Tensile reinforcement concrete spray body supporting method for deep soft roadway

A technology of reinforced concrete and concrete, which is applied in the direction of earthwork drilling, tunnel, tunnel lining, etc., can solve problems such as difficulties in deep roadway support, and achieve the goals of avoiding slurry cracking, reducing roadway deformation and repair work, and speeding up construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

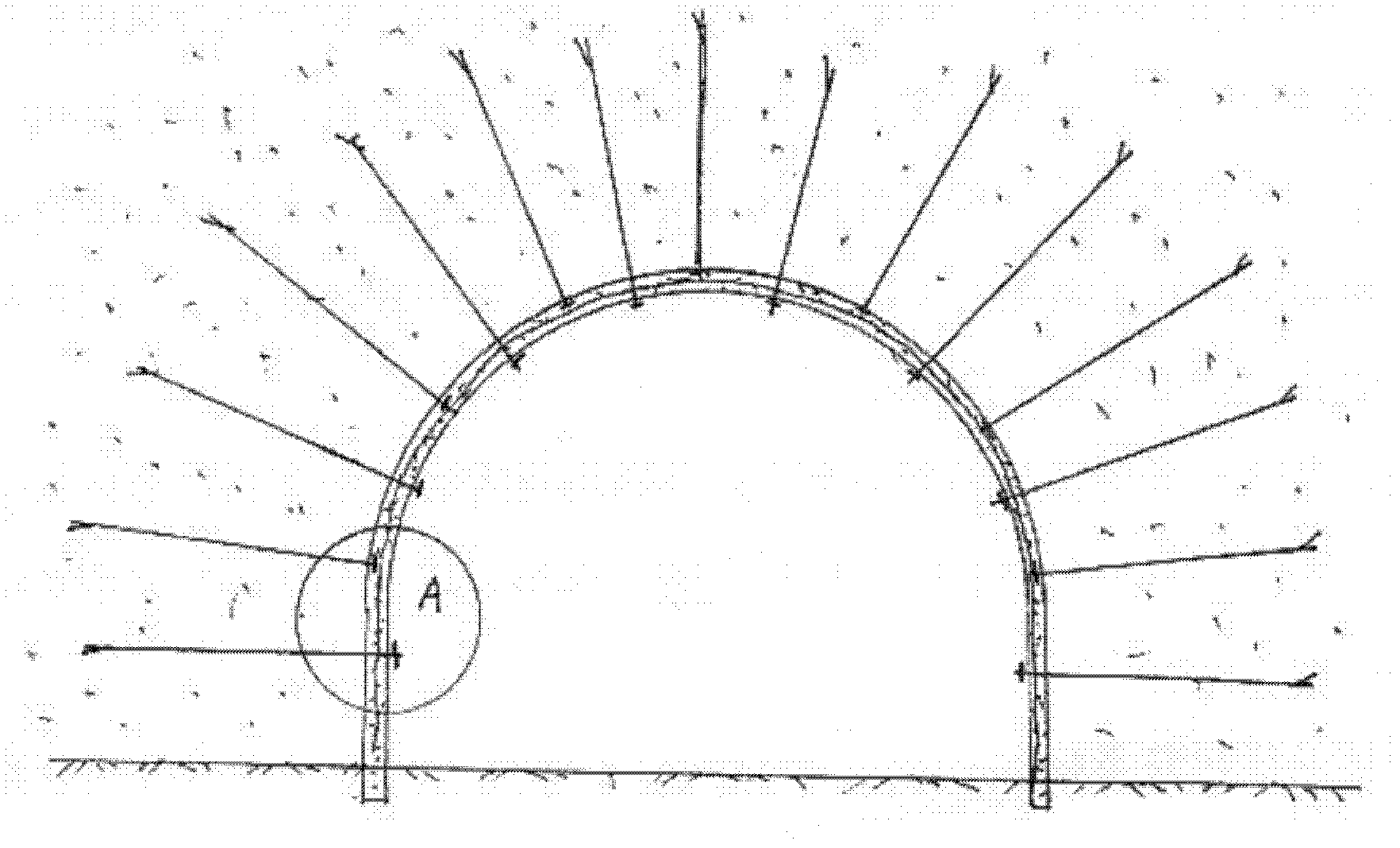

