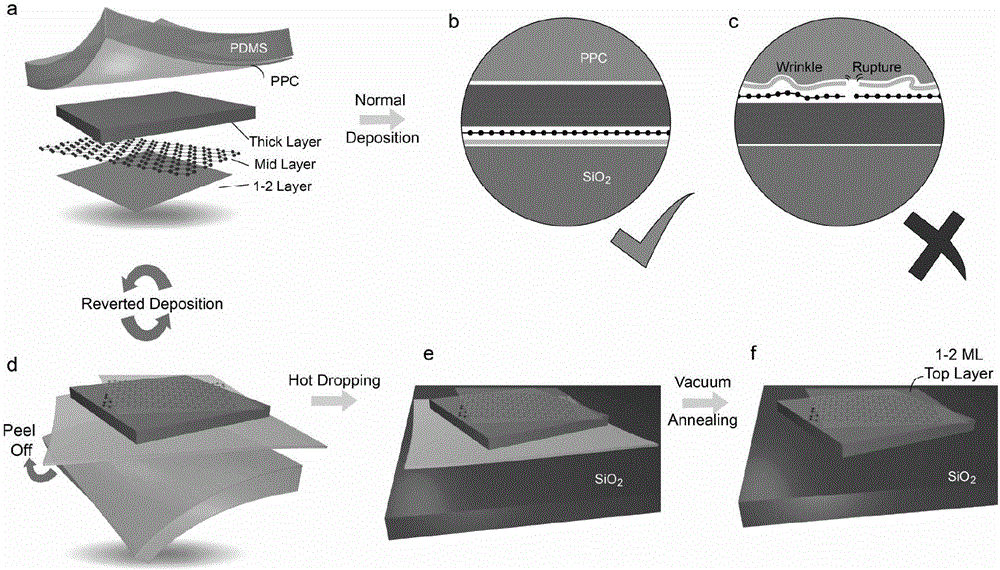

Method for putting pure ultrathin two-dimensional materials on stacking top layer

A two-dimensional material and stacking technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that PPC cannot stick to the bottom material and the bottom material is curled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

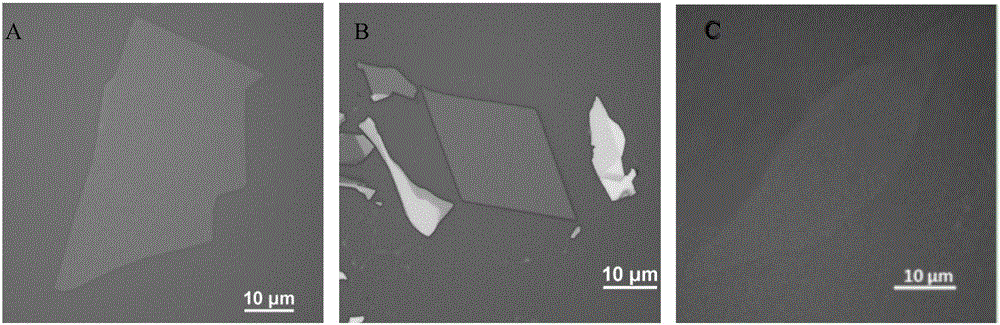

Examples

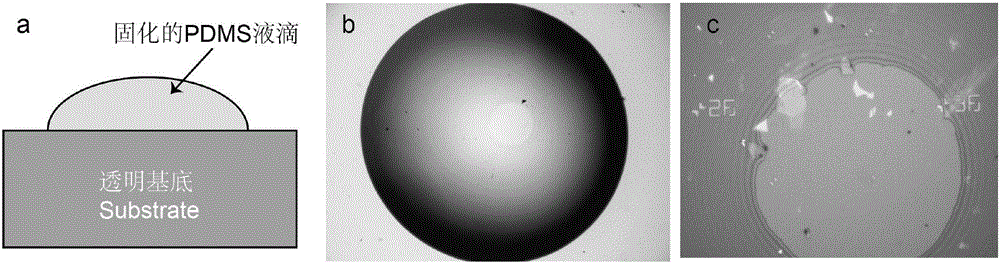

Embodiment 1

[0035] MoS with a thickness of about 5nm 2 A few layers of materials are transferred to the second layer of ultra-thin h-BN with only two atomic layers by using the first layer of h-BN with a thickness of about 15nm, and finally form a planar heterojunction with a three-layer structure and adhere to the surface of PPC superior. The PPC is coated on a solid arc-shaped PDMS prepared by the droplet method. After peeling off the 3-layer structure from PDMS, place it upside down on the surface of a clean silicon wafer, and prepare half of the MoS 2 Tunneling field effect transistor with two atomic layers of BN coverage (see Figure 7 , 1, 2, 3, 4, 9, 10 electrodes in figure a, where figure b shows the IV curve between electrodes 2-3, and figure c shows the field effect curve between electrodes 2-3), and the other half is normal MoS2 FET (see Figure 7 , 5, 6, 7, 8 electrodes in figure a, among them, figure d shows the IV curve between electrodes 6-7, and figure e shows the field...

Embodiment 2

[0037] The single-layer graphene is bonded with a layer of h-BN with a thickness of about 15nm, and finally a planar heterojunction with a 2-layer structure is formed and adhered to the surface of the PPC. The PPC is coated on a solid arc-shaped PDMS prepared by the droplet method. After the two-layer structure was peeled off from the PDMS, it was placed upside down on the surface of a clean silicon wafer, and a heterogeneous structure of ultra-pure top layer graphene on the surface of boron nitride was prepared. Since the structure maintains the flatness and purity of graphene, it can be used for scanning tunneling microscope observation and research on its electrical properties such as ultra-high mobility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com