Machine tool

A technology for changing machine tools and tools, applied in the field of machine tools, can solve the problems of prolonging the production efficiency of machine tools and reducing the action time of tool changing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

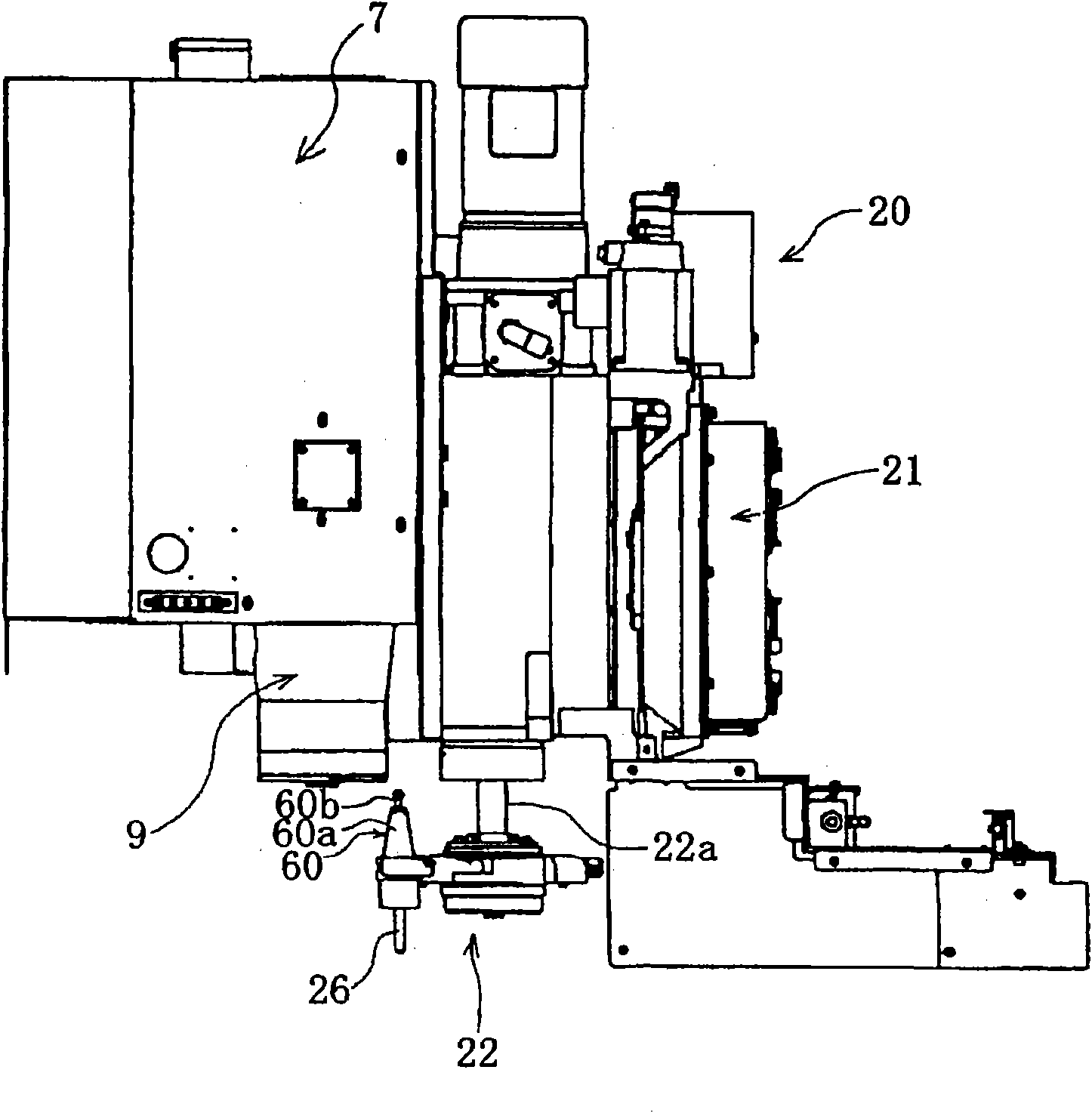

[0026] DETAILED DESCRIPTION OF THE INVENTION The present invention will be described in detail below with reference to the accompanying drawings showing preferred embodiments.

