Patents

Literature

41 results about "Replacement - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

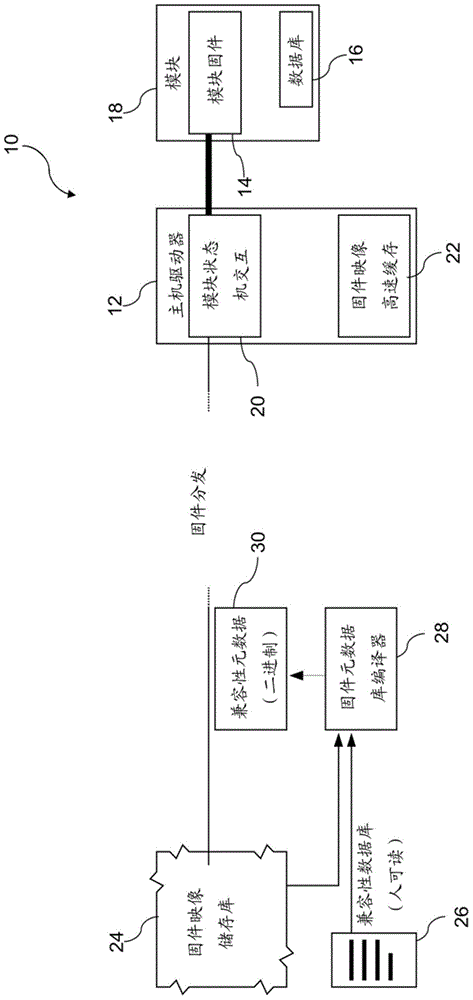

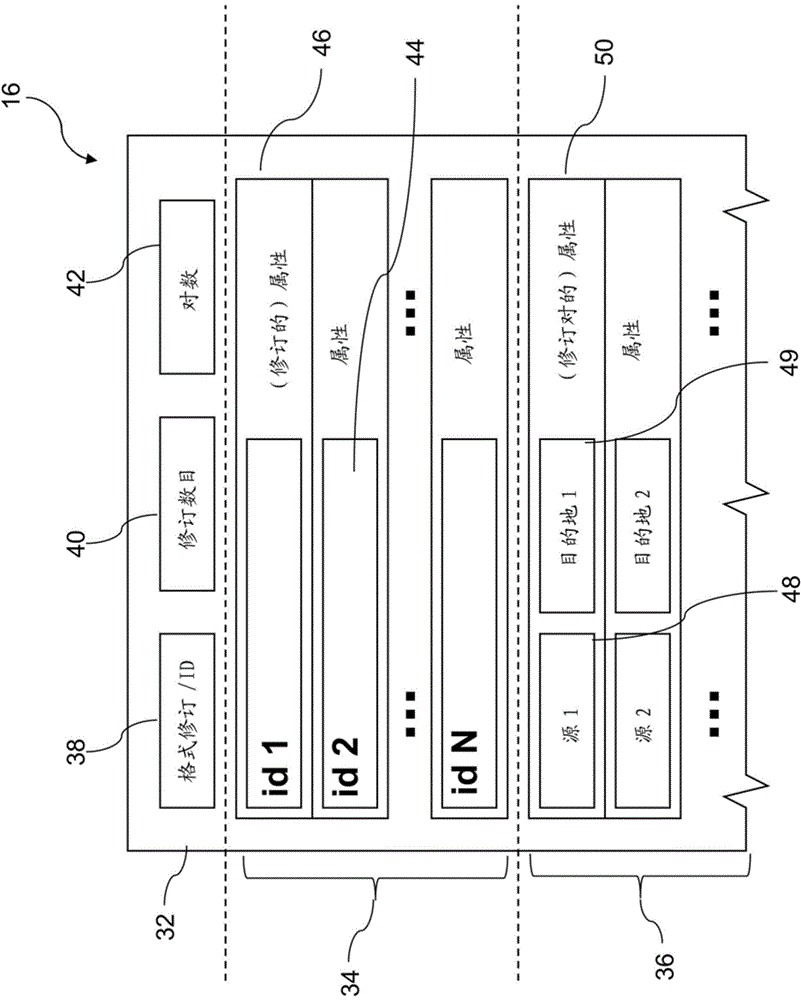

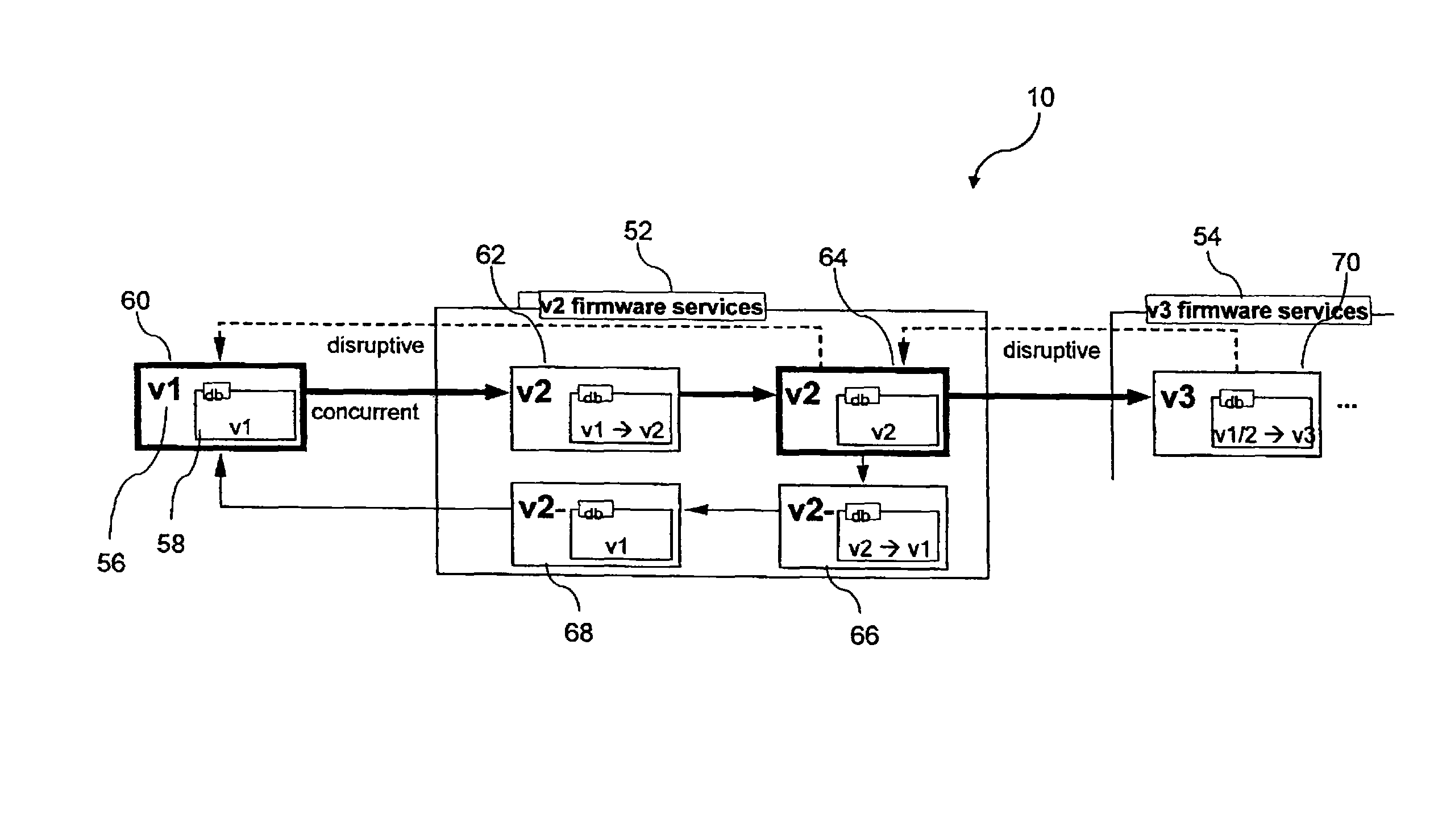

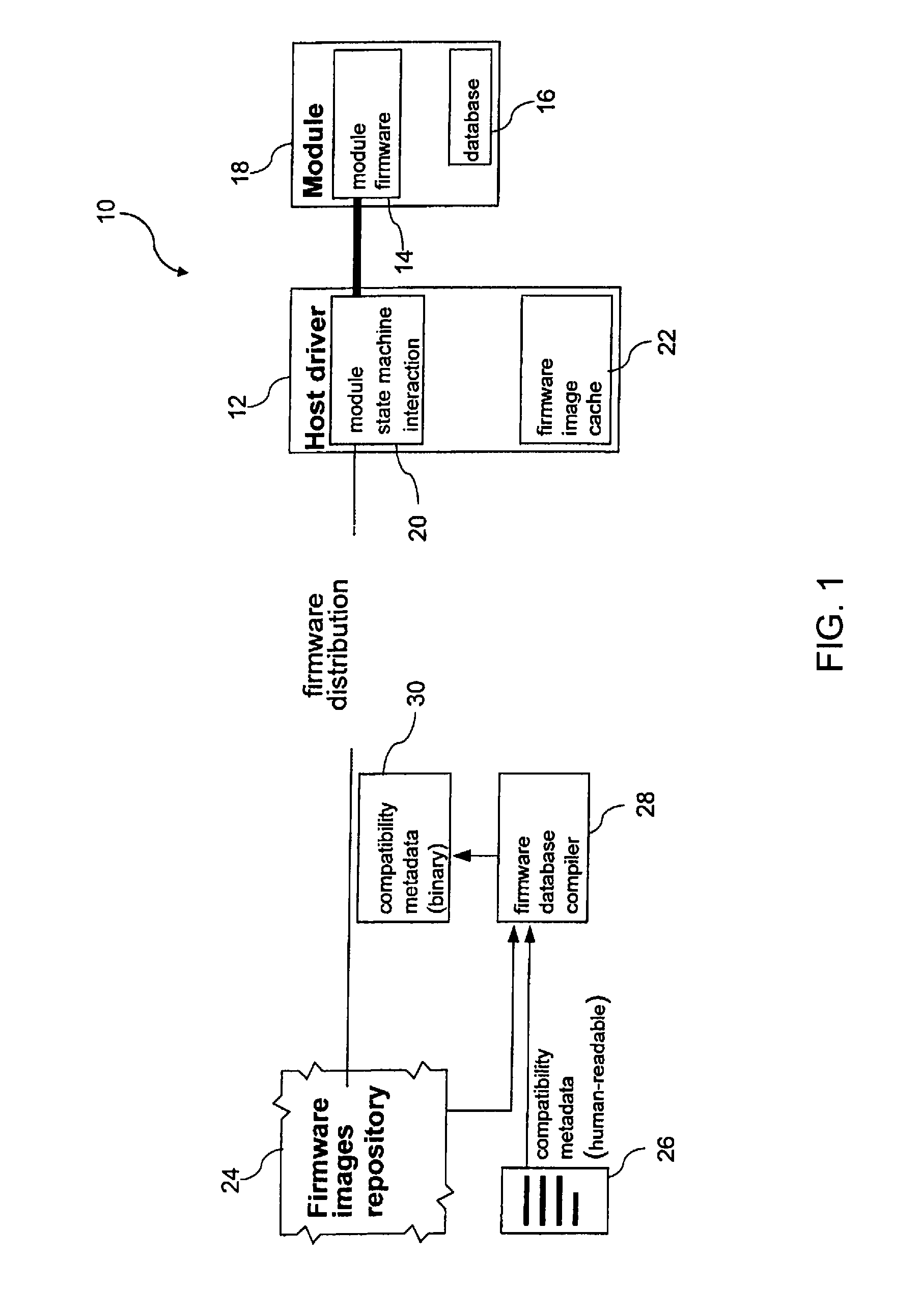

Software version management

InactiveUS20140157251A1Efficient downgradeVersion controlSpecific program execution arrangementsTemporal informationComputer compatibility

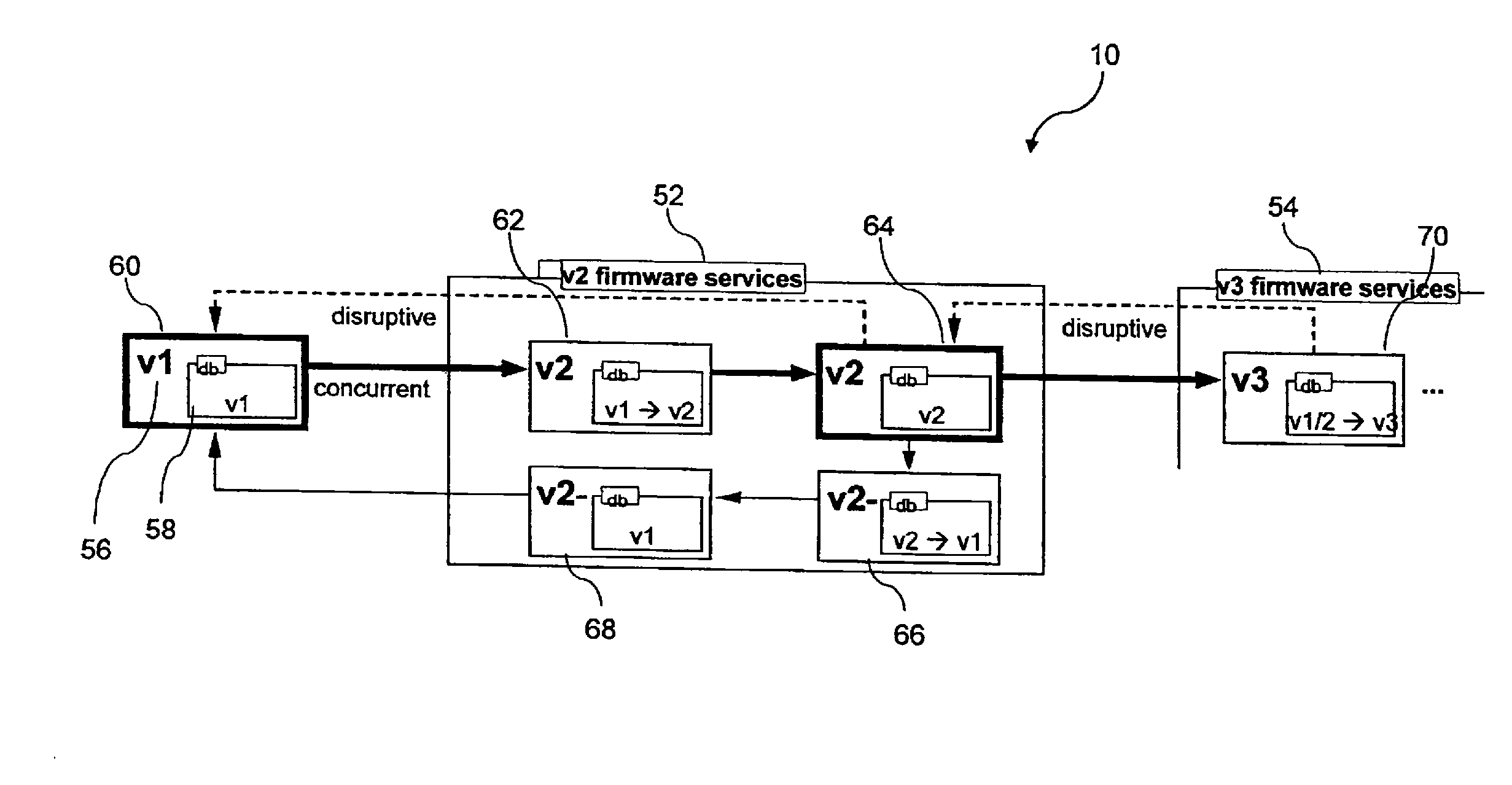

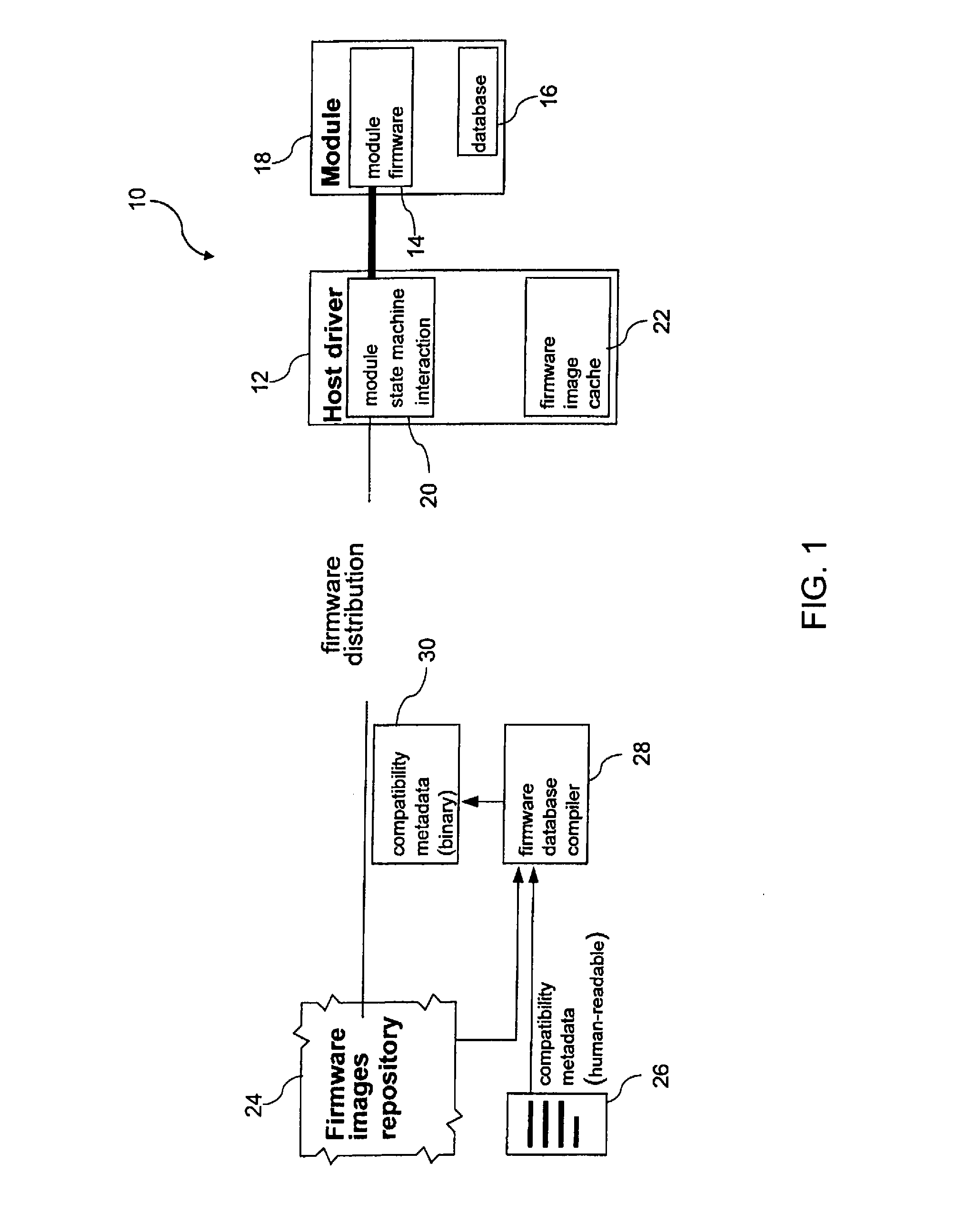

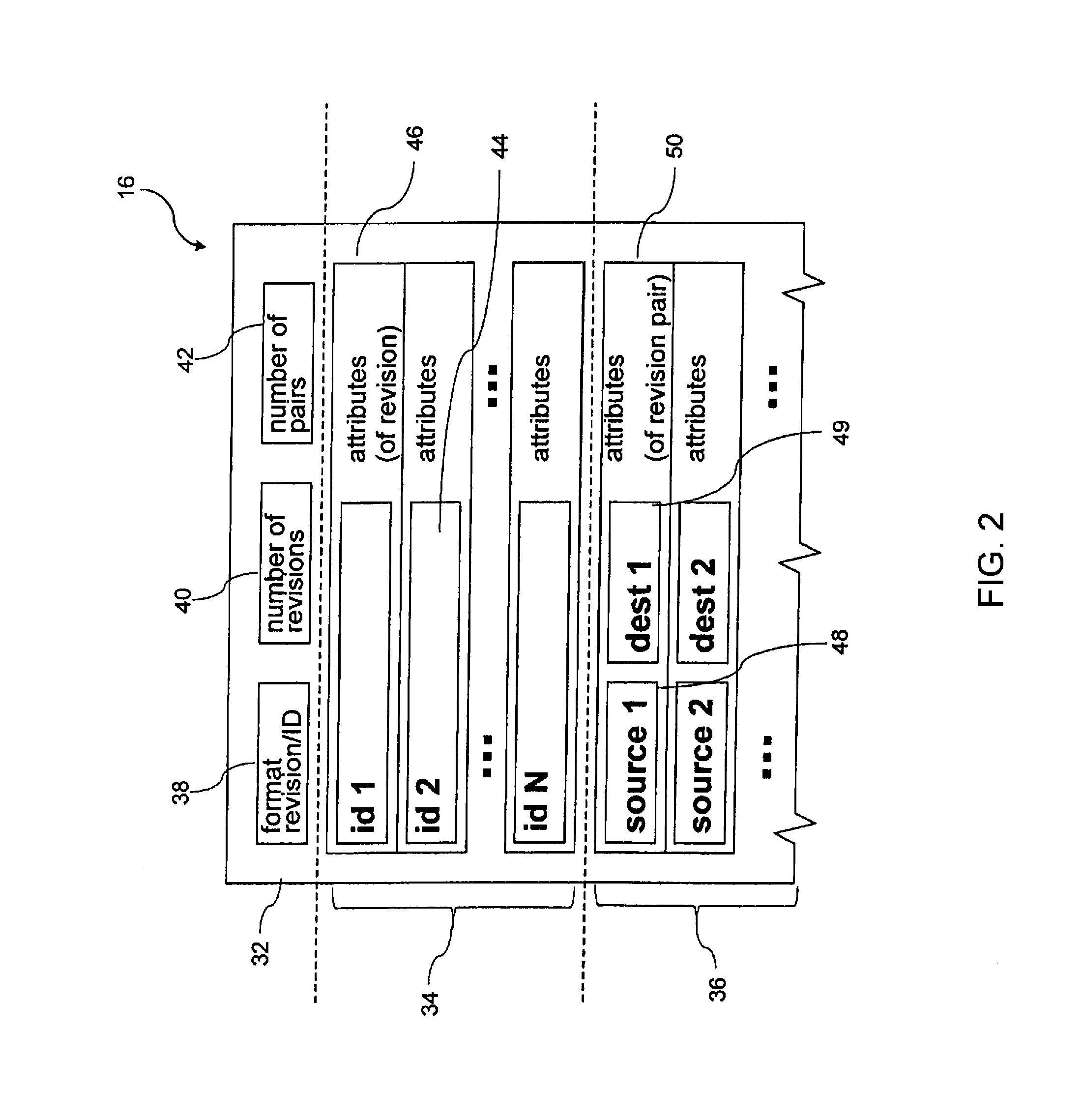

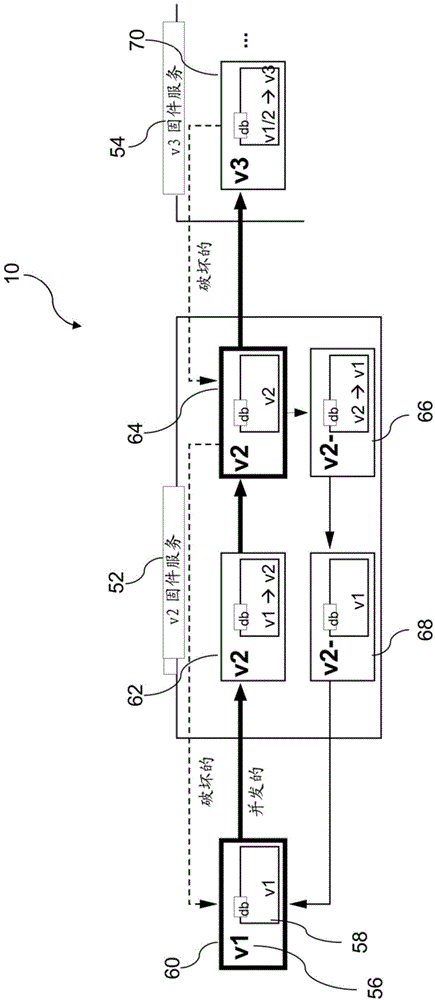

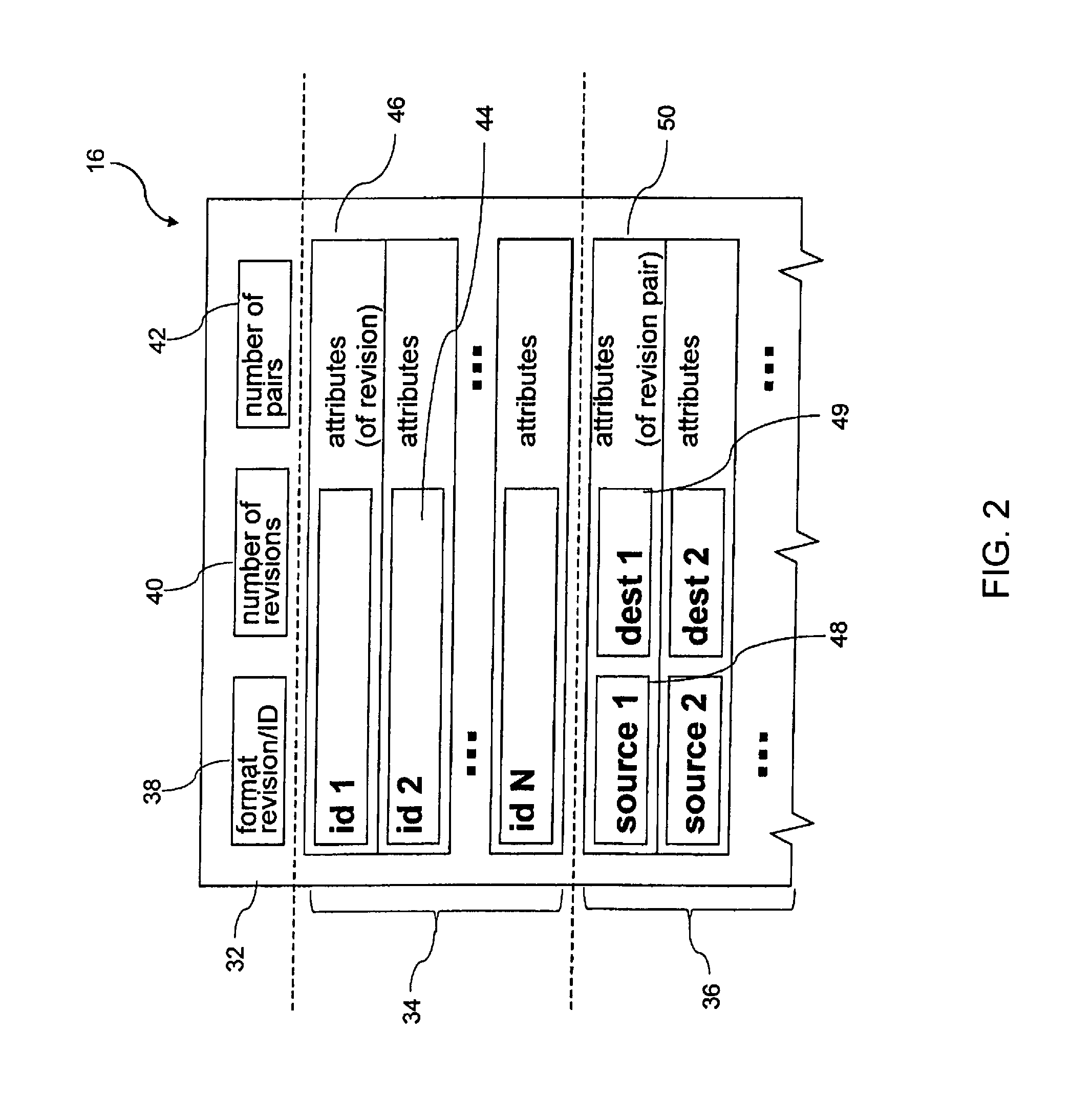

A software version management system comprising a host driver and at least one software module. The host driver comprises migration means to start, stop and replace the software modules on a computer system in response to replacement actions. The system is characterized by the software module being a downgradable software module comprising a compatibility database specifying dependencies between different versions of the software module; the migration means further comprising i) at least a status means to retrieve temporal information from the downgradable software module; ii) at least a downgrading means responsive to a replacement action to downgrade the downgradable software module to a particular downgrade version and to the status means, the downgrading means identifying an intermediate version of the downgradable software module; the host driver comprising restarting means responsive to the report of the completion of the intermediate version to load and start the downgrade version of the software module.

