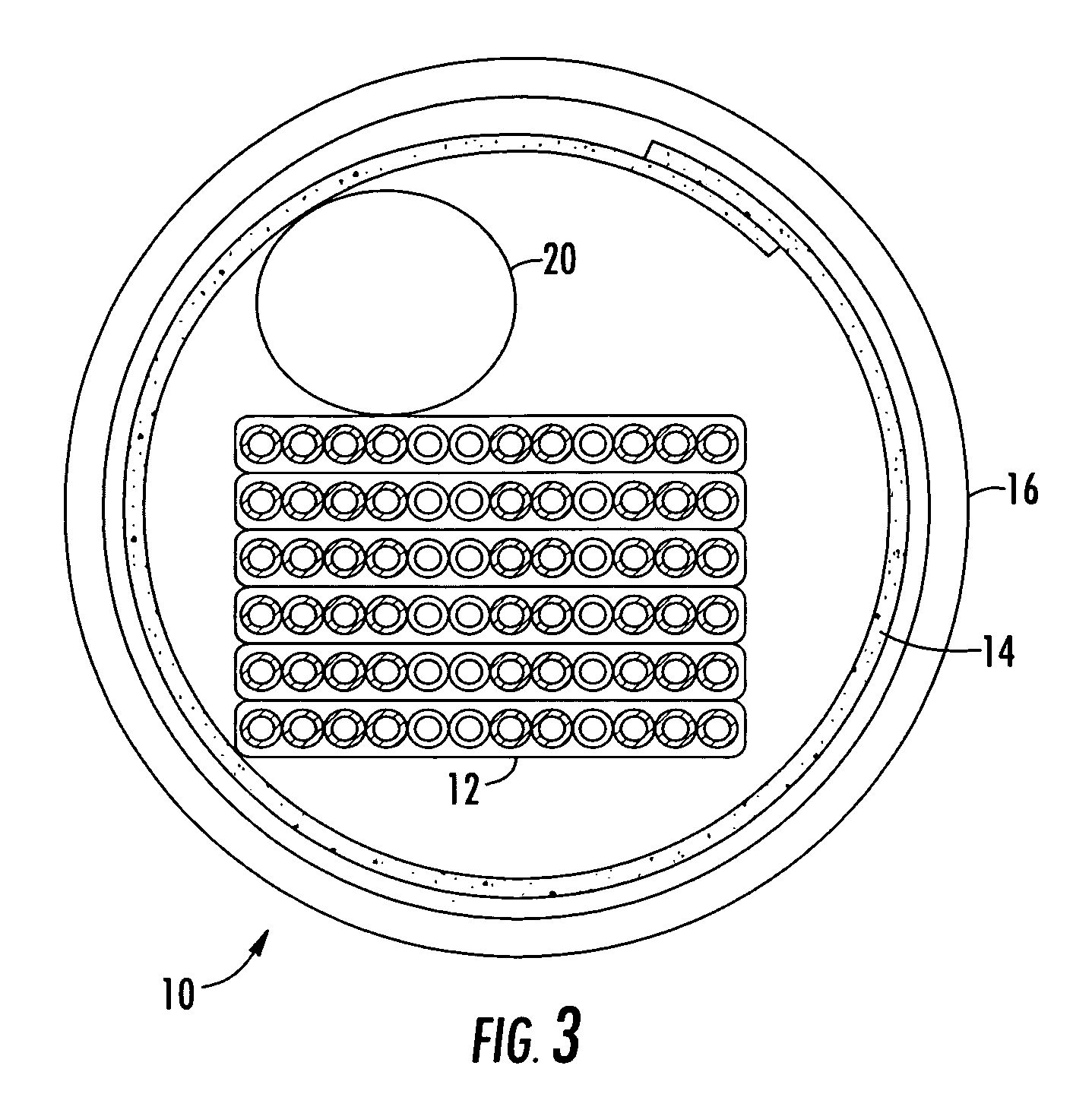

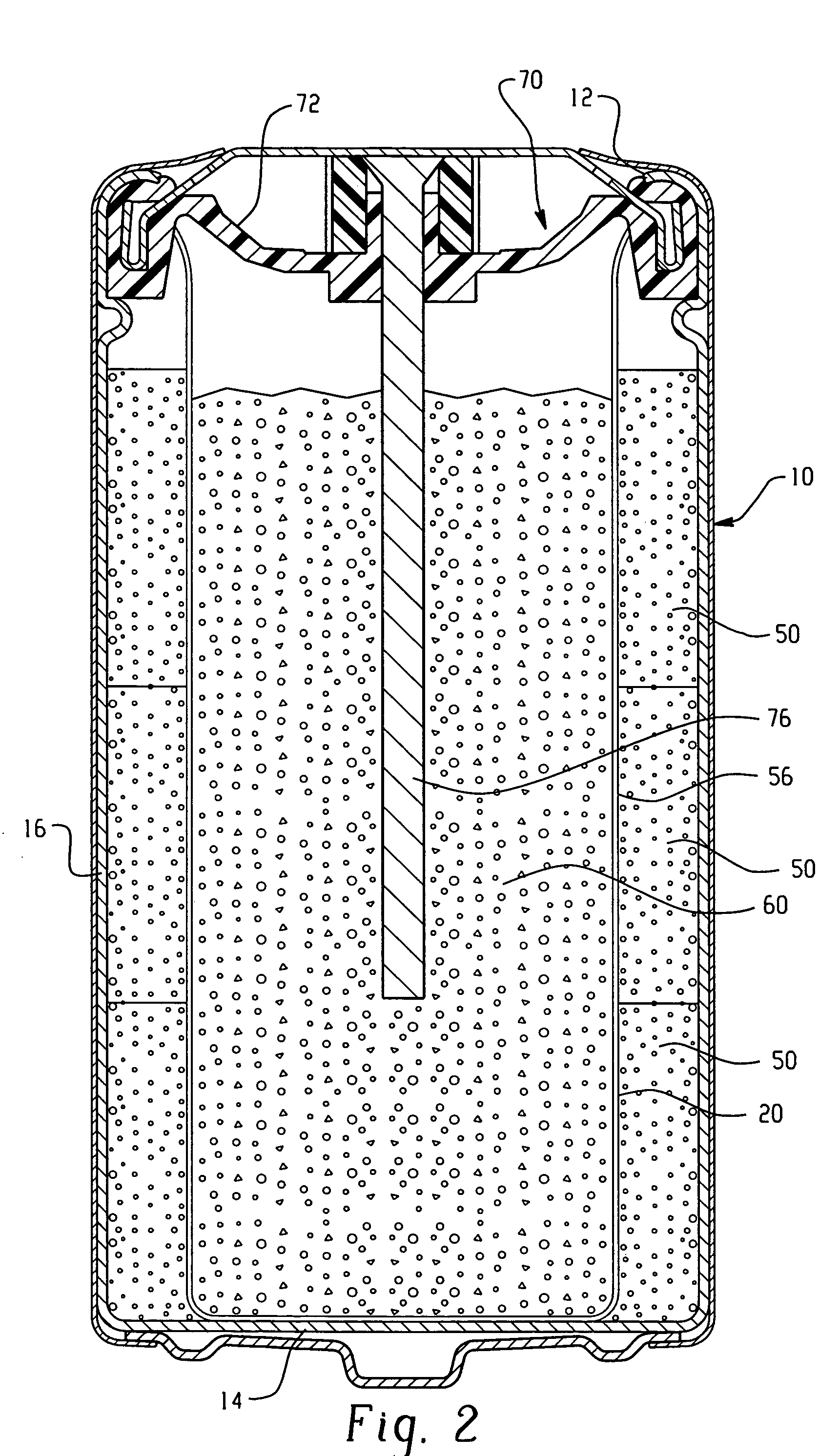

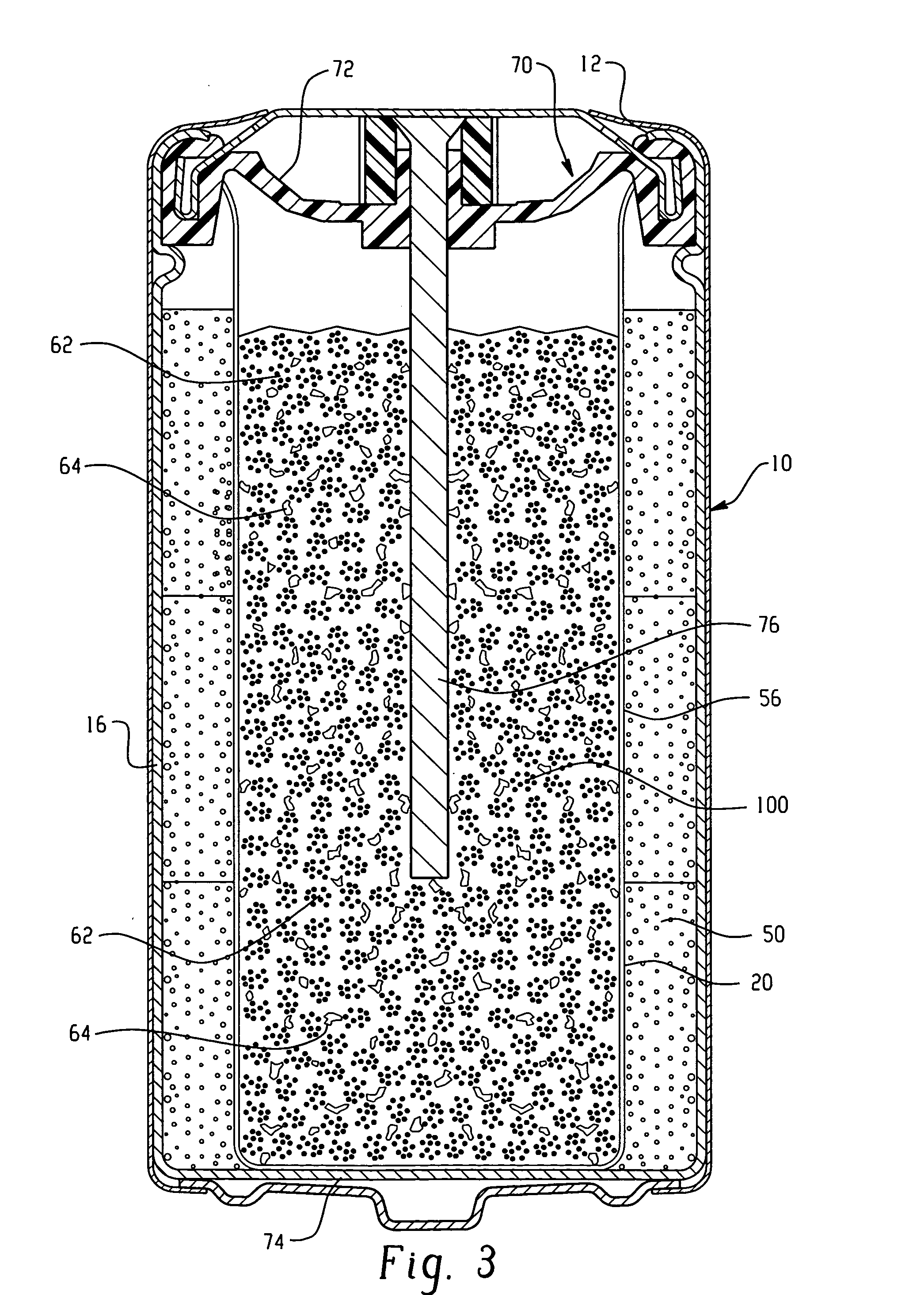

Electrochemical cell

ActiveUS20050181278A1Electrode carriers/collectorsActive material electrodesZincElectrochemical cell

A cylindrical alkaline electrochemical cell is disclosed that includes a gel free anode. The anode includes a free flowing zinc powder with a preassembly tap density between 1.6 g / cc and 2.9 g / cc. In one embodiment, zinc powder with the desired tap density may be obtained by mixing zinc agglomerates with zinc flakes.