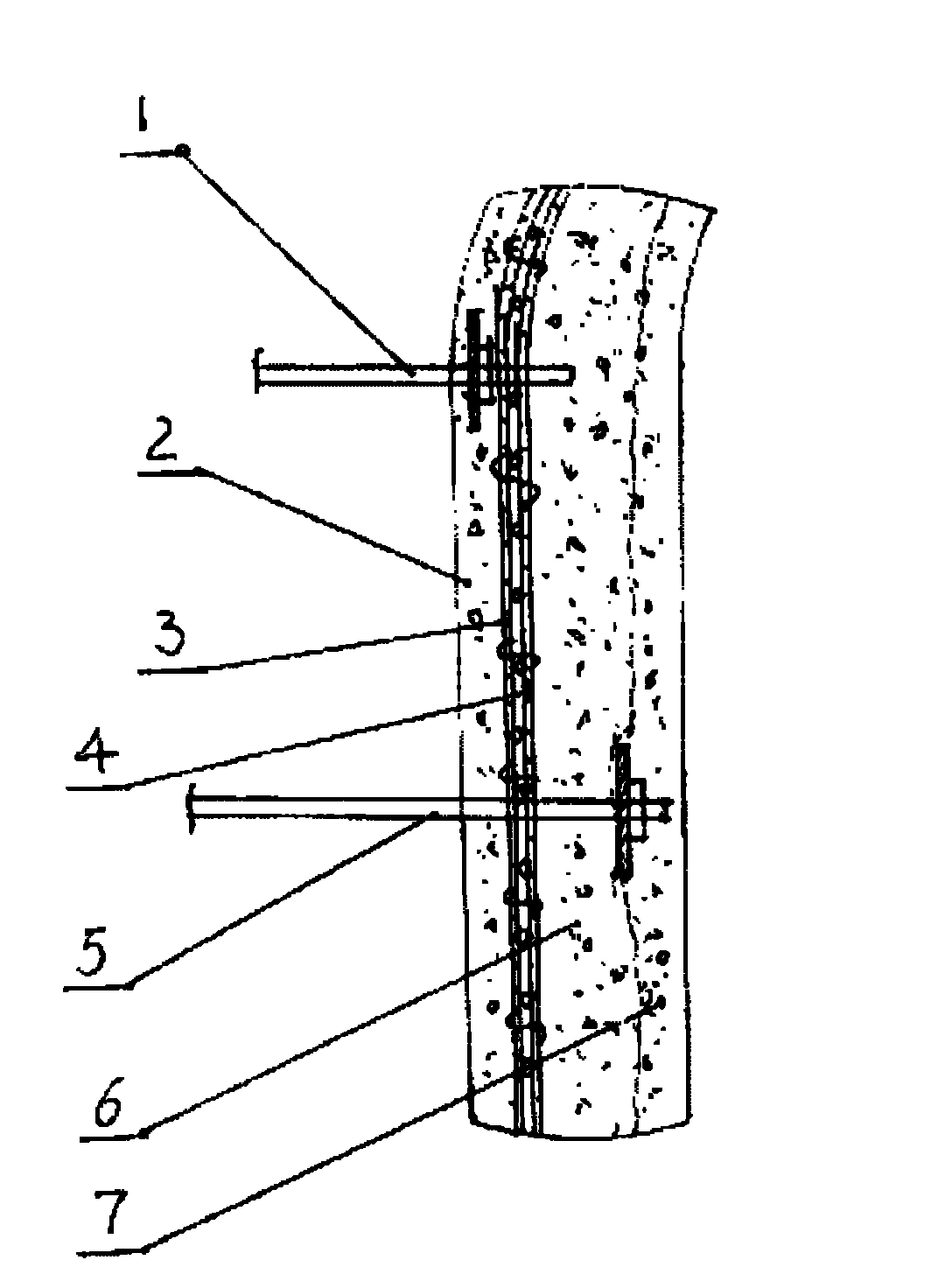

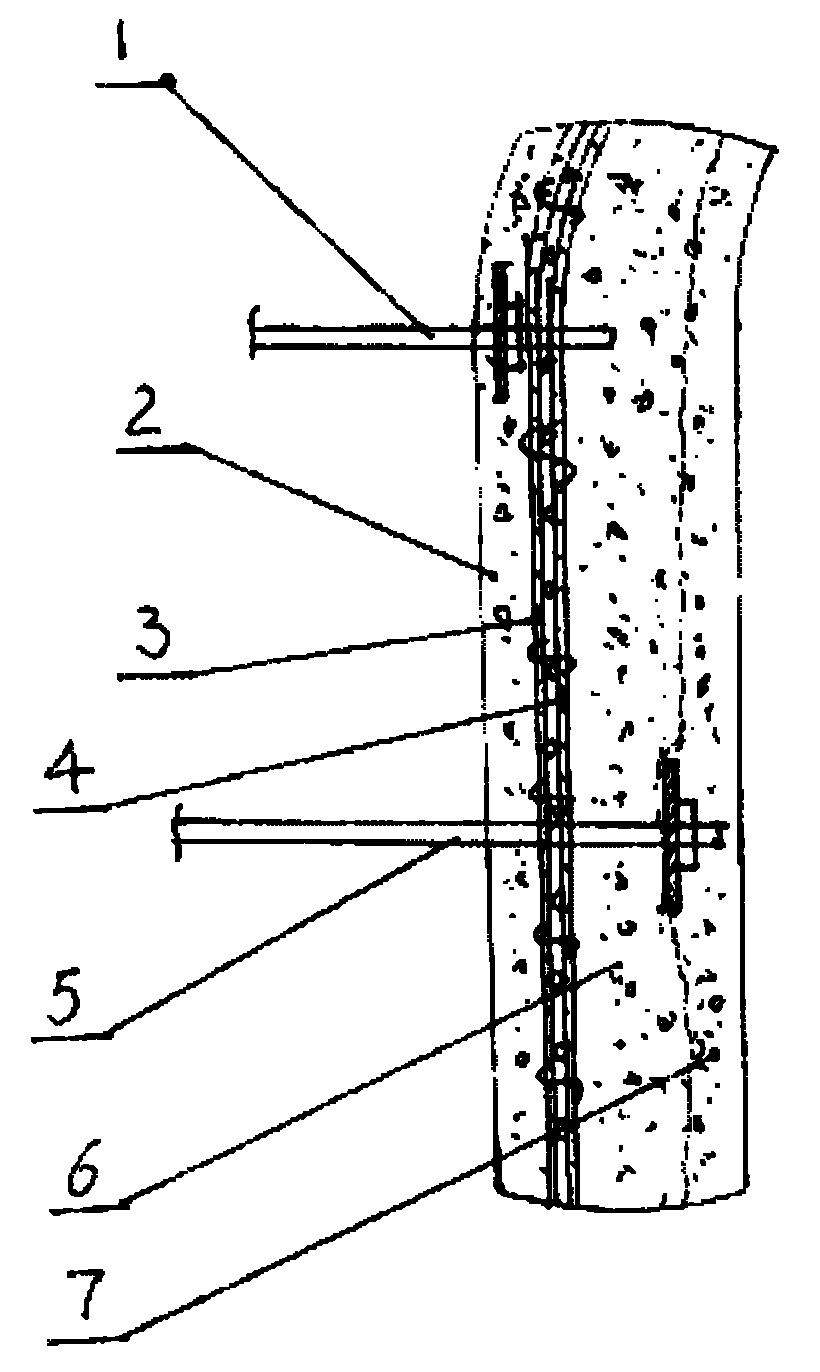

[0020] The -850 horizontal transport downhill and other deep roadways constructed by the applicant's coal mine, due to the large buried depth, the surrounding rocks showed obvious softening and weakening phenomena, and due to the influence of geological structure and denudation boundaries, the roadway exposed red layers in many places, resulting in soft surrounding rocks , the strength is reduced, and the conventional anchor-mesh spraying secondary support process cannot meet the roadway support requirements. Therefore, we have innovatively adopted tensile reinforced concrete spray body support technology in roadways such as -850 level three mining and transportation down the mountain, effectively controlling The deformation of the deep soft rock roadway is guaranteed, and the support effect is ensured (such as figure 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com