Owner:IBM CORP

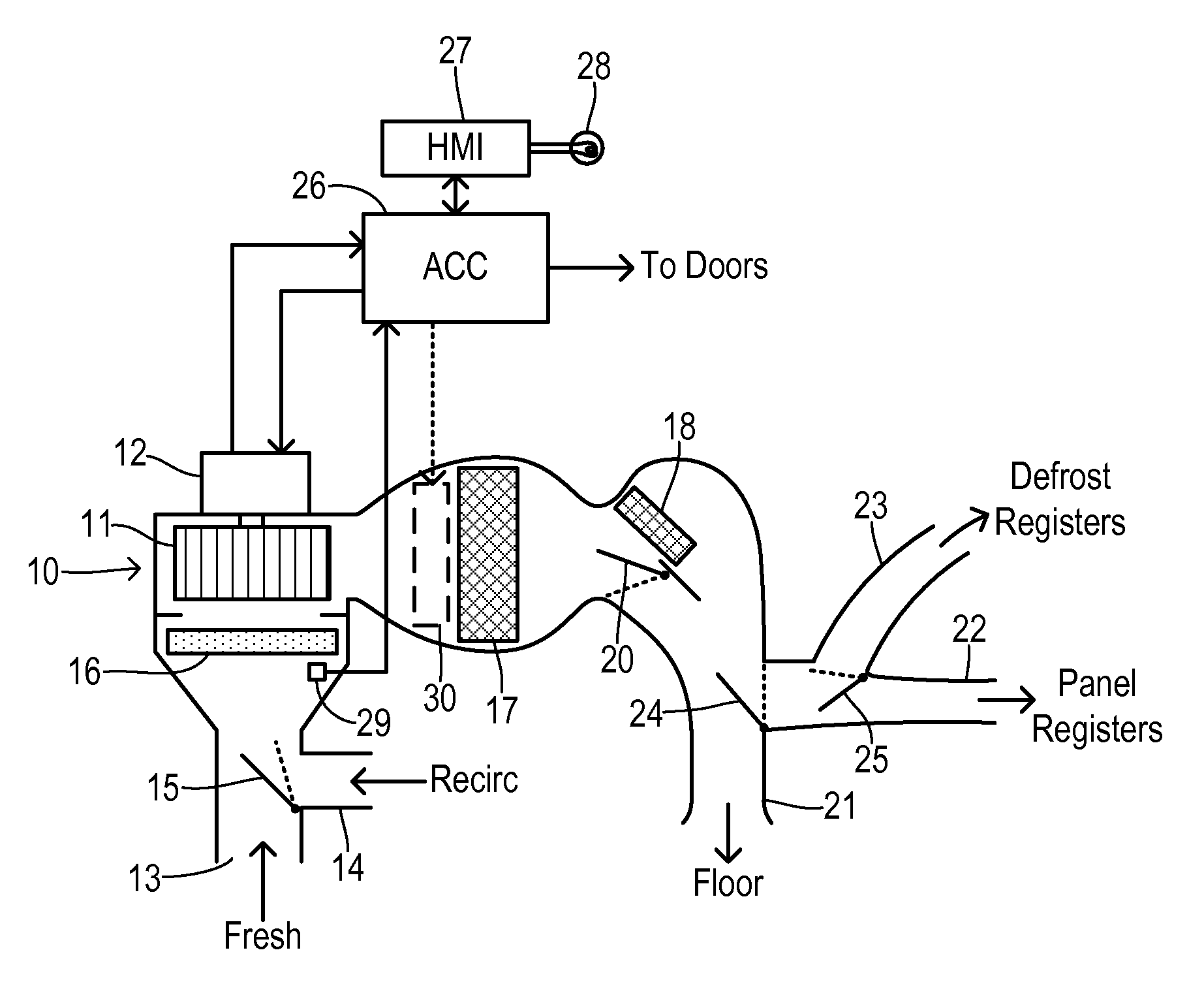

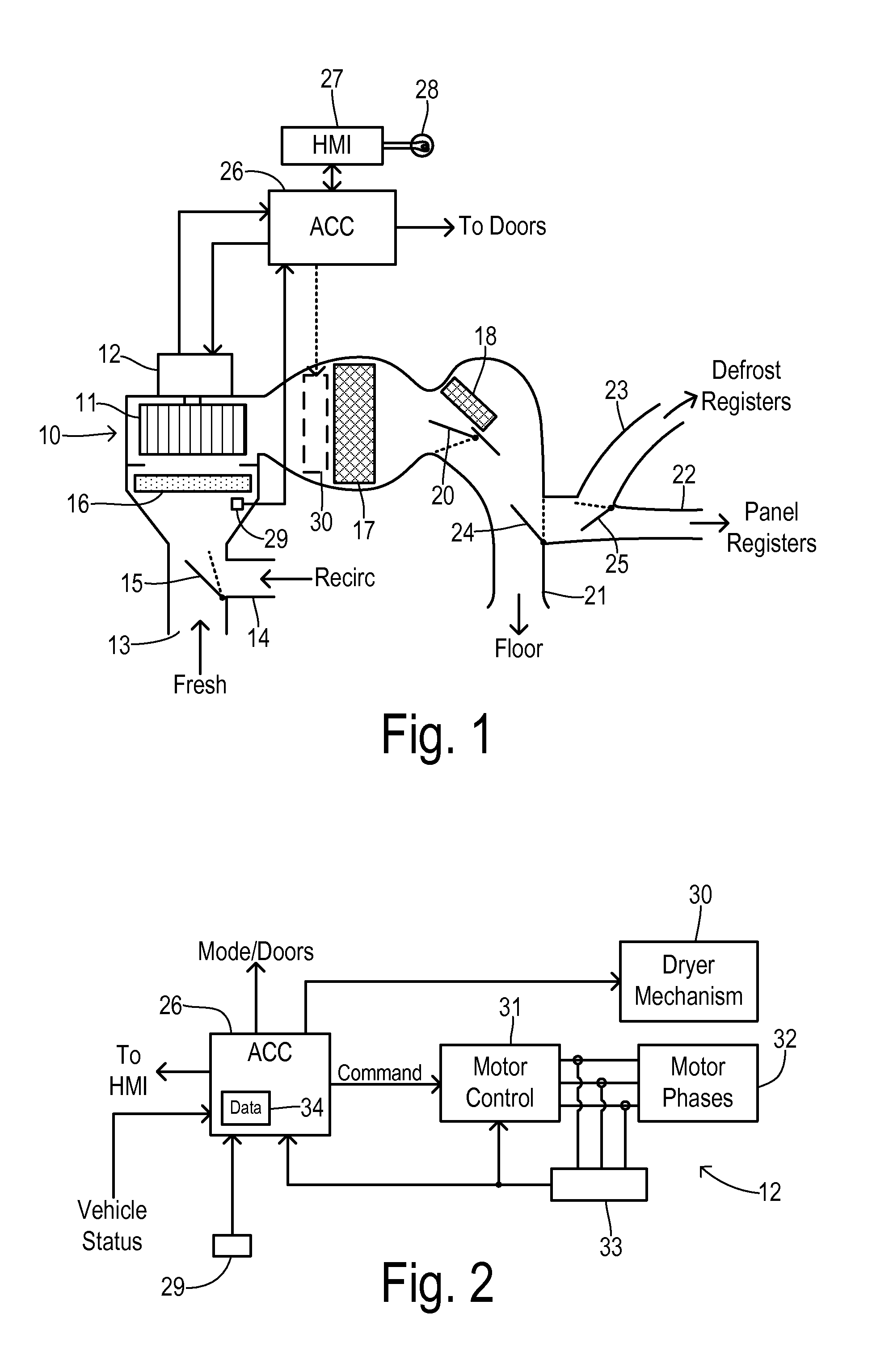

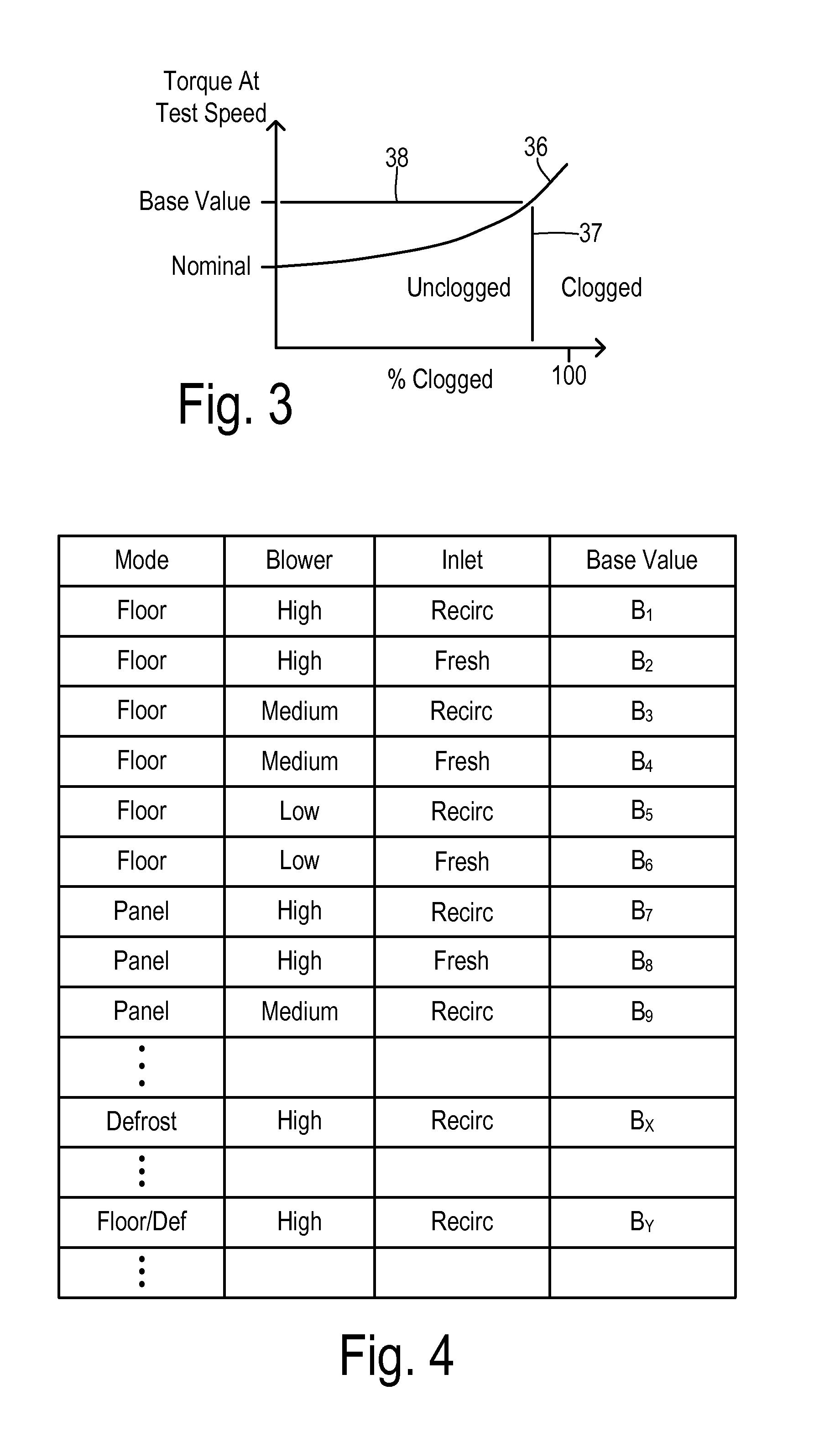

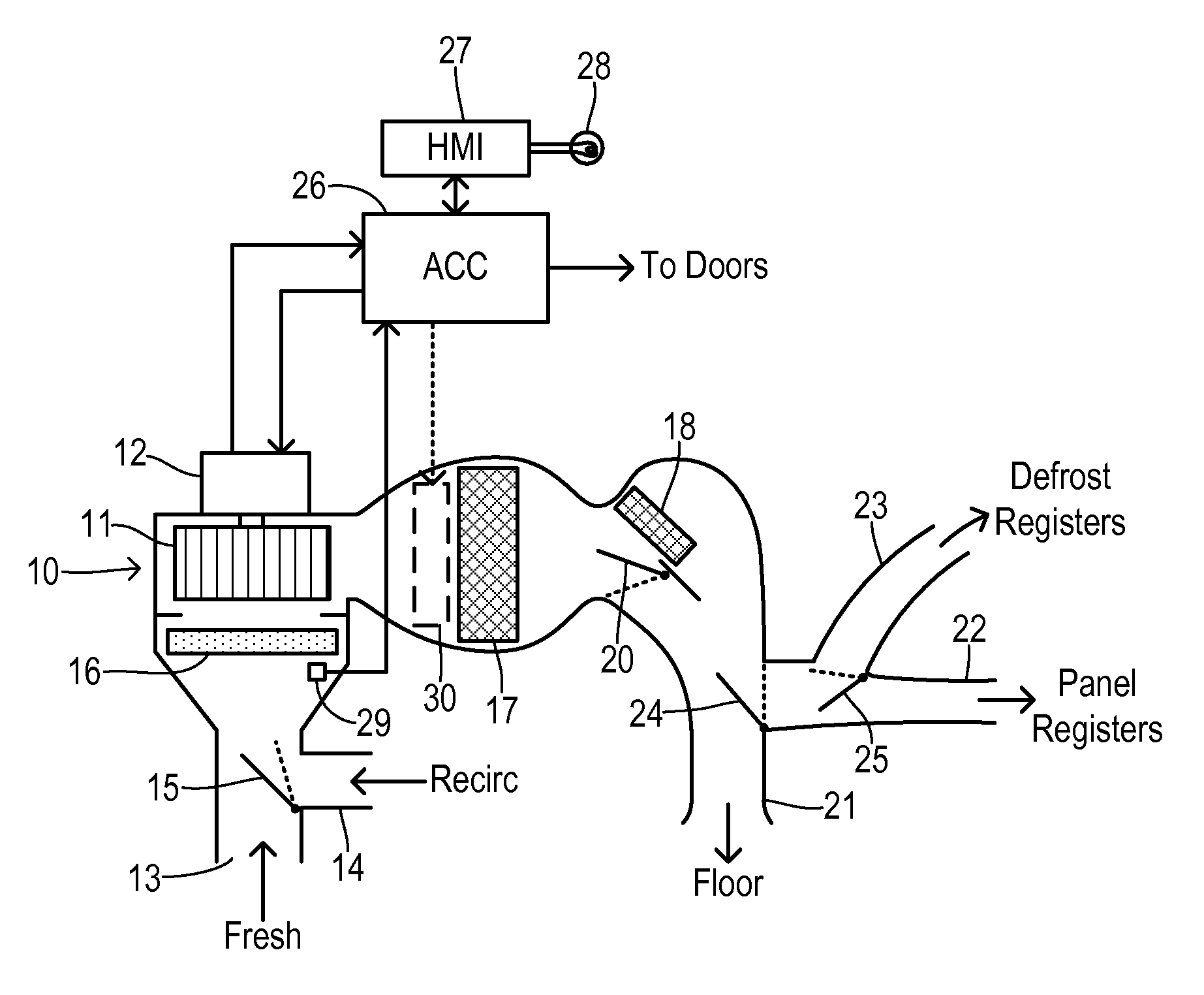

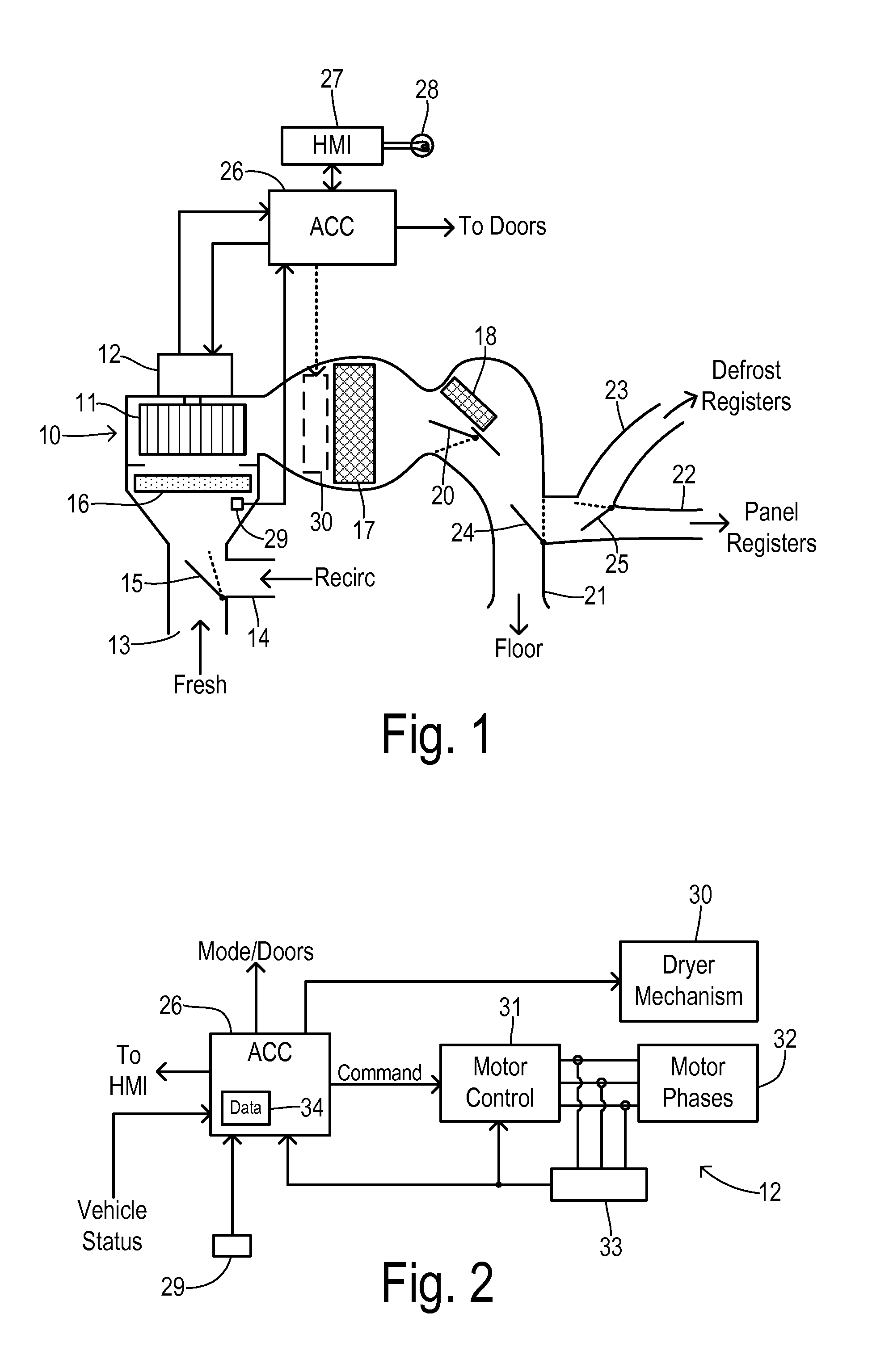

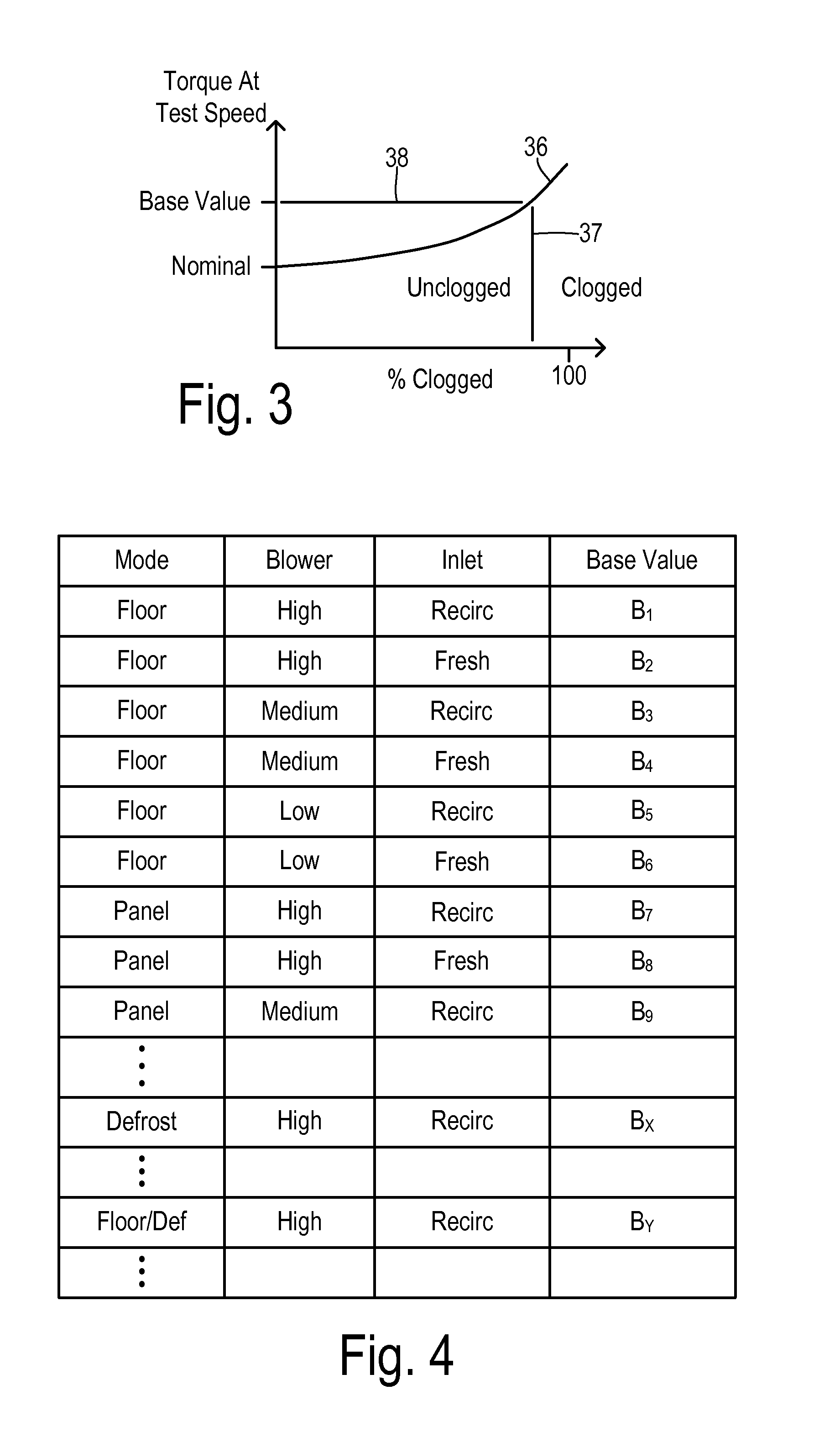

Monitoring Air Filter Status in Automotive HVAC System

ActiveUS20130288585A1Saving userDecreased ventilation performanceAir-treating devicesRailway heating/coolingAir filterReplacement - action

A method is provided for monitoring for a clogged or unclogged state of an air filter in an automotive HVAC system. The HVAC system includes a blower having a blower motor providing a driven airflow. A plurality of outlet registers is controllable to provide a plurality of circulation modes. An evaporator selectably cools the driven airflow, and the air filter passes the driven airflow. The method enters a baseline condition, wherein the baseline condition includes applying a moisture purge to the evaporator and selection of a predetermined circulation mode. The blower motor is controlled to maintain a testing speed. An energization of the blower motor is quantified while maintaining the testing speed. The energization is compared to a base value derived according to the baseline condition with the air filter in an unclogged state. A replacement action is triggered when the energization is greater than the base value.

Owner:FORD GLOBAL TECH LLC

Software version management system and method

The invention relates to a software version management system. The software version management system comprises a host driver and at least one software module. The host driver comprises migration used for starting, stopping and replacing the software modules on a computer system in response to replacement actions. The system is characterized in that: the software module is a downgradable software module comprising a compatibility database specifying dependencies between different versions of the software module; the migration means further comprises i) at least a status means to retrieve temporal information from the downgradable software module; ii) at least a downgrading means responsive to a replacement action to downgrade the downgradable software module to a particular downgrade version and to the status means, with the downgrading means identifying an intermediate version of the downgradable software module; and the host driver comprises restarting means responsive to the report of the completion of the intermediate version to load and start the downgrade version of the software module.

