High dispersion gel-free white carbon black and its preparing method

A gel-free white carbon black, high-dispersion technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of high cost, less product variety, low reinforcement performance, etc., and achieves the reduction of water consumption and electricity consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is a kind of highly dispersed gel-free white carbon black, which contains SiO with a weight percentage of more than 99% 2 , the specific surface area of highly dispersed gel-free silica is 320m 2 / g~380m 2 / g, wherein the primary particle size <11 nanometers.

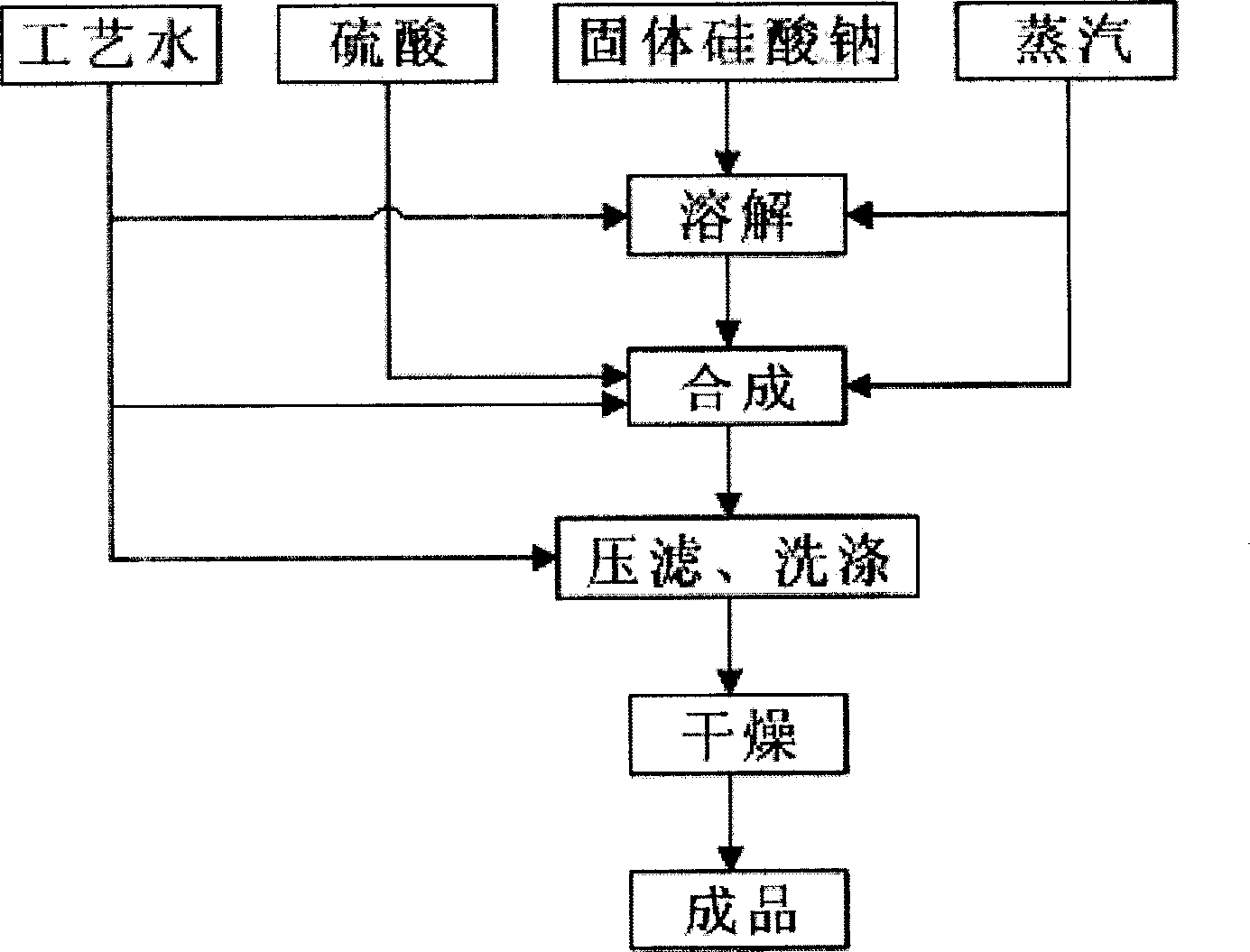

[0039] A method for preparing highly dispersed gel-free white carbon black, the raw materials used include sodium silicate, concentrated sulfuric acid and water with a concentration of 90% to 99% by mass, and the method includes the following steps:

[0040] 1) First add sodium silicate in the synthesis tank, then add water to dissolve;

[0041] 2) Add sulfuric acid with a mass percentage concentration of 90 to 99% in the synthesis tank to carry out a chemical reaction, and add the stabilizer Na 2 SO 4 , adding an appropriate amount of dispersant Na 2 SO 4 , it is necessary to stir while reacting, and the stirring speed is controlled in the range of 40-200 rpm;

[0042] 3) After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com