Preparation method and application for pitch-based hard carbon nanosheet

A nanosheet, asphalt-based technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, restricting wide-scale application, easy to pollute the environment, etc., and achieve rich sources. , excellent cycle performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1. Add 100g of medium-temperature coal tar pitch into a round-bottomed flask, heat it in an oil bath until it melts, add 30g of p-toluenedimethanol, mix well, add 5g of p-toluenesulfonic acid, continue heating to 160°C for 3 hours, and the system is Viscous liquid, take out after cooling to room temperature.

[0020] Step 2. Put 20g of sodium chloride into a ball mill jar, add an appropriate amount of zirconia balls to it, add 12g of ethanol, and mill at a speed of 400rpm for 4 hours. After taking out the mixture, evaporate the ethanol to dryness, and separate the sample from the zirconia balls to obtain micron grade sodium chloride template.

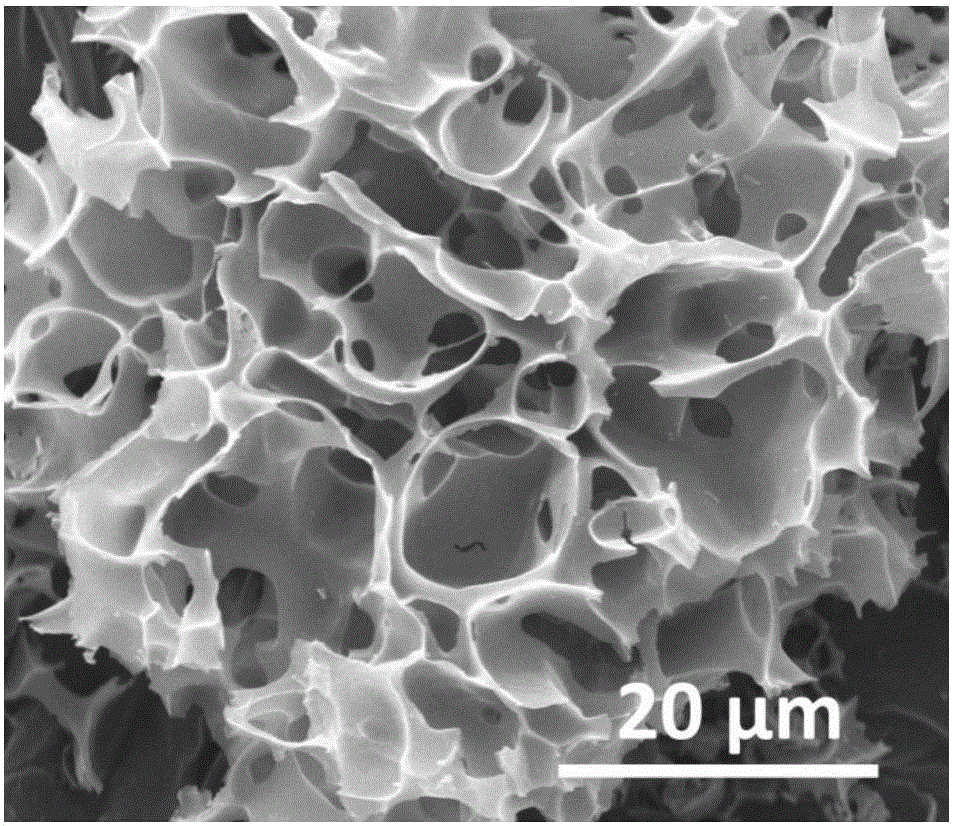

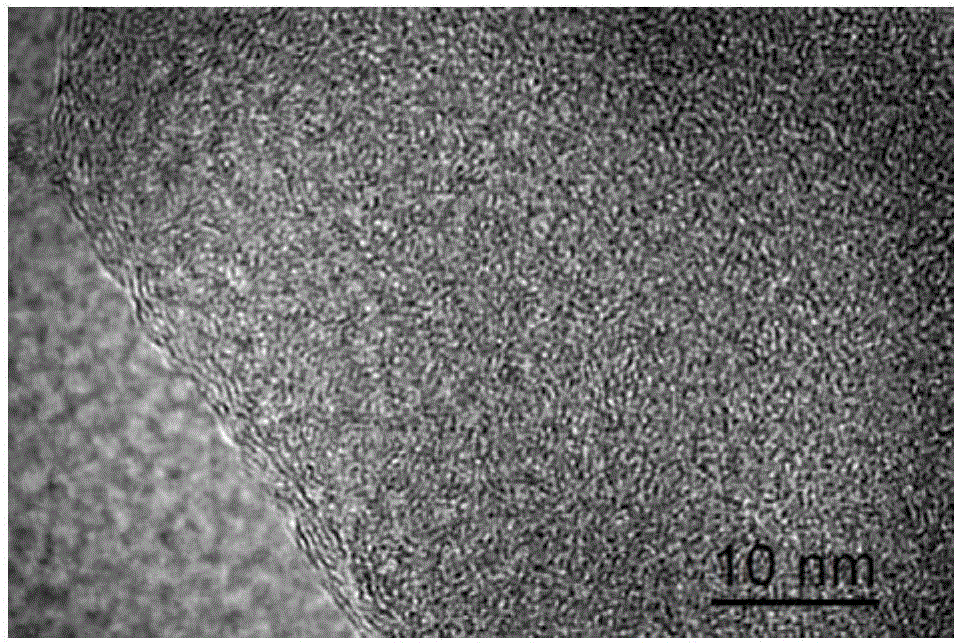

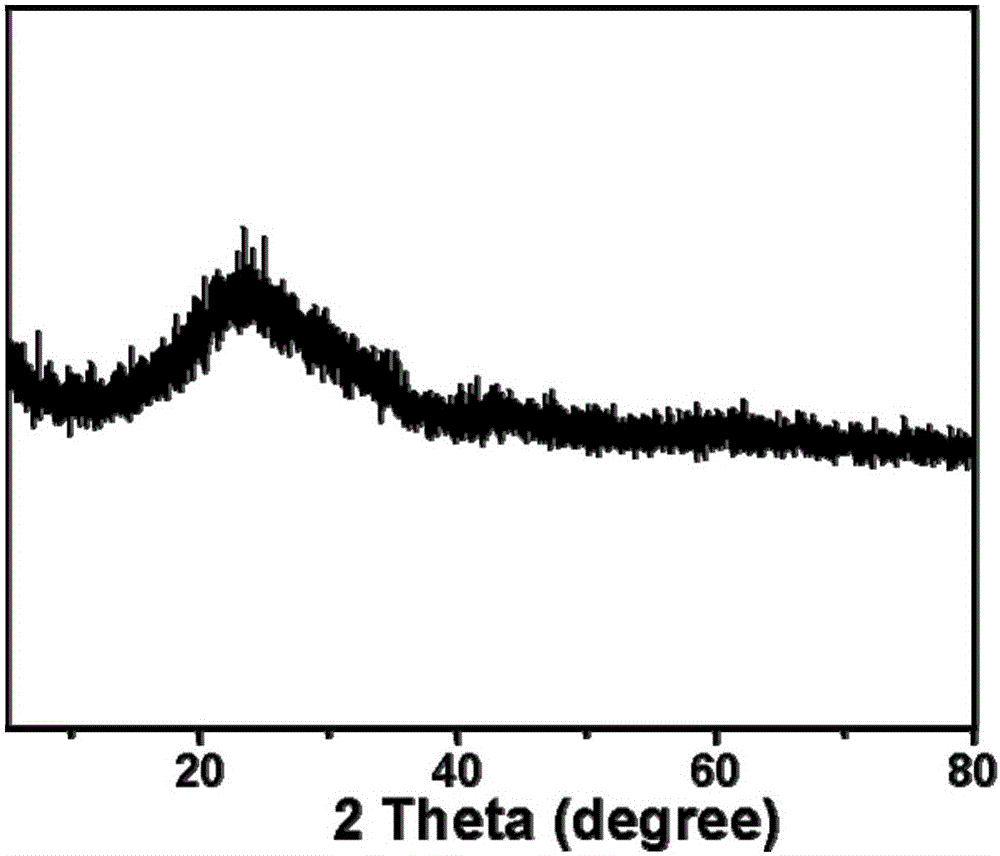

[0021] Step 3. Dissolve 2 g of the modified asphalt powder prepared in step 1 in 30 g of NMP, add 20 g of the sodium chloride template prepared in step 2, heat and evaporate the NMP in an oil bath at 200° C. to dryness. Carbonize the obtained mixture, raise the temperature to 650°C at 5°C / min under the protection of nitroge...

Embodiment 2

[0024] Step 1. Add 100g of medium-temperature coal tar pitch into a round-bottomed flask, heat it in an oil bath until it melts, add 30g of p-toluenedimethanol, mix well, add 7g of p-toluenesulfonic acid, continue heating to 160°C for 3 hours, and the system is Viscous liquid, take out after cooling to room temperature.