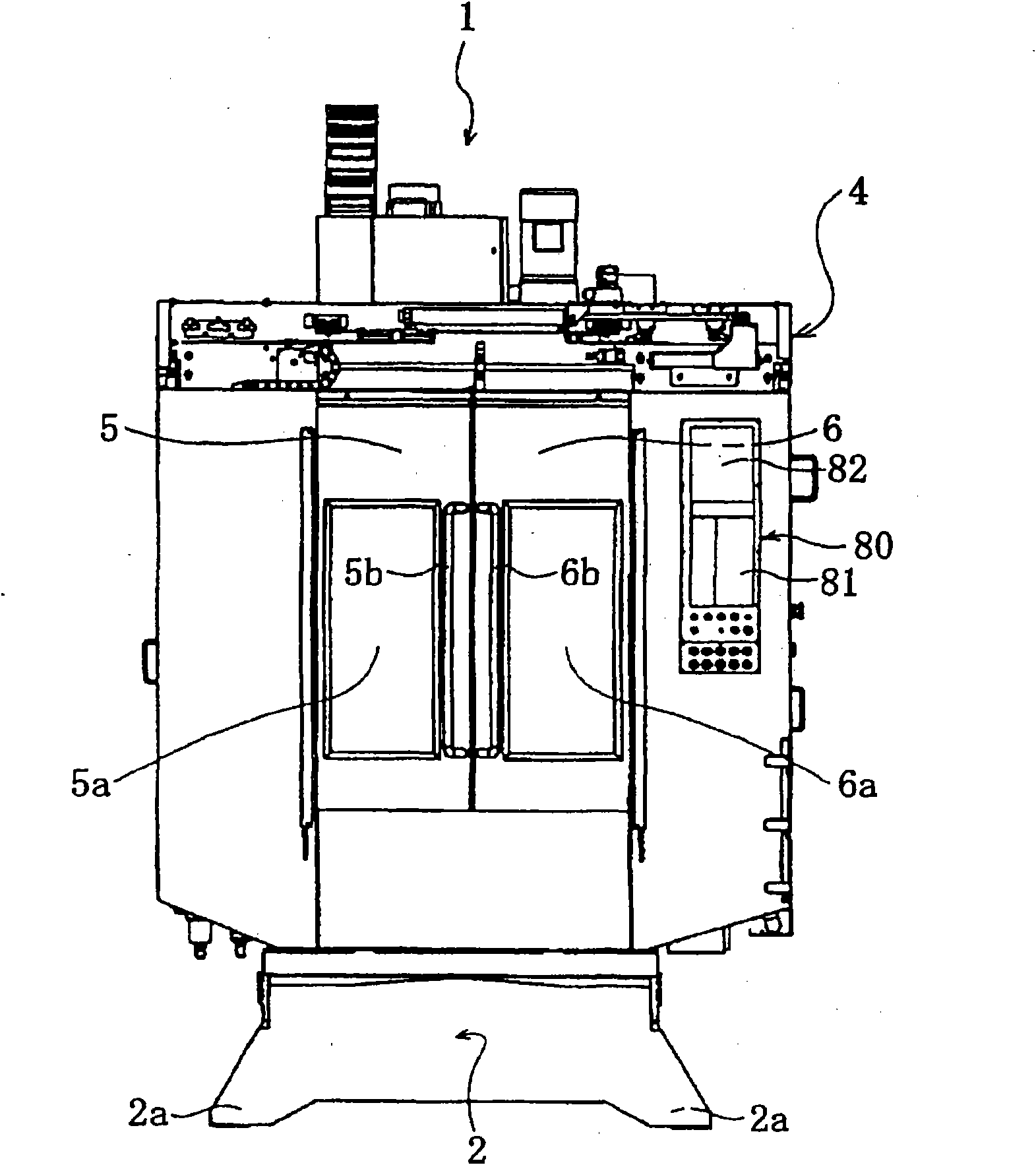

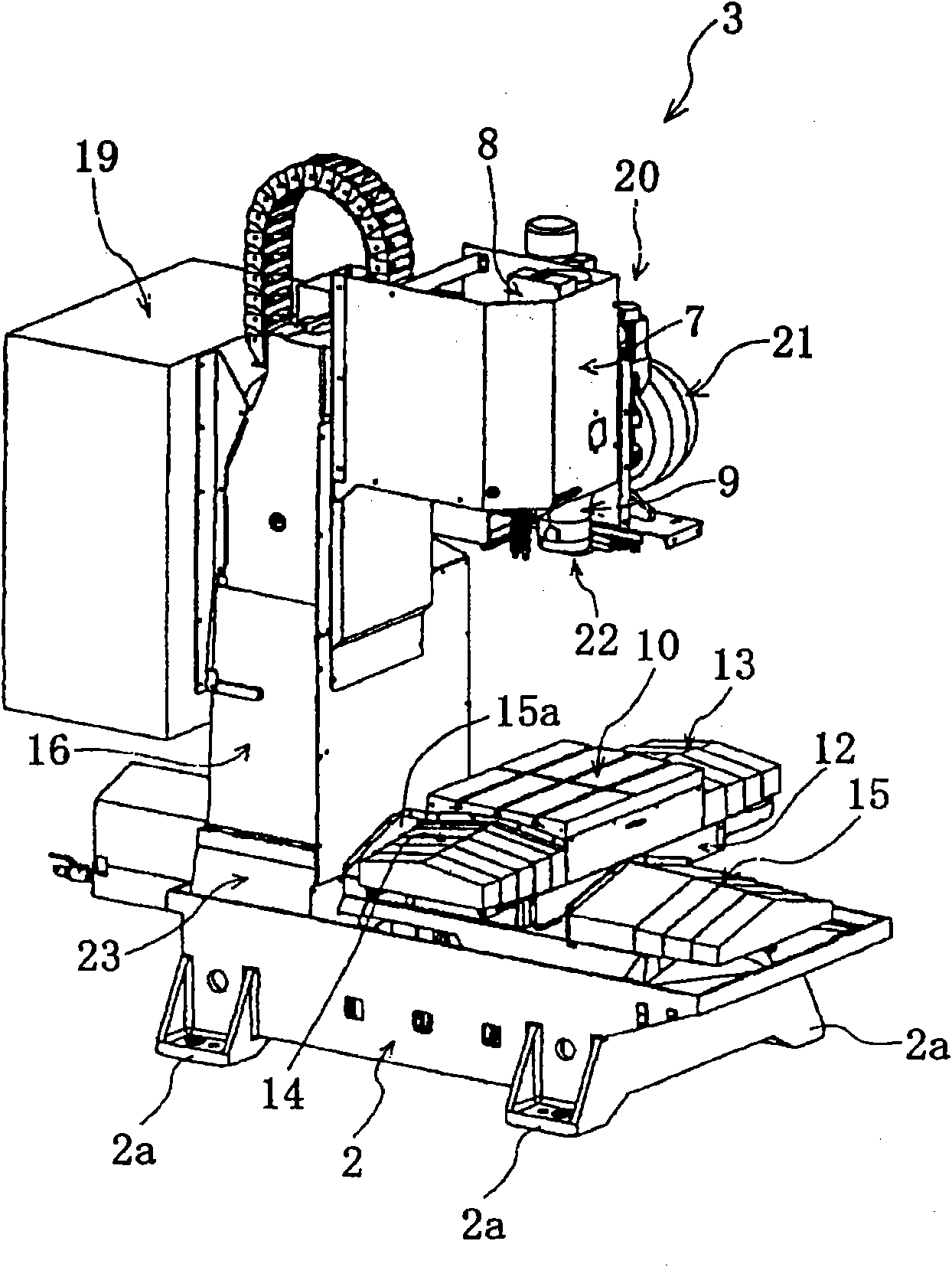

[0027] Such as figure 1 As shown, a machining center 1 (a machine tool according to the present invention) includes a base 2 made of cast iron and a protective shutter 4 covering the upper part of the base 2 . The protective baffle 4 will be arranged on the machine tool body 3 on the abutment 2 (referring to figure 2 ) surrounded by the outside.

[0028] Such as figure 1 , figure 2 As shown, the base 2 is a rectangular parallelepiped casting long in the Y-axis direction (front-back direction). The base 2 is arranged on the floor surface through the leg portions 2a, and the leg portions 2a are arranged at four corners of the lower part. The height of the foot portion 2a is adjustable. The height adjustment of the foot portion 2a is for the workbench 10 of the machine tool body 3 (refer to figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com