Owner:INT BUSINESS MASCH CORP

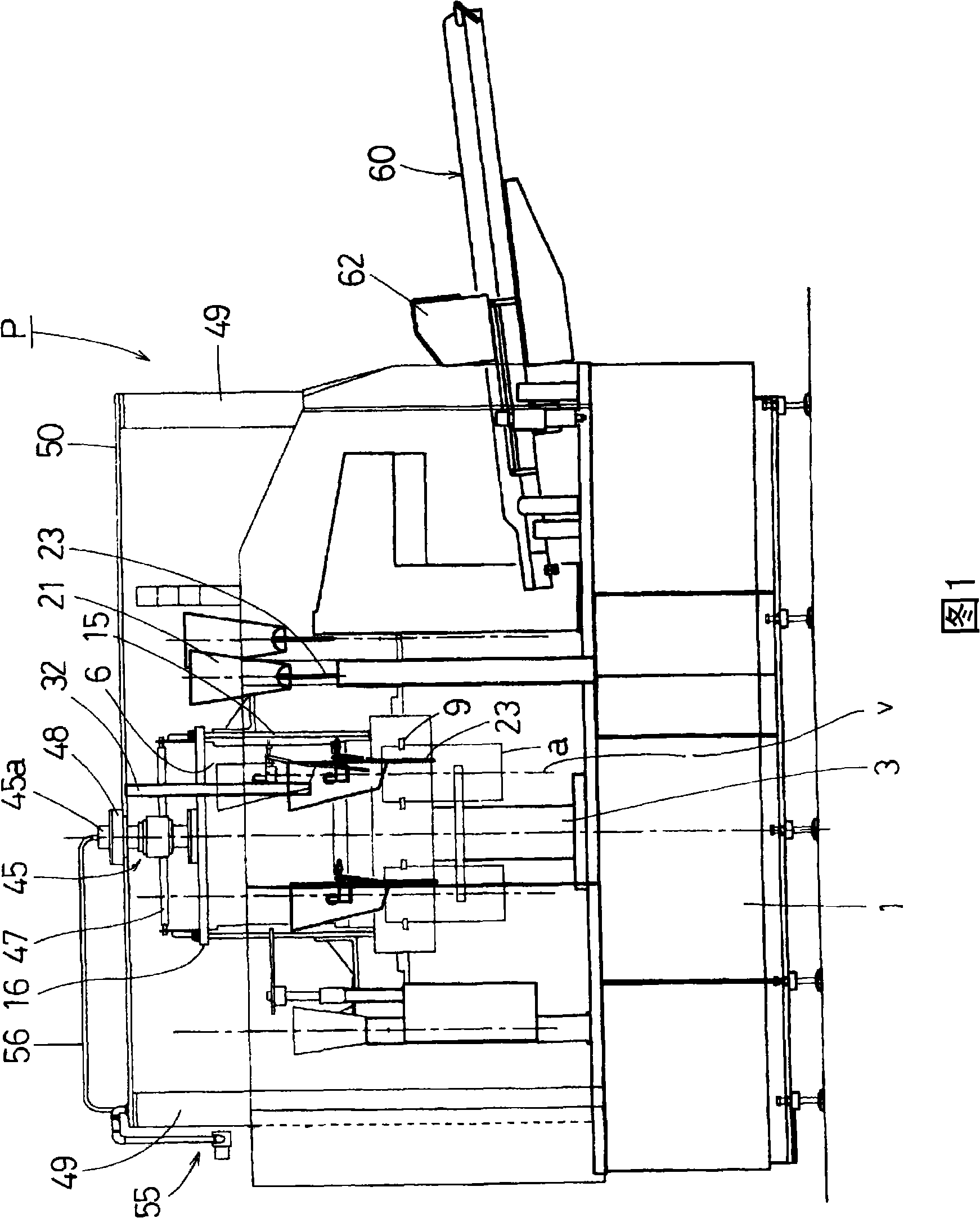

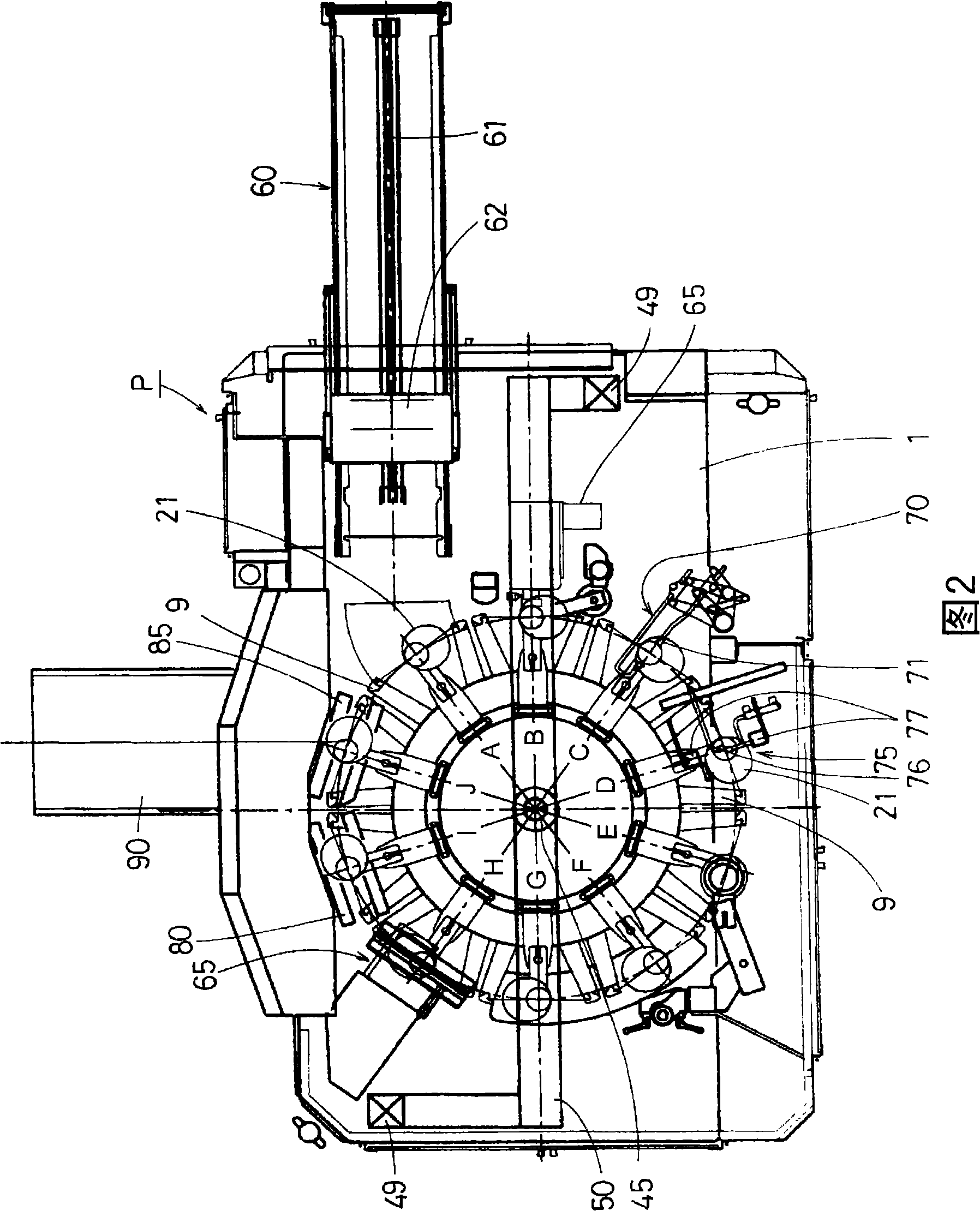

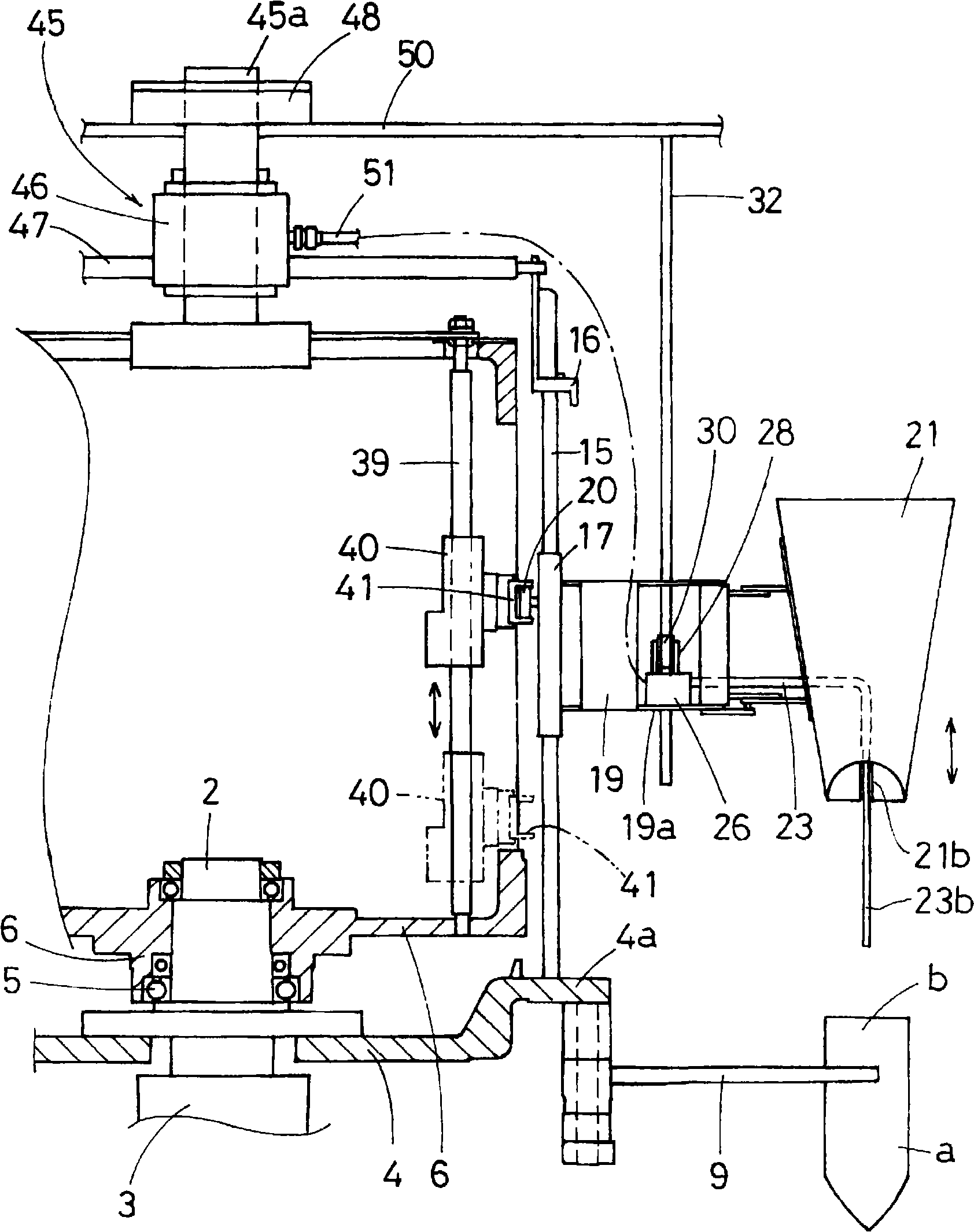

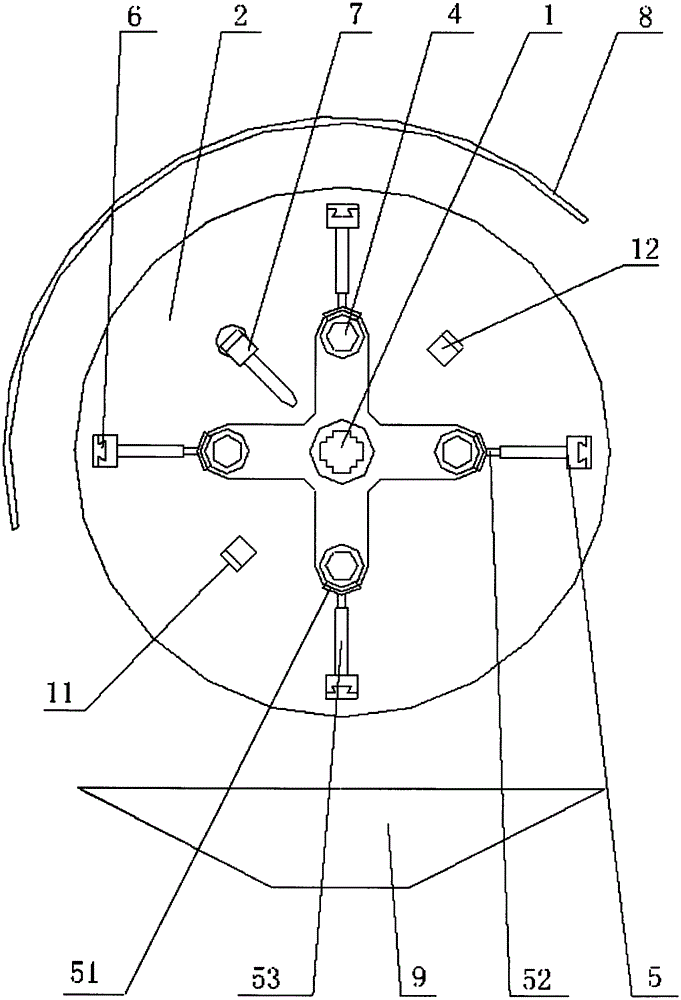

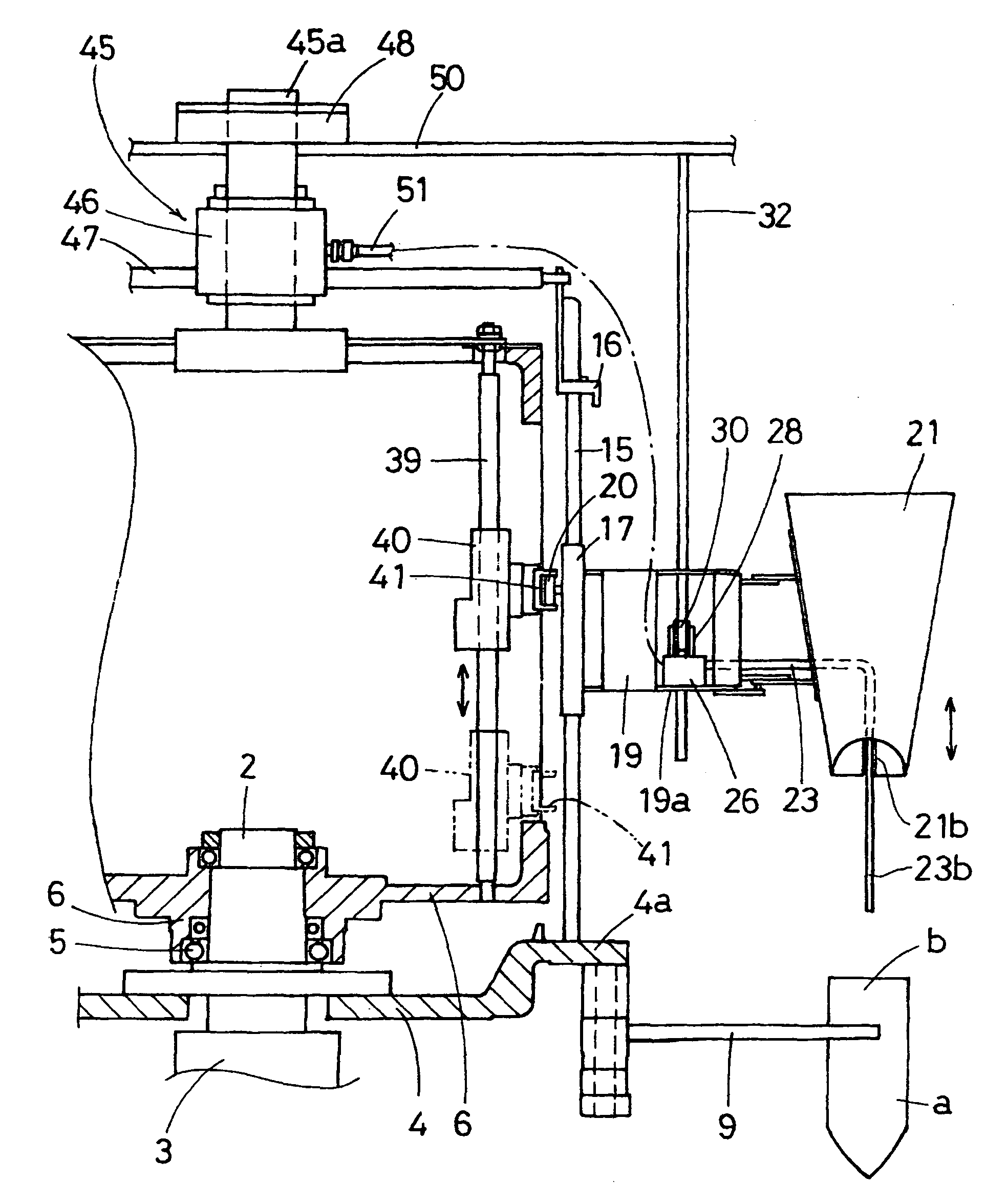

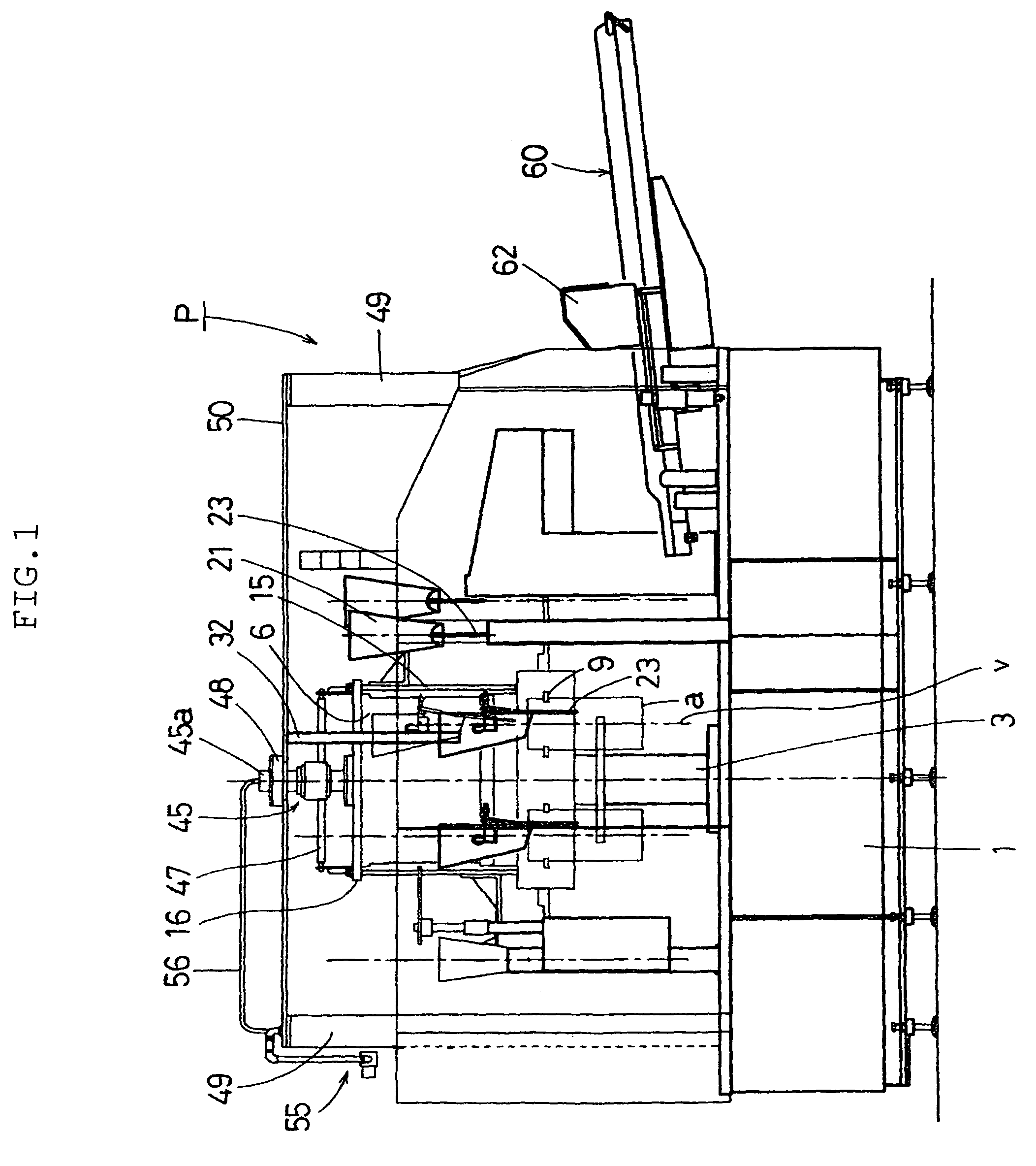

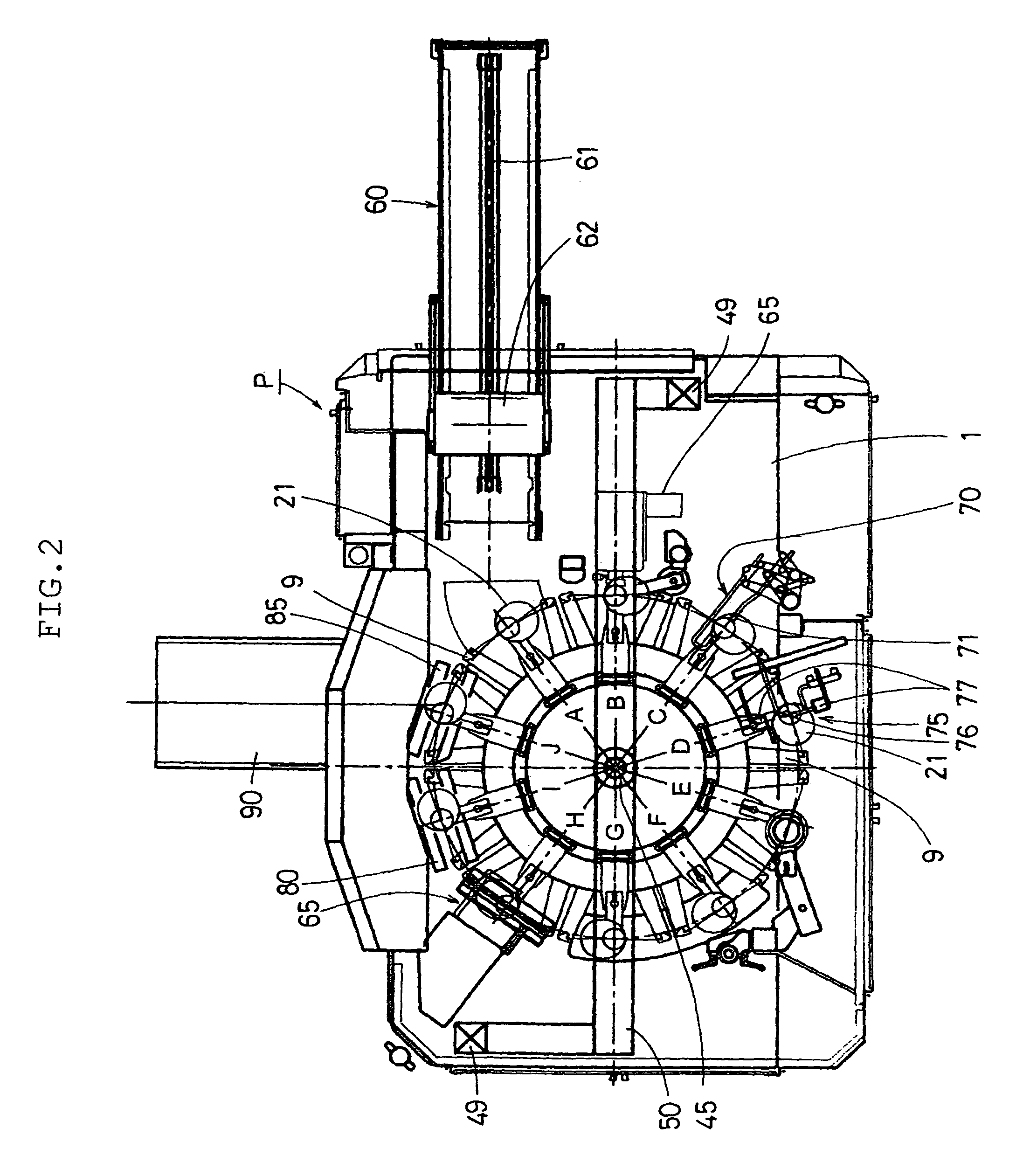

Method for Placing Inert Gas in Gas-Filling Packaging Machine

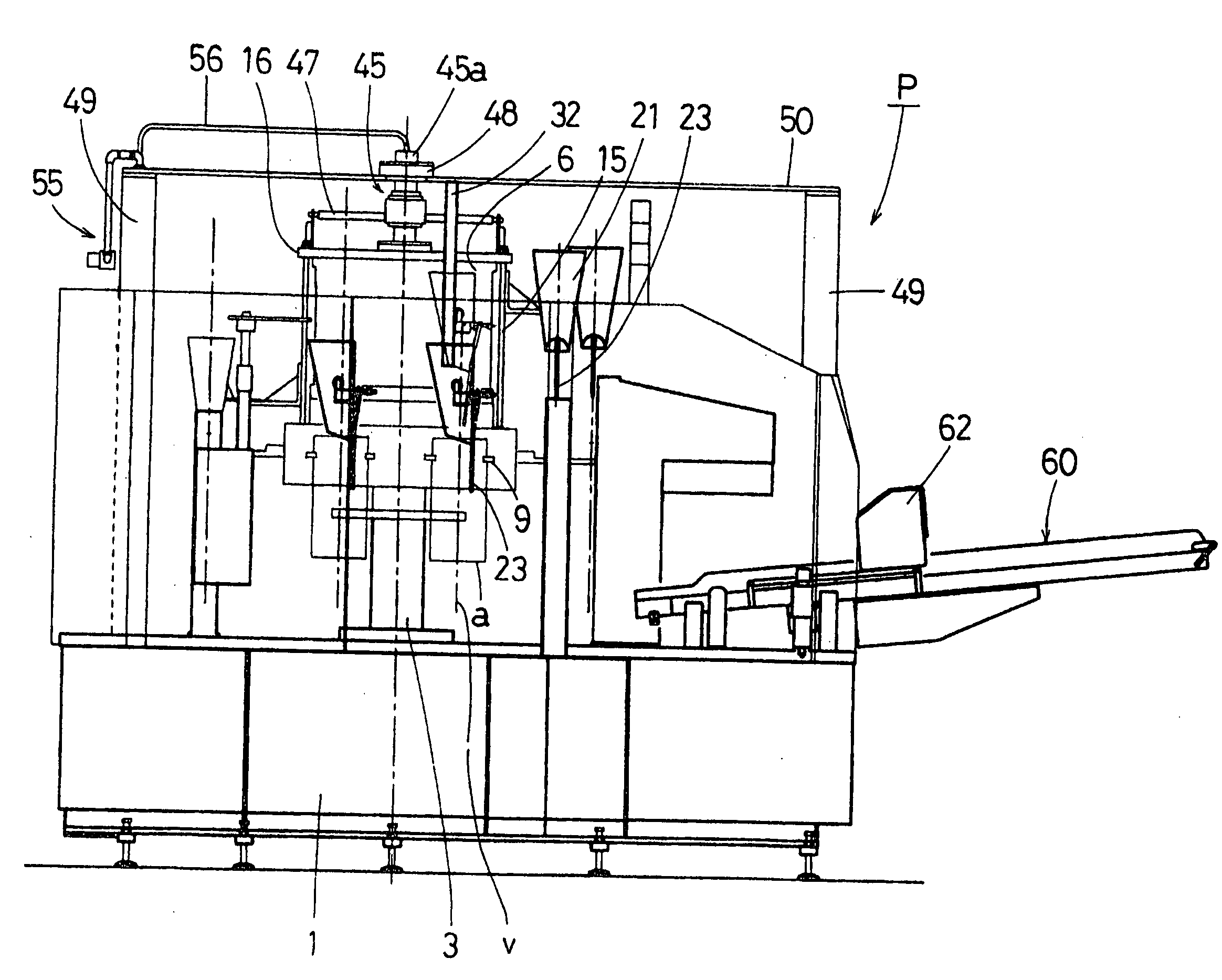

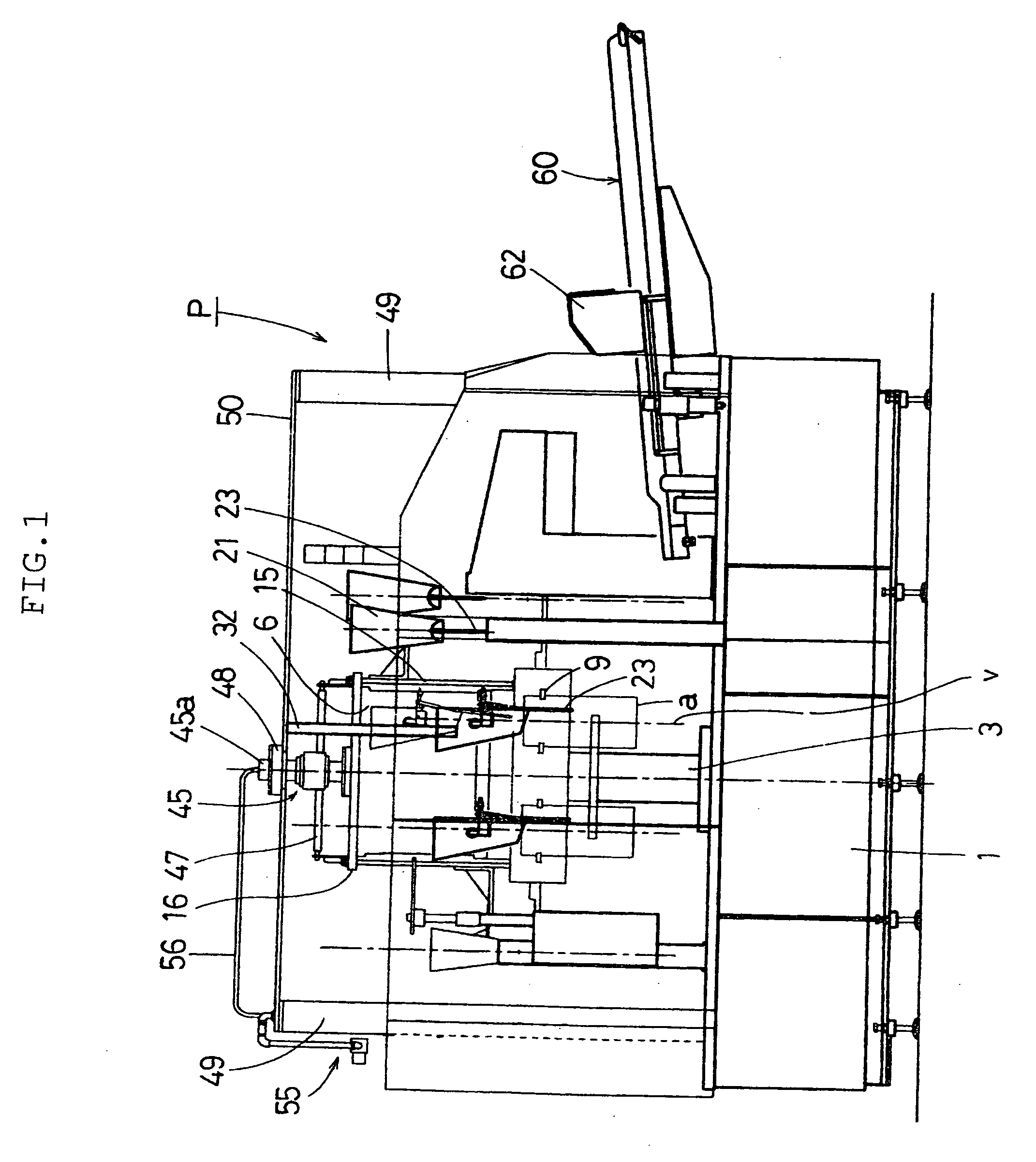

ActiveUS20090223172A1Increase replacement rateAvoid stickingCapsCap application using vaccuumAttitude controlProduct gas

[PROBLEMS] To provide an inert gas placing method for a gas-filling and packaging machine, in which troubles occurring when a gas-filling nozzle is inserted into a packaging bag are eliminated and in which a gas replacement rate is increased.[MEANS FOR OVERCOMING PROBLEMS] A gas-filling nozzle (23) is provided at a filling funnel (21) in correspondence with each grip (9) of a rotating body, and the gas-filling nozzle (23) has a forward end (23b) controlled by a nozzle attitude control unit (25) so as to approach or recede from an imaginary normal line v passing through the center of the drop opening of the filling funnel. In the process preceding a filling process, the drop opening of the filling funnel and the forward end of the gas-filling nozzle brought close to the normal line v are inserted from the opened bag opening b into a package bag a, and at the same time, the forward end is separated from the normal line v and moved toward a corner of the package bag. In the process following the filling process, inert gas jetted from the gas filling nozzle and air in the package bag are replaced with each other, and in a postprocess on the downstream side, the replacement action between the inert gas and the air is promoted with the bag opening b substantially closed by a shutter unit (65).

Owner:GENERAL PACKER

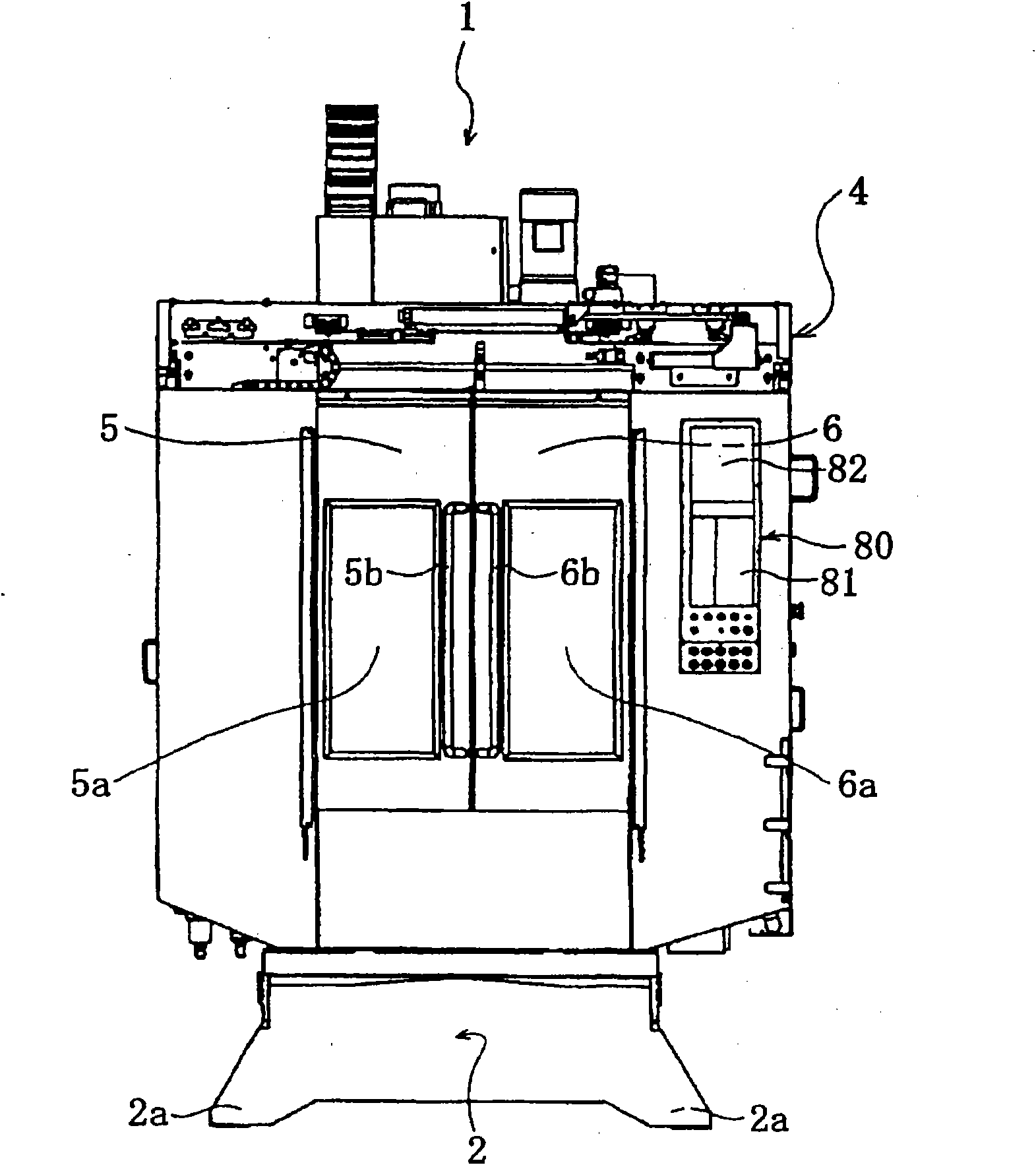

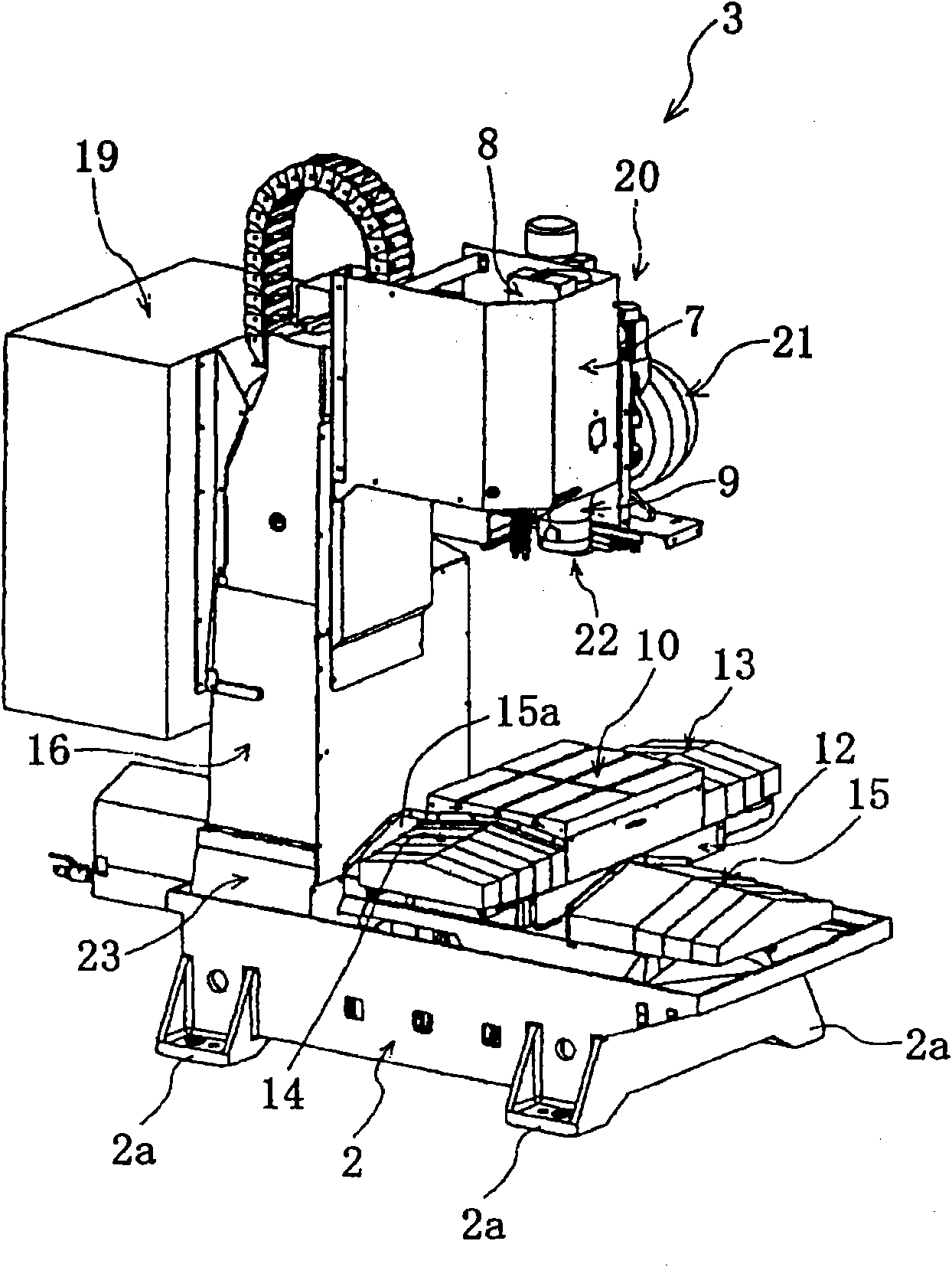

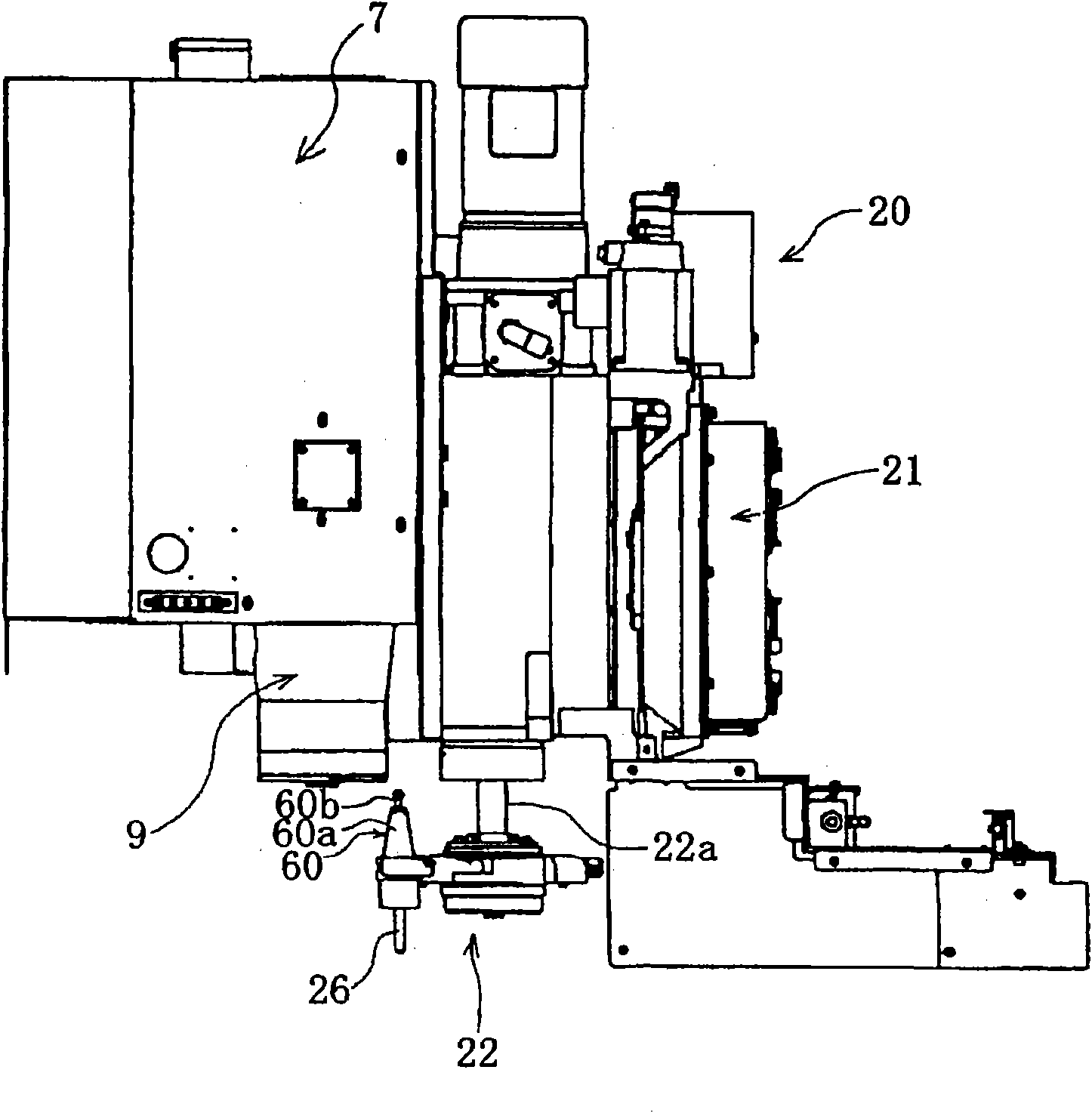

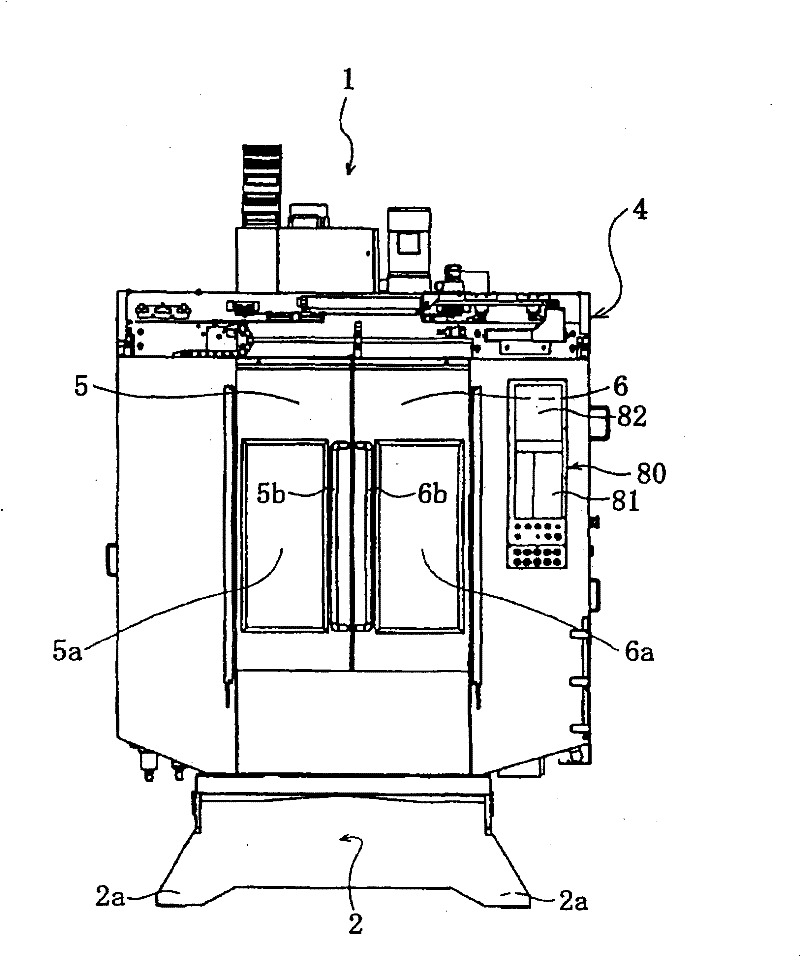

Machine tool

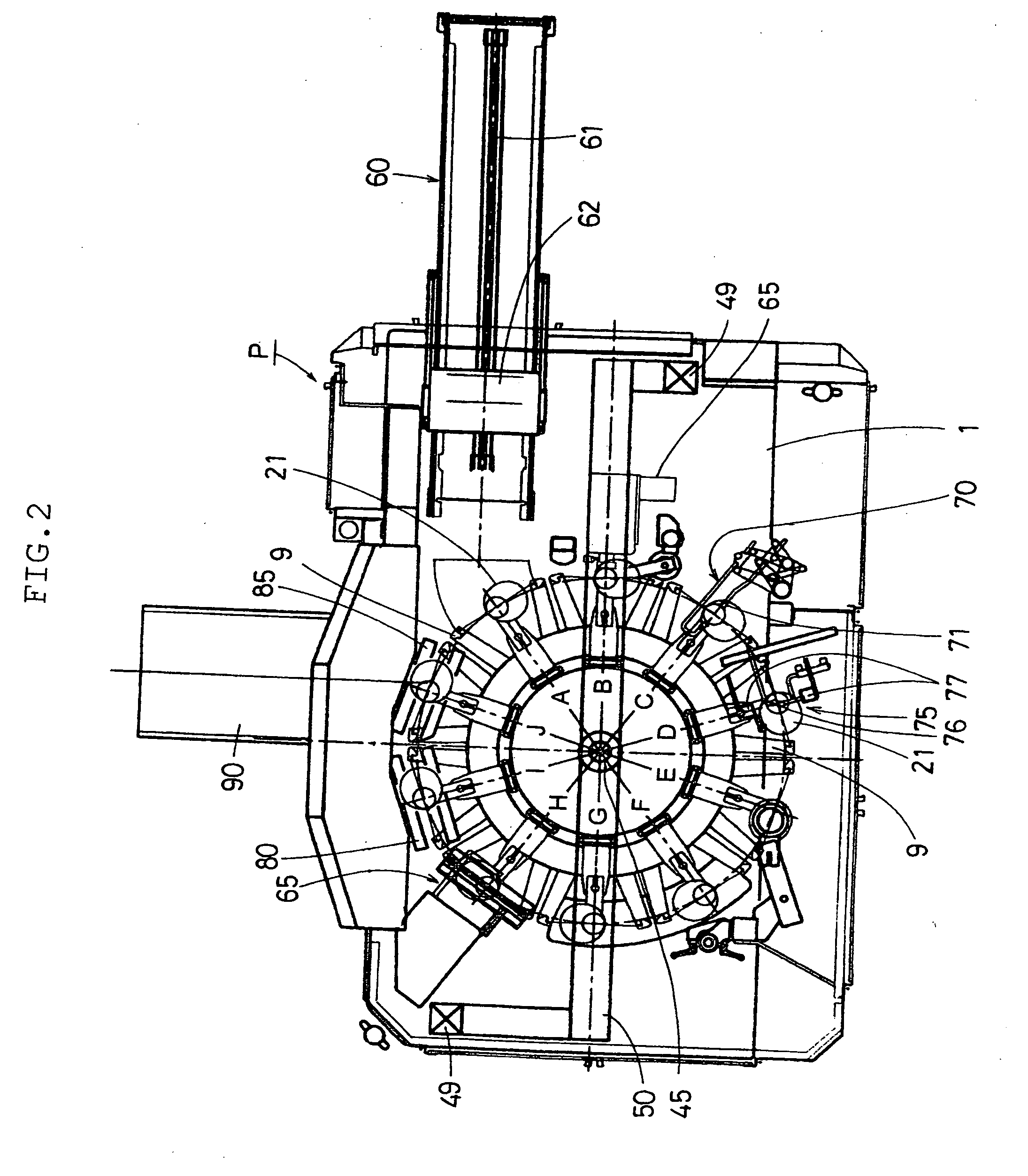

ActiveCN101549466AMeasurement/indication equipmentsPositioning apparatusReplacement - actionEngineering

A machine tool stores the time for determining the clogging status of the filter. A control device performs tool replacement to the tool replacement device for a longer time only if the pass time is long from the stored time of the time storing section. A pressure difference detecting sensor accurately detects the fore-and-after pressure difference of the filter in the longer replacement time. A judgement section accurately determines the clogging of the filter based on the exact pressure difference detected by the pressure difference detecting sensor. The longer replacement action of the tool replacement device is performed only after a preset-time is passed after the last clogging judgement has been performed. The production efficiency of the machine tool is scarcely declined.

