Non-peelabel insole and manufacturing method

a manufacturing method and non-peelable technology, applied in the field of insoles, can solve the problems of increased process efficiency, time-consuming and inefficient, and large amount of work, and achieve the effects of improving the productivity and efficiency of the manufacturing process, saving production time, and simplifying the entire process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]These and other objectives, features, and advantages of the present invention will become apparent from the following detailed description, the accompanying drawings, and the appended claims.

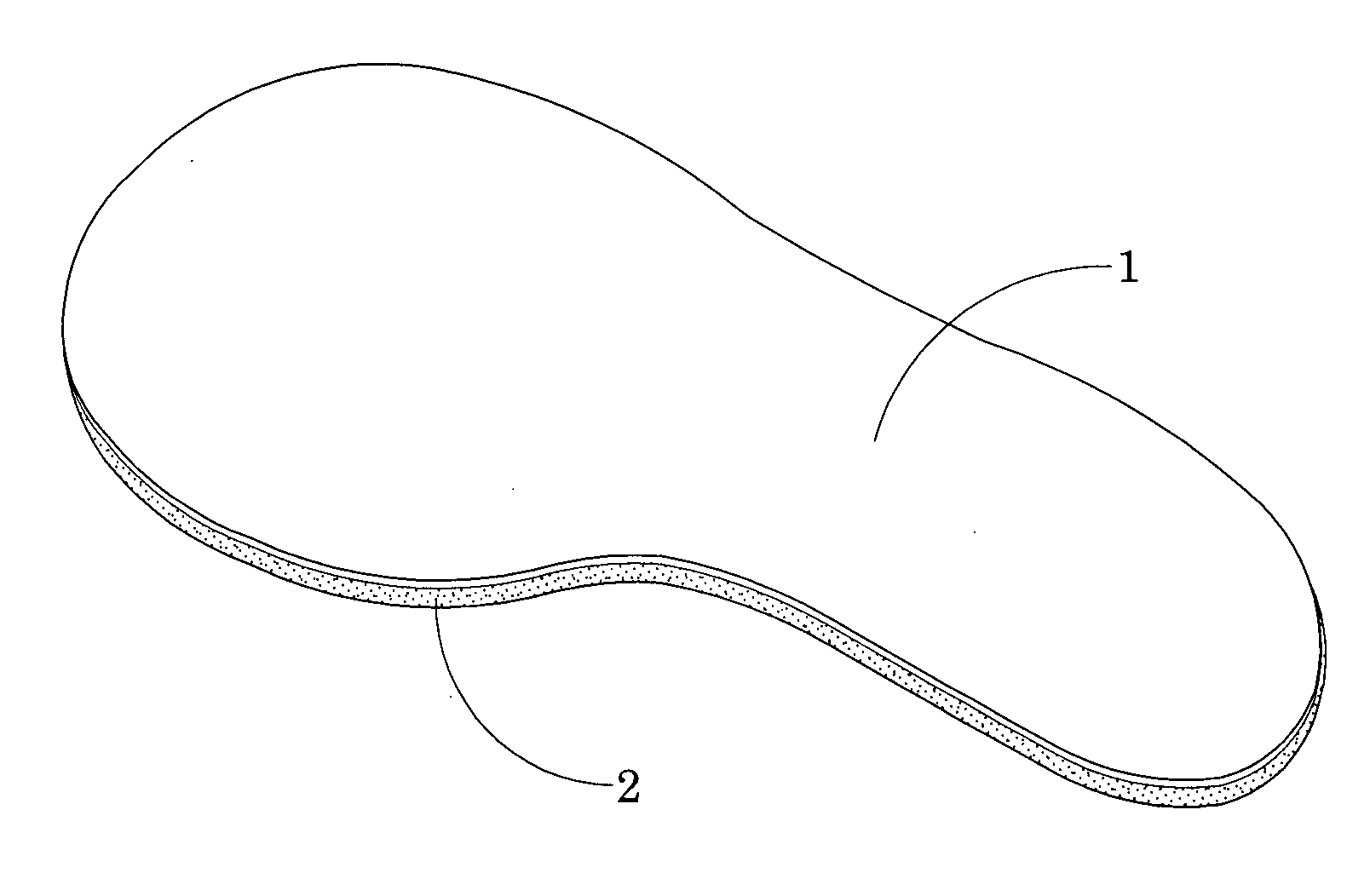

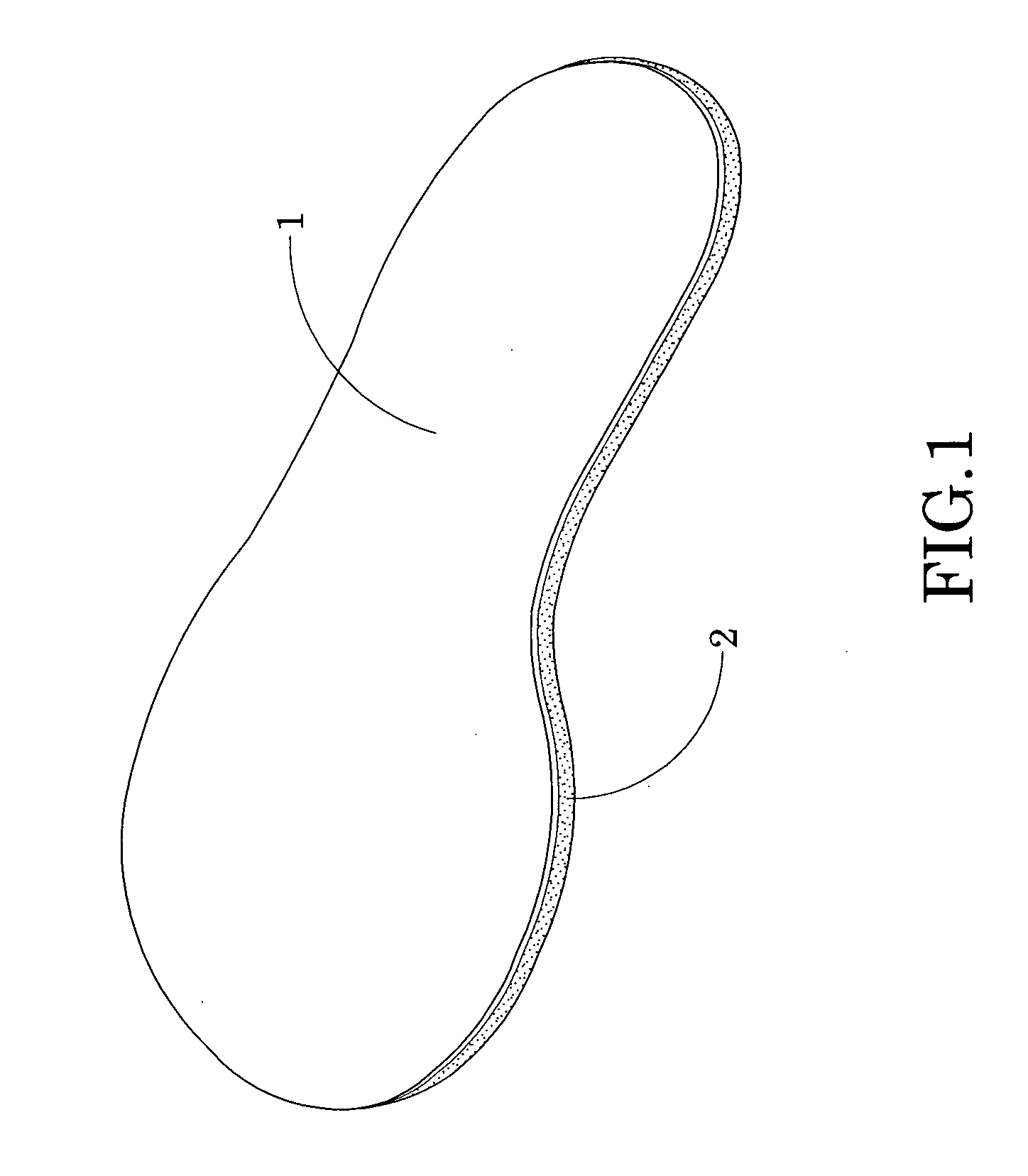

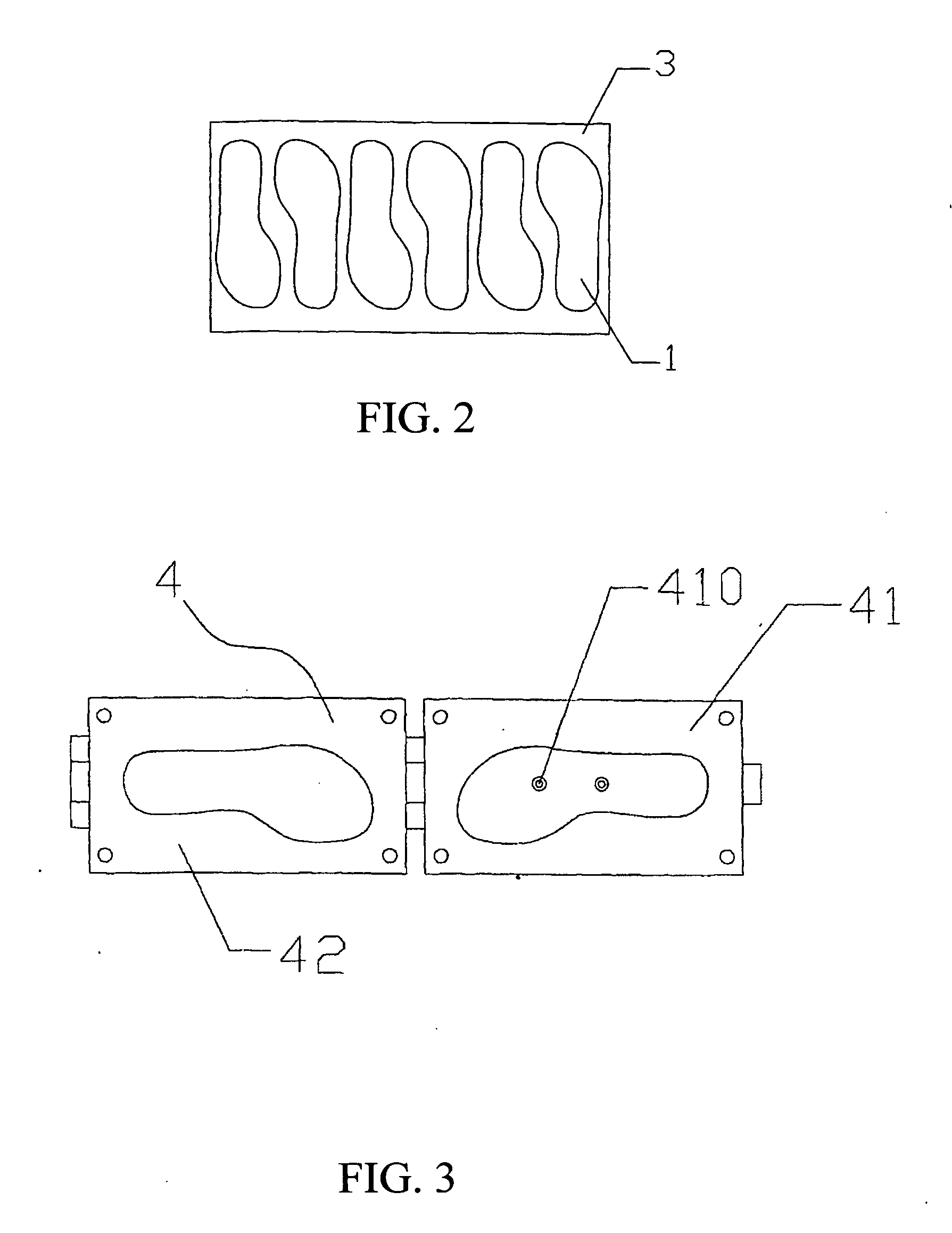

[0046]Referring to FIGS. 1 and 6 of the drawings, a non-peelable insole according to a preferred embodiment of the present invention is illustrated, wherein the insole comprises a first layer 1 and a second layer 2 integrally and continuously formed with the first layer 1 in a glue-less manner, wherein the first layers 1 are preferably trimmed and cut from a first sheet, such as leather, rubber or the like, and embodied as PU material (polyurethane). The second layer 2 is preferably formed via mold injecting process, so as to integrally and automatically bond with the first layer 10, embodied as PU layer, via heat or melting to form the bonding therebetween. Accordingly, the non-peelable insole pad can be a removable insole received in the shoe. Accordingly, the first layer 1 has a top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com