Owner:ENERGIZER BRANDS

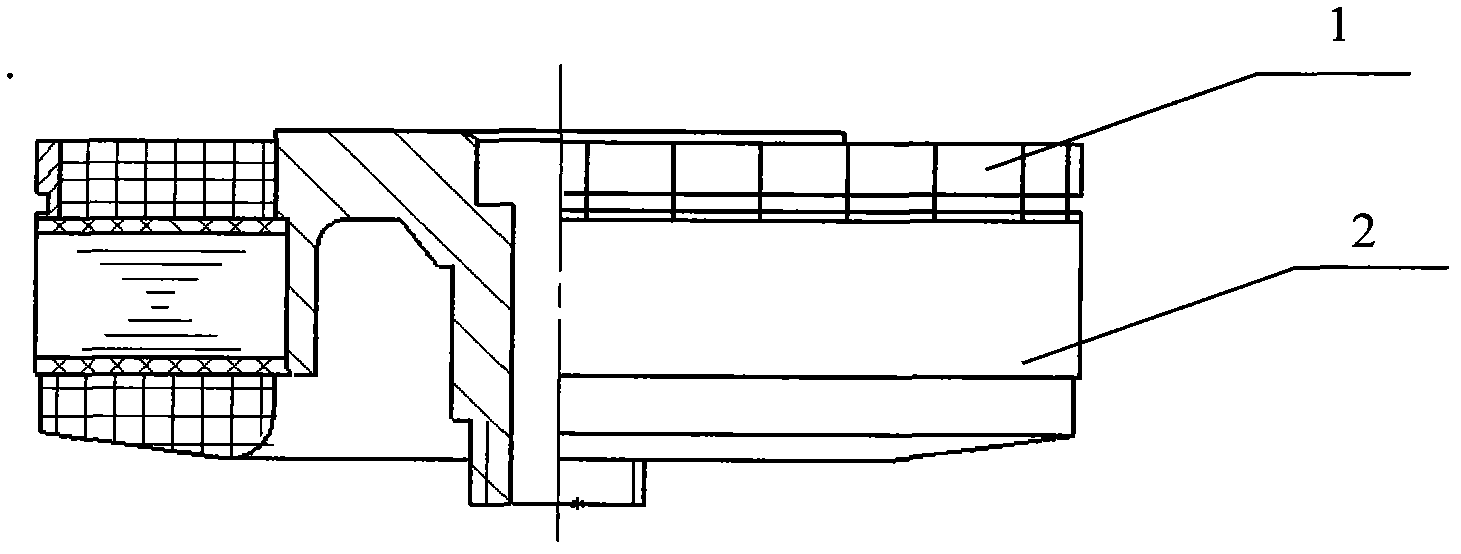

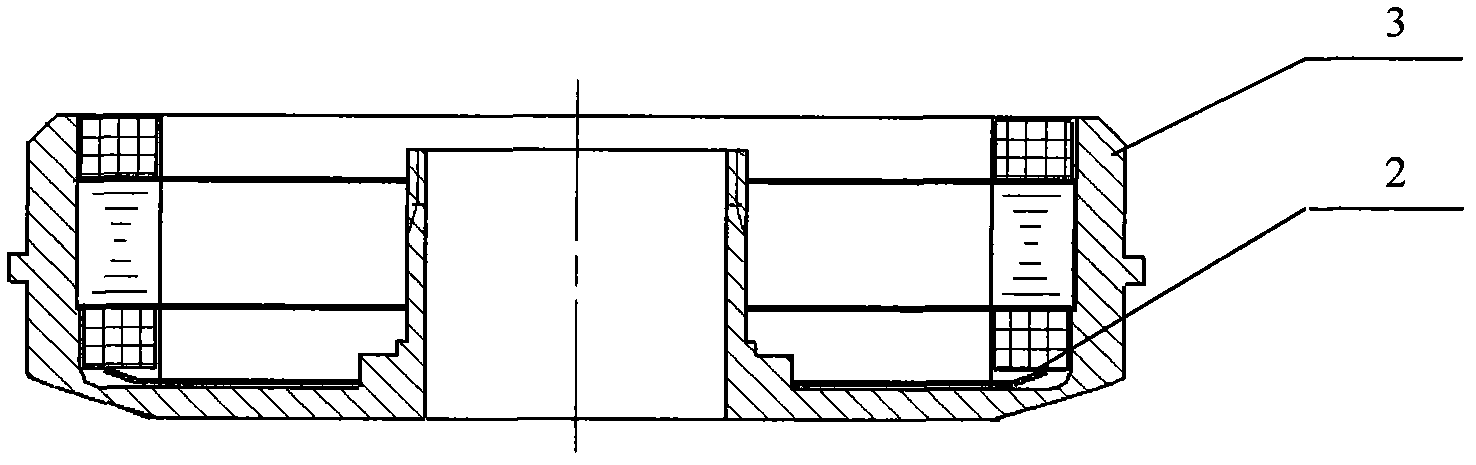

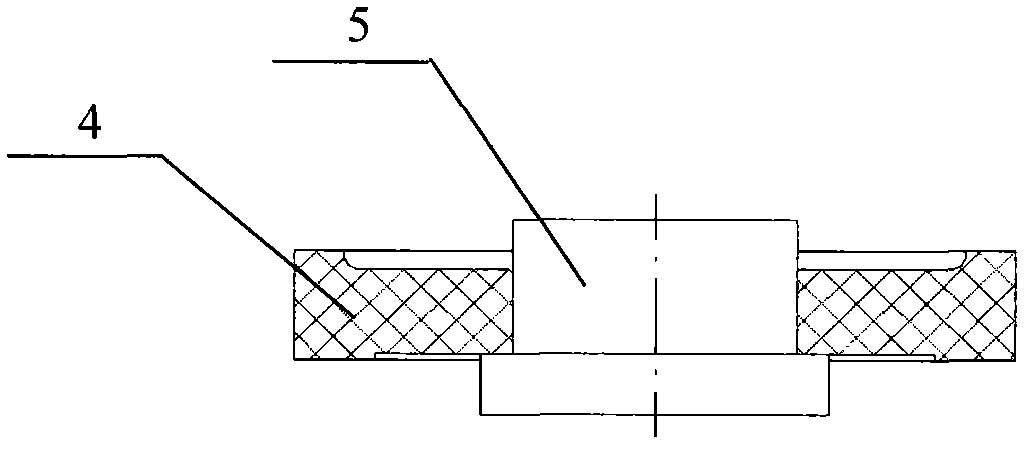

Bonding and potting method for aerial integrated motor

InactiveCN102306989AOvercoming the deficiency of roundness deviationManufacturing dynamo-electric machinesAdhesiveEngineering

The invention relates to a bonding and potting technology method for an aerial integrated motor, wherein the method covers a bonding method, preparation of a potting material for an elastic film, a potting die and a potting method. According to the invention, an elastic film is employed as a carrier and a characteristic of shape expansion by squeezing is utilized, so that an end commutator is isolated from an adhesive and a potting material and it can be ensured that there is no superfluity at the surface of the commutator after the bonding and potting processing; meanwhile, an axiality after the potting processing can also be ensured. Besides, the elastic film comprises the following components according to mass percentage: 100% of GN 521 raw material; 100% of a GN 521 vulcanizing agent; and 10% to 50% of a filler. According to the invention, bonding and potting production and processing problems of an aerial integrated motor are solved and a purpose that a circularity of a commutator meets a requirement after the bonding and potting processing of the aerial integrated motor can be achieved; meanwhile, an effect that the surface of the commutator on the winding is free of gel after the bonding and potting processing is realized; and a defect of a circularity deviation of an inserted motor can be overcome.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Polyimide resin and application thereof, two-layer adhesiveless base material and preparation method of two-layer adhesiveless base material

ActiveCN104672448AImprove performanceHigh insulation resistanceCircuit susbtrate materialsMetal layered productsHigh humidityCopper foil

The invention discloses polyimide resin, a preparation method and an application thereof, a two-layer adhesiveless base material and a preparation method of the two-layer adhesiveless base material. The polyimide resin comprises nano-silica which is modified by polyimide resin and a silane coupling agent dispersed in the polyimide resin, wherein polyimide resin is an intercondensation polymer of aromatic dianhydride and aromatic diamine; and the polyimide resin polymer is taken as a resin insulating layer by the two-layer adhesiveless base material. Compared with the prior art, the polyimide resin composition disclosed by the invention is capable of significantly improving the performance of the two-layer adhesiveless base material, so that the insulation resistance of the surface of a copper foil is enhanced; and meanwhile, the adhesive strength, the ion migration resistance, high-temperature and high-humidity oxidation resistance and corrosion resistance of the copper foil and the polyimide insulating layer are enhanced.