Owner:BROTHER KOGYO KK

Method for placing inert gas in gas-filling and packaging machine

InactiveCN101258074AIncrease replacement rateResolve staggered insertion errorsPackaging by pressurising/gasifyingAttitude controlEngineering

The present invention provides an inert gas placing method for a gas- filling and packaging machine, in which troubles occurring when a gas-filling nozzle is inserted into a packaging bag are eliminated and in which a gas replacement rate is increased. A gas-filling nozzle (23) is provided at a filling funnel (21) in correspondence with each grip (9) of a rotating body, and the gas-filling nozzle (23) has a forward end (23b) controlled by a nozzle attitude control means (25) so as to approach or recede from an imaginary normal line v passing through the center of the drop opening of the filling funnel. In the process preceding a filling process, the drop opening of the filling funnel and the forward end of the gas-filling nozzle brought close to the normal line v are inserted from the opened bag opening b into a package bag a, and at the same time, the forward end is separated from the normal line v and moved toward a corner of the package bag. In the process following the filling process, inert gas jetted from the gas filling nozzle and air in the package bag are replaced with each other, and in a postprocess on the downstream side, the replacement action between the inert gas and the air is promoted with the bag opening b substantially closed by a shutter means (65).

Owner:GENERAL PACKER

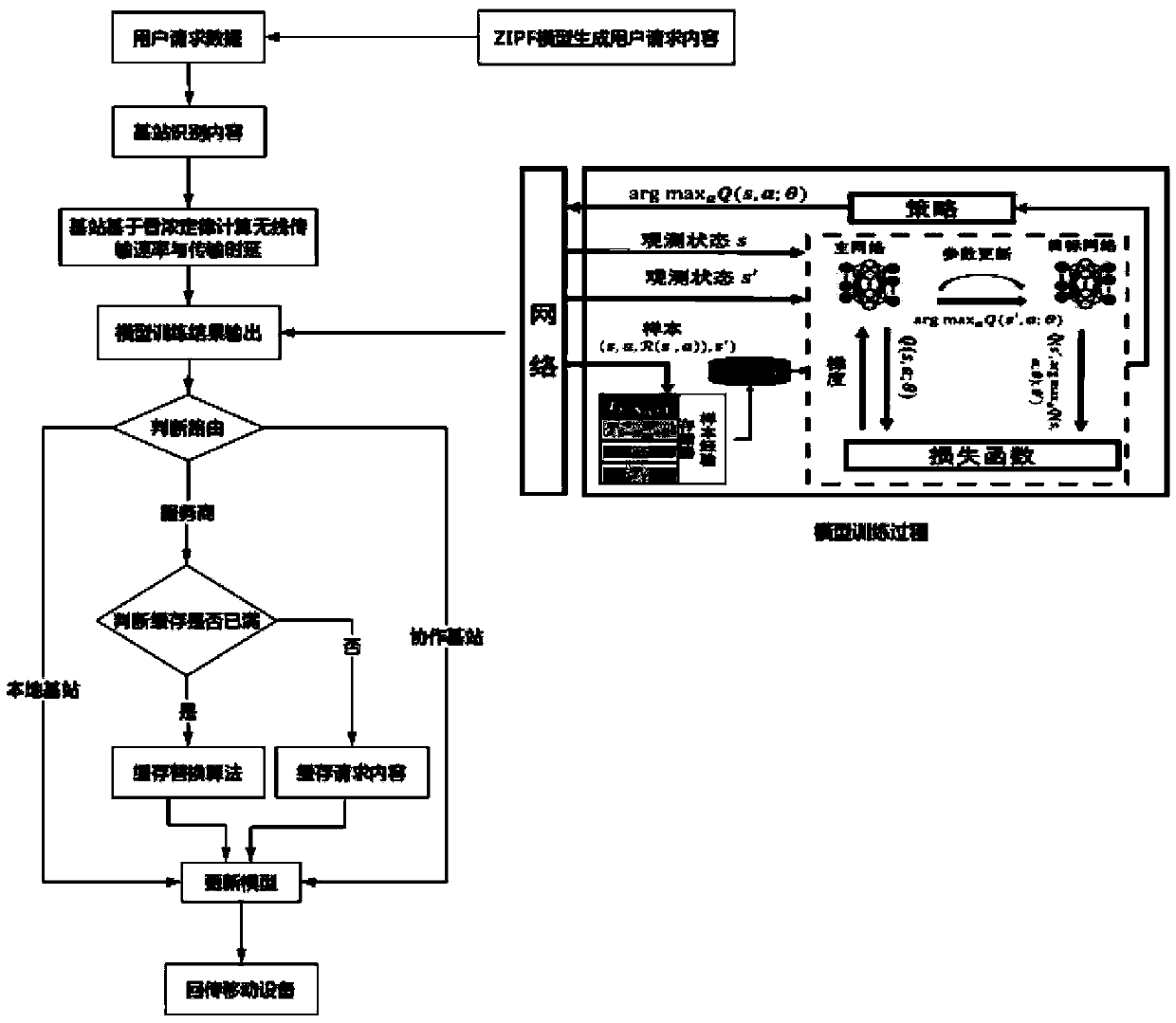

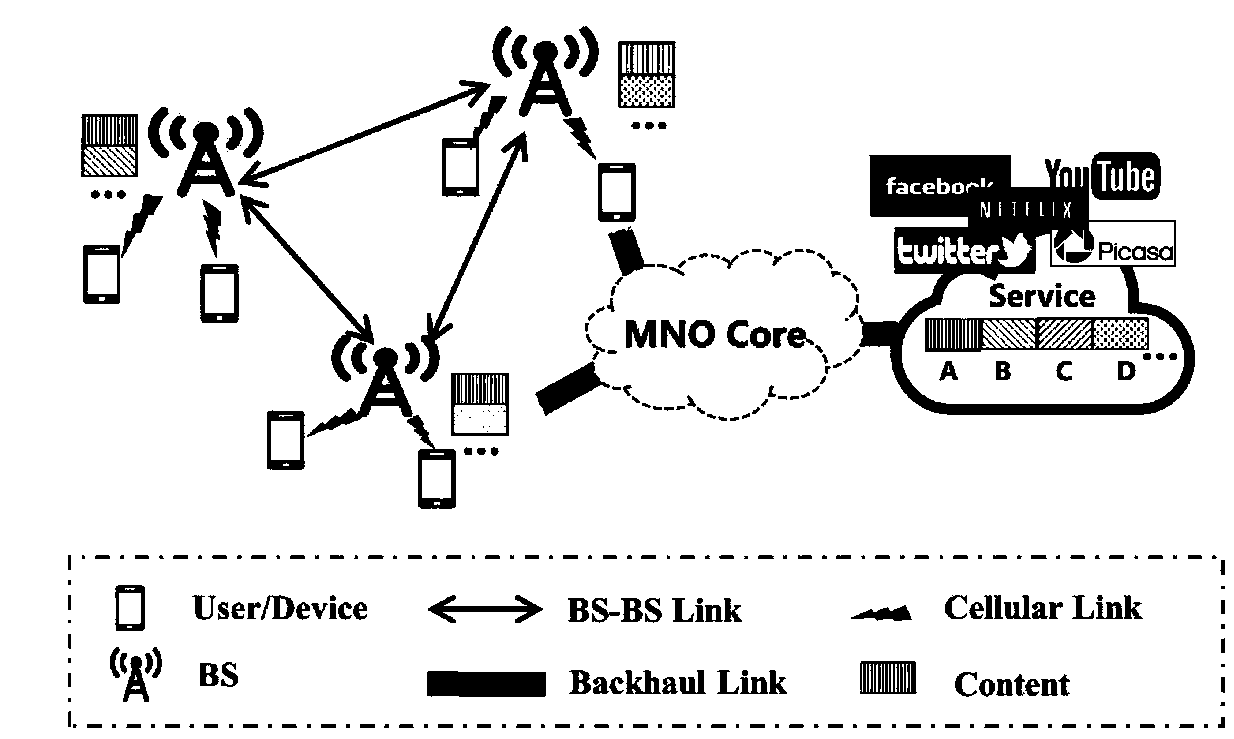

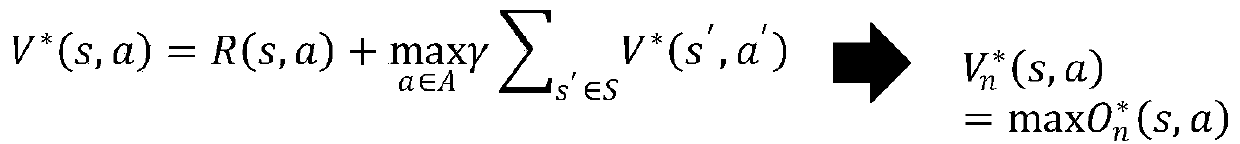

Mobile network edge cooperation cache model construction method based on machine learning

ActiveCN110312277AImprove caching capacityReduce access delayData switching networksWireless communicationAccess timeReplacement - action

The invention discloses a mobile network edge cooperation cache model construction method based on machine learning. The method comprises the steps of 1, establishing a network training model according to content request data sent by a user; 2, enabling a judgement routing module in the network training model to carry out base station identification on content request data sent by a user accordingto an adaptive selection action requirement; step 3, enabling an updating module in the network training model to perform cache replacement on the local base station according to replacement action requirements; and 4, repeating the steps 1-3 until the network training model is stable, so that the user access time delay can be remarkably reduced, the cache hit rate is improved, and the backbone network flow pressure is relieved.

Owner:派欧云计算(上海)有限公司

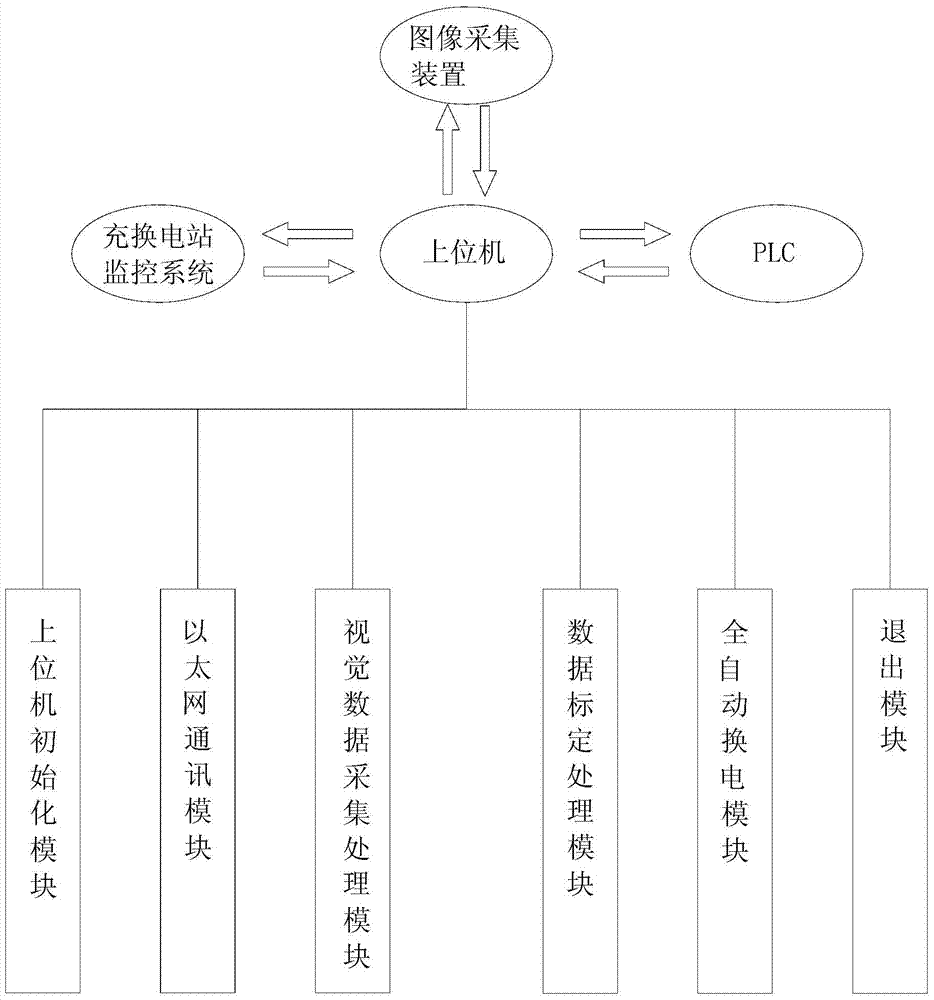

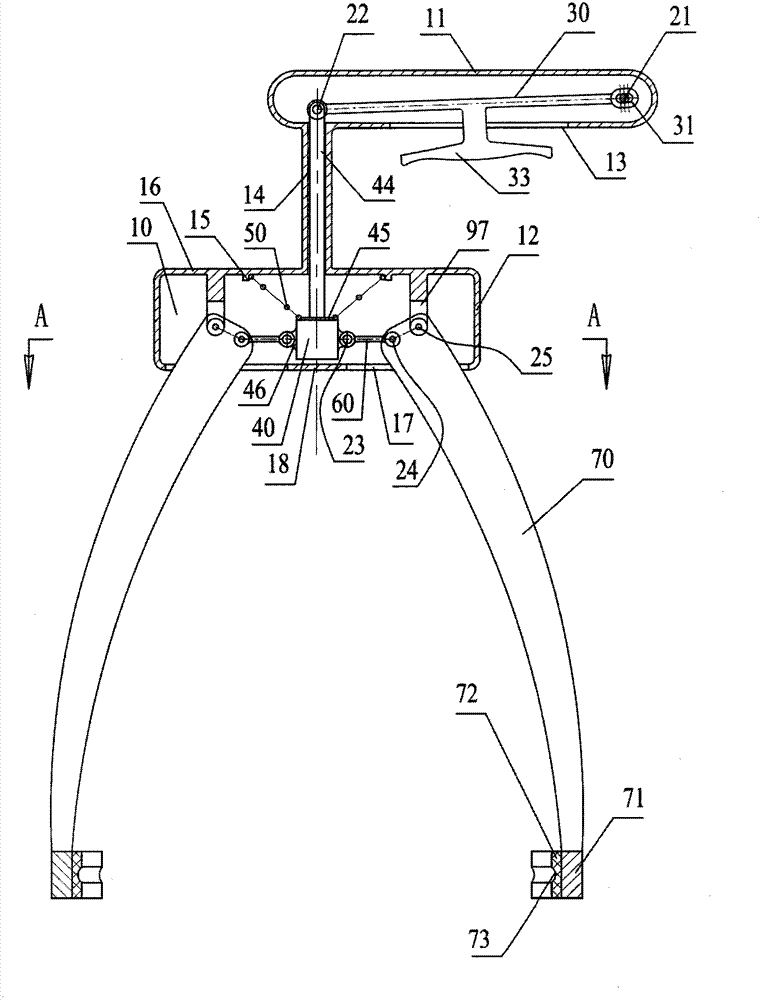

Fully-automatic battery replacement control system and method for electric vehicle

ActiveCN103693024AHigh degree of automationHigh control precisionElectric propulsion mountingElectric/fluid circuitProgrammable logic controllerControl system

The invention belongs to the field of mechanical automation, and particularly relates to a fully-automatic battery replacement control system and a fully-automatic battery replacement control method for an electric vehicle. The system comprises an upper computer, an image acquisition device and a PLC (programmable logic controller), wherein the upper computer communicates with the image acquisition device and the PLC respectively; the image acquisition device is used for acquiring the image information of the electric vehicle driven into a battery replacement station for battery replacement and a battery to be replaced; the upper computer is used for converting the image information, which is provided by the image acquisition device, of the electric vehicle and the battery to be replaced into the position coordinate data, required by the PLC, of a mechanical hand at each station, and transmitting the position coordinate data to the PLC through a bus interface; the PLC is used for controlling the mechanical hand to finish specific battery replacement actions. The control system is high in automation degree and battery replacement efficiency.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Software version management for executing replacement actions

InactiveUS9411576B2Efficient downgradeVersion controlProgram loading/initiatingTemporal informationComputerized system

A software version management system comprising a host driver and at least one software module. The host driver comprises migration means to start, stop and replace the software modules on a computer system in response to replacement actions. The system is characterized by the software module being a downgradable software module comprising a compatibility database specifying dependencies between different versions of the software module; the migration means further comprising i) at least a status means to retrieve temporal information from the downgradable software module; ii) at least a downgrading means responsive to a replacement action to downgrade the downgradable software module to a particular downgrade version and to the status means, the downgrading means identifying an intermediate version of the downgradable software module; the host driver comprising restarting means responsive to the report of the completion of the intermediate version to load and start the downgrade version of the software module.

