Method for placing inert gas in gas-filling and packaging machine

一种惰性气体、充气包装的技术,应用在通过加压/气化包装、包装、在特殊气体条件下包装物件等方向,能够解决气体置换率差、填充时间增加、喷嘴扎刺等问题,达到气体置换率提高、充气作业顺畅、简单机械结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

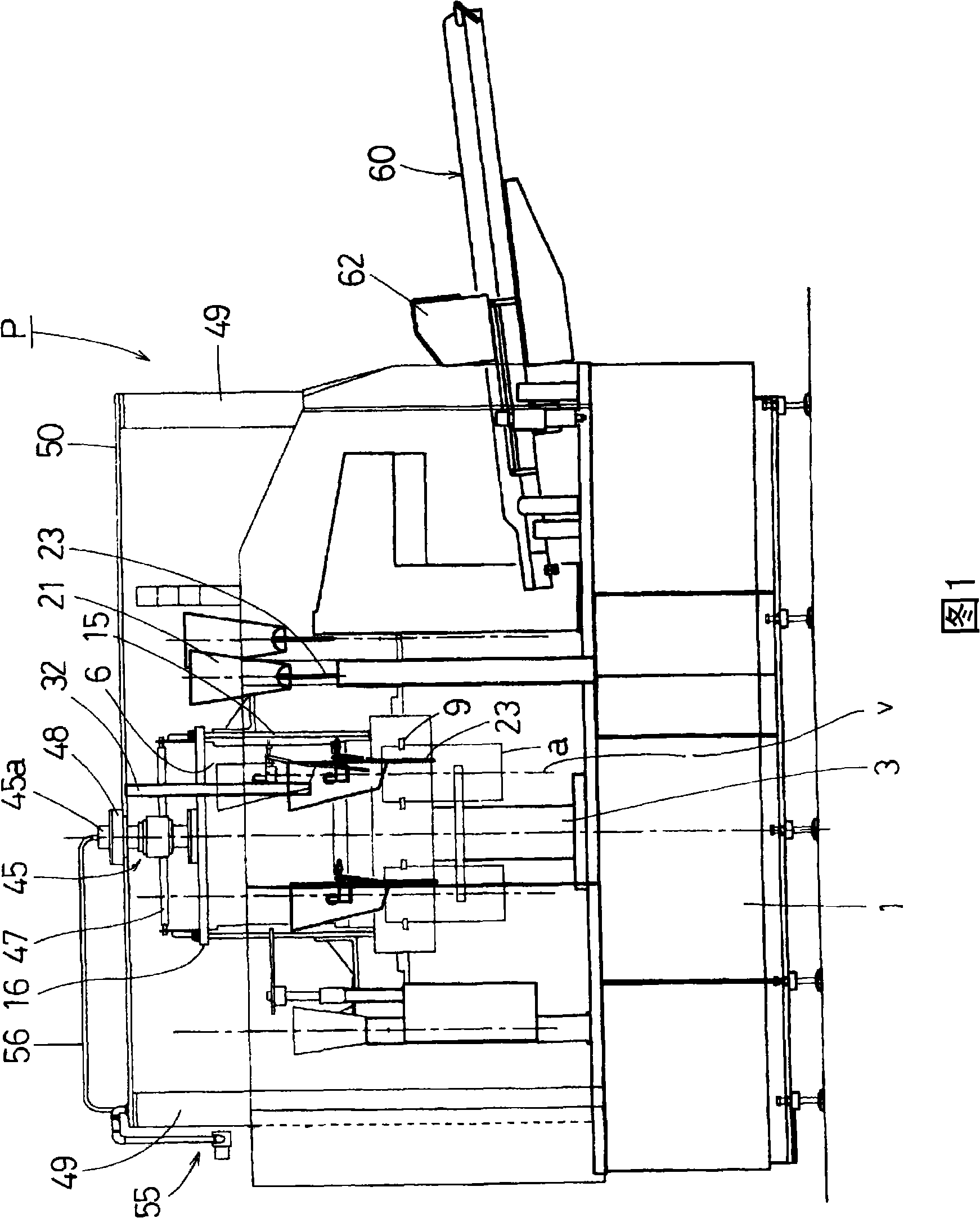

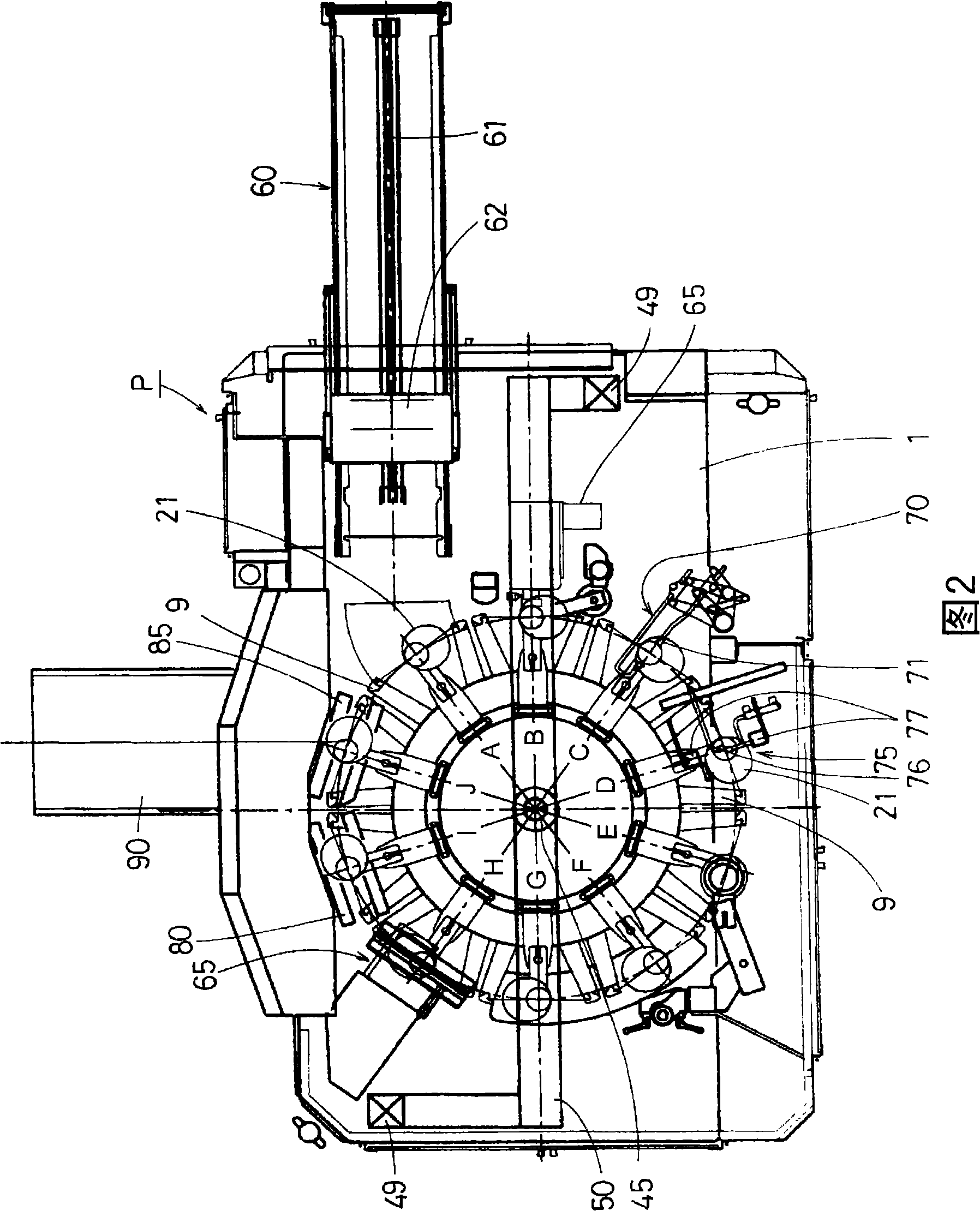

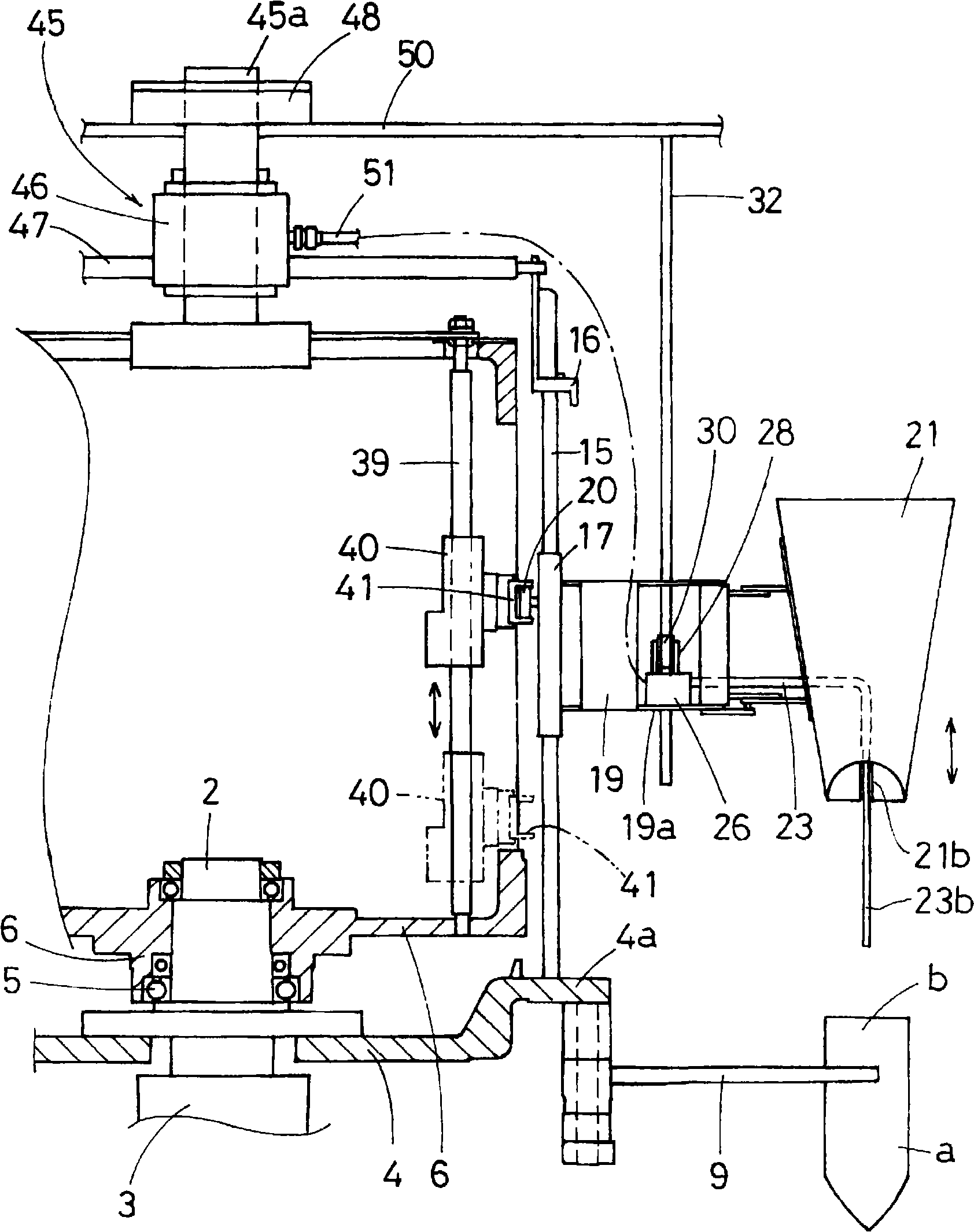

[0015] The preferred embodiment of the present invention will be described below with reference to the accompanying drawings. Fig. 1 is a side view of an air packaging machine employing the inert gas filling method of the air packaging machine of the present invention. Fig. 2 is a plan view of an air packaging machine using the inert gas filling method of the air packaging machine of the present invention. image 3 It is a side view showing the configuration of the rotating body, the filling funnel and its surroundings. Figure 4 It is an explanatory diagram of the nozzle attitude control device. Fig. 5 is a filling hopper and an inflation nozzle, the relative position relationship with the packaging bag, and the expanded view of the cam guide shown in the whole process. Figure 6 It is a partial side view of the shutter device showing a state in which the bag mouth is closed and the gas is replaced. Figure 7 yes Figure 6 A top view of the gate device in .

[0016] An a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com