Owner:GUANGDONG DANBOND TECH

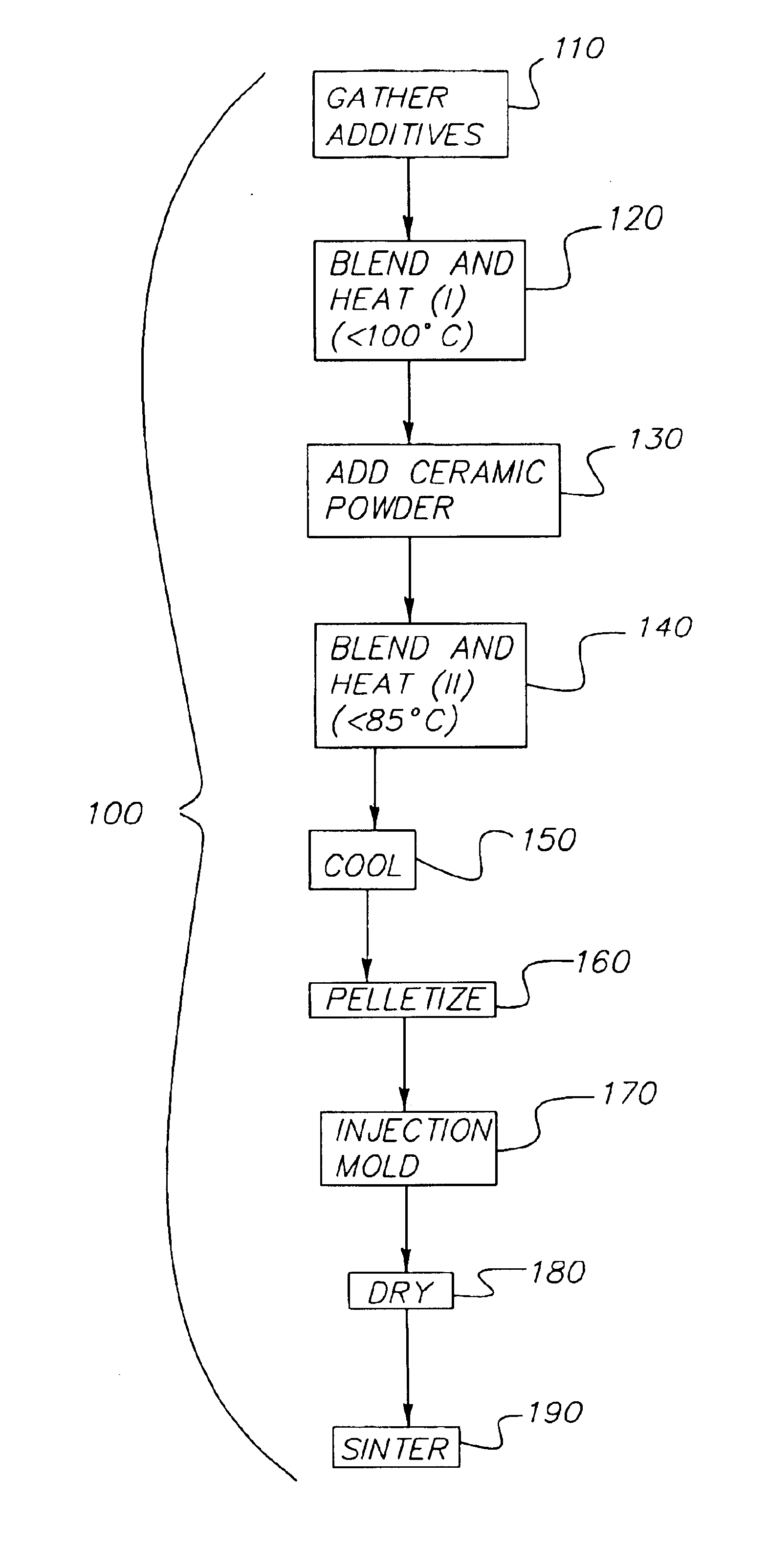

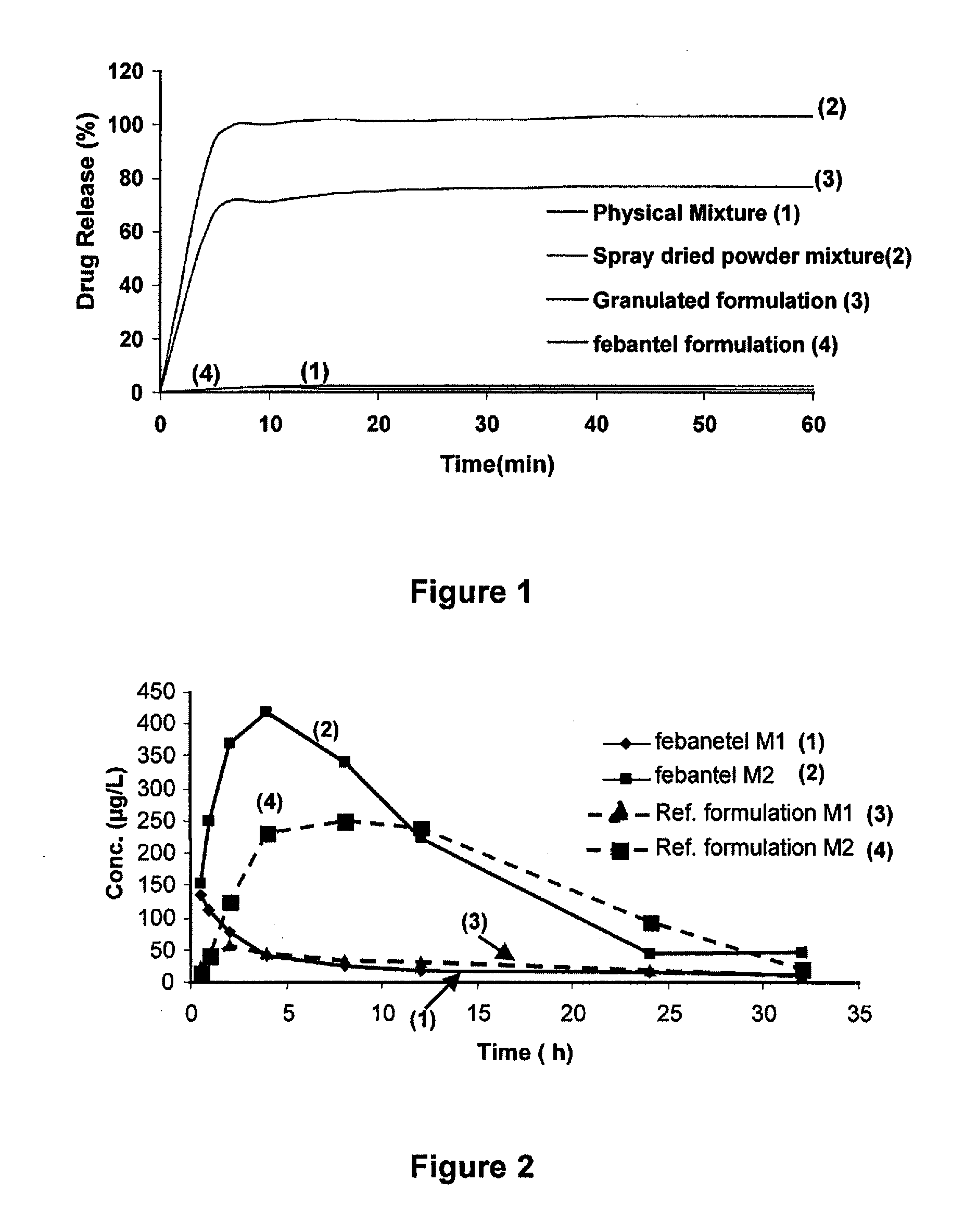

Injection molding of ceramic powders using non-gel forming water soluble organic binders

A method for compounding gel-free injection molding feed stock for injection molding net-shape ceramic parts, including the steps of: mixing inorganic particles with non-gel forming water soluble organic binders having molecular weight between 1000 and 1,000,000 and that are between 0.5 weight % and 10 weight % based upon the inorganic particles, along with plasticizers, water and processing aids in a mixer to form a mixture, wherein the non-gel forming water soluble organic binders are composed of high and low molecular weight organic binders; compounding the mixed inorganic particles and the non-gel forming water soluble organic binders at a high temperature in the range of between 70° and 98° Centigrade, under shear force, to form a homogenous viscous slurry in the range of 5×103 and 7×104 Pa.sec at a shear rate of 10 sec−1; cooling the homogenous viscous slurry to room temperature to form a compounded solid mass.

Owner:EASTMAN KODAK CO

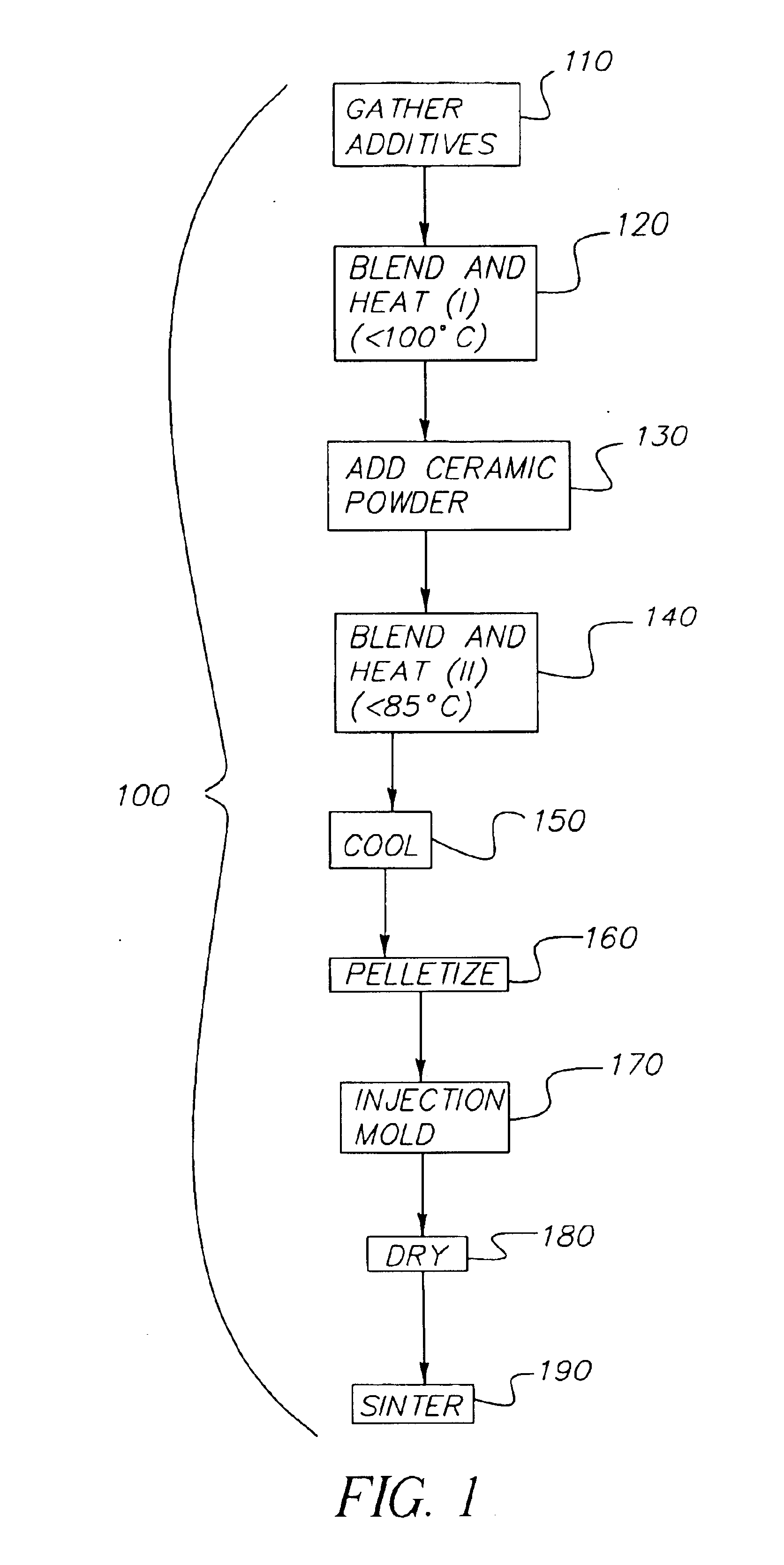

Aqueous coacervate compositions suitable for making powders and water-soluble formulations of biologically-active agents

InactiveUS20110294864A1Easily water-dispersibleGood for healthBiocideAntipyreticActive agentNon ionic

Aqueous gel-free two-phase coacervate compositions including a coacervate phase and an equilibrium water phase, comprising a mixture of:(a) a poorly water-soluble bio-active agent,(b) a tensio-active system consisting of non-ionic tensio-active agents,(c) one or more water-soluble carriers for said poorly water-soluble bio-active agent, said carriers being selected from the group consisting of maltodextrins and polyols, and(d) water.Such coacervate compositions may be dried into solid dosage forms from which rapid release of the bio-active agent can be obtained.