Owner:IBM CORP

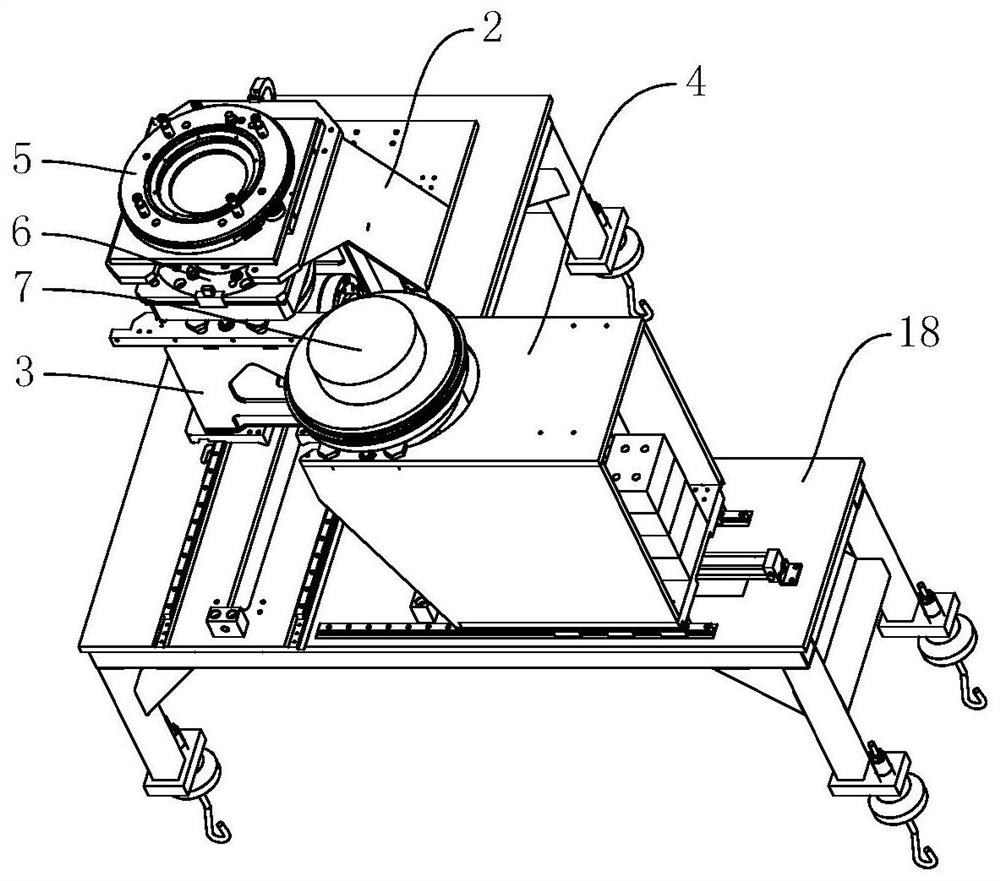

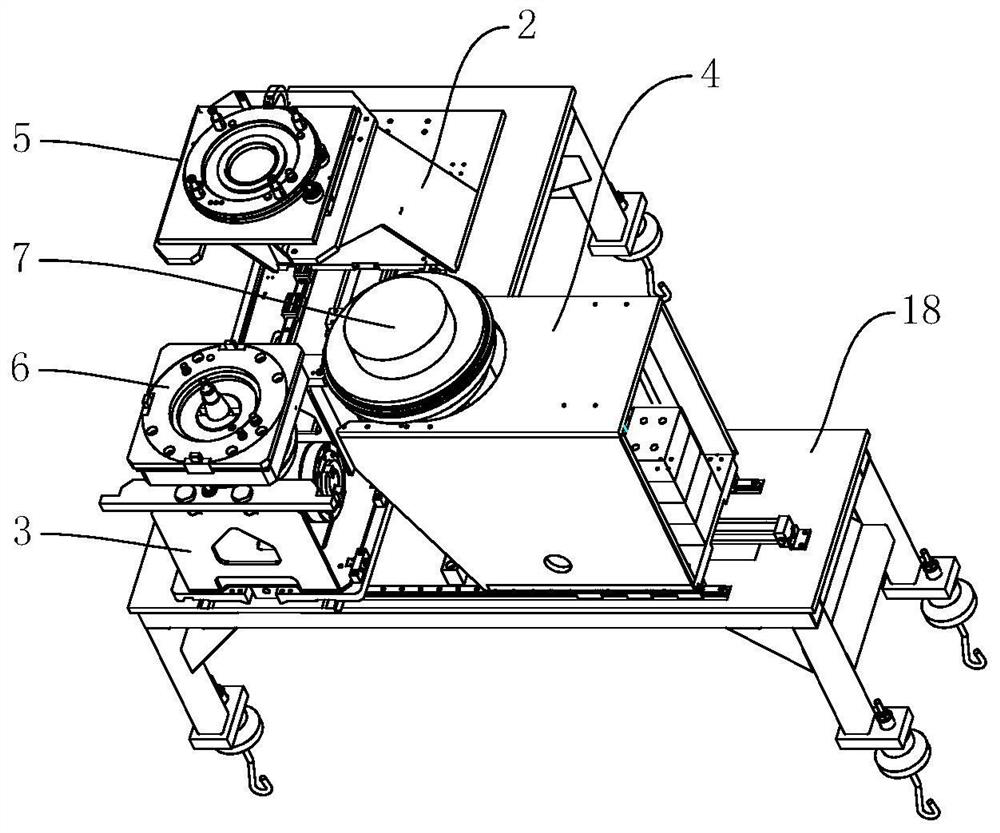

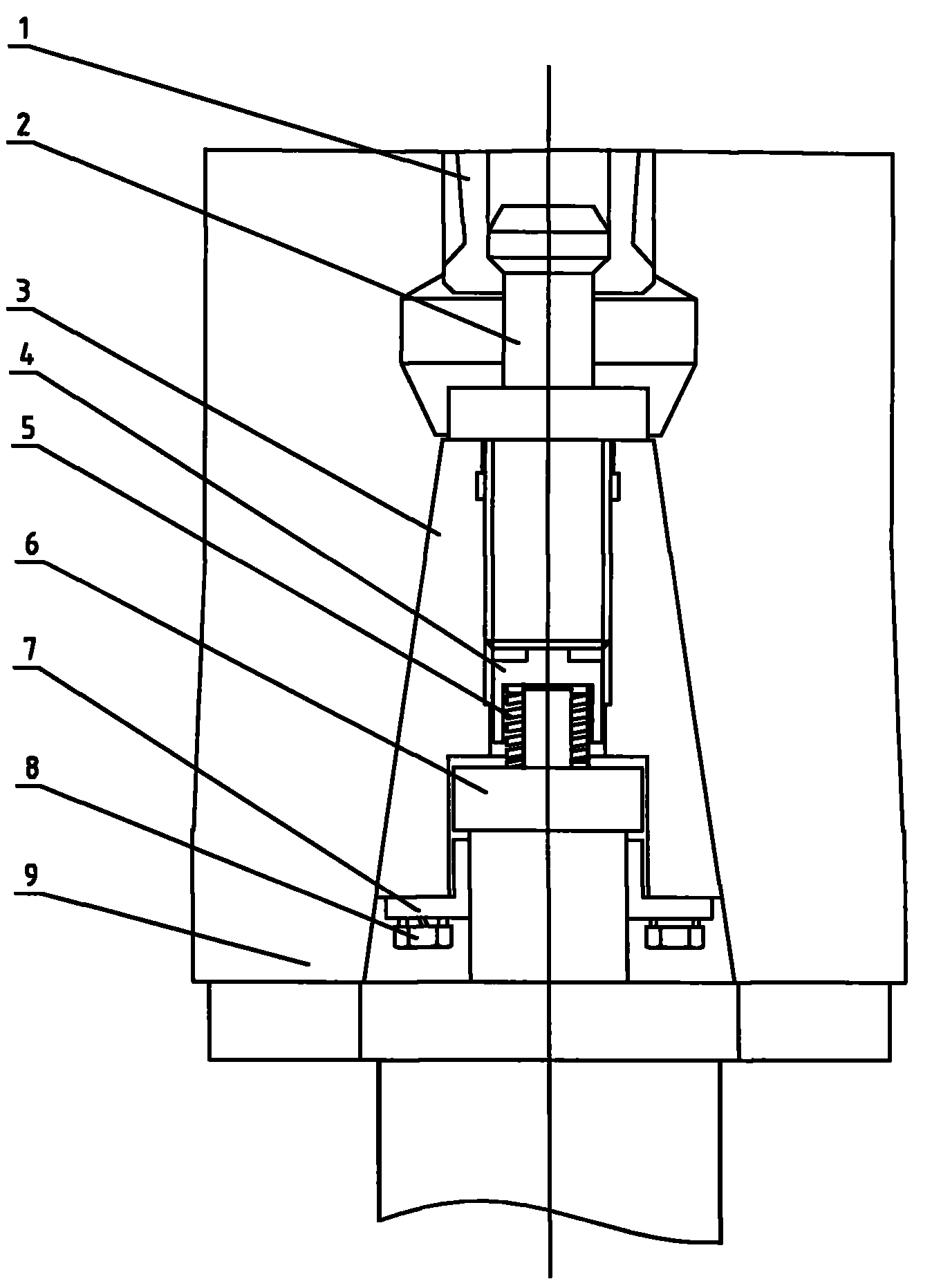

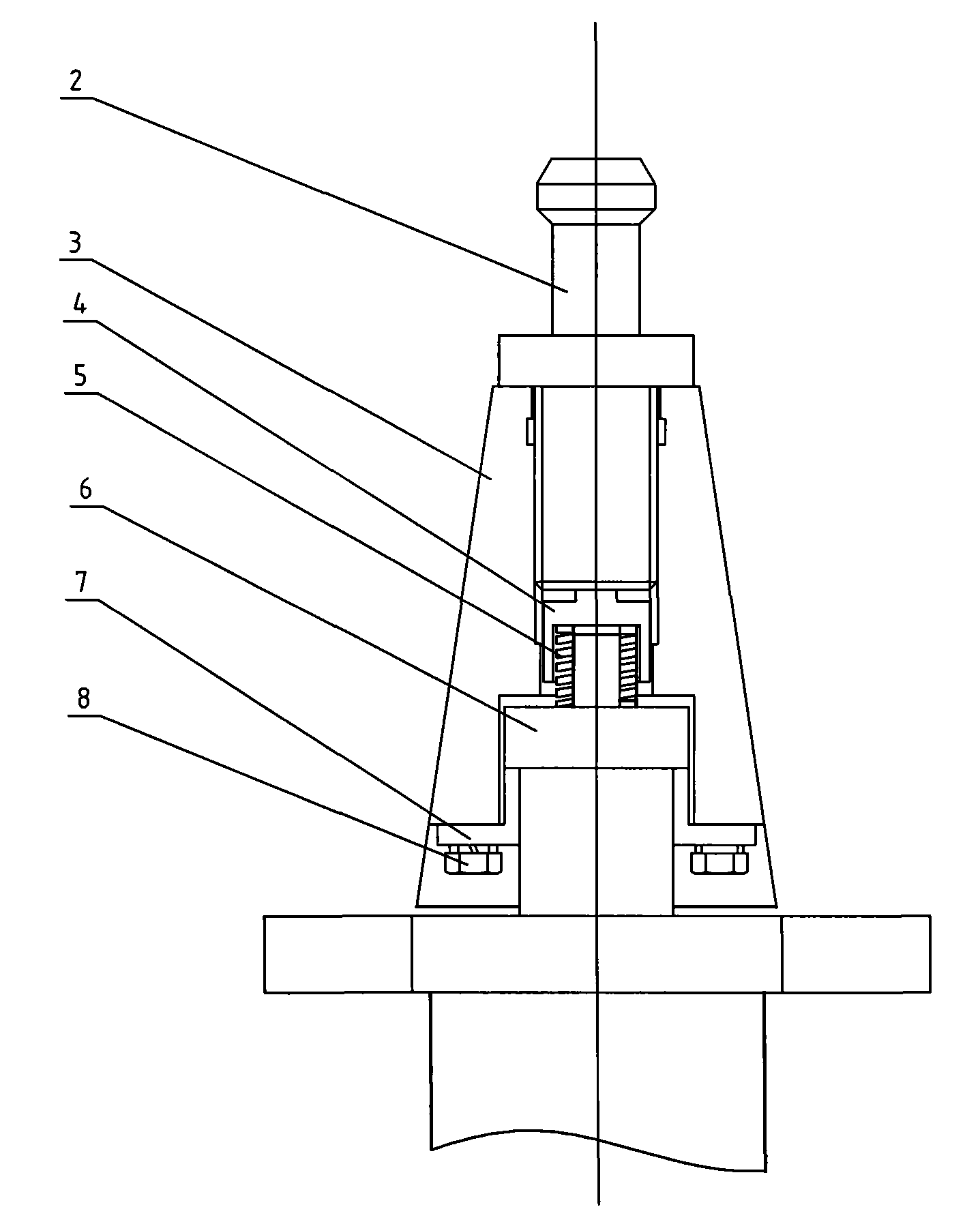

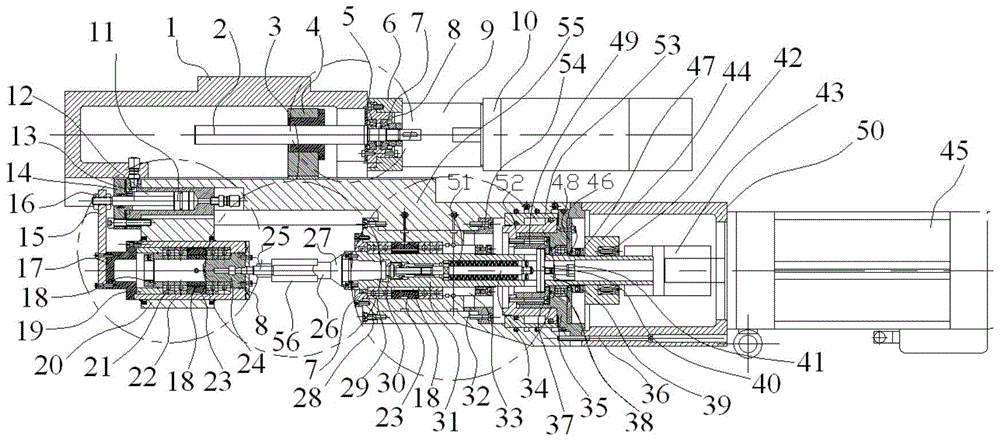

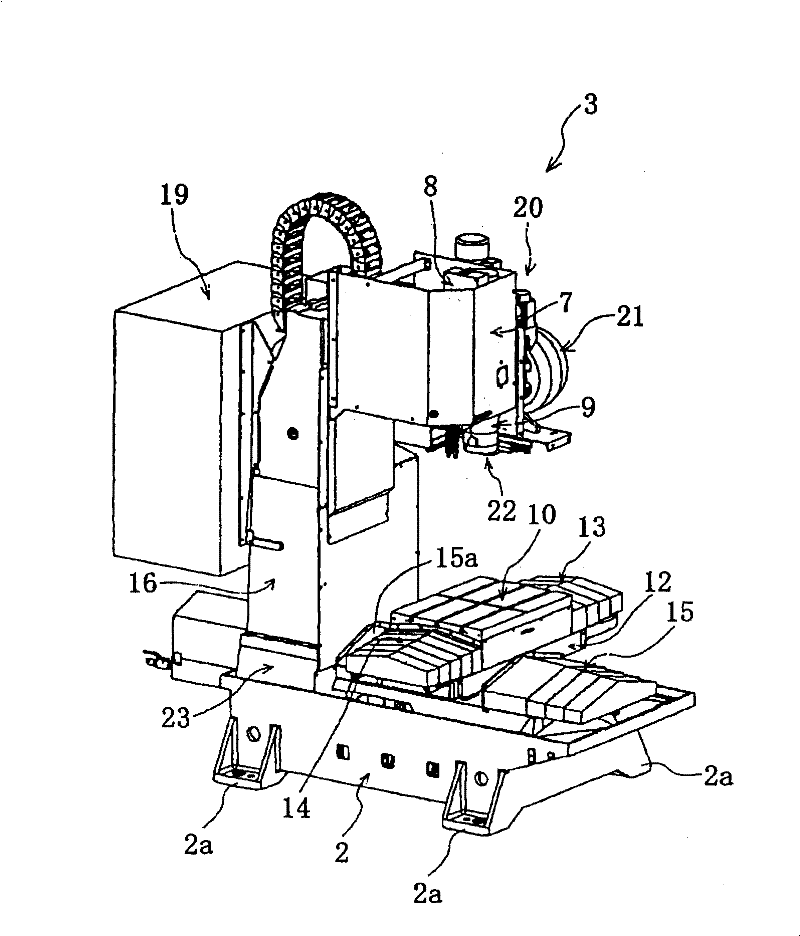

Direct-drive type numerical control hobbing cutter frame

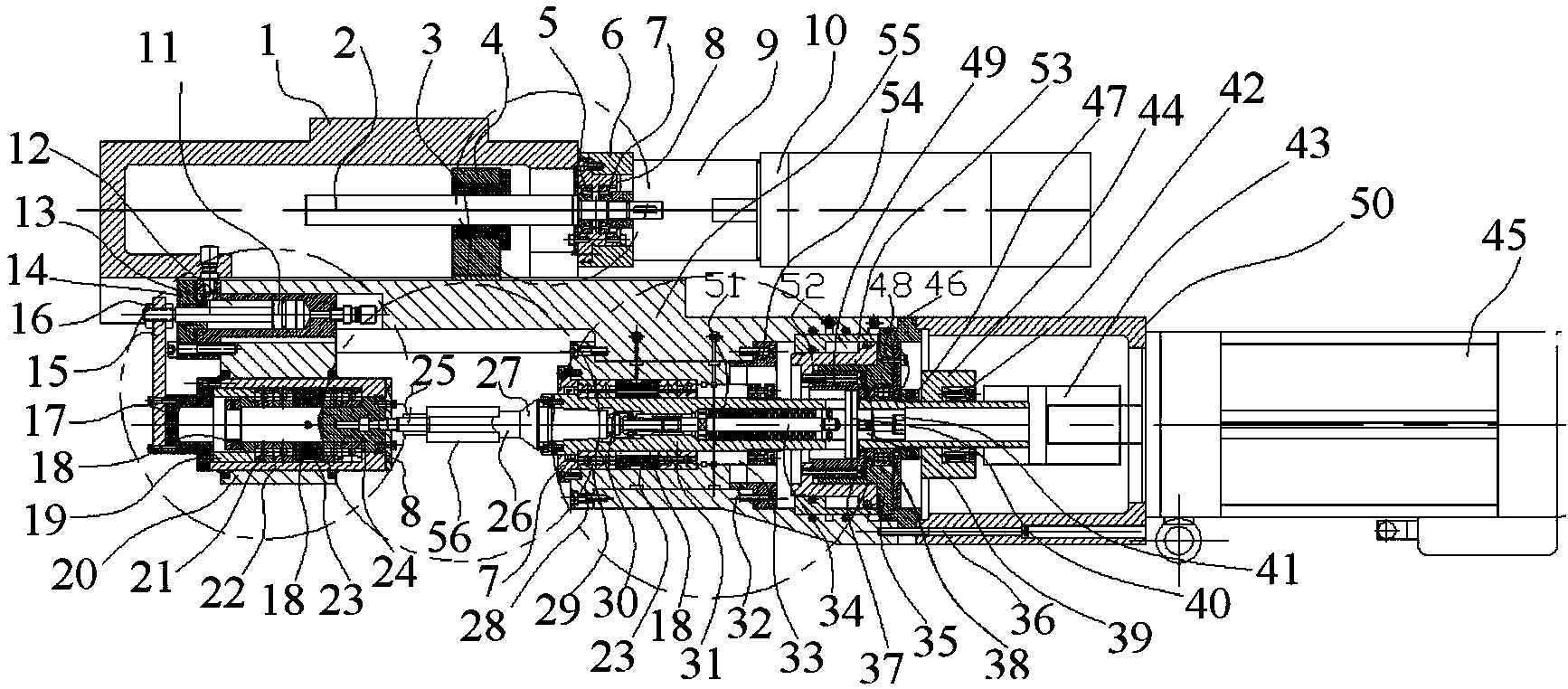

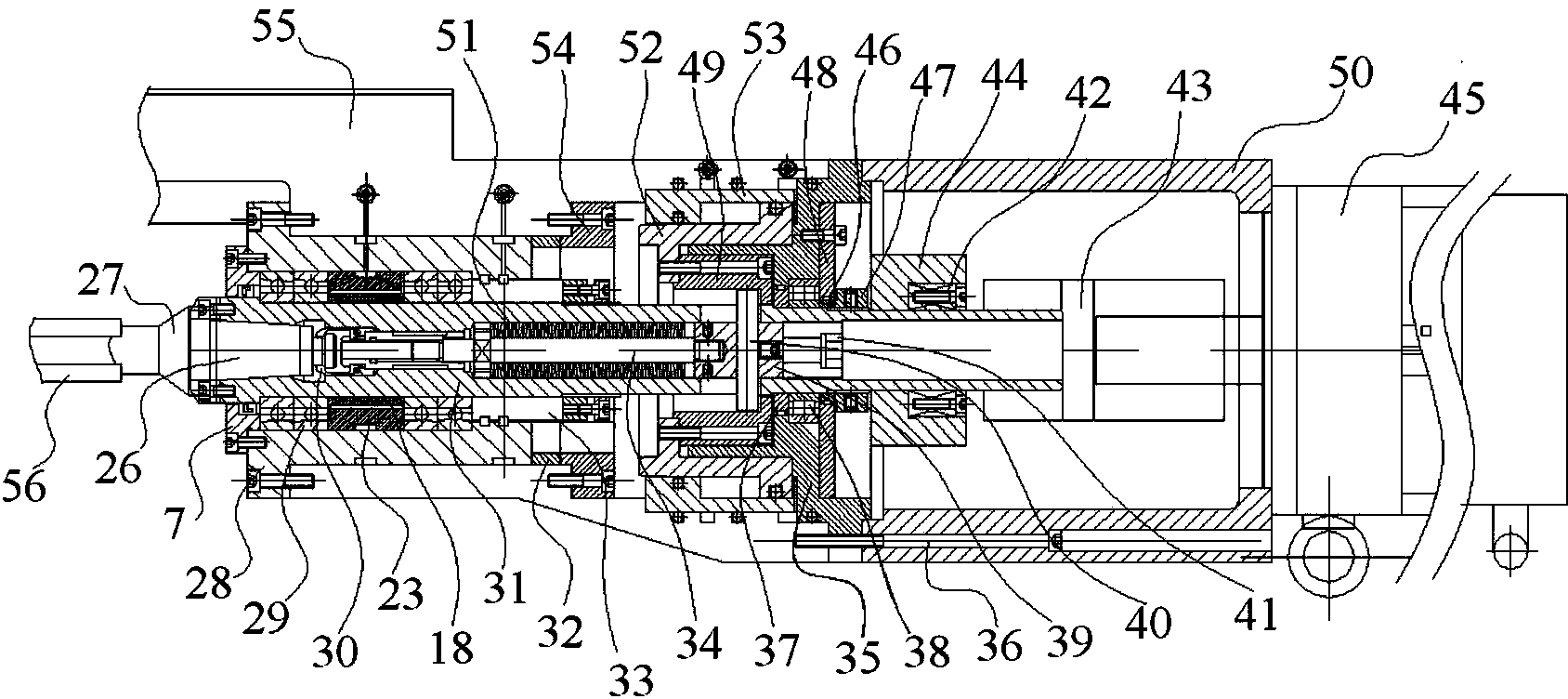

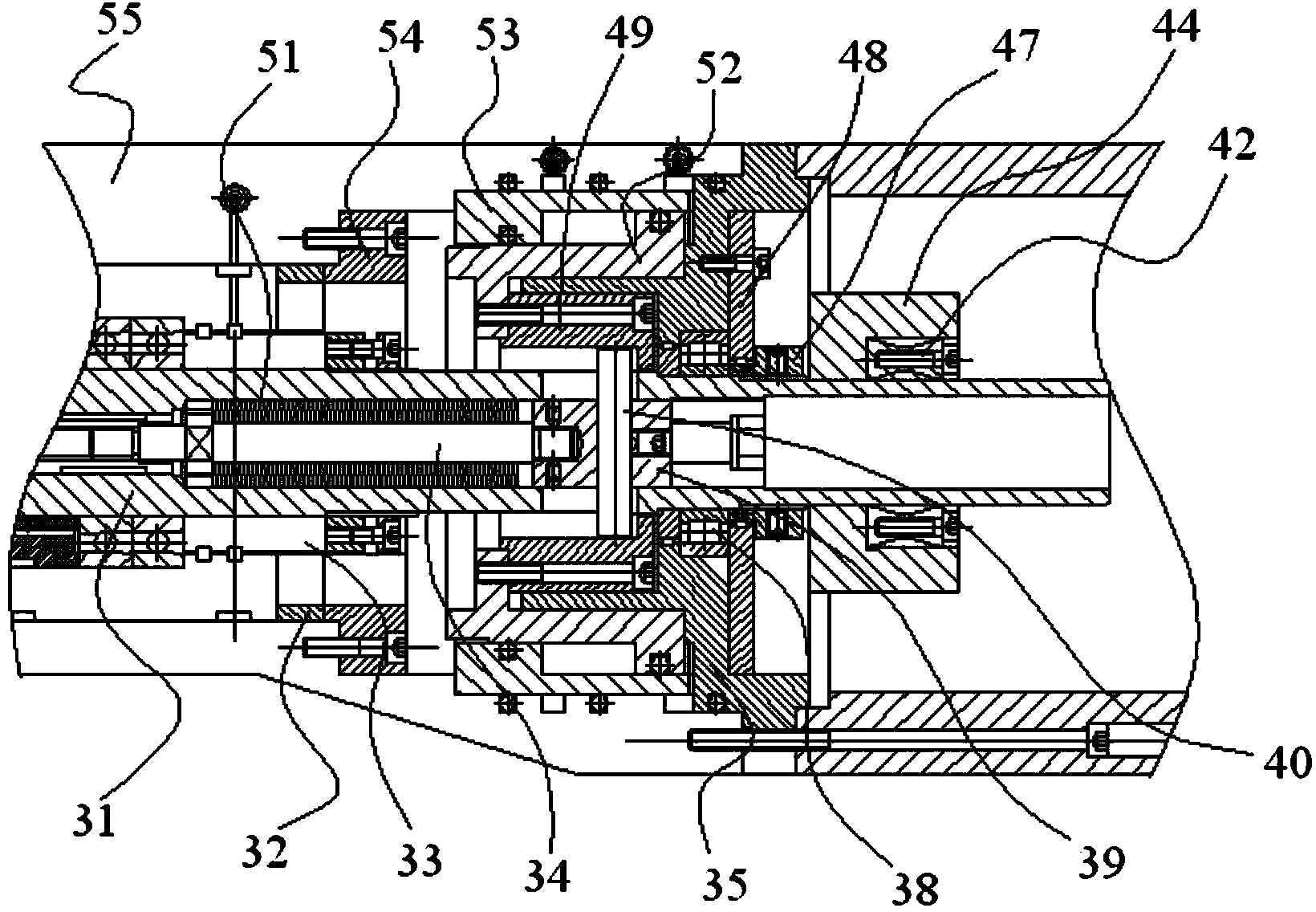

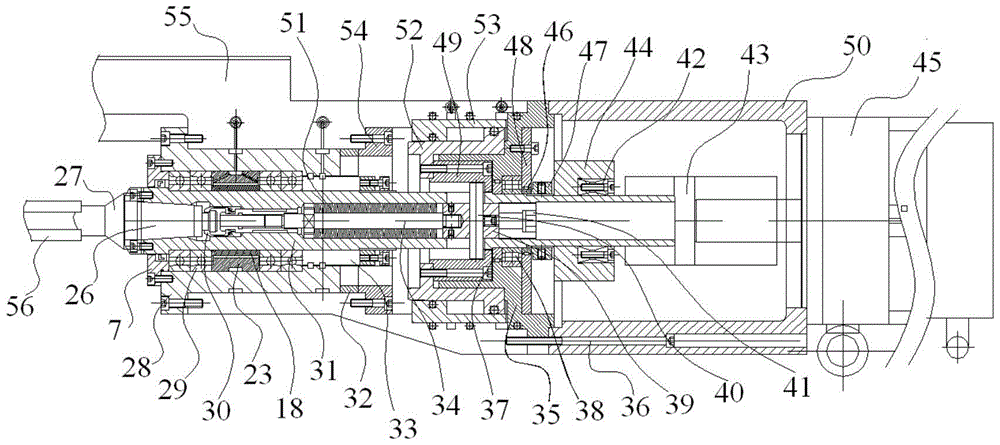

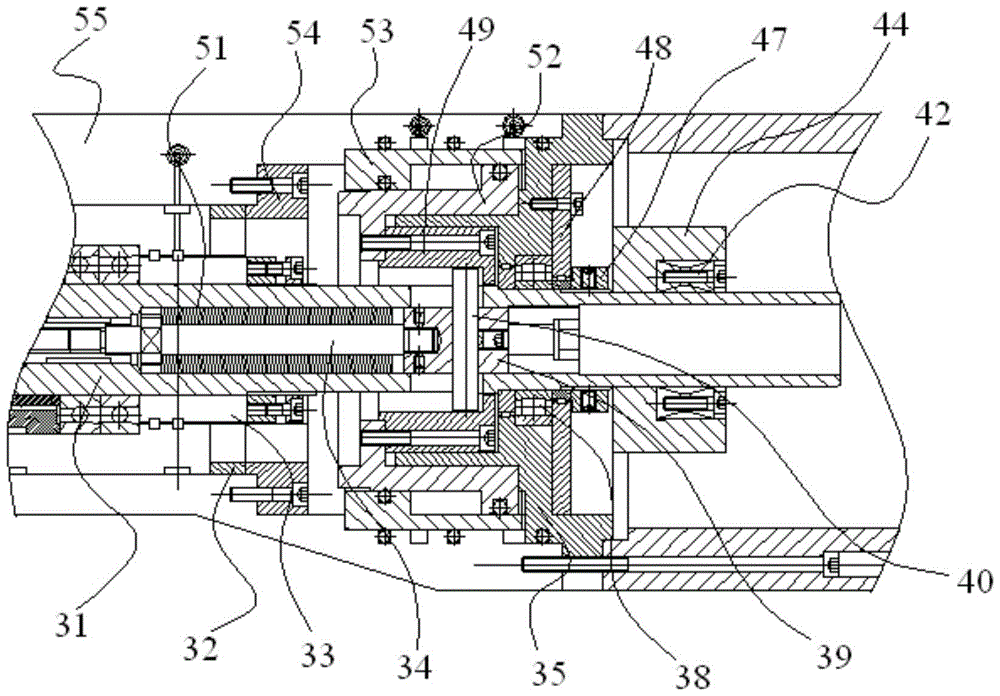

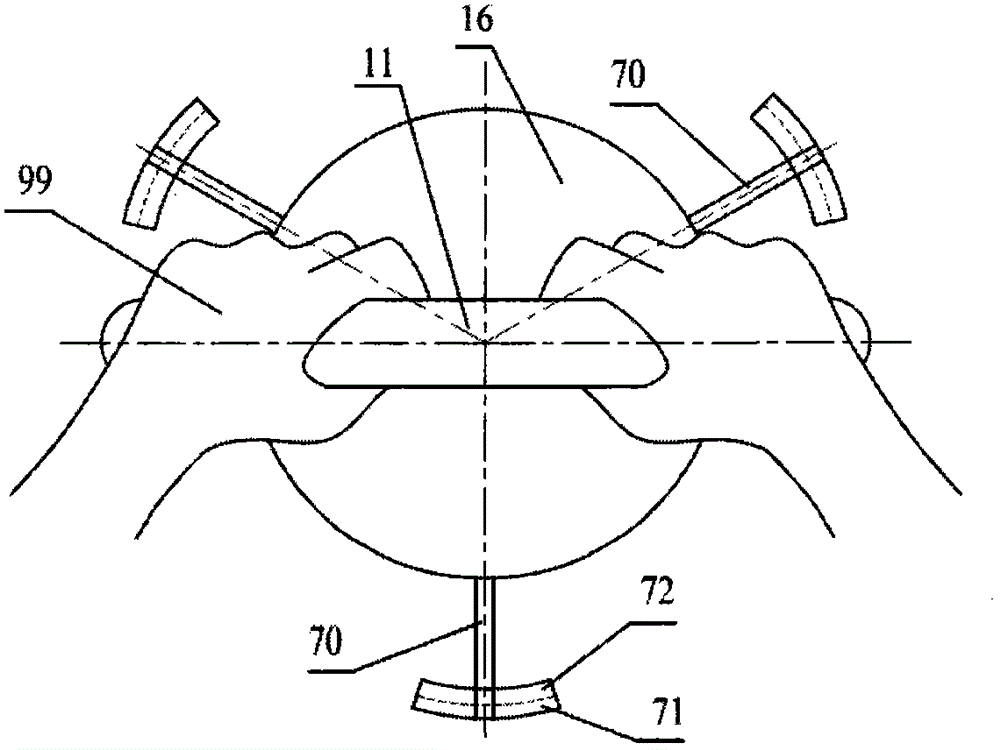

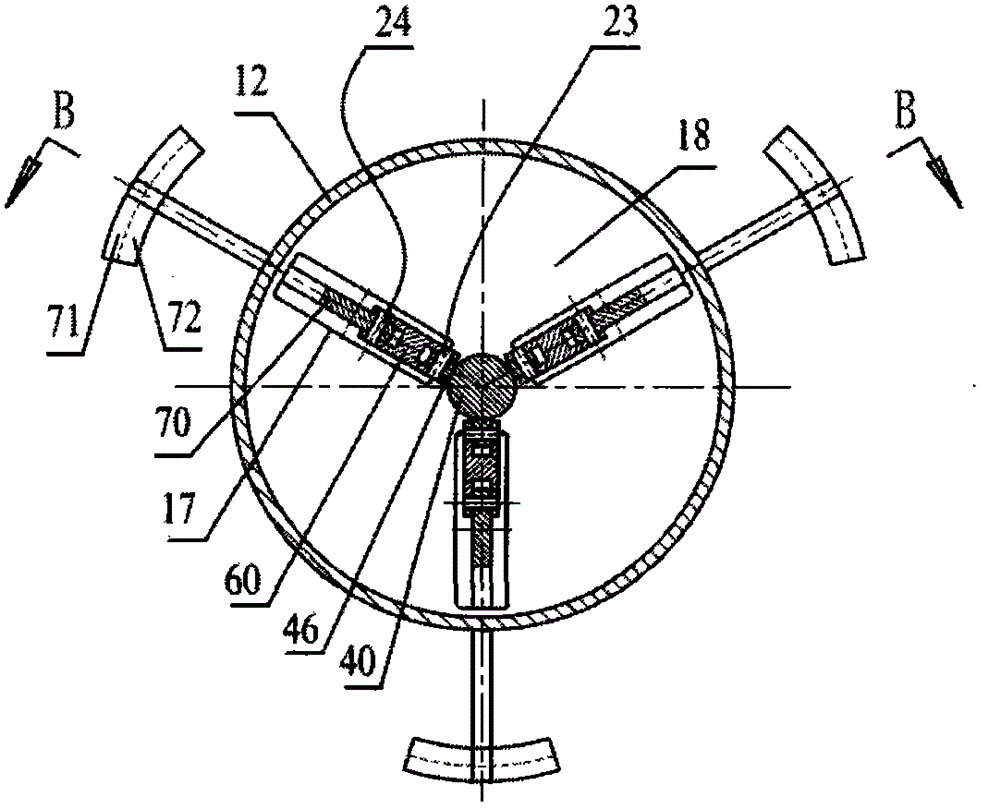

ActiveCN104070245AGuaranteed installation accuracyReliable actionGear-cutting machinesGear teethNumerical controlHobbing

The invention discloses a direct-drive type numerical control hobbing cutter frame. The direct-drive type numerical control hobbing cutter frame comprises a cutter frame body, a cutter frame sliding plate, a cutter frame main shaft assembly, a cutter rod assembly, a cutter frame auxiliary supporting assembly and a channeling cutter assembly; the cutter frame body comprises a cutter frame main body; the cutter frame sliding plate comprises a sliding plate body; the sliding plate body and the channeling cutter assembly are arranged on the cutter frame main body; the left side of the upper half portion of the sliding plate body is provided with a semicircular support and the right side of the upper half portion of the sliding plate body is provided with a cutter frame main shaft installing hole; the cutter frame auxiliary supporting assembly is arranged on the semicircular support; the cutter frame main shaft assembly is partially arranged in the cutter frame main shaft installing hole; one end of the cutter rod assembly is connected with the cutter frame main shaft assembly and the other end of the cutter rod assembly is connected with the cutter frame auxiliary supporting assembly; the cutter frame auxiliary supporting assembly is arranged on the semicircular support of the sliding plate and is opposite to the cutter frame main shaft assembly. The direct-drive type numerical control hobbing cutter frame is short in cutter replacement time, stable and reliable in cutter replacement action, high in rotating and machining accuracy and simple and compact in structure.

