Organic granular plugging agent for CO2-driving high-temperature low-permeation water-sensitive oil deposit and preparation method thereof

A technology of organic particles and plugging agents, which is applied in the direction of chemical instruments and methods, bulk chemical production, drilling compositions, etc., can solve the problems of low permeability layer not being activated, large permeability difference, etc., and achieve the response time Controllable, strong erosion resistance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

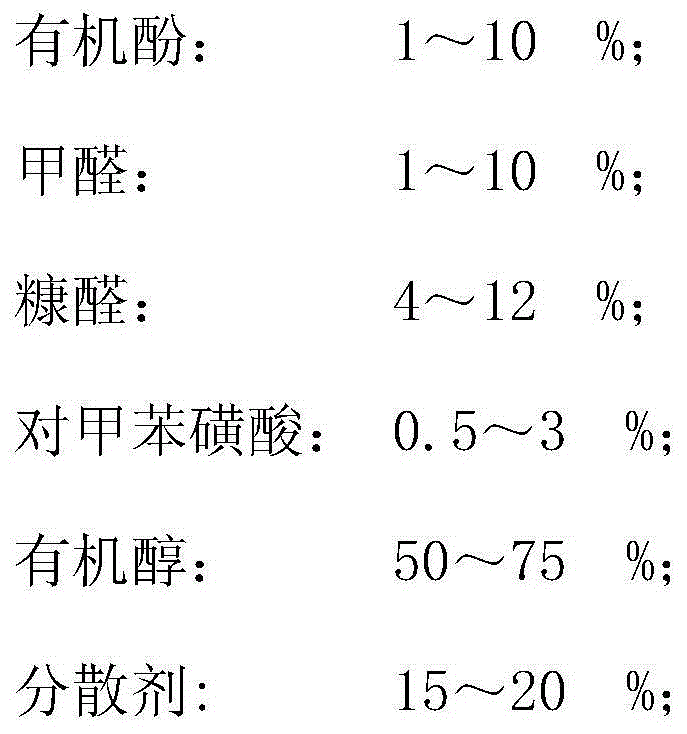

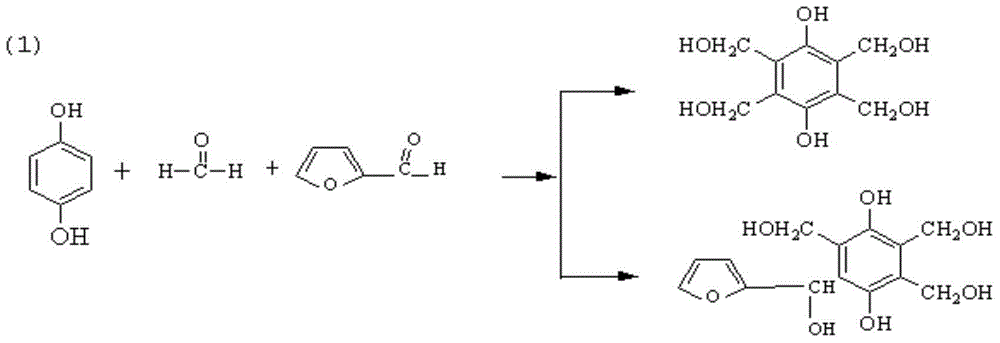

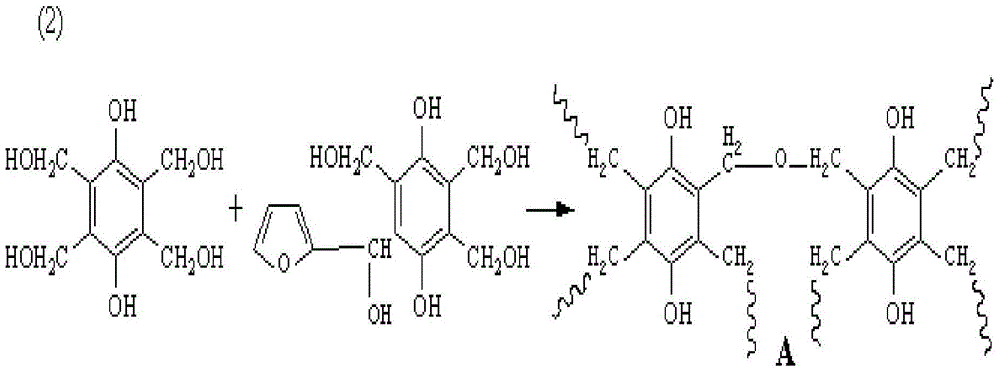

Method used

Image

Examples

Embodiment 1

[0025] Add 3g of hydroquinone, 3g of formaldehyde, 5.6g of furfural, 1.13g of catalyst, 70g of alcohol, and 17.27g of dispersant into a 250ml three-necked flask, and then heat it to 100°C; if not stirred, the resulting particles will have a large particle size ; If stirring, the generated particle size is smaller; the products generated with stirring and without stirring are respectively filtered and dried, and the yields are both 92.83%.

Embodiment 2

[0027] Add 4.5g of hydroquinone, 10g of formaldehyde, 11g of furfural, 2.3g of catalyst, 56.7g of alcohol, and 15.5g of dispersant into a high-temperature and high-pressure reactor, and pass in CO 2 Then pressurized to 10MPa, and then heated to 126°C; the particles generated were more than those in Example 1; the yield was 95.81%.

Embodiment 3

[0029] 8g of hydroquinone, 10g of formaldehyde, 10g of furfural, 2g of catalyst, 50g of alcohol, and 20g of dispersing agent were added to a 250ml three-neck flask respectively, and then heated to 126°C; the particles produced were more than those in Example 2; the yield was 96.32 %.

[0030] CO 2 Model experiment of sand flooding pipe plugging

[0031] Experimental steps: Grind the sand, dry it, fill it into a 30cm sand filling pipe, saturate it with water and oil, place the sand filling pipe for 24 hours for aging, water flooding to a comprehensive water content of 98%, and end the water flooding; 2PV carbon dioxide Flood (make a slug) until the displacement pressure is stable; inject 0.6PV plugging agent solution; place the sand filling pipe in an oven at 126°C for 48 hours, and then perform CO 2 Flood until the displacement pressure stabilizes. Record the injection pressure, the volume of produced oil and water at each stage and calculate the corresponding recovery degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Recovery factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com