Owner:UNIV GENT

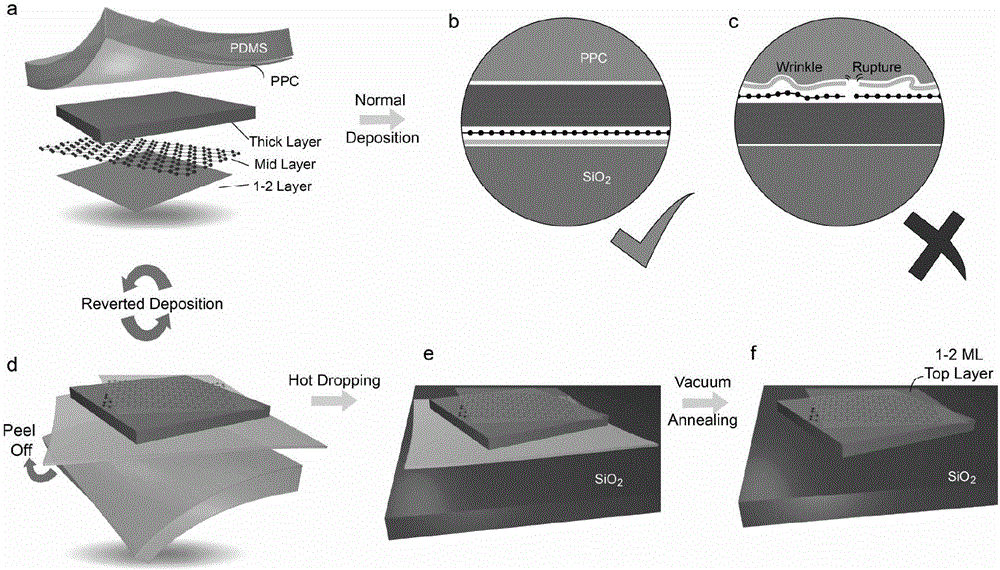

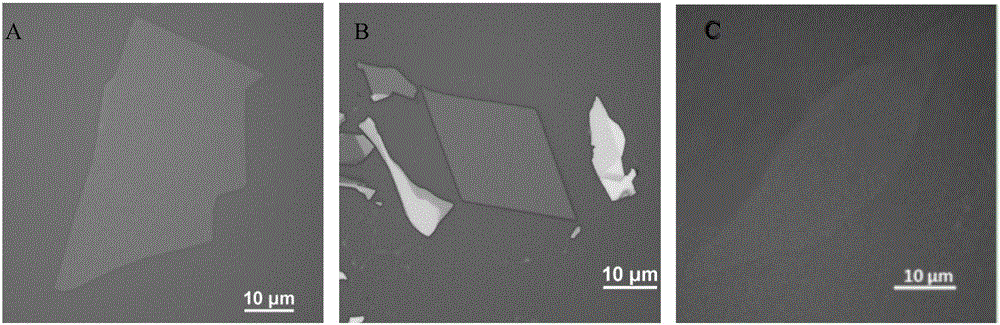

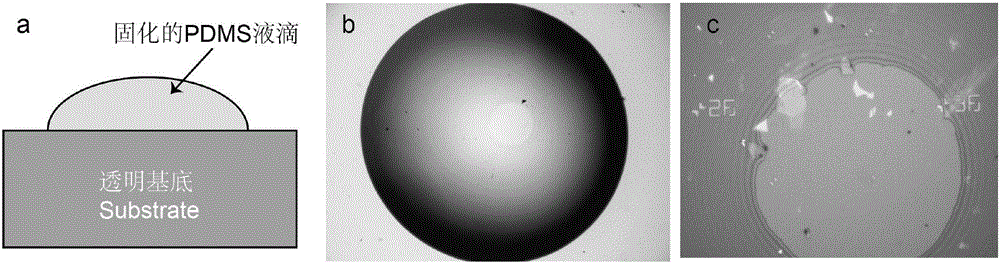

Method for putting pure ultrathin two-dimensional materials on stacking top layer

ActiveCN106409687AImprove purityHigh surface cleanliness requirementsSemiconductor/solid-state device manufacturingSemiconductor devicesPolymeric surfaceHeterojunction

The present invention provides a method for putting pure ultrathin (the lowest layer is a monatomic layer) two-dimensional materials with high quality, ultra flatness and without glue residual on the stacking plane heterojunction top layer. The method comprises: transferring the two-dimensional materials to the surface of the viscous polymer, after repeating the step many times, and obtaining a two-dimensional heterojunction structure; and performing mechanical separation of the viscous polymer which has a surface with the heterojunction structure, putting the viscous polymer on a substrate to allow the stacking structure to perform fusion and remaining and to be an inversion state, performing the technology such as vacuum annealing and the like, completely volatilizing the polymer pressed at the bottom of the materials, and completing the purpose that the ultrathin (the lowest layer is a monatomic layer) two-dimensional materials are putted to the stacking top layer.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cationic polymerization system and preparation method of high-unsaturation-degree isoolefin copolymer

ActiveCN105646757AImprove copolymerization reactivityIncrease unsaturationCationic polymerizationSolution polymerization

The invention relates to a cationic polymerization system and a preparation method of a high-unsaturation-degree isoolefin copolymer. The polymerization system and a polymerization method can improve the feeding amount of multiolefin copolymerization monomers in the system, high-molecular-weight, high-unsaturation-degree (high multiolefin content) and substantially gel-free copolymer product can be obtained, the monomer conversion rate is relatively high, the reaction efficiency of a catalyst and the copolymerization monomers is high, the catalyst cost is low, and industrial application value is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glue-free reconstituted veneer and preparing method thereof

ActiveCN112643814AHigh mechanical strengthGood dimensional stabilityWood veneer joiningPressure impregnationWood veneerPolymer science

Belongs to the technical field of wood processing. In order to solve the problem that an adhesive agent is adopted in an existing reconstituted veneer, and consequently, poisonous and harmful volatile matter is released, the preparing method of the glue-free reconstituted veneer comprises the steps that a fast-growing wood veneer is subjected to delignification by using a delignification solution to obtain a delignified wood sample; 80% of water in the delignified wood sample is removed through cold pressing; and after hot-pressing drying, a glue-free reconstituted veneer is obtained. According to the preparing method, hydroxyl on the surface of cellulose and hemicellulose is exposed through delignification, a multiple hydrogen-bond network is formed under pressure, and high mechanical strength and high size stability of the reconstituted veneer are given. In the preparing method, no adhesive agent is used, the reconstituted veneer is low in cost, simple in process and short in time, zero volatile of formaldehyde is really realized; the problems are solved that a great amount of the adhesive agent is used in artificial timbers, the indoor environment is polluted, and the human body health is harmed; and the glue-free reconstituted veneer has a higher market value.

