Super-early-strength fluoride-free alkali-free liquid accelerator and preparation method thereof

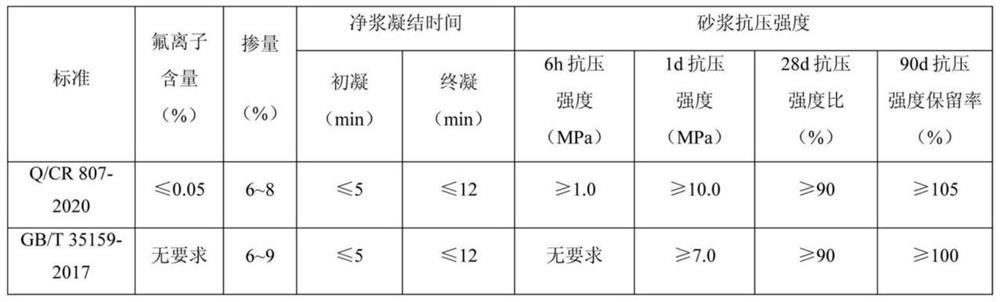

A technology of super early-strength type and quick-setting agent, which is used in the preparation of liquid quick-setting agent, super-early-strength type fluorine-free alkali-free liquid quick-setting agent, and the field of super-early-strength type fluorine-free alkali-free liquid quick-setting agent. Solve the problems of excessive alkali content, high compressive strength, and no guidance plan, and achieve the effects of low active adsorption center, improved early strength, and shortened setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