Owner:ZHEJIANG RICHUANG MECHANICAL & ELECTRICAL TECH

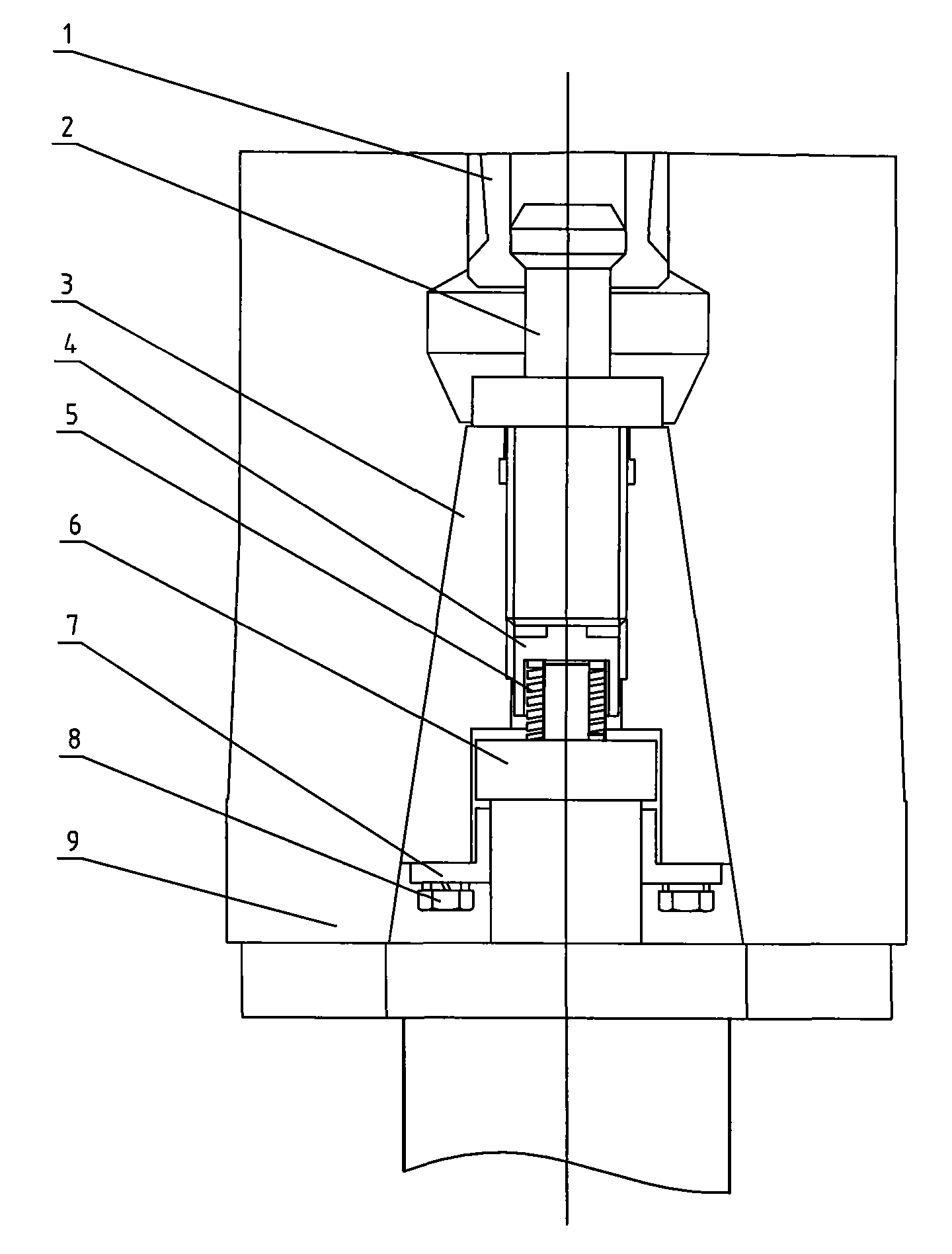

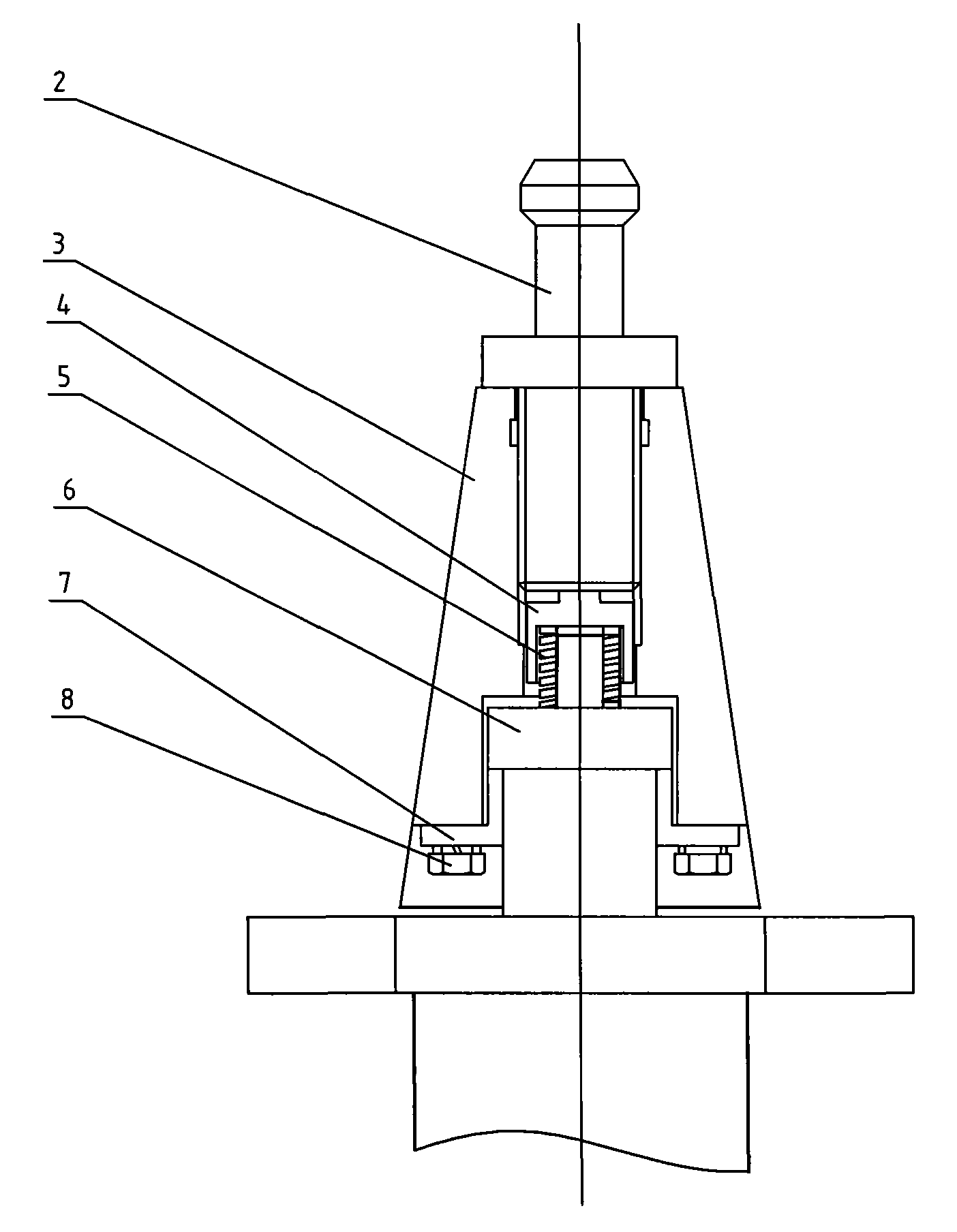

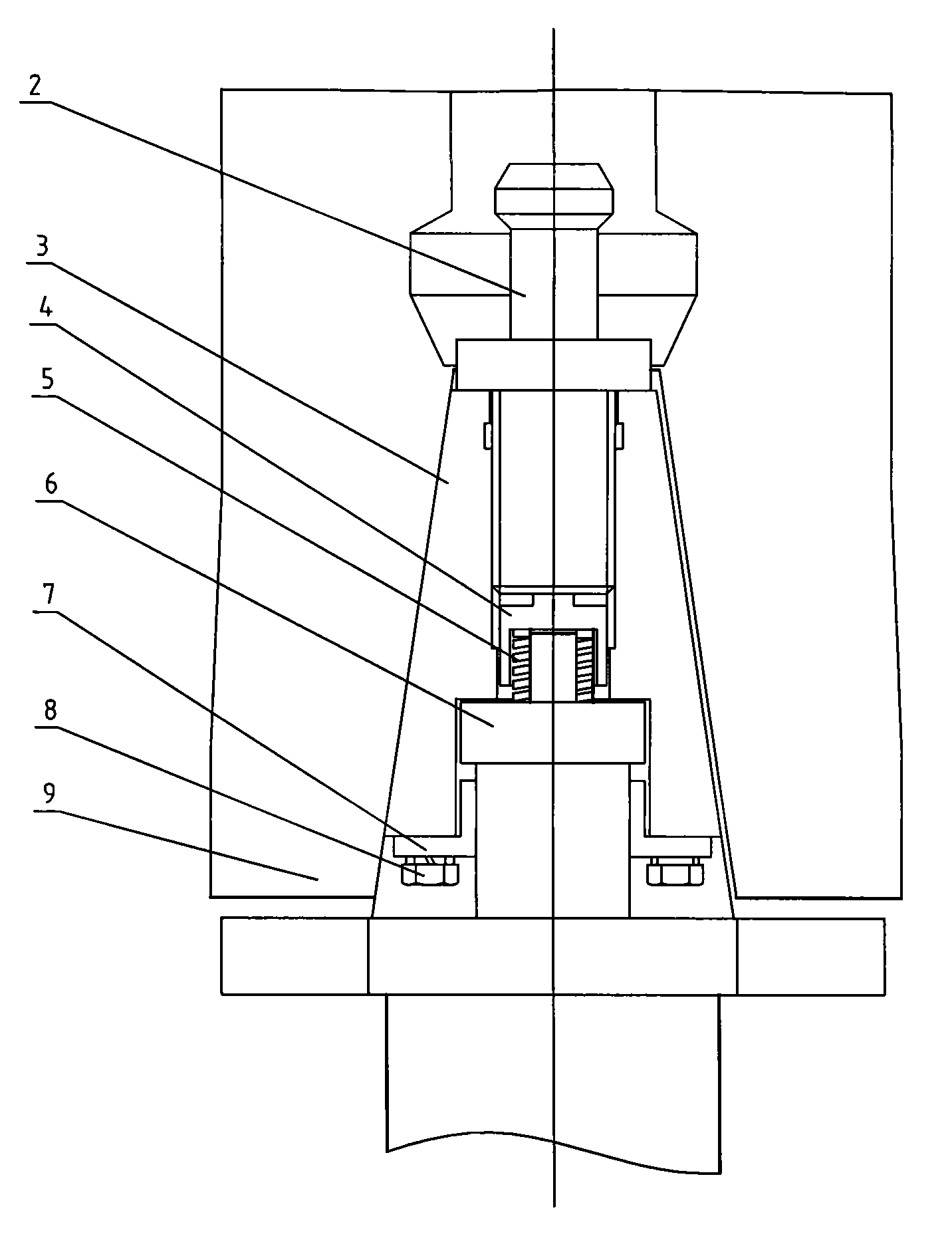

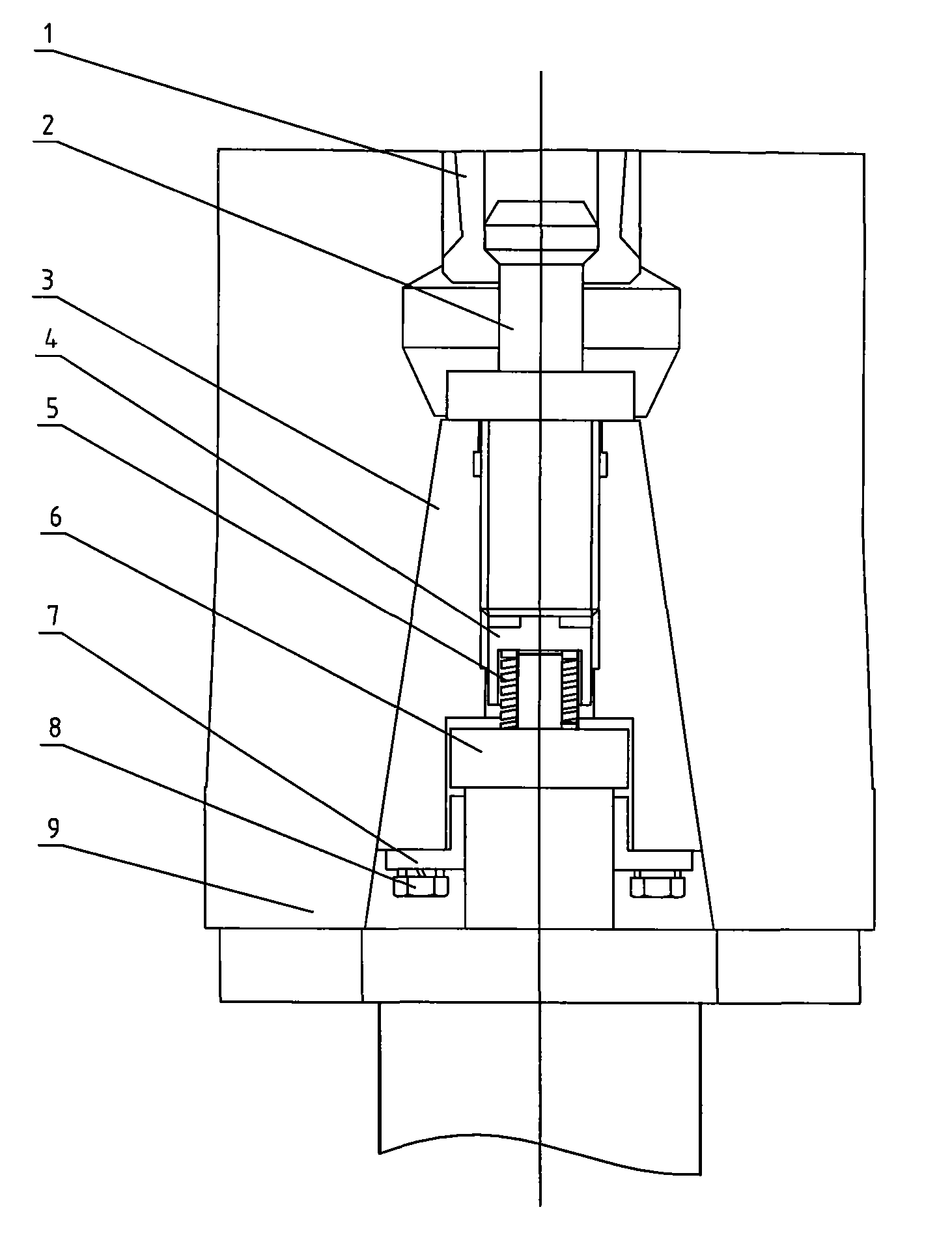

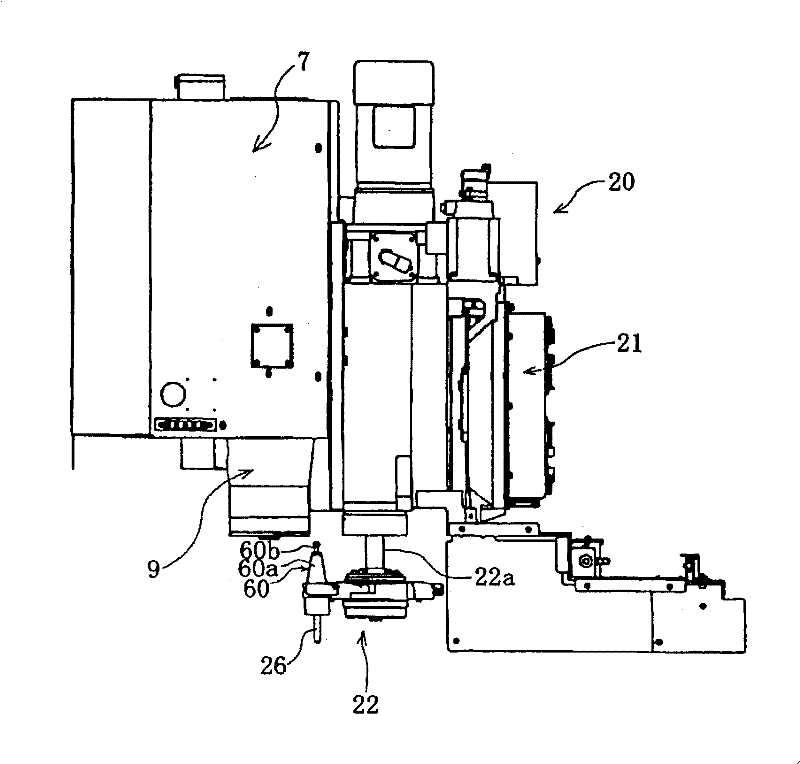

Installing structure of taper shank with attached cutting head

InactiveCN101559565APrevent looseningAvoid downtimePositioning apparatusMetal-working holdersDrive shaftReplacement - action

The invention relates to an installing structure of a taper shank with an attached cutting head, which is characterized in that: a press cover is fastened and connected at the lower end of the taper shank through a screw, a drive shaft is limited in a cavity formed by the press cover and the taper shank through a boss thereof, installation gap is formed at the connection and installation part of the taper shank and an auxiliary drive shaft; a spring is arranged on a short shaft at the upper end of the drive shaft, and a pull stud is connected with the taper shank through a thread. The installing structure can avoid the situation of shutdown after a sliding pillow of a main shaft receives greater resistance; meanwhile, the spring provides the elastic pre-tightening force for the thread connection part of the pull stud and the taper shank, thereby preventing the situation that a claw of the main shaft can not pull the attached cutting head to the installation position after the pull stud is loose. The installing structure can not only reasonably solve the difficult automatic replacement of the cutting head caused by rigid connection of the taper shank, but also provide the pre-tightening force for the thread connection part, thereby preventing the looseness of the thread of the pull stud, protecting the smooth completion of the replacement action of the attached cutting head of a five-face gantry machining center and simultaneously improving the machining efficiency.

Owner:无锡桥联数控机床有限公司

Monitoring air filter status in automotive HVAC system

ActiveUS9120366B2Low costAvoid weightAir-treating devicesRailway heating/coolingAir filterReplacement - action

A system and methods are provided for monitoring for a clogged or unclogged state of an air filter in an automotive HVAC system. The HVAC system includes a blower having a blower motor providing a driven airflow. A plurality of outlet registers is controllable to provide a plurality of circulation modes. An evaporator selectably cools the driven airflow, and the air filter passes the driven airflow. The method enters a baseline condition, wherein the baseline condition includes applying a moisture purge to the evaporator and selection of a predetermined circulation mode. The blower motor is controlled to maintain a testing speed. An energization of the blower motor is quantified while maintaining the testing speed. The energization is compared to a base value derived according to the baseline condition with the air filter in an unclogged state. A replacement action is triggered when the energization is greater than the base value.

Owner:FORD GLOBAL TECH LLC

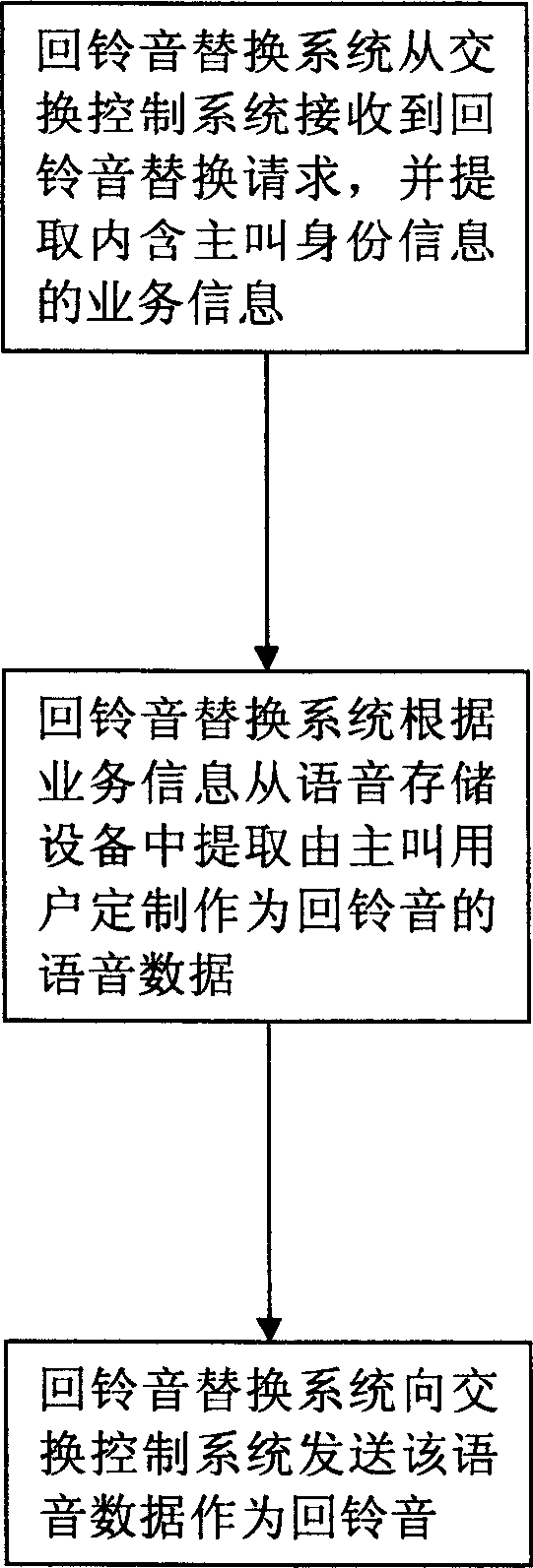

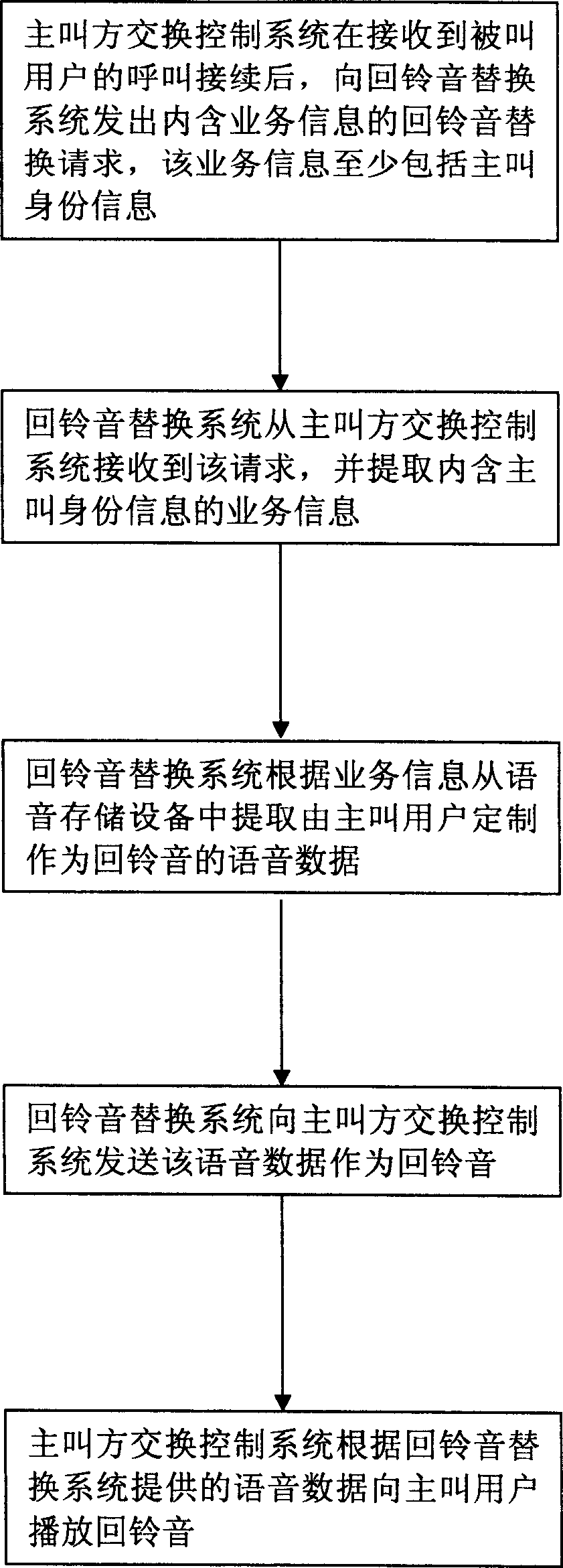

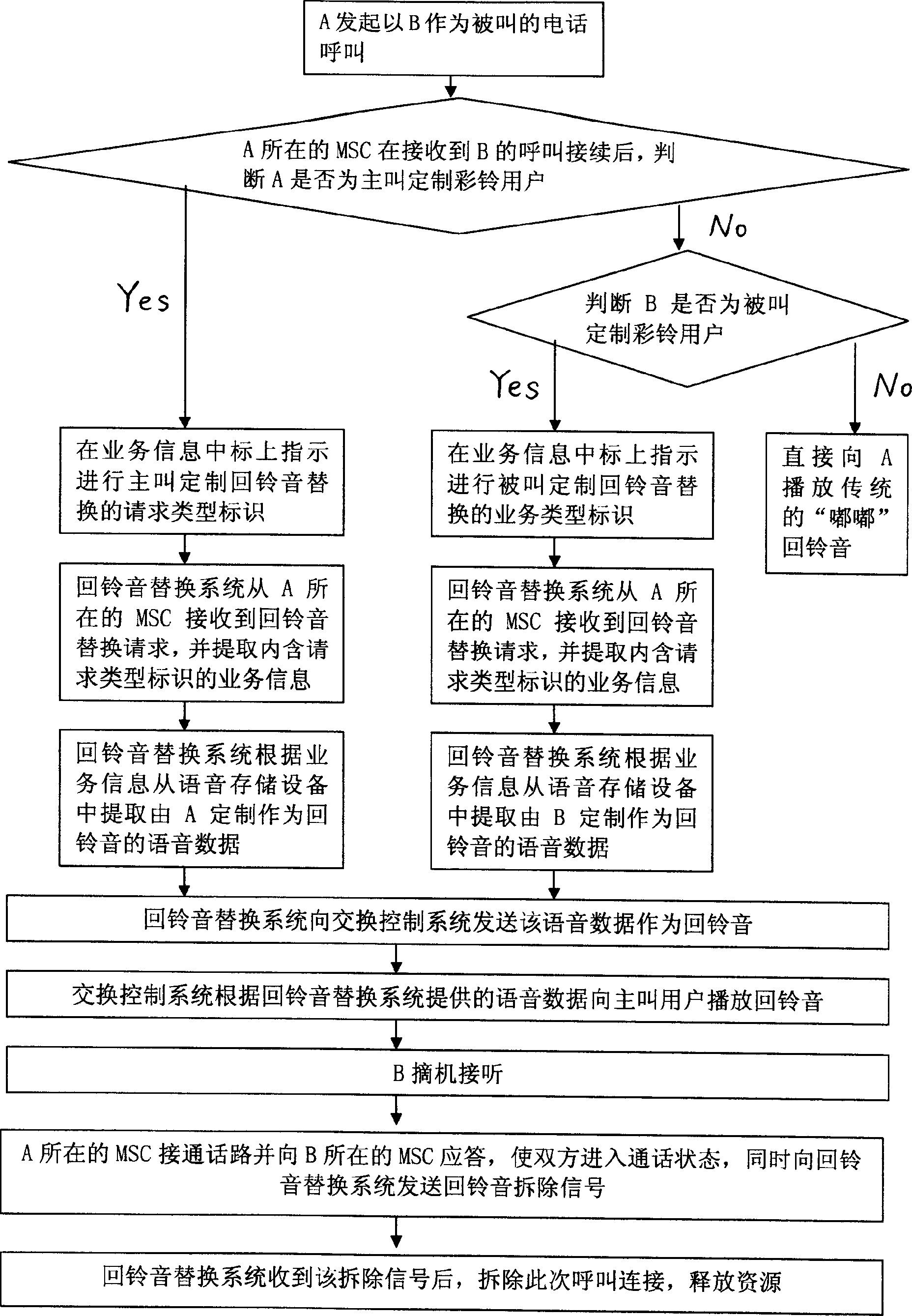

Telephone communication network capable of replacing telephone call ring back tone

It is a kind of telephone communication network that can realize telephone calling back-ring replacement. It comprises switch control system and back-ring replacement system. The back-ring replacement system includes voice storage equipment that stores the back-ring voice data customized by calling user. This back-ring replacement system performs the back-ring replacement action according to the following steps: (1) this system receives the back-ring replacement request from the switch control system, and extracts the business information that contains the calling identification information; (2) this system gets the back-ring voice data that customized by calling user; (3) this system sends this voice data to the switch control system as the back-ring.

Owner:全观友

Instrument machine tool provided with infrared detection unit

ActiveCN105522401AImprove cooling effectEasy to useAutomatic control devicesMeasurement/indication equipmentsInfraredEngineering

The invention provides an instrument machine tool provided with an infrared detection unit. The instrument machine tool comprises a workpiece clamping mechanism and a tool clamping mechanism, wherein an infrared transmitter and an infrared receiver are arranged on two sides of the tool clamping mechanism; the tool clamping mechanism comprises a positioning shaft sleeved with a tool plate, at least two tool movement grooves are formed in the tool plate, and tools are arranged in the tool movement grooves in a penetrating manner; tool pushing mechanisms are arranged in the tool movement grooves and provided with tool locking / automatically unlocking mechanisms, tool returning mechanisms are arranged in the tool movement grooves, and the tool pushing mechanisms provided with sliding guide rail mechanisms and push sliding driving mechanisms; a tool capture mechanism is arranged on the positioning shaft. The instrument machine tool has the beneficial effects as follows: whether a tool is in place or not is detected automatically by the aid of infrared rays, and time and labor are saved; multiple groups of tools are arranged in the tool plate in a hidden manner and are safe to use, various actuating mechanisms for tool replacement are reasonably arranged, and the tool replacement action is stable and smooth.

Owner:林宗升

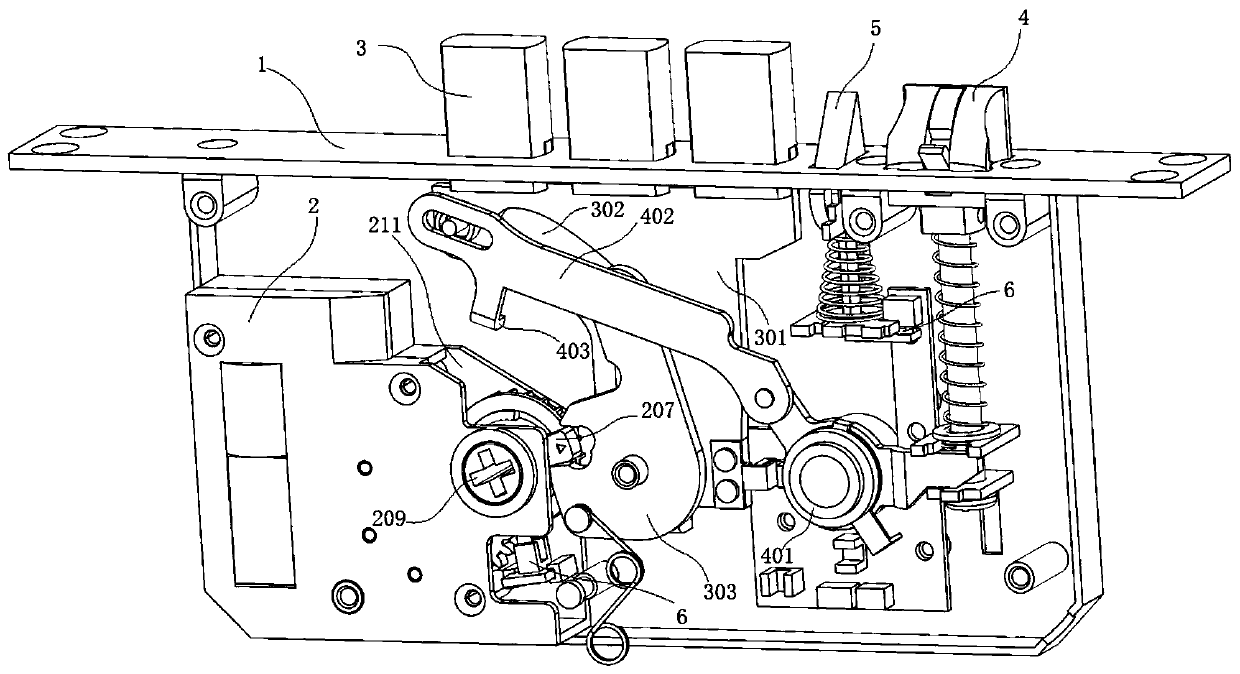

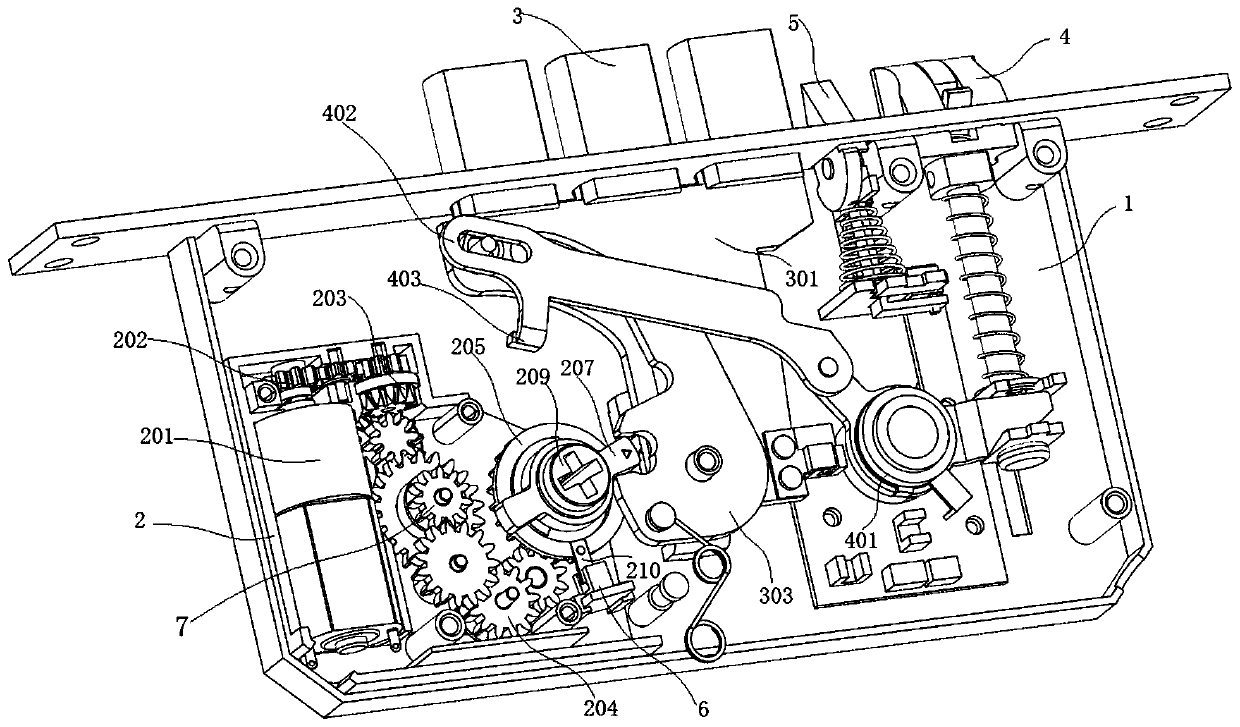

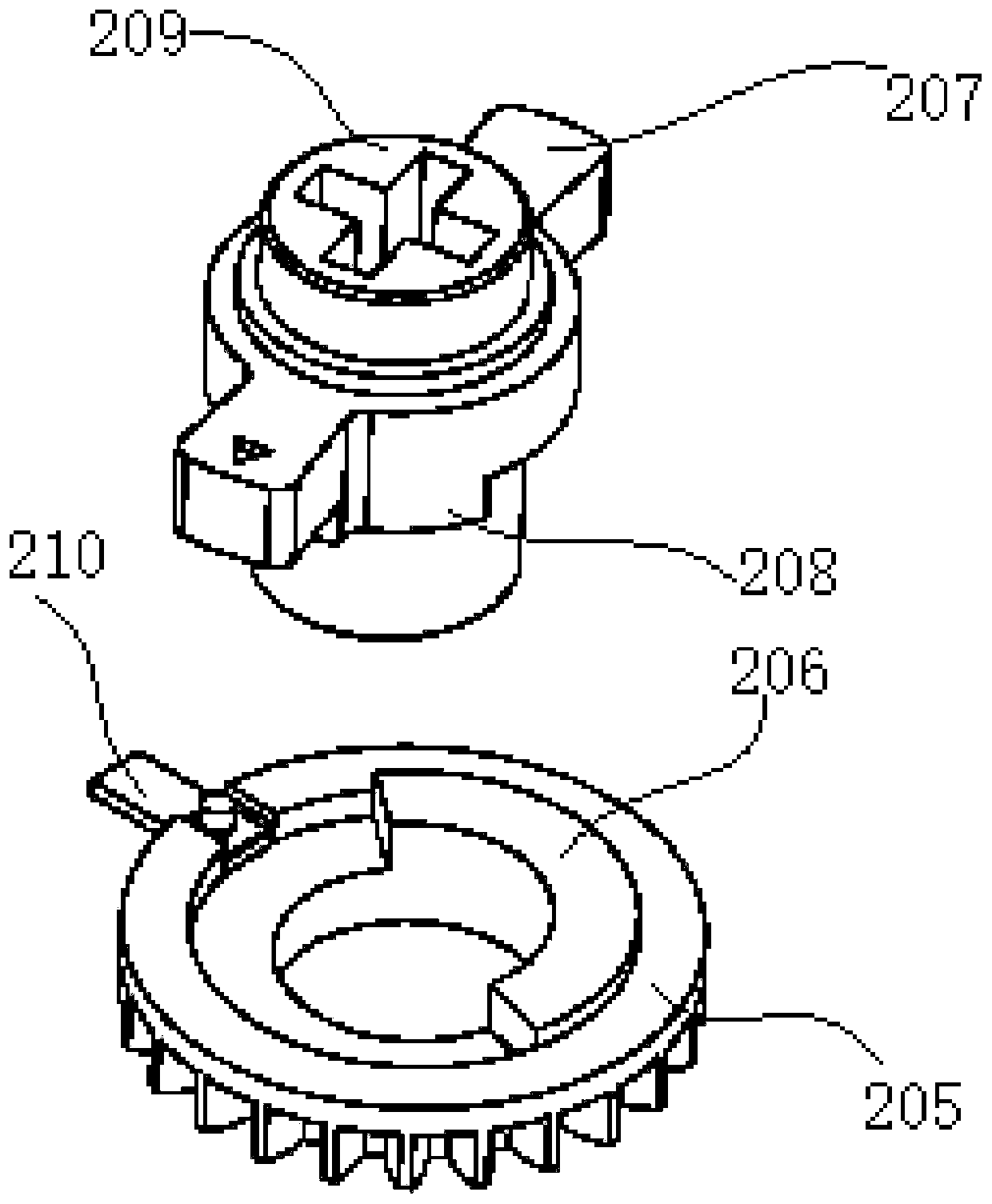

Anti-theft lock with modular drive device

PendingCN110541619AAvoid falling looseImprove maintenance efficiencyNon-mechanical controlsReplacement - actionAnti theft

The invention discloses an anti-theft lock with a modular drive device. The anti-theft lock comprises a lock body and a driving module. A spring bolt and a transmission device are arranged in the lockbody. The transmission device is connected with the spring bolt. The driving module comprises a driving box body and a driving mechanism. The driving box body is arranged in the lock body. A notch isformed in the side, close to the transmission device, of the driving box body. The driving mechanism is fixed in the driving box body. One end of the driving mechanism is exposed in the notch and islinked with the transmission device, so that the driving device drives the transmission device to eject the spring bolt out of the lock body or withdraw the spring bolt into the lock body. According to the anti-theft lock with the modular drive device, a plurality of gears in the driving device are arranged in the box body connected with the lock body, when the gears in the driving device need tobe replaced, only the whole box body needs to be detached from the lock body, the replacement action can be completed by replacing the box body with a new box body internally provided with driving gears, the situation that gears are scattered and fall off is avoided, the maintenance efficiency of the lock body is improved, and the stability and reliability of the lock body can be improved.