Owner:NORTHEAST FORESTRY UNIVERSITY

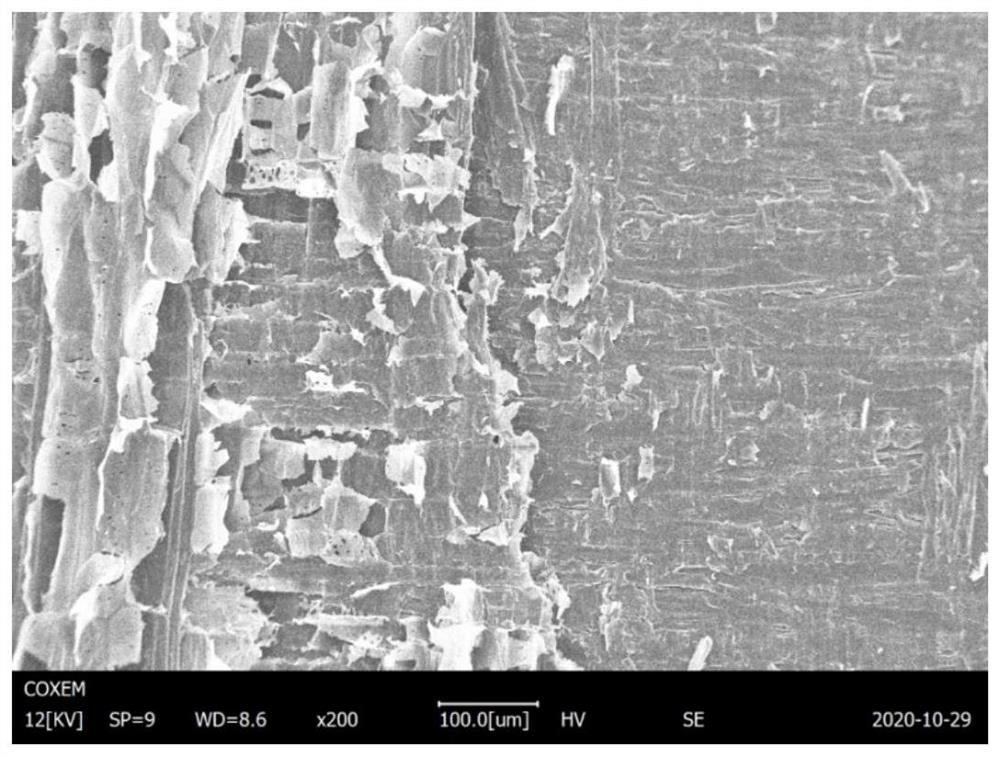

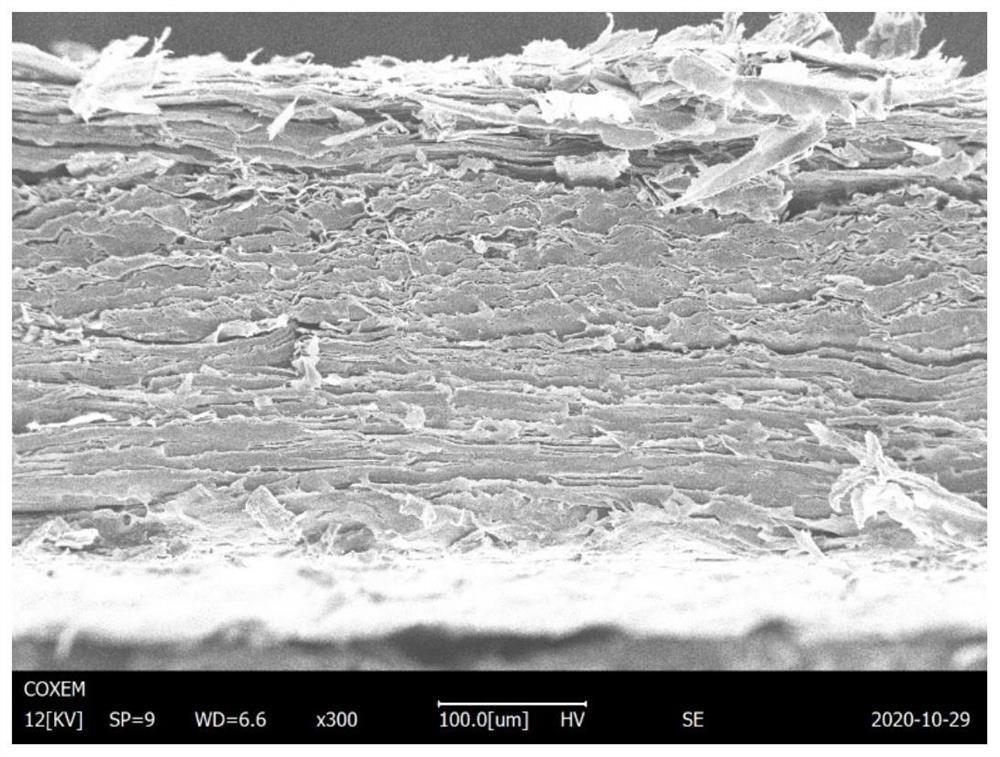

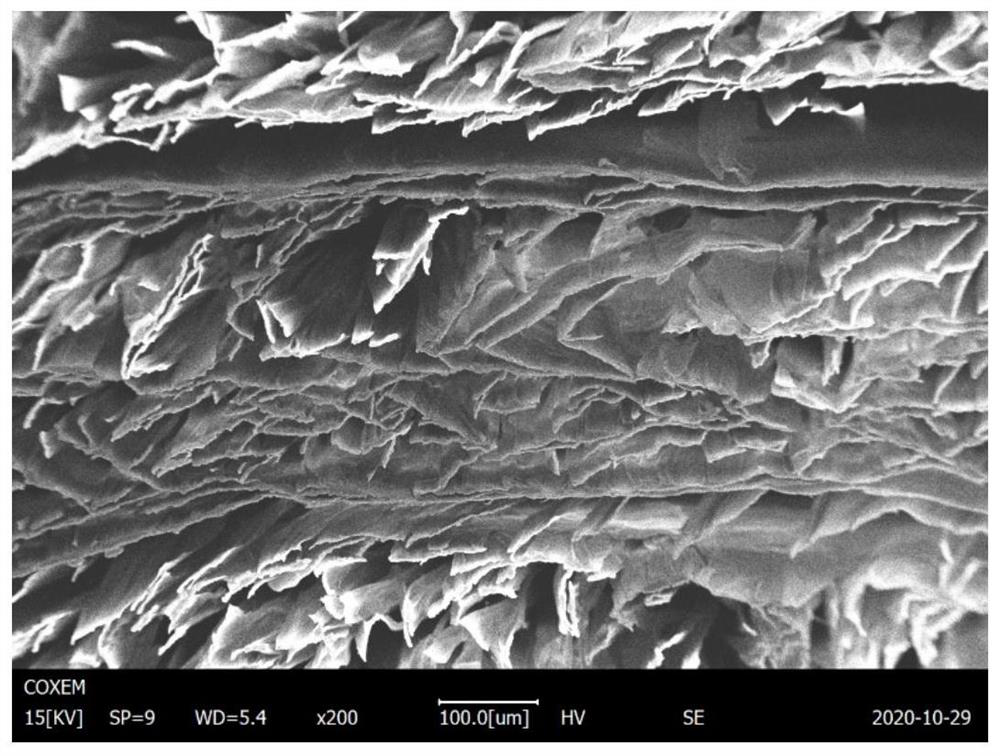

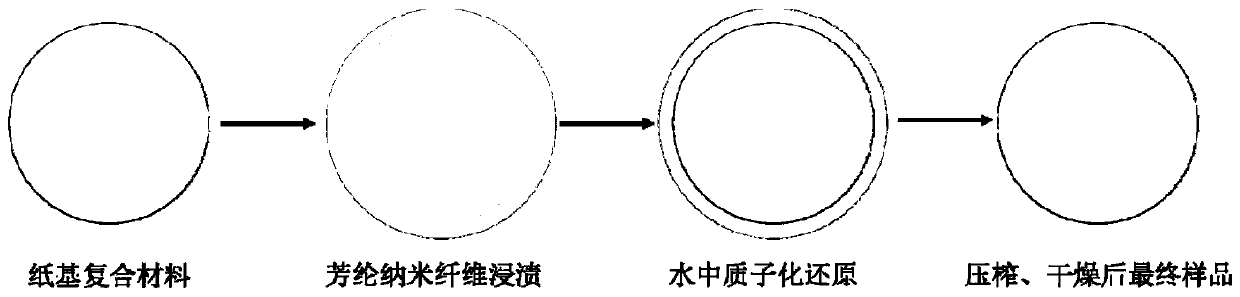

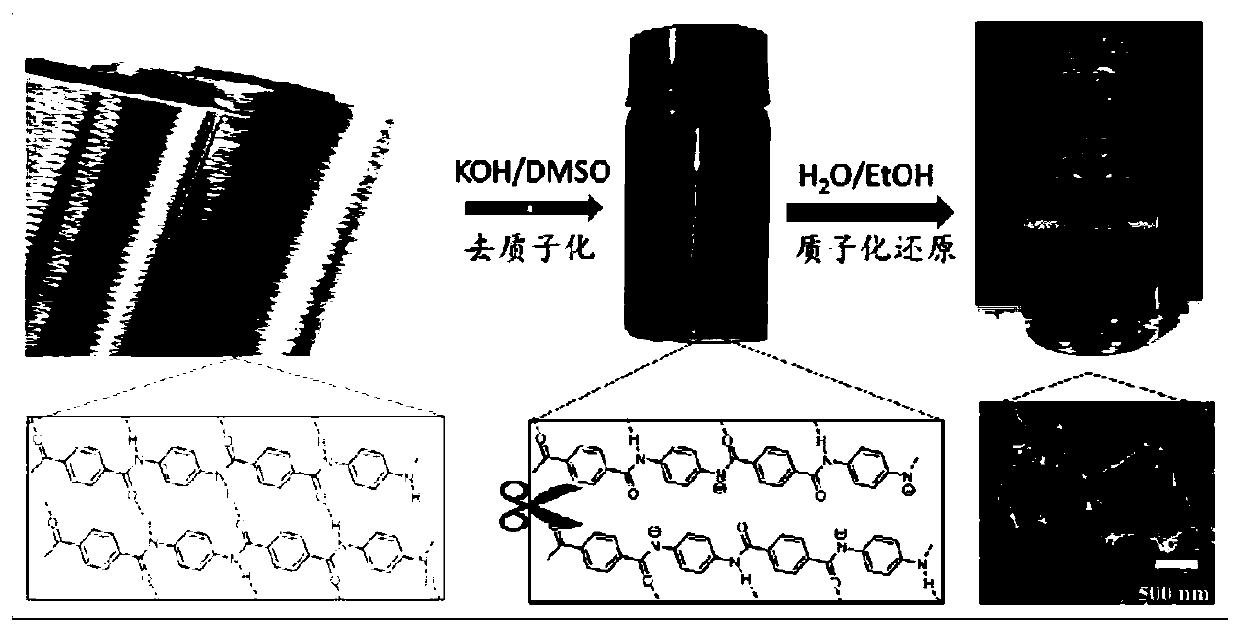

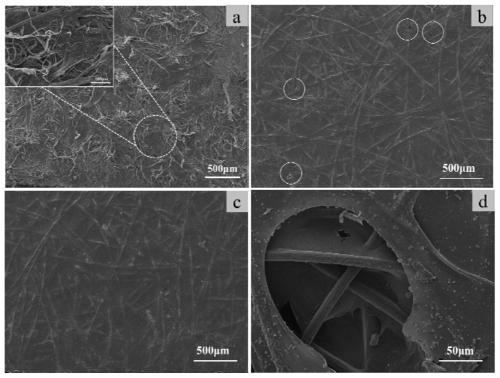

Method for in-situ reinforcement of performance of paper-based material by aramid nanofibers