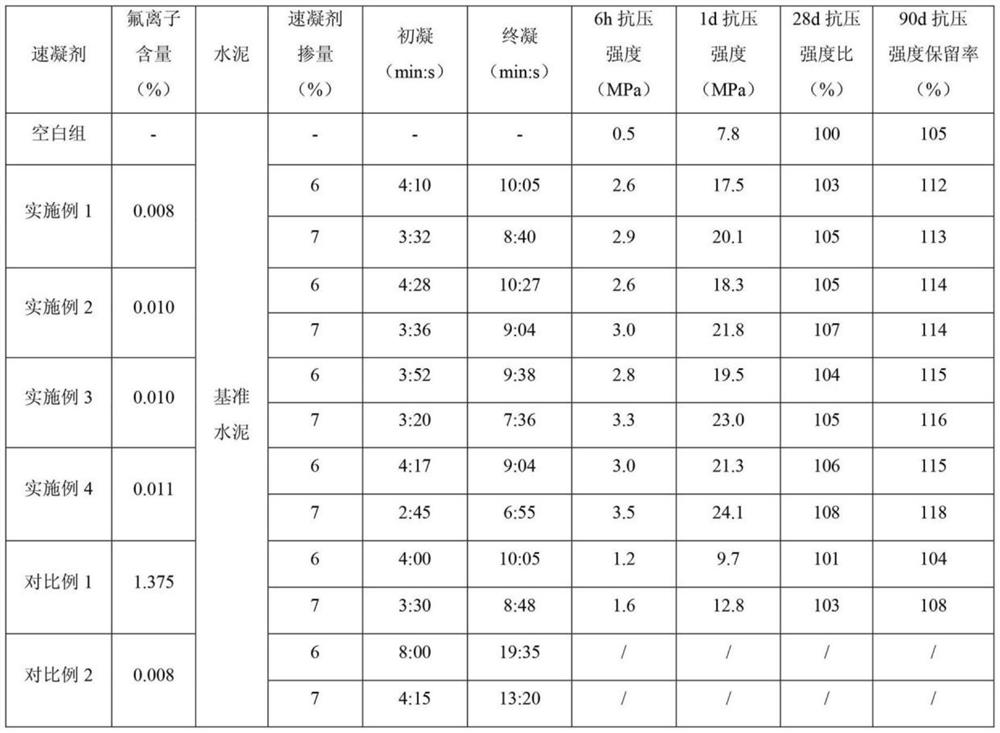

Embodiment 1

[0022] Embodiment 1: The ultra-early-strength type fluorine-free and alkali-free liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: 60% aluminum sulfate, 7.5% organic solubilizer, 1.0% stable agent, 2.0% early strength agent, 0.5% pH regulator, the balance is water, the sum of the mass percentages of the above components is 100%. The above-mentioned aluminum sulfate is industrial-grade aluminum sulfate octadecahydrate with an alumina content of 16.2%. The above-mentioned organic solubilizer is formed by mixing (stirring evenly) the three components of component A, component B and component C in a mass ratio of 2:2:1, wherein component A is diethanolamine, component B It is N,N-dimethylformamide, and component C is triethylenetetramine. The stabilizer is superfine sepiolite, the pH regulator is p-toluenesulfonic acid, and the early strengthening agent is lithium sulfate.

[0023] The preparation m...

Embodiment 2

[0024] Embodiment 2: The ultra-early-strength type fluorine-free and alkali-free liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: 62% aluminum sulfate, 8.5% organic solubilizer, 1.5% stable agent, 1.5% early strength agent, 0.5% pH regulator, the balance is water, the sum of the mass percentages of the above components is 100%. The above-mentioned aluminum sulfate is industrial-grade aluminum sulfate octadecahydrate with an alumina content of 16.5%. The above-mentioned organic solubilizer is formed by mixing (stirring evenly) the three components of A component, B component and C component in a mass ratio of 2.5:2.5:1, wherein A component is triethanolamine, and B component It is N-methyldiethanolamine, and component C is triethylenetetramine; the stabilizer is pseudoboehmite, the pH regulator is oxalic acid, and the early strength agent is nano-silica sol.

[0025] The preparation method of the...

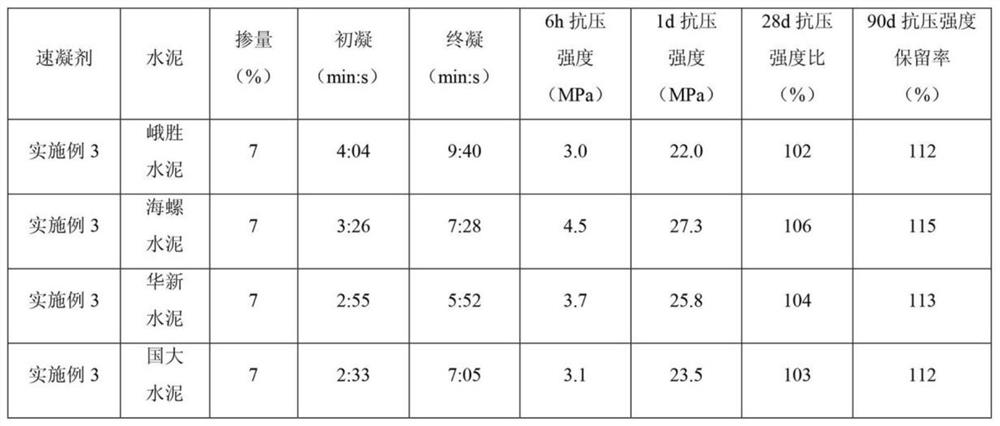

Embodiment 3

[0026] Embodiment 3: The ultra-early-strength type fluorine-free and alkali-free liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: 62% aluminum sulfate, 10% organic solubilizer, 1.0% stable agent, 1.5% early strength agent, 1.0% pH regulator, and the balance is water, the sum of the mass percentages of the above components is 100%. The above-mentioned aluminum sulfate is industrial-grade aluminum sulfate octadecahydrate with an alumina content of 16.5%. The above-mentioned organic solubilizer is formed by mixing (stirring evenly) the three components of component A, component B and component C in a mass ratio of 3:3:1, wherein component A is monoethanolamine, and component B It is N,N-dimethylethanolamine, and component C is diethylenetriamine; the stabilizer is ultrafine sepiolite, the pH regulator is formic acid, and the early strength agent is nano-aluminum sol.

[0027] The preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com