Owner:广东好太太智能家居有限公司

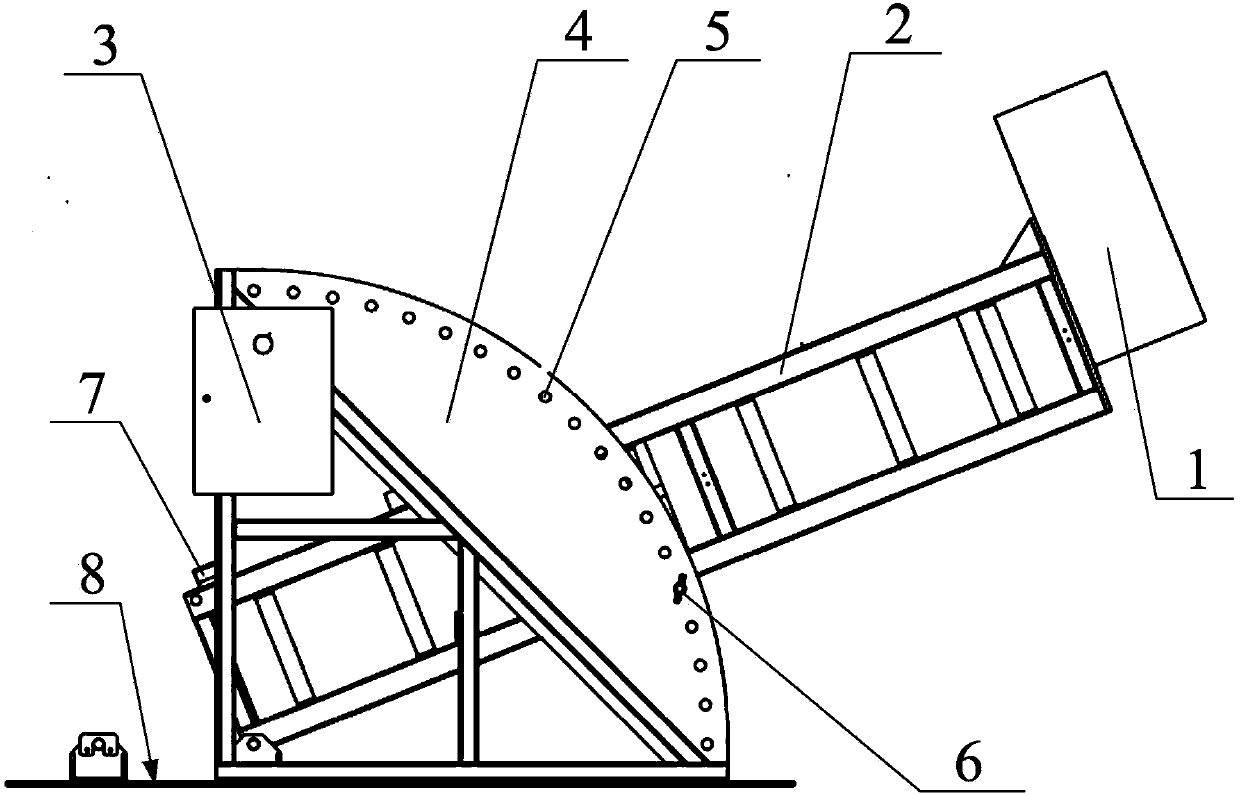

Battery shock testing table

ActiveCN104198150ARealize impact testGuaranteed impact resistanceShock testingElectrical batterySimulation

The invention discloses a battery shock testing table. During use, the distance between the testing table and the ground is adjusted by rotating a travel support and specifically is adjusted by matching of a travel switch and limit holes. The travel switch can be a bolt, and the bolt is inserted into the limit holes at different positions to fix and position the travel support. Meanwhile, when the travel support triggers a limit switch, the travel support cannot rotate continuously; a connecting rope is driven to pull up the battery by a certain height via the lifting device, a clutch is instantly separated from a battery, the battery freely falls off, and battery replacement action of an electric vehicle is simulated, shock test on the battery is realized, and shock resistance of the battery is guaranteed.

Owner:STATE GRID CORP OF CHINA +2

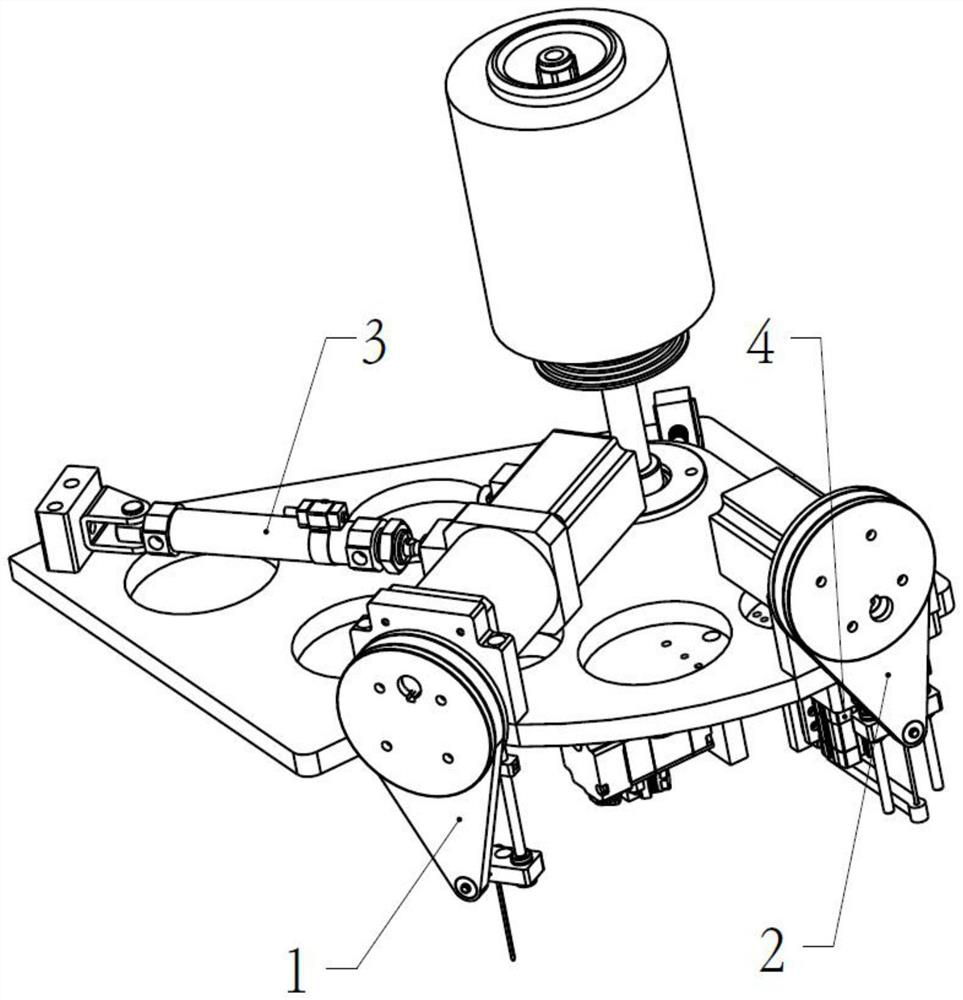

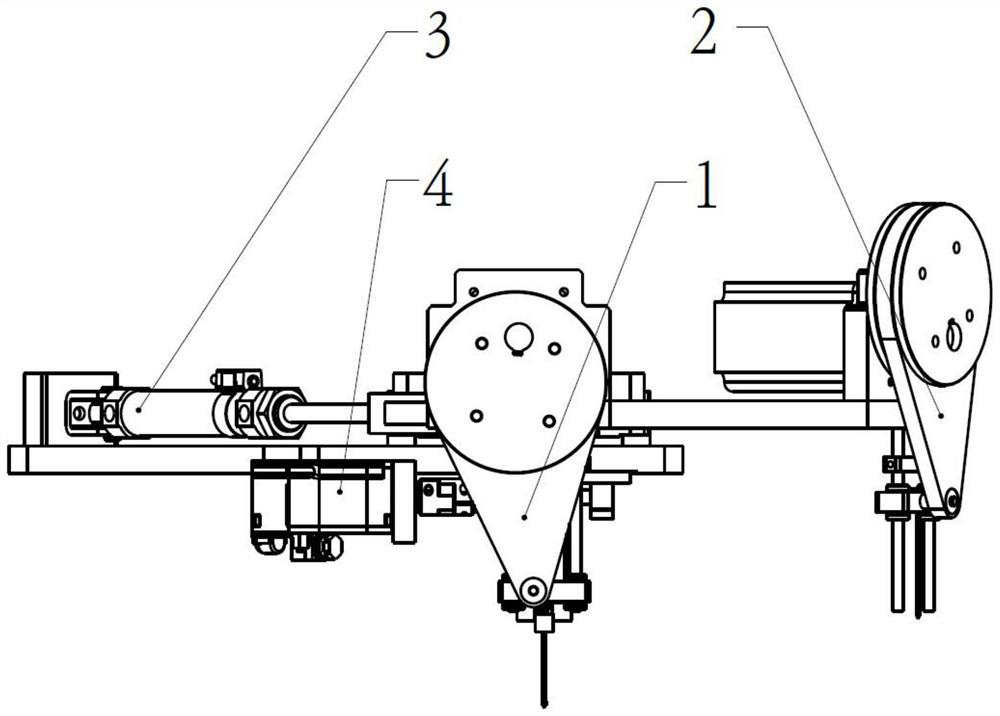

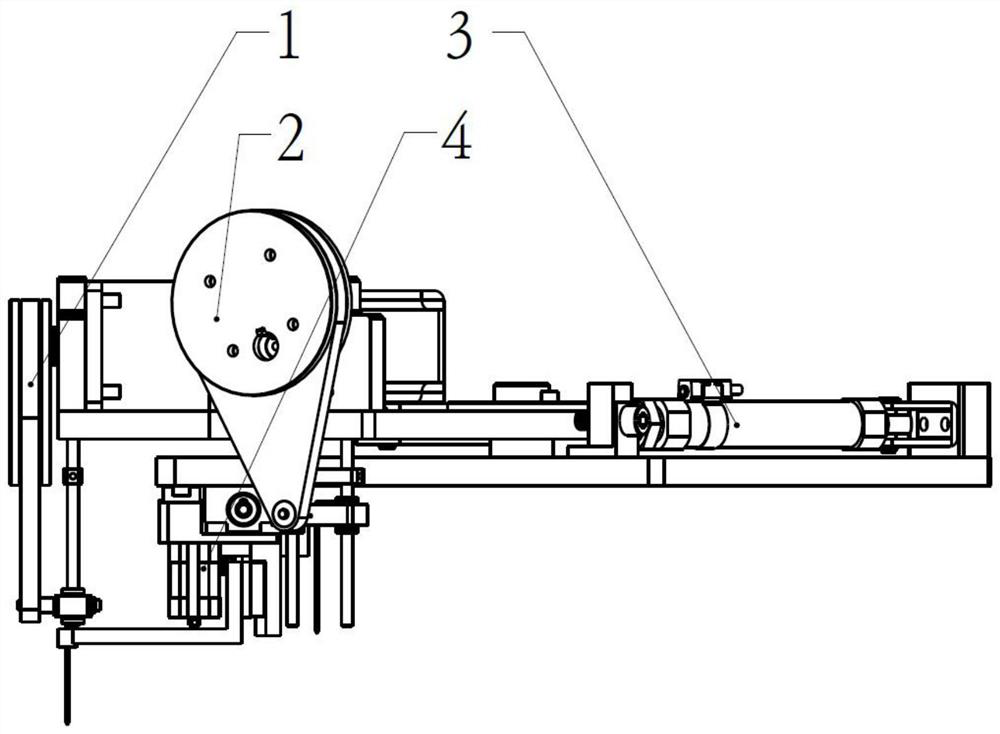

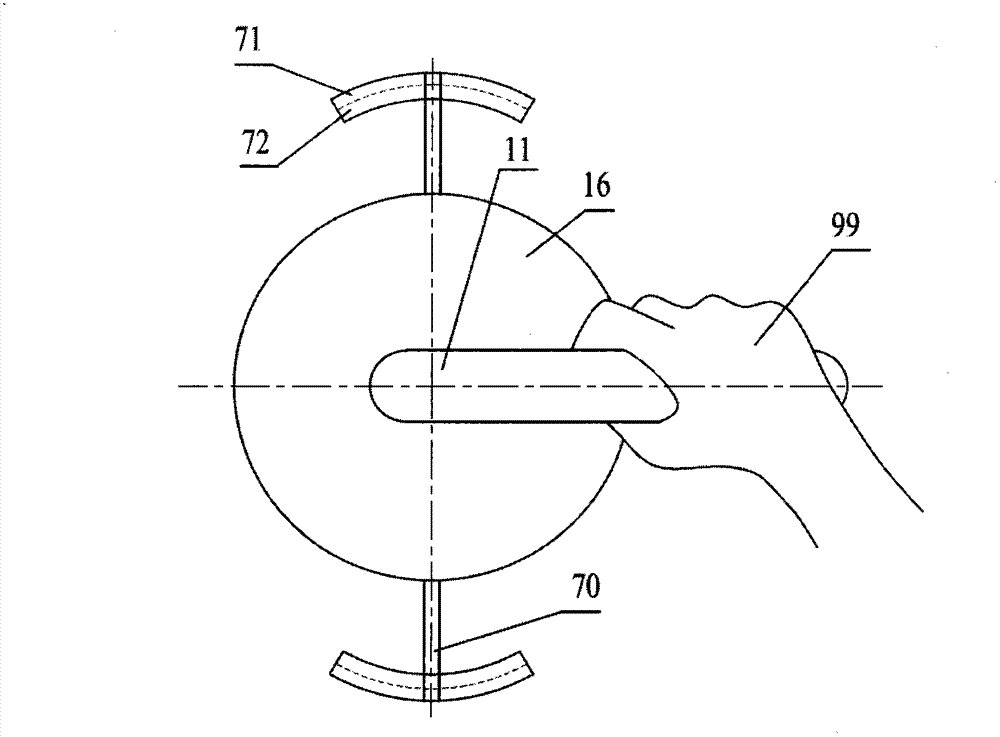

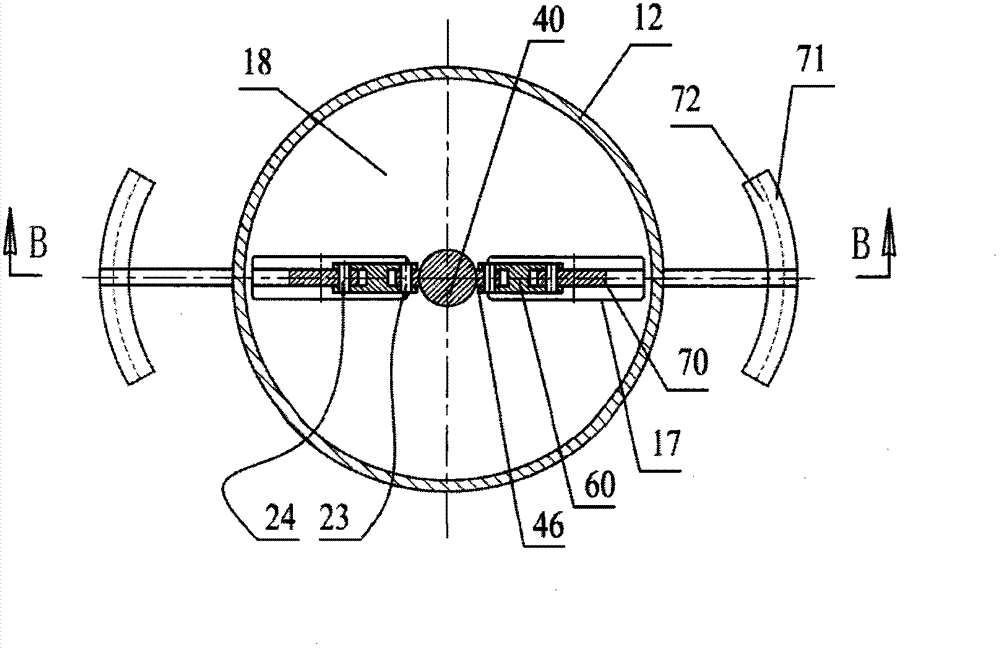

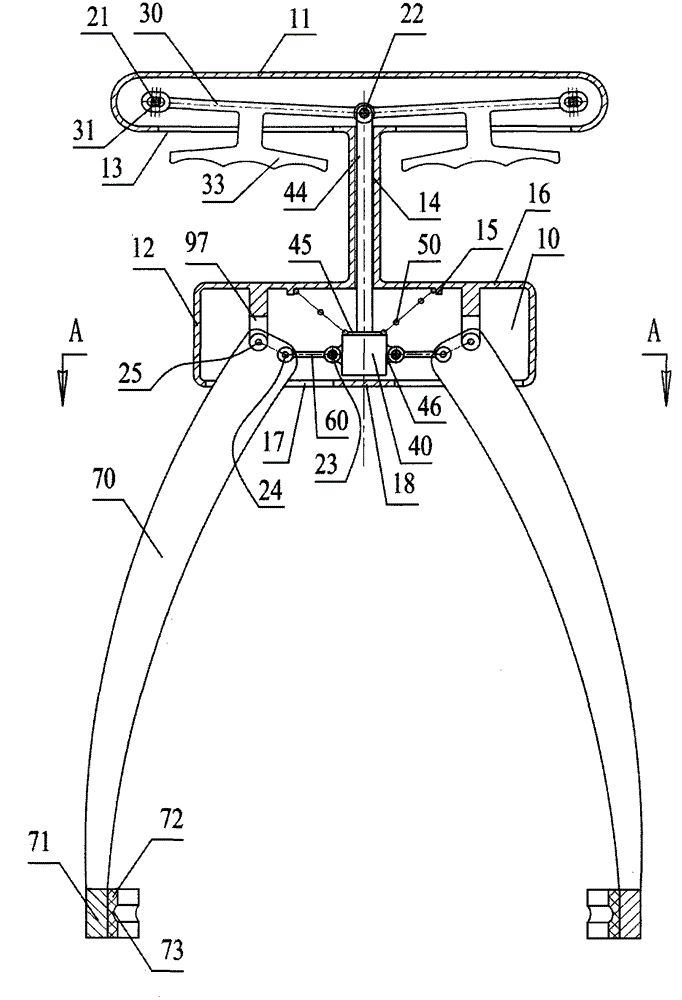

Sandwich structure composite material preform sewing head with pre-puncturing function

ActiveCN111705440AStitched securelyReduce frictionPressersThread-break detectorsCircular discBall screw

The invention discloses a sandwich structure composite material preform sewing head with a pre-puncturing function, and belongs to the technical field of sewing devices. The sandwich structure composite material preform sewing head comprises a pre-puncturing mechanism, a sewing mechanism, a swinging mechanism and a presser foot mechanism, wherein the pre-puncturing mechanism drives a pre-puncturing crank disc to drive a pre-puncturing needle to realize pre-puncturing action by virtue of a servo motor and a speed reducer; the sewing mechanism drives a sewing crank disc to drive a sewing needleto realize sewing action by virtue of a servo motor; the pre-puncturing mechanism and the sewing mechanism are mounted on a swinging plate; the swinging mechanism pushes the swinging plate by virtue of an aluminum tube cylinder to realize replacement action of the pre-puncturing needle and the sewing needle; the presser foot mechanism drives a ball screw by virtue of a servo motor to drive a standard cylinder to horizontally move; and the cylinder drives a presser foot to move up and down. The sandwich structure composite material preform sewing head is compact in structure, realizes automaticsewing of a sandwich structure composite material, and improves production efficiency and product consistency.

Owner:TIANJIN POLYTECHNIC UNIV

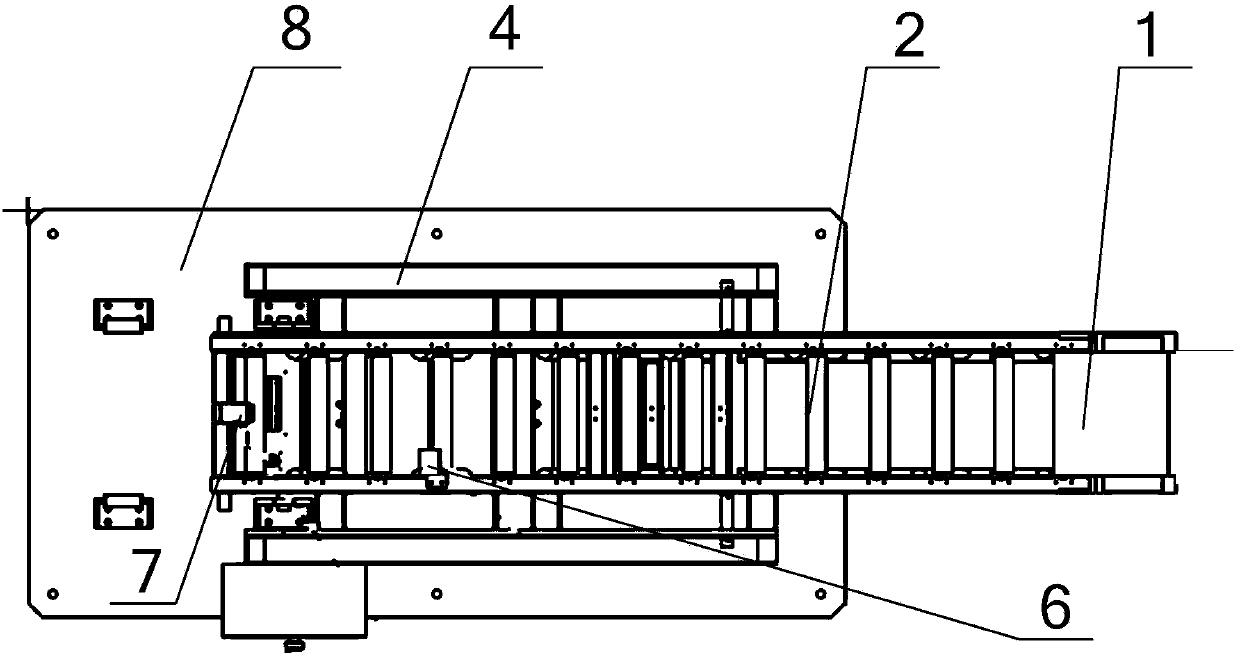

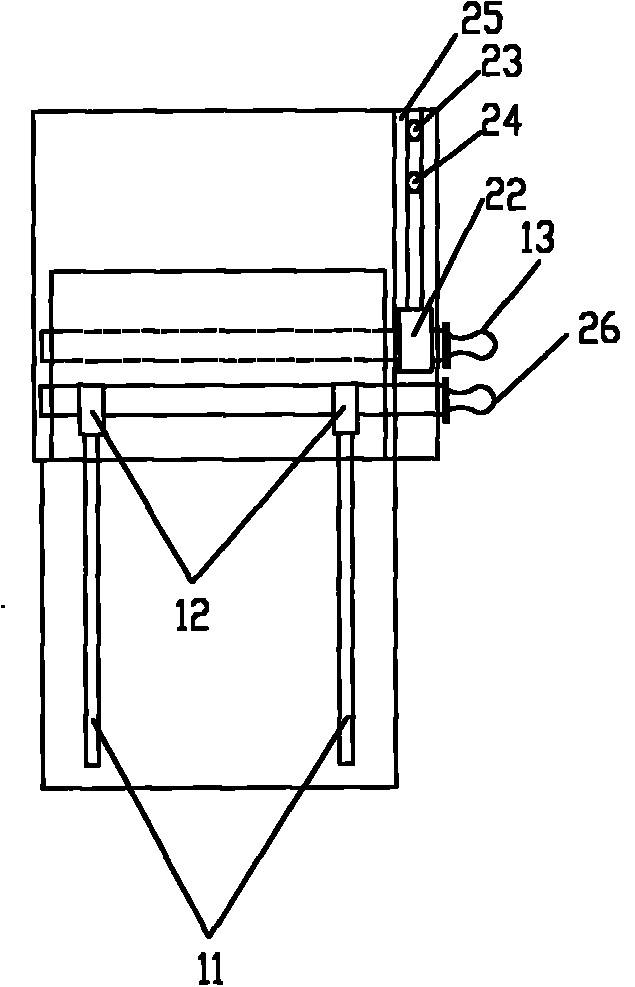

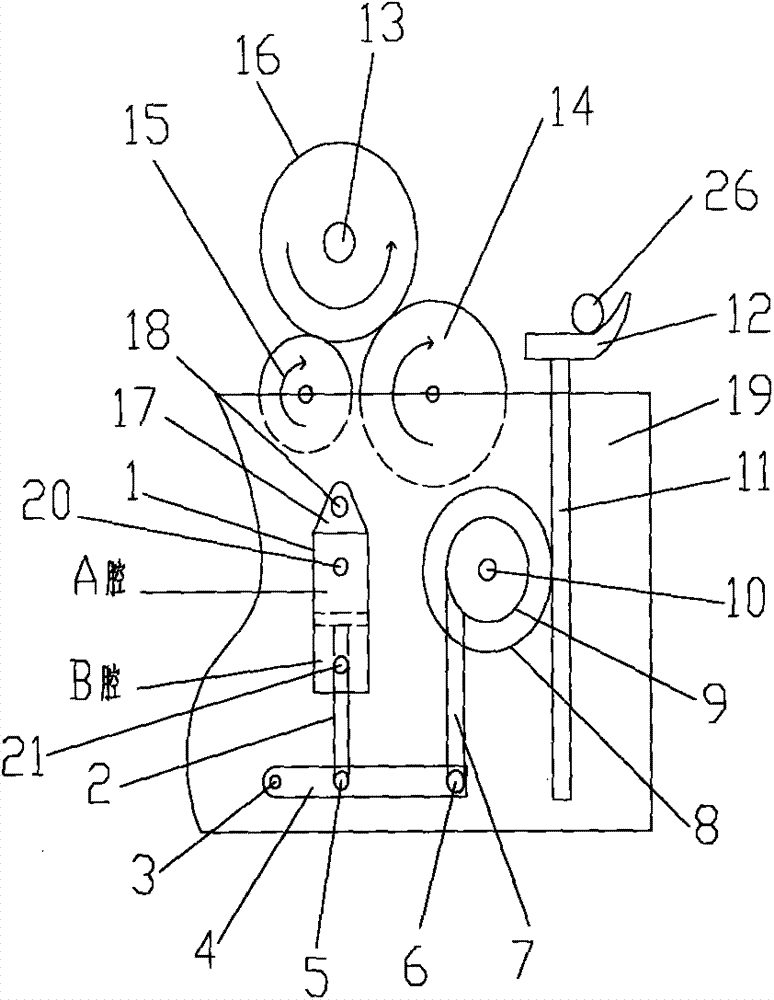

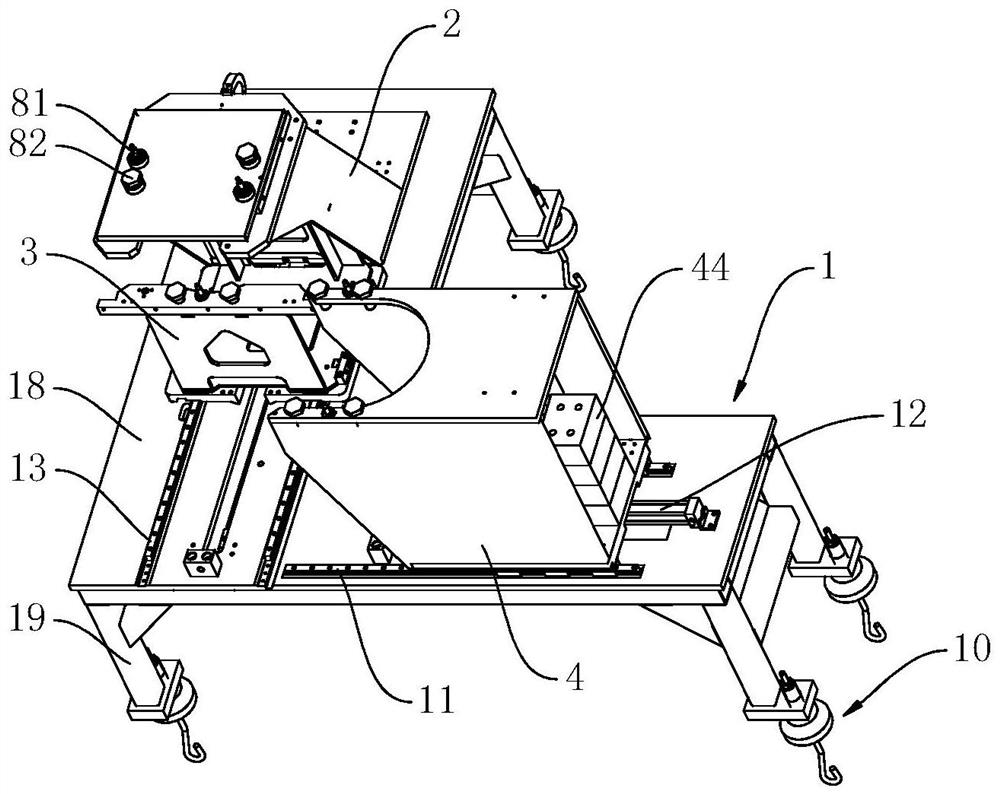

Novel automatic bar replacing device of cotton lapping machine

InactiveCN104724525AAutomatic bar changeChange bars in timeWebs handlingGear wheelReplacement - action

The invention provides an automatic bar replacing device of a cotton lapping machine. A cylinder body of an air cylinder 1 is fixedly mounted on a wallboard 19 of the cotton lapping machine through a mounting seat 17 and a bolt 18, an air cylinder telescopic shaft 2 is connected with a connecting rod 4 through a pin shaft 5, one end of the connecting rod 4 is mounted on the wallboard 19 through a pin shaft 3, the other end of the connecting rod 4 is connected with one end of a chain 7 through a pin shaft 6, the other end of the chain 7 is connected with a chain wheel 9 so as to achieve a meshing function, the chain wheel 9 and a gear 8 are parallelly and axially mounted through a shaft 10 and a key bar which are mounted on the wallboard 19, the chain wheel 9 is close to one side of the wallboard 19, the gear 8 is in meshed connection with a rack 11, the rack 11 is connected with a bracket 12, and sensors 23 and 24 are mounted on a wallboard 25. The automatic bar replacing device has the advantages of capability of achieving automatic and timely bar replacement, accuracy in bar replacement action, safety and stability.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

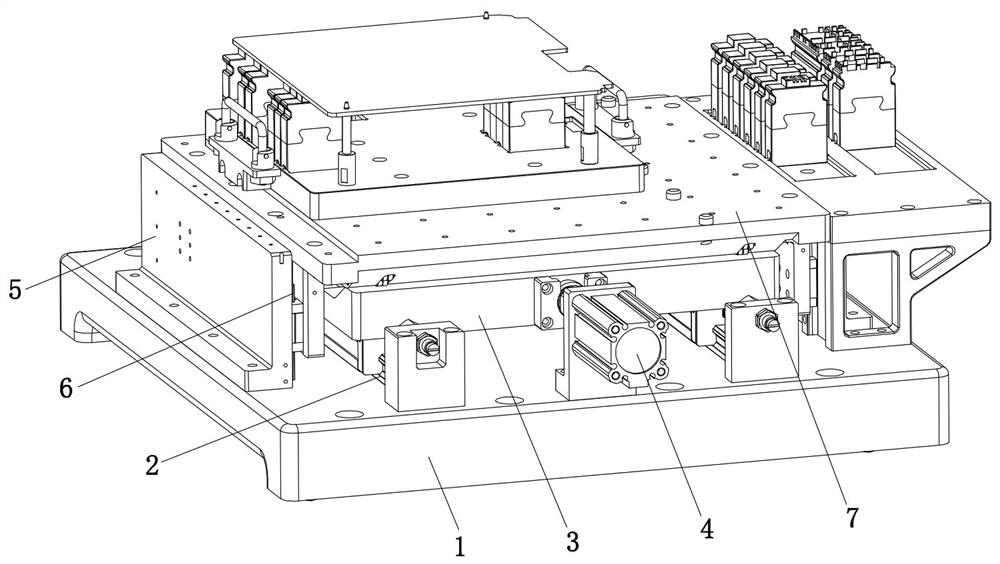

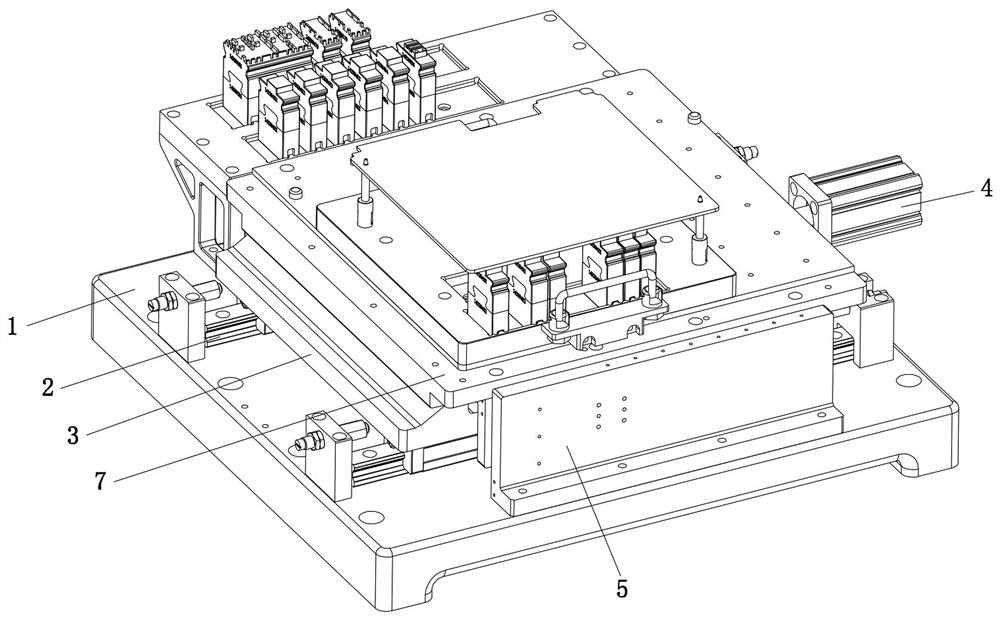

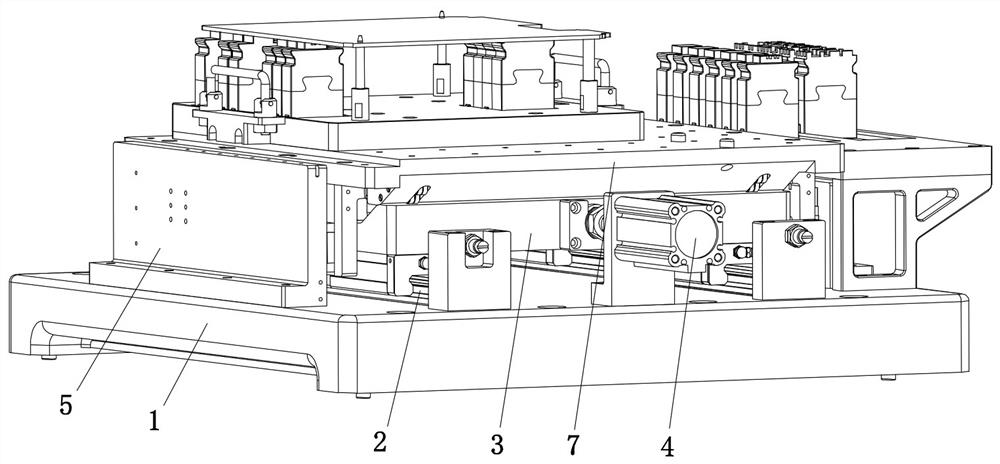

Three-station automatic head library

ActiveCN113798868AImplement position conversionRelatively simple logicFeeding apparatusLarge fixed membersReplacement - actionMachine tool

The invention discloses a three-station automatic head library. The three-station automatic head library comprises a head library base assembly and a head library support assembly, the head library base assembly comprises a bottom plate, an X-direction linear rail, an X-direction oil cylinder, a Y-direction linear rail, a first Y-direction oil cylinder and a second Y-direction oil cylinder, and the head library support assembly comprises a first head library support, a second head library support and a third head library support. The first head library support and the second head library support are installed on the Y-direction linear rail in a sliding manner, the first head library support is connected with a piston rod of the first Y-direction oil cylinder, the second head library support is connected with a piston rod of the second Y-direction oil cylinder, the third head library support is installed on the X-direction linear rail in a sliding manner, and the third head library support is connected with a piston rod of the X-direction oil cylinder. After being installed and debugged, the three-station automatic head library is arranged at one side of a machine tool body. According to the three-station automatic head library, the three-station automatic head replacement action of three different accessory heads in an unmanned state can be realized, and the space between a workbench surface and a machine tool stand column is completely not occupied after the three-station automatic head library is mounted.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

Method for placing inert gas in gas-filling packaging machine

ActiveUS8534032B2Increase replacement rateAvoid stickingPackaging by pressurising/gasifyingEngineeringProduct gas

A filling method including a preceding filling process in which the drop opening of the filling funnel and the forward end of the gas-filling nozzle brought close to the normal line are inserted from the opened bag opening into a package bag, and at the same time, the forward end is separated from the normal line and moved toward a corner of the package bag. The method further includes a following filling process in which inert gas jetted from the gas filling nozzle and air in the package bag are replaced with each other, and a postprocess on the downstream side in which the replacement action between the inert gas and the air is promoted with the bag opening substantially closed by a shutter unit.

