Carboxyl terminated dendritic polymer adsorption material and preparation method thereof

An adsorption material and dendritic technology, which is applied in the field of carboxyl-terminated dendritic polymer adsorption materials and their preparation, can solve the problems of difficult regeneration of adsorption adsorption materials, small adsorption capacity, low bulk density, etc., and achieves wide application range and action efficiency. Increased, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

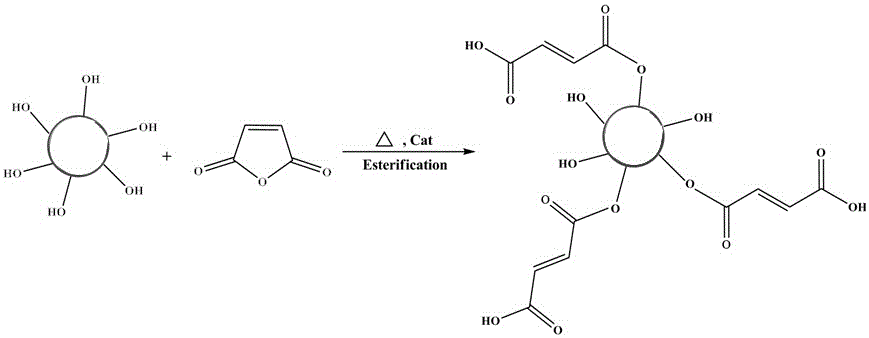

[0027] The present invention relates to the preparation method of carboxyl-terminated dendritic polymer adsorption material, comprises the following steps:

[0028] 1) Preparation of hydroxyl-terminated dendrimers:

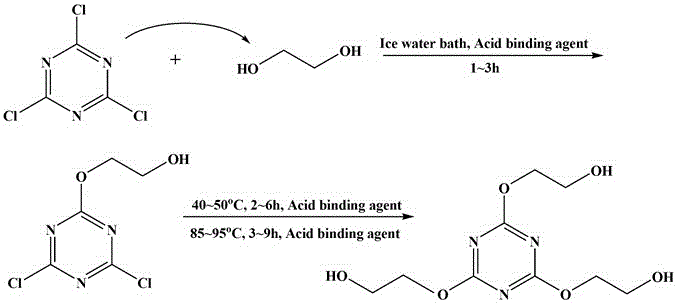

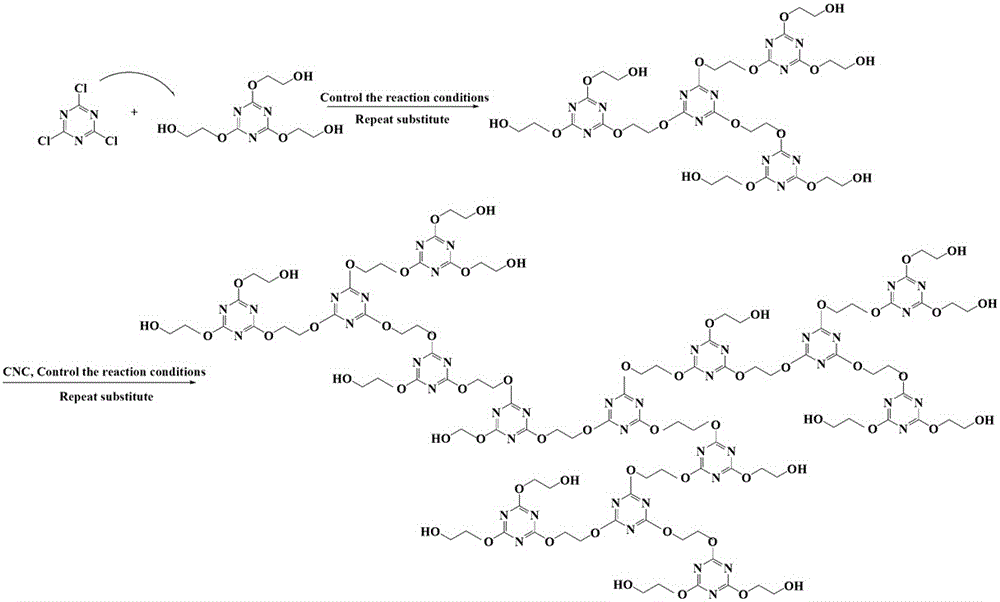

[0029] The first step: Weigh 5-10mmol of diol and dissolve it in 40-80mL of acetone; according to the molar ratio of diol to cyanuric chloride (3-4):1, dissolve cyanuric chloride in 50 -100mL of acetone or tetrahydrofuran, under the condition of nitrogen protection and ice-water bath, add dropwise to the acetone solution of dihydric alcohol; stir for 1-3h, slowly raise the temperature to 40-50°C, stir for 2-6h, and finally raise the temperature to 85-95°C, stirring and reacting for 3-9h, adding an acid-binding agent continuously during the reaction to maintain a pH of 5-6, and obtaining a crude product of a first-generation hydroxyl-terminated dendritic polymer;

[0030] Step 2: Repeatedly extract and wash the crude product of the first-generation hydroxyl-termin...

Embodiment 1

[0039] 1) Preparation of hydroxyl-terminated dendrimers:

[0040] Step 1: Dissolve 5mmol of dibasic alcohol in 80mL of acetone; Dissolve cyanuric chloride in 100mL of acetone according to the molar ratio of dibasic alcohol and cyanuric chloride to 3:1, store under nitrogen protection and ice Add dropwise to the acetone solution of dibasic alcohol under the condition of water bath; stir for 1 hour, slowly raise the temperature to 50°C, stir for 2 hours, finally raise the temperature to 95°C, stir for 3 hours, keep adding acid-binding agent during the reaction to maintain the pH of 6. Prepare a crude product of a first-generation hydroxyl-terminated dendritic polymer;

[0041] Step 2: Repeatedly extract and wash the crude product of the first-generation hydroxyl-terminated dendrimer with acetone, and vacuum filter to obtain the first-generation hydroxyl-terminated dendritic polymer;

[0042] The third step: with cyanuric chloride as the core and the first generation of hydroxyl...

Embodiment 2

[0049] 1) Preparation of hydroxyl-terminated dendrimers:

[0050] The first step: Weigh 7mmol dihydric alcohol and dissolve it in 60mL acetone; according to the ratio of dihydric alcohol and cyanuric chloride molar ratio of 3.5:1, dissolve cyanuric chloride in 75mL acetone, under nitrogen protection and ice Add dropwise to the acetone solution of dibasic alcohol in a water bath; stir for 2 hours, slowly raise the temperature to 45°C, stir for 4 hours, and finally raise the temperature to 90°C, stir for 6 hours, and keep adding acid-binding agents during the reaction to maintain the pH at 5. Prepare a crude product of a first-generation hydroxyl-terminated dendritic polymer;

[0051]Step 2: Repeatedly extract and wash the crude product of the first-generation hydroxyl-terminated dendrimer with acetone, and vacuum filter to obtain the first-generation hydroxyl-terminated dendritic polymer;

[0052] The third step: with cyanuric chloride as the core and the first generation of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com