[0025] Step 2. Put 20g of sodium chloride into a ball mill jar, add an appropriate amount of zirconia balls to it, add 10g of ethanol, and mill at a speed of 400rpm for 4 hours. After taking out the mixture, evaporate the ethanol to dryness, and separate the sample from the zirconia balls to obtain micron grade sodium chloride template.

[0026] Step 3. Dissolve 2 g of the modified asphalt powder prepared in step 1 in 40 g of NMP, add 20 g of the sodium chloride template prepared in step 2, and evaporate the NMP to dryness in an oil bath at 200° C. Carbonize the obtained mixture, raise the temperature to 750°C at 5°C / min under the protection of nitrogen in a...

Embodiment 3

[0029] Step 1. Add 100g of medium-temperature coal tar pitch into a round-bottomed flask, heat it in an oil bath until it melts, add 30g of p-toluenedimethanol, mix well, add 7g of p-toluenesulfonic acid, continue heating to 170°C for 2 hours, and the system is Viscous liquid, take out after cooling to room temperature.

[0030] Step 2. Put 20g of sodium chloride into a ball mill jar, add an appropriate amount of zirconia balls to it, add 8g of ethanol, and ball mill for 5 hours at a speed of 300rpm. After taking out the mixture, evaporate the ethanol to dryness, and separate the sample from the zirconia balls to obtain micron grade sodium chloride template.

[0031] Step 3. Dissolve 2 g of the modified asphalt powder prepared in step 1 in 35 g of NMP, add 40 g of the sodium chloride template prepared in step 2, and evaporate the NMP to dryness in an oil bath at 200° C. Carbonize the obtained mixture, raise the temperature to 850°C at 5°C / min under the protection of nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com