Owner:GENERAL PACKER

Installing structure of taper shank with attached cutting head

InactiveCN101559565BPrevent looseningAvoid downtimePositioning apparatusMetal-working holdersDrive shaftReplacement - action

The invention relates to an installing structure of a taper shank with an attached cutting head, which is characterized in that: a press cover is fastened and connected at the lower end of the taper shank through a screw, a drive shaft is limited in a cavity formed by the press cover and the taper shank through a boss thereof, installation gap is formed at the connection and installation part of the taper shank and an auxiliary drive shaft; a spring is arranged on a short shaft at the upper end of the drive shaft, and a pull stud is connected with the taper shank through a thread. The installing structure can avoid the situation of shutdown after a sliding pillow of a main shaft receives greater resistance; meanwhile, the spring provides the elastic pre-tightening force for the thread connection part of the pull stud and the taper shank, thereby preventing the situation that a claw of the main shaft can not pull the attached cutting head to the installation position after the pull studis loose. The installing structure can not only reasonably solve the difficult automatic replacement of the cutting head caused by rigid connection of the taper shank, but also provide the pre-tightening force for the thread connection part, thereby preventing the looseness of the thread of the pull stud, protecting the smooth completion of the replacement action of the attached cutting head of afive-face gantry machining center and simultaneously improving the machining efficiency.

Owner:无锡桥联数控机床有限公司

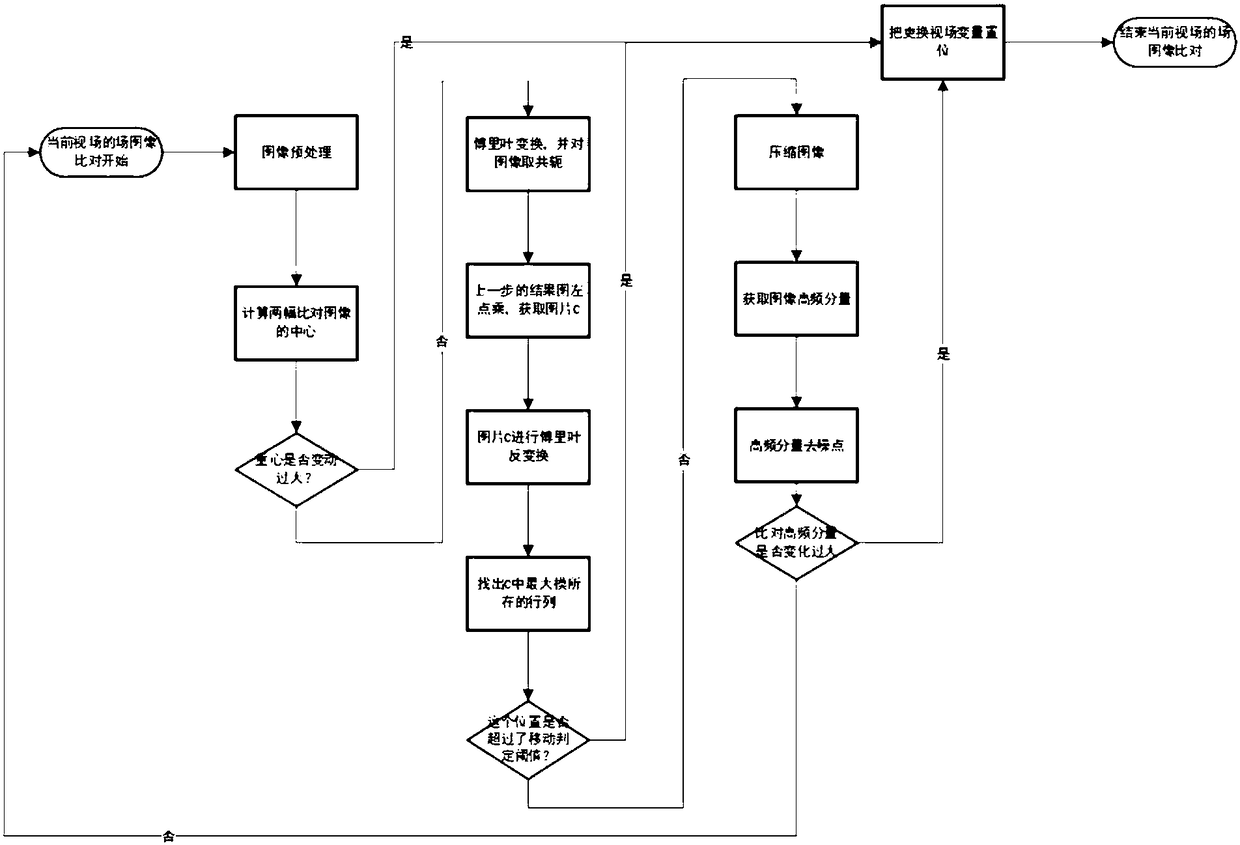

Fiber-measurement non-freezing field-of-view replacement automatic-determination algorithm

ActiveCN108510498AImprove experienceImprove efficiencyImage enhancementImage analysisFiberReplacement - action

The invention provides a fiber-measurement non-freezing field-of-view replacement automatic-determination algorithm. The algorithm includes: step 1, setting a judgment variable, and starting a determination thread, which is used for recording whether image field-of-view contents change, and starting a corresponding processing thread, wherein the changes include changes generated by focusing and changes generated by field-of-view switching or moving; and step 2, starting the determination thread for image field-of-view content change determination after image preprocessing, firstly, adopting center-of-gravity and correlation determination, according to a determination result, determining whether a high-frequency component of a compressed image is used to continue determination, finally, sending a determination result to a main thread, and according to the determination result, deciding whether field-of-view replacement action is executed. Through the algorithm, fiber measurement efficiency can be improved, and repeated measurement can be eliminated.

Owner:BEIJING UNITED VISION TECH

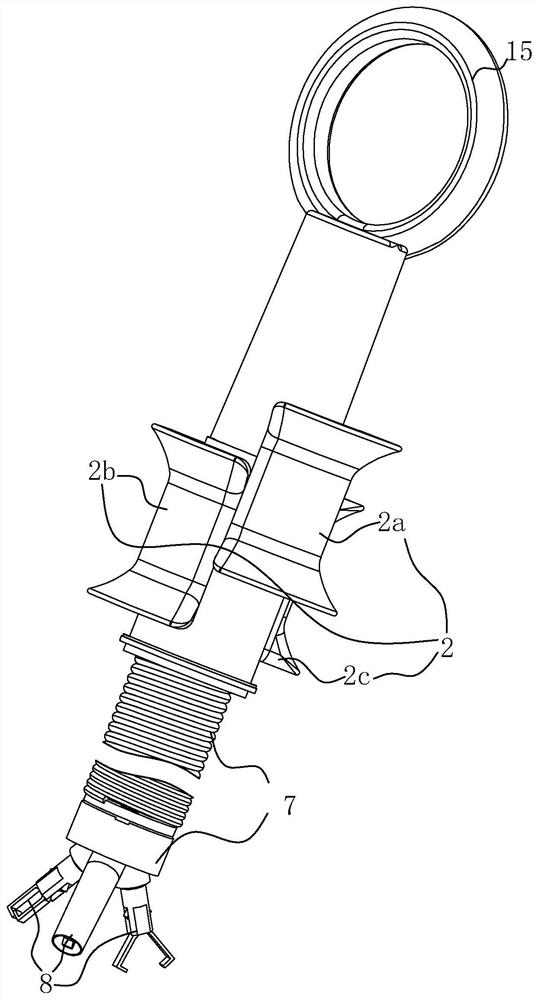

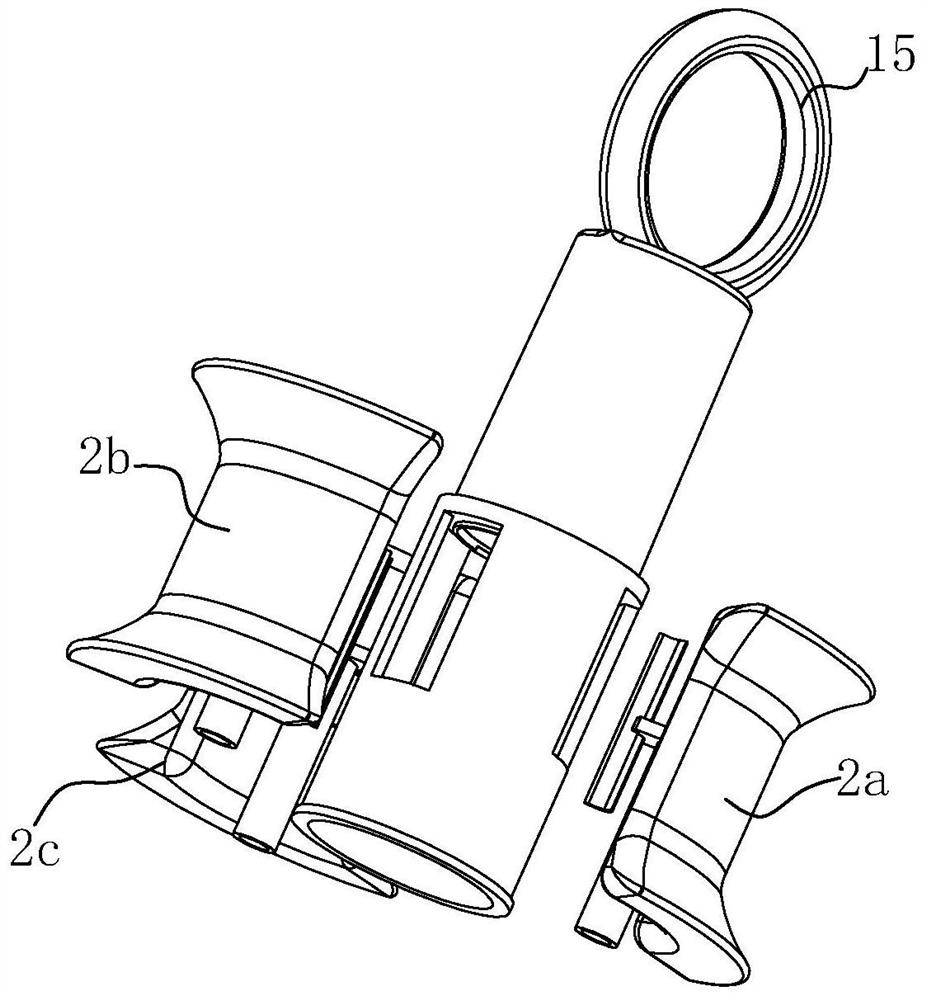

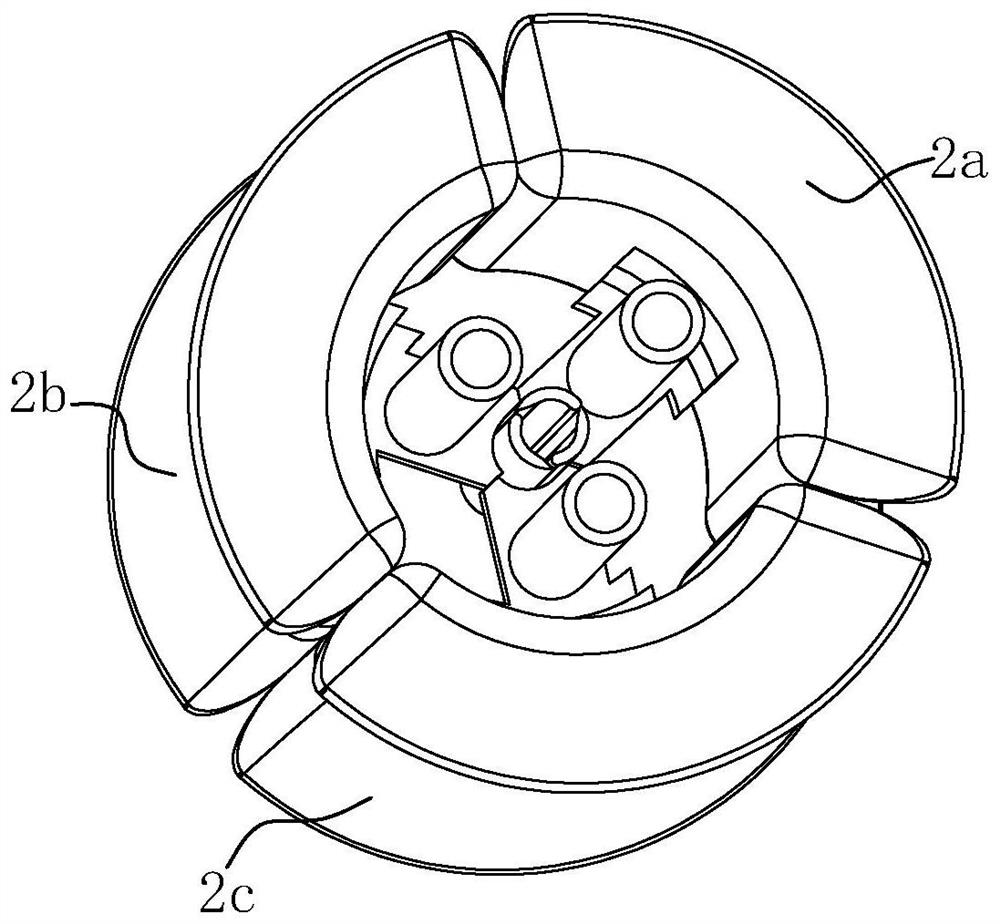

Special single-handle two-jaw grasping forceps

Special single-handle two-jaw grasping forceps comprise a housing and an operating controlling part, wherein two ends of a first cylindrical pin are fixed in boss holes of a hollow handle haft, a long slot hole of a force rod swings and moves laterally within a narrow range relative to the first cylindrical pin, a second cylindrical pin is hinged with a cylindrical splitting pin hole of a vertical cylinder, the force which is acted on a corrugated handle is combined with the conical spring replacement action through a flat circular hole, and the vertical cylinder and an allocation disk are driven to move vertically along the inner hole of a circular pipe. Particularly, two allocation pin seats are arranged on the outer ring of the allocation disk symmetrically, holes of the allocation pin seats and large connection rod splitting holes of an H-shaped connection rod are hinged through a three cylindrical pin, small connection rod splitting holes and arc jaw connection holes are hinged through a fourth cylindrical pin, arc jaw supporting seat holes and hanging pin holes are hinged through a fifth cylindrical pin, two arc jaws which are arranged symmetrically are controlled flexibly, synchronous swinging is achieved, and smooth fragile articles can be taken out from high-temperature environment through single-hand operation.

Owner:中国化学工程第四建设有限公司

A multi-head hemostatic clip that is convenient for shifting operation

The invention relates to a hemostatic clip and a multi-head hemostatic clip that is convenient for shifting operation, comprising an inner cylinder and a sheath tube, the inner cylinder is covered with a movable sleeve, the inner cylinder is hollow, and the wall of the inner cylinder is provided with a groove along the length direction. The chute, the inner wall of the moving sleeve is provided with a slider, the slider is set in the chute, the moving sleeve can move relative to the inner cylinder through the slider and the chute; a rotating mechanism is arranged between the inner cylinder and the sheath, and the rotation The mechanism pulls and controls different operating rods by rotating and adjusting the pulling mechanism, and after the operating ends of several operating rods pass through the sheath tube, several hemostatic clips are connected. The present invention can use the same operating handle to control a plurality of different operating levers respectively, eliminating the need for taking out and inserting different surgical instruments during endoscopic surgery, saving time for instrument replacement during endoscopic surgery, and reducing the operating time for patients. body burden.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

Quick bearing device for high-pressure occasion

InactiveCN114727511AReduce replacement actionsSolve and optimize automatic replacement issuesPrinted circuit assemblingCircuit board tools positioningStructural engineeringReplacement - action

The invention discloses a quick bearing device for a high-pressure occasion, which comprises a base, a side pushing assembly, a sliding lower seat, a support, a sliding upper seat and a sliding supporting assembly, and the base is horizontally arranged; the sliding lower seat is horizontally arranged on the base in a sliding manner; the side pushing assembly is arranged on one side of the base and connected with the sliding lower base. The number of the supports is two, and the two supports are vertically arranged on the two sides of the base in parallel. The sliding upper seat is arranged between the two supports and connected to the supports in a sliding mode in the vertical direction. The sliding supporting assembly is arranged on the upper portion of the sliding lower base and the lower portion of the sliding upper base. The sliding supporting assembly is connected with the sliding lower base and the sliding upper base. When the sliding lower base slides horizontally, horizontal thrust is converted into jacking force through the sliding supporting assembly. Automatic jacking, supporting and limiting effects on the bottom die are achieved through transverse thrust, the high bearing function is achieved, the equipment structure is simplified, the bottom die replacement action is reduced, and the replacement efficiency is improved.

Owner:中山市兴禾自动化有限公司

A direct-drive CNC gear hobbing tool holder

ActiveCN104070245BGuaranteed installation accuracyReliable actionGear-cutting machinesGear teethNumerical controlHobbing

The invention discloses a direct-drive type numerical control hobbing cutter frame. The direct-drive type numerical control hobbing cutter frame comprises a cutter frame body, a cutter frame sliding plate, a cutter frame main shaft assembly, a cutter rod assembly, a cutter frame auxiliary supporting assembly and a channeling cutter assembly; the cutter frame body comprises a cutter frame main body; the cutter frame sliding plate comprises a sliding plate body; the sliding plate body and the channeling cutter assembly are arranged on the cutter frame main body; the left side of the upper half portion of the sliding plate body is provided with a semicircular support and the right side of the upper half portion of the sliding plate body is provided with a cutter frame main shaft installing hole; the cutter frame auxiliary supporting assembly is arranged on the semicircular support; the cutter frame main shaft assembly is partially arranged in the cutter frame main shaft installing hole; one end of the cutter rod assembly is connected with the cutter frame main shaft assembly and the other end of the cutter rod assembly is connected with the cutter frame auxiliary supporting assembly; the cutter frame auxiliary supporting assembly is arranged on the semicircular support of the sliding plate and is opposite to the cutter frame main shaft assembly. The direct-drive type numerical control hobbing cutter frame is short in cutter replacement time, stable and reliable in cutter replacement action, high in rotating and machining accuracy and simple and compact in structure.

Owner:ZHEJIANG RICHUANG MECHANICAL & ELECTRICAL TECH

Special dual-handle three-jaw grasping forceps

Special dual-handle three-jaw grasping forceps comprise a housing and an operating controlling part, wherein two ends of a first cylindrical pin are fixed in boss holes of a hollow handle haft, a long slot hole of a force rod swings and moves laterally within a narrow range relative to the first cylindrical pin, a second cylindrical pin is hinged with a cylindrical splitting pin hole of a vertical cylinder, the force which is acted on a corrugated handle is combined with the conical spring replacement action through a flat circular hole, and the vertical cylinder and an allocation disk are driven to move vertically along the inner hole of a circular pipe. Particularly, three allocation pin seats are arranged on the outer ring of the allocation disk symmetrically, holes of the allocation pin seats and large connection rod splitting holes of an H-shaped connection rod are hinged through a three cylindrical pin, small connection rod splitting holes and arc jaw connection holes are hinged through a fourth cylindrical pin, arc jaw supporting seat holes and hanging pin holes are hinged through a fifth cylindrical pin, three arc jaws which are arranged symmetrically are controlled flexibly, synchronous swinging is achieved, and smooth fragile articles can be taken out from high-temperature environment through bi-hand operation.

Owner:ZHEJIANG QIANJIANG MOTORCYCLE

Machine tool

ActiveCN101549466BMeasurement/indication equipmentsPositioning apparatusEngineeringReplacement - action

A machine tool stores the time for determining the clogging status of the filter. A control device performs tool replacement to the tool replacement device for a longer time only if the pass time is long from the stored time of the time storing section. A pressure difference detecting sensor accurately detects the fore-and-after pressure difference of the filter in the longer replacement time. A judgement section accurately determines the clogging of the filter based on the exact pressure difference detected by the pressure difference detecting sensor. The longer replacement action of the toolreplacement device is performed only after a preset-time is passed after the last clogging judgement has been performed. The production efficiency of the machine tool is scarcely declined.

Owner:BROTHER KOGYO KK

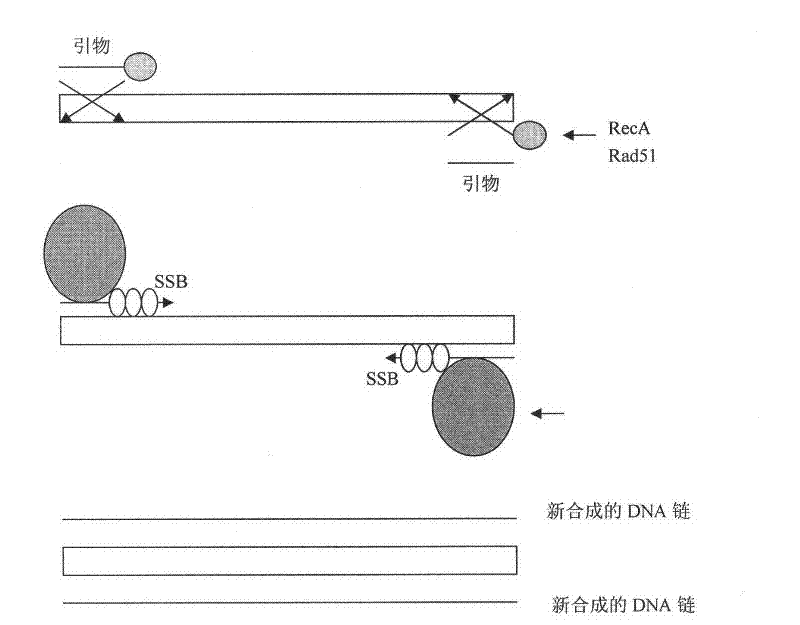

Reactive reagent of nucleic acid amplification by chain replacement at room temperature and nucleic acid amplification method at room temperature thereof

ActiveCN101712973BAvoid cross contaminationSimple and fast responseMicrobiological testing/measurementMicroorganism based processesPolyethylene glycolPotassium

The invention discloses a reactive reagent of nucleic acid amplification by chain replacement at room temperature, belonging to the field of molecular biology and comprising the following components: Tricine buffer solution, potassium chloride, magnesium chloride, dithiothreitol, polyethylene glycol (PEG), ATP, dNTPs, phosphocreatine, a primer pair, SSB protein, colon bacillus RecA protein, yeastRad 51 protein and Bsu DNA polymerase. The invention also discloses a nucleic acid amplification method at room temperature. The nucleic acid amplification of high sensitivity for non-instrument dependent single or multi-sequence single tube type amplification is realized at the room temperature under the chain replacement action of the yeast Rad 51 protein and the colon bacillus RecA protein. The method is used for realizing efficient nucleic acid amplification by the chain replacement under the condition of room temperature, has less use time and simple operation, and omits a traditional heat circulation by a PCR. The technique is also suitably applied to non-laboratory detecting places with a large number of samples.

Owner:程奇 +1

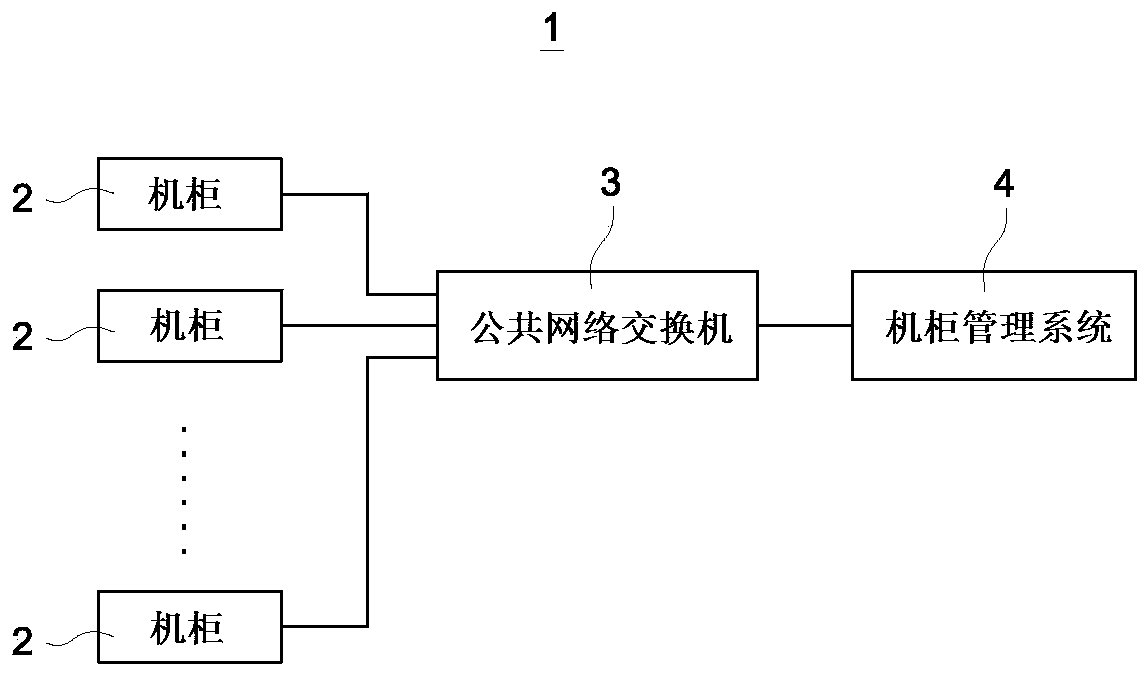

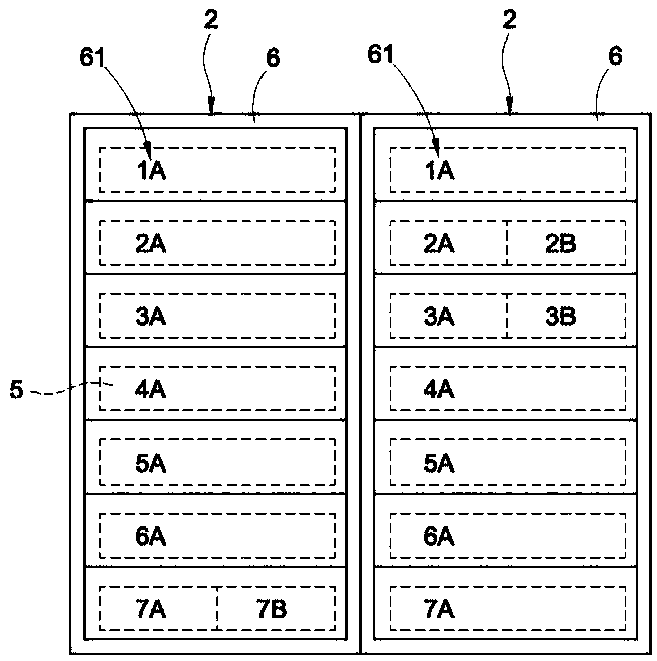

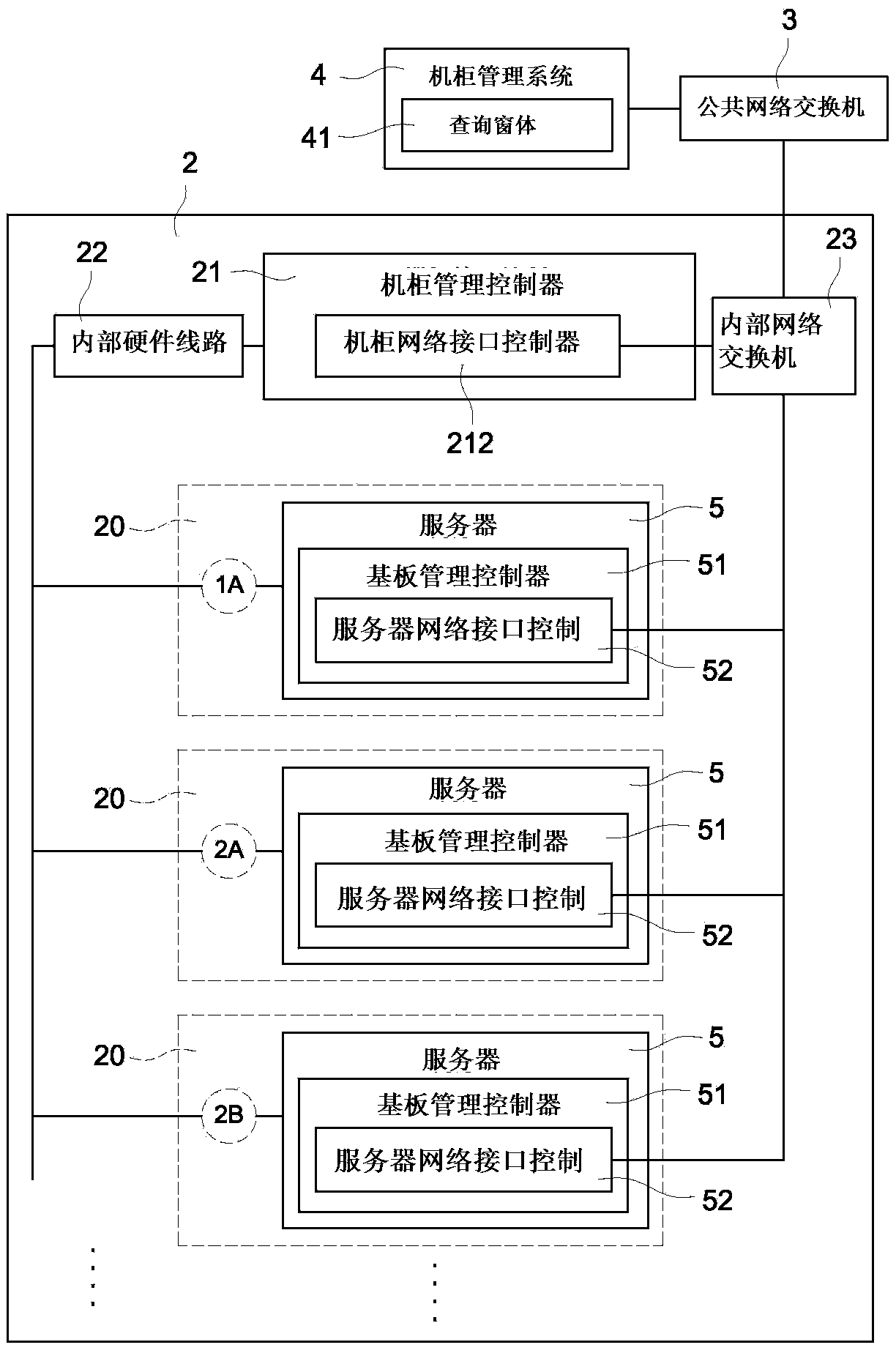

Intelligent cabinet and network protocol address management method thereof

InactiveCN109889615AReduce workloadAvoid the risk of human errorSupport structure mountingTransmissionNetworking protocolData center

The invention discloses an intelligent cabinet and a network protocol address management method thereof. The intelligent cabinet comprises a cabinet management system, a cabinet management controller,an internal hardware line, a plurality of server slots and servers arranged in the server slots, and the cabinet management controller is connected with substrate management controllers of the servers arranged in the server slots through the internal hardware line. The cabinet management system judges whether any server is replaced or not by means of a cabinet management controller and a group ofinternal hardware circuits, and determines a target server slot of a replacement action when judging that the server is replaced. According to the cabinet management system, a network protocol address bound with a target server slot is used for replacing a network protocol address originally used by a substrate management controller of a replaced server, so that the binding effect of the server slot, the server and the network protocol address is maintained. Thus, comprehensive network protocol address management and maintenance of all cabinets and servers in the data center are achieved.

Owner:AIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com