Method for manufacturing organic light emitting display device

A light-emitting display, organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

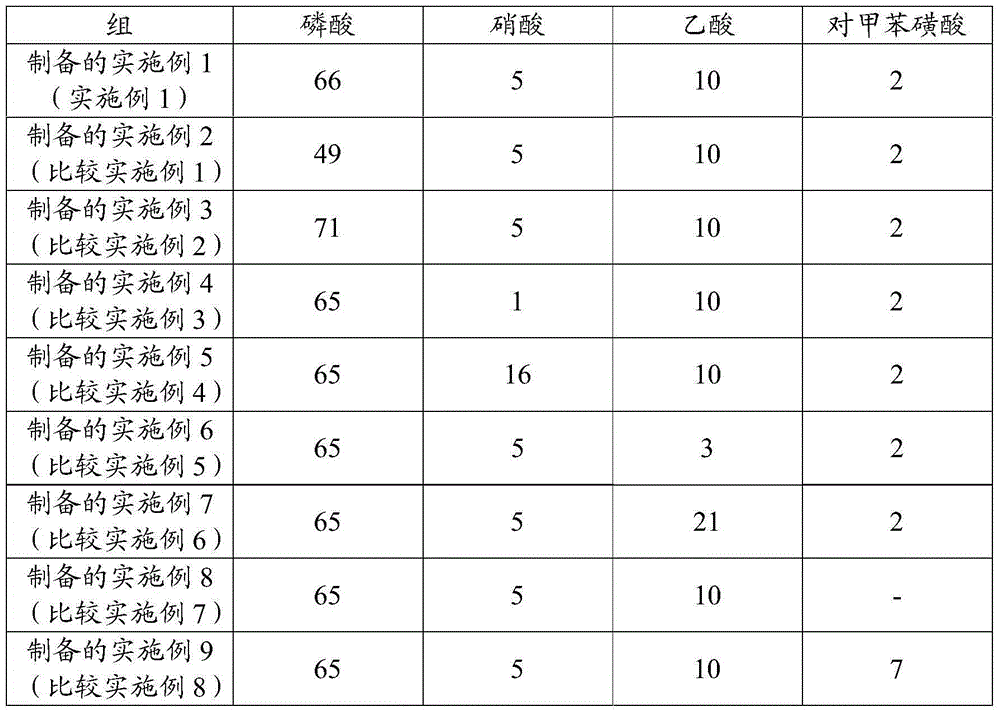

[0078] Examples and Comparative Examples

[0079] (1) Preparation of etchant composition

[0080] Etchant compositions having various constituent components and contents listed in Table 1 below and including the balance of water were prepared.

[0081] [Table 1]

[0082]

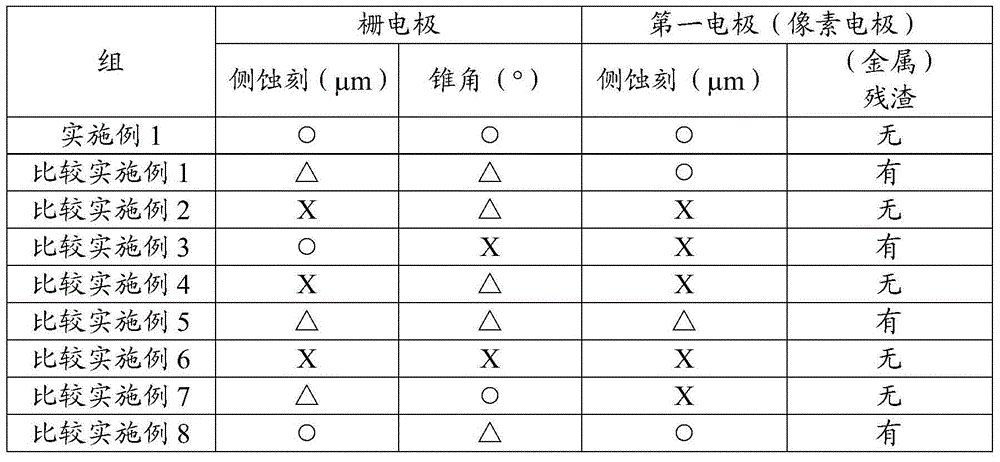

[0083] (2) Formation of metal wires

[0084] 1) Gate electrode

[0085] A Mo / Al / Mo metal layer is formed on a glass substrate by a deposition method, and the formed layer metal layer is etched using each of the above-mentioned etchant compositions to form a gate electrode.

[0086] 2) The first electrode

[0087] A gate electrode, a source electrode, and a drain electrode are formed on the glass substrate, and then a passivation layer is formed on the glass substrate. Thereafter, a laminated layer structure of ITO / APC(AgPdCu) / ITO was formed on the passivation layer, and then etched using the respective etchant compositions described above to form the first electrode. Here, the drain electrode and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com