Method for preparing alkyl glucoside

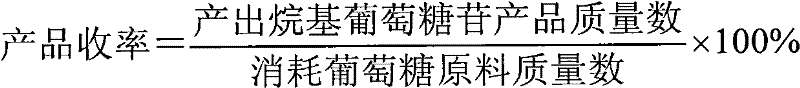

A technology of alkyl glucoside and glucose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low reaction yield, complicated operation, and high difficulty in post-processing, and achieve good color and luster, single The effect of less sugar residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Glucose and C 8 Alcohol (octanol) was reacted at 100° C. for 5 hours under vacuum conditions in the presence of a composite catalyst;

[0031] The vacuum degree is 2000Pa (equivalent to 15.00mmHg);

[0032] The composite catalyst is composed of main catalyst, co-catalyst and co-catalyst;

[0033] The main catalyst is dodecylbenzenesulfonic acid;

[0034] The promoter is sulfurous acid;

[0035] Cocatalyst is sulfamic acid;

[0036] The weight ratio of main catalyst, procatalyst and cocatalyst is:

[0037] Main catalyst: co-catalyst: co-catalyst=1: 0.16: 0.02;

[0038] The weight consumption of composite catalyst is 2% of glucose weight;

[0039] Glucose and C 8 The molar ratio of alcohol (octanol) is 1: 3;

[0040] (2) Then lower the temperature to 80°C, add NaOH to neutralize the system pH to 8, and obtain light yellow alkyl glucoside and C 8 Alcohol (octanol) mixture;

[0041] (3) dealcoholization under 200Pa vacuum, dealcoholization temperature is 120 ℃...

Embodiment 2

[0044] (1) Glucose and C 10 Alcohol (decyl alcohol) was reacted at 120° C. for 2 hours under vacuum conditions in the presence of a composite catalyst;

[0045] The vacuum degree is 1500Pa (equivalent to 11.25mmHg);

[0046] The composite catalyst is composed of main catalyst, co-catalyst and co-catalyst;

[0047] The main catalyst is p-toluenesulfonic acid;

[0048] Promoter is phosphoric acid;

[0049] Cocatalyst is sulfamic acid;

[0050] The weight ratio of main catalyst, procatalyst and cocatalyst is:

[0051] Main catalyst: co-catalyst: co-catalyst=1: 0.12: 0.04;

[0052] The weight consumption of composite catalyst is 0.5% of glucose weight;

[0053] Glucose and C 10 The molar ratio of alcohol (decanol) is 1: 3;

[0054] (2) Then lower the temperature to 70°C, add sodium methoxide to neutralize the system pH to 6, and obtain nearly colorless alkyl glucoside and C 10 Alcohol (decanol) mixture;

[0055] (3) dealcoholization under 100Pa vacuum, dealcoholization t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com