ActiveCN111304955AImprove retentionDoes not affect operationReinforcing agents additionPaper/cardboardNanofiberUltimate tensile strength

The invention discloses a method for in-situ reinforcement of performance of paper-based material by aramid nanofibers. Aramid fiber dissolving solutions with different concentrations are used for treating different aramid fiber paper-based composite materials. According to the method, the strength performance and the breakdown performance of the paper-based composite material can be improved to agreat extent, the satisfactory effect can be achieved on improvement of the performance of the paper-based composite material, operation is convenient and easy, glue-free reinforcement is achieved, the material can be used under complex conditions, and the method is high in applicability and has good application prospects.

Owner:SHAANXI UNIV OF SCI & TECH

Composite packaging bag for beverages and production method of composite packaging bag

InactiveCN103434235ALow oxygen permeabilityLight weightSynthetic resin layered productsLaminationLow-density polyethylenePolyamide

The invention discloses a composite packaging bag for beverages and relates to the technical field of beverage packaging bags. Films made of three raw materials, namely low density polyethylene, two-way stretch polyamide and polyvinylidene chloride are subjected to low / high-pressure rolling no-glue compositing, then are cured, cooled and sliced, and are subjected to thermal inductance pressing and cutting to form a bag. A production method has the energy-saving effect and is low in pollution. The produced composite packaging bag is high in tensile strength, low in oxygen permeation rate, resistant to oil, high temperature and low temperature, high in air impermeability, low in specific gravity, low in cost, quick and novel in packaging, and has the environment-friendly effect.

