Composite microporous membrane used as lithium ion battery diaphragm as well as preparation method and application thereof

A technology of lithium ion battery and microporous membrane is applied in the field of composite microporous membrane and its preparation, which can solve the problems of complex manufacturing method and process and high membrane cost, and achieve the effects of good safety, stable performance and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

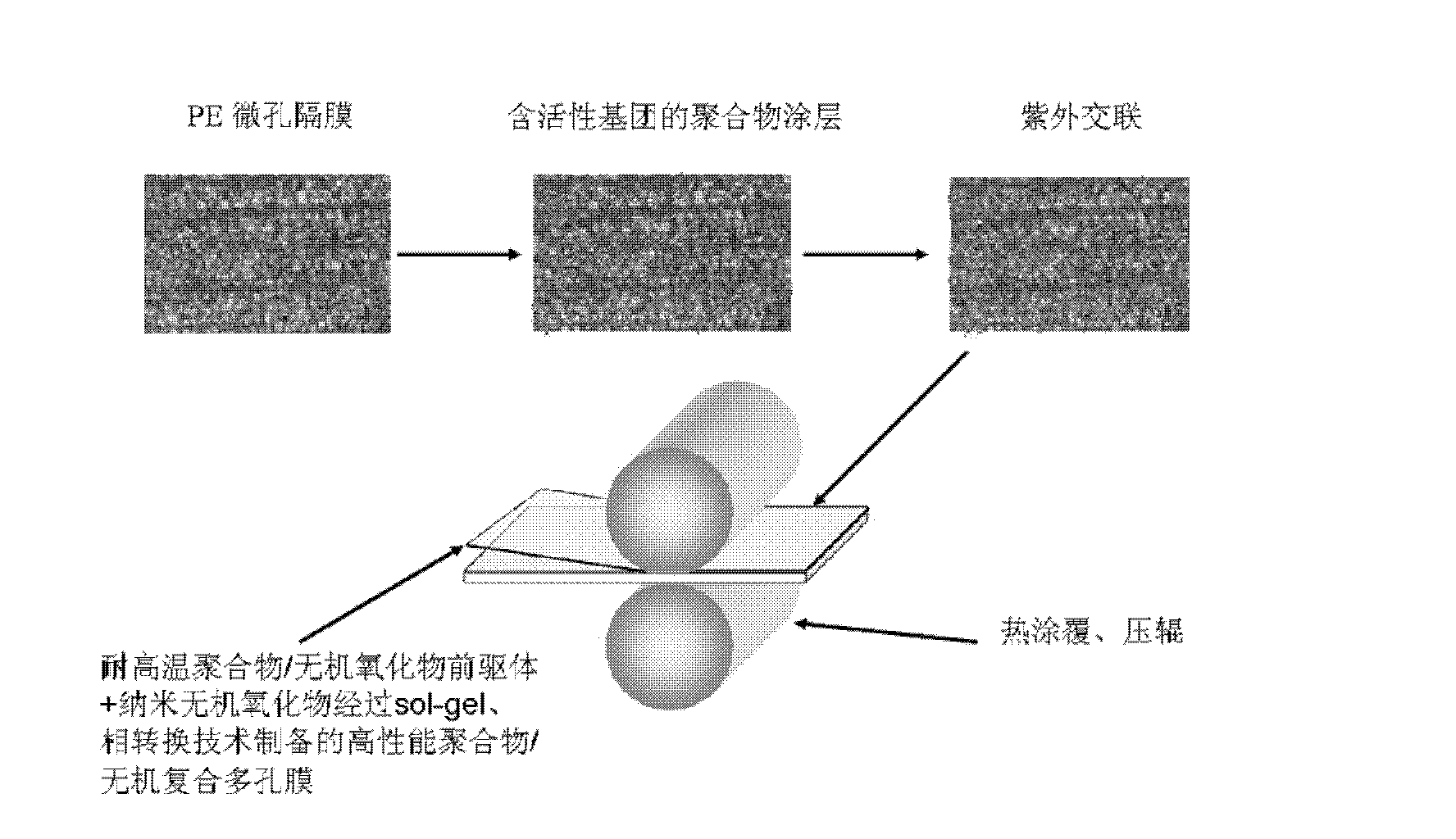

Method used

Image

Examples

Embodiment 1

[0045] Dissolve photosensitive polyethyl cinnamate acrylate (PCEM) with active hydrogen in acetone solvent, prepare a modified solution a with a mass concentration of 1%, and then apply a polypropylene porous skeleton membrane (thickness 8 μm, porosity 40 %, the average pore size is 0.6 μm) is immersed in the above-mentioned modification solution, and the modified microporous membrane is obtained through UV cross-linking and anchored and introduced active hydrogen groups on the surface of the membrane micropores.

[0046] The above-mentioned modified microporous membrane was immersed in the modified solution b (1% polyimide with hydroxyl group, 5% SiO with a particle size of 1 μm 2 , 10% LiBr, 0.05% TEOS, the solvent is acetone); the temperature is controlled at 10°C, and then 0.05% ammonia water is added to the solution, and taken out after about 15 hours.

[0047] Immerse the above-mentioned modified microporous membrane into a phase transfer agent (acetone: water=5:1, volum...

Embodiment 2

[0049] Dissolve photosensitive poly(hydroxyethyl methacrylate-co-cinnamate ethyl acrylate) (P(HEMA-co-CEA) with active hydrogen in acetone solvent to prepare a modified solution with a mass concentration of 20% a. Then the polypropylene porous skeleton membrane (thickness is 60 μm, porosity 76%, pore diameter 0.4 μm) is immersed in the above-mentioned modification solution, obtains through UV cross-linking and obtains through anchoring and introduces the active hydrogen group on the surface of membrane micropores Modified Microporous Membranes.

[0050] The above-mentioned modified microporous membrane is immersed in the modification solution b (40% polyethylene terephthalate with hydroxyl, 60% MgO with a particle size of 10 μm, 80% DMF, 30% TEOS, and the solvent is NMP); The temperature is controlled at 80°C, and then 60% ammonia water is added to the solution, and taken out after about 0.5 hours.

[0051] Immerse the above-mentioned modified microporous membrane into a phas...

Embodiment 3

[0053] Dissolve photosensitive poly(hydroxyethyl methacrylate-co-cinnamate ethyl methacrylate) (P(HEMA-co-CEMA) with active hydrogen in tetrahydrofuran solvent, and prepare a modified solution with a mass concentration of 10%. Liquid a. Then the polyethylene porous skeleton membrane (membrane thickness between 30 μm, porosity 50%, pore size 0.5 μm) is immersed in the above-mentioned modifying solution, which is anchored by UV cross-linking and introduced into the membrane microporous surface. Microporous membranes modified by hydrogen groups.

[0054] The above-mentioned modified microporous membrane was immersed in the modified solution b (20% polyamide-imide with hydroxyl group, 30% SiO with a particle size of 5 μm 2 , 50% PEO, 15% TEOS, the solvent is pyridine); the temperature is controlled at 50° C., then 25% ammonia water is added to the solution, and it is taken out after about 7.0 hours.

[0055] Immerse the above-mentioned modified microporous membrane into a phase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com