Owner:SHANDONG JUQIANG BIOLOGICAL FOOD

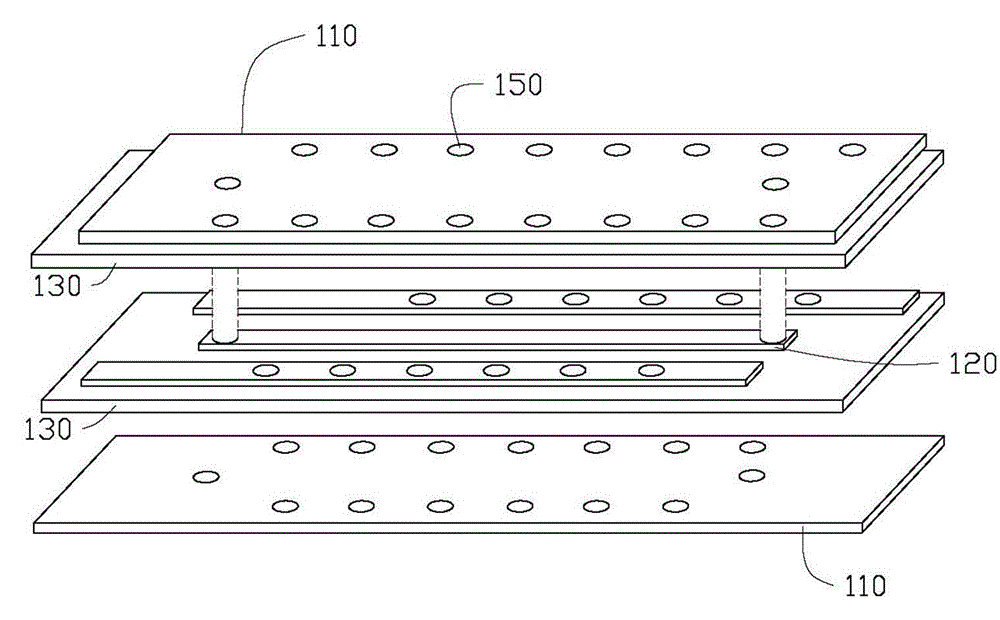

Structural assembly and method

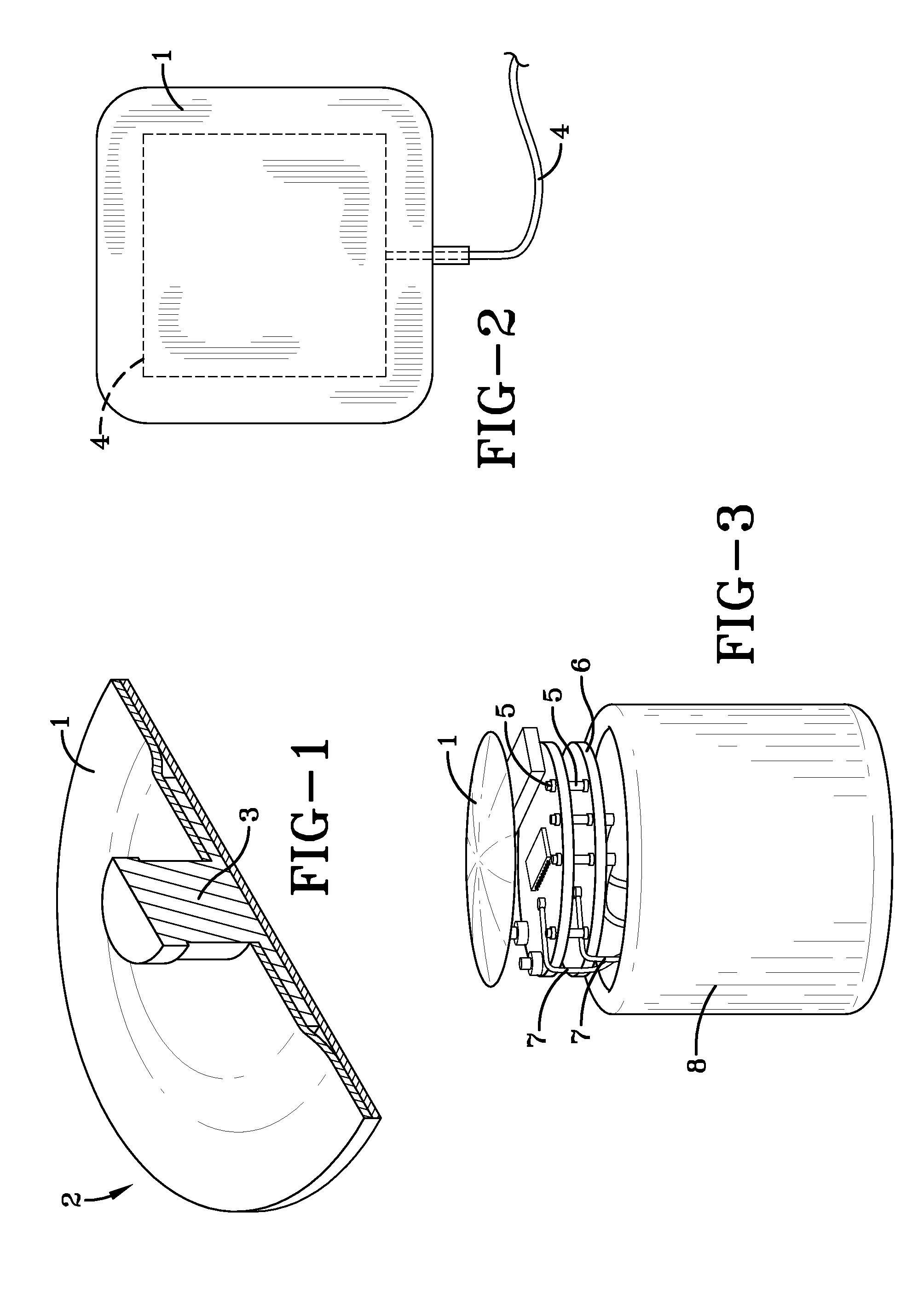

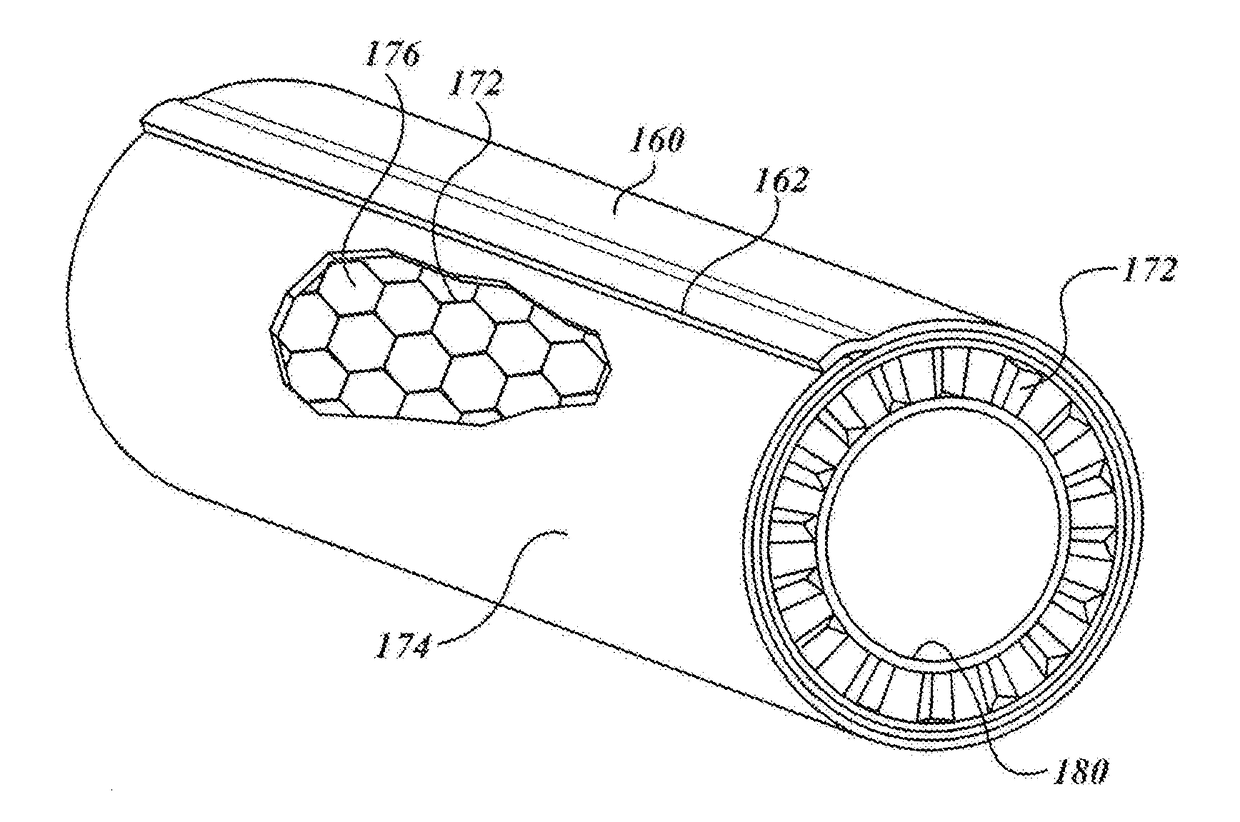

A structural assembly includes a first member defining a matrix material, and a second member defining a skin. The skin has a roughed surface of hooks or barbs. The second member is engaged to the first member to define a mechanically interlocked assembly. The assembly may include an open-cell matrix material in a glue-less connection. The assembly may include a chemical bond in addition to a mechanical bond. The assembly may include internal layers of pre-impregnated composite fiber and resin. The skin member may act as a jig for a green composite member. The skin member may be deformed in a press to present a non-planar surface for such other members as may be attached to it. Assemblies may be formed with mechanical interconnection in place of glue or adhesive connections. Assemblies may be formed to may light, thin-walled pipe, flasks, pressure vessels and so forth.

Owner:SADR CHANGIZE

Separation of denatured proteins in free solution

InactiveUS20060160235A1Improve compatibilityMaterial analysis by electric/magnetic meansPeptide preparation methodsSulfateElectrophoresis

The present invention relates generally to the separation of proteins in free solution using electrophoresis. The invention provides gel-free methods of separating proteins that involve the use of a mixture of alkyl sulfates of different carbon chain lengths.

Owner:CORNELL RES FOUNDATION INC

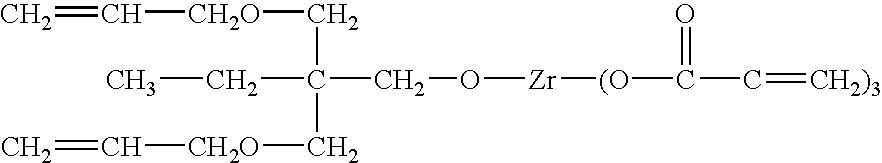

Reactive and gel-free compositions for making hybrid composites

A substantially reactive and gel-free composition which comprises:a. particles capable of reaction with a radiation curable resin;b. a coupling agent for modification of the surface of said particles;c. a radiation curable resin;d. a radiation curable salt capable of inhibiting gel formation in said composition.Upon radiation cure of the composition, composites with excellent mechanical properties are obtained

Owner:SURFACE SPECIALTIES

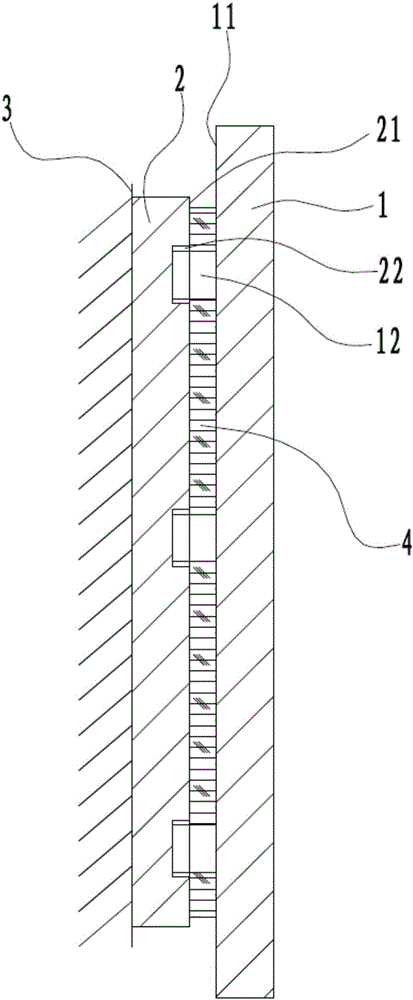

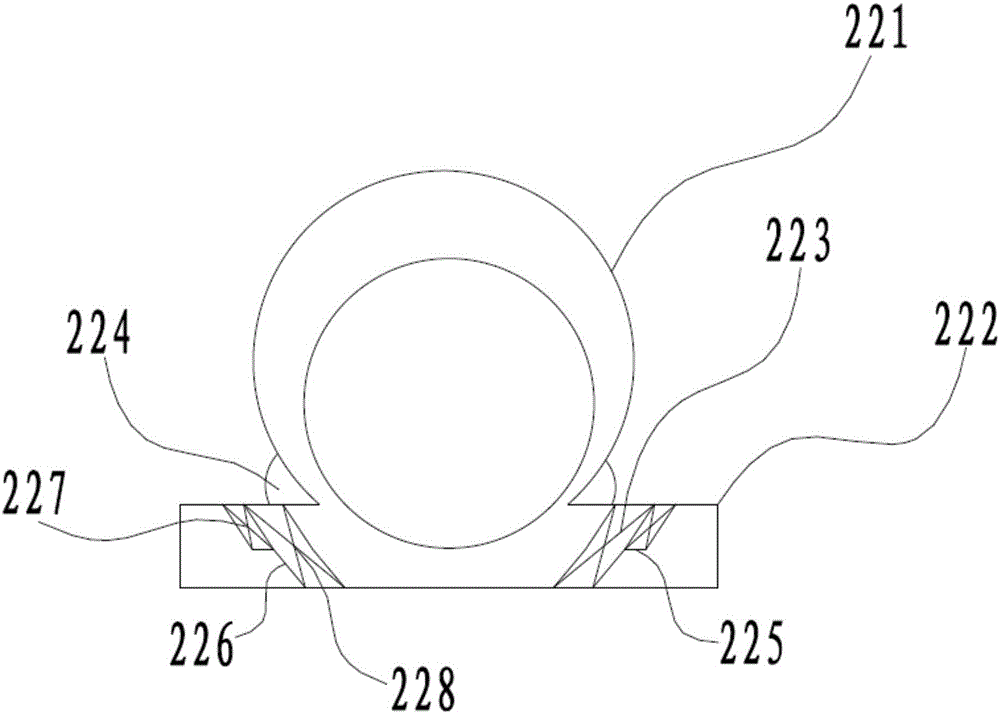

Adjustable gelling-free installation structure for dry hanging of indoor large-specification stone materials

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com