Special dual-handle three-jaw grasping forceps

A three-jaw clamp, double-handle technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problem of not being able to find, and achieve the effects of avoiding slippage, convenient operation and novel concept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained with reference to the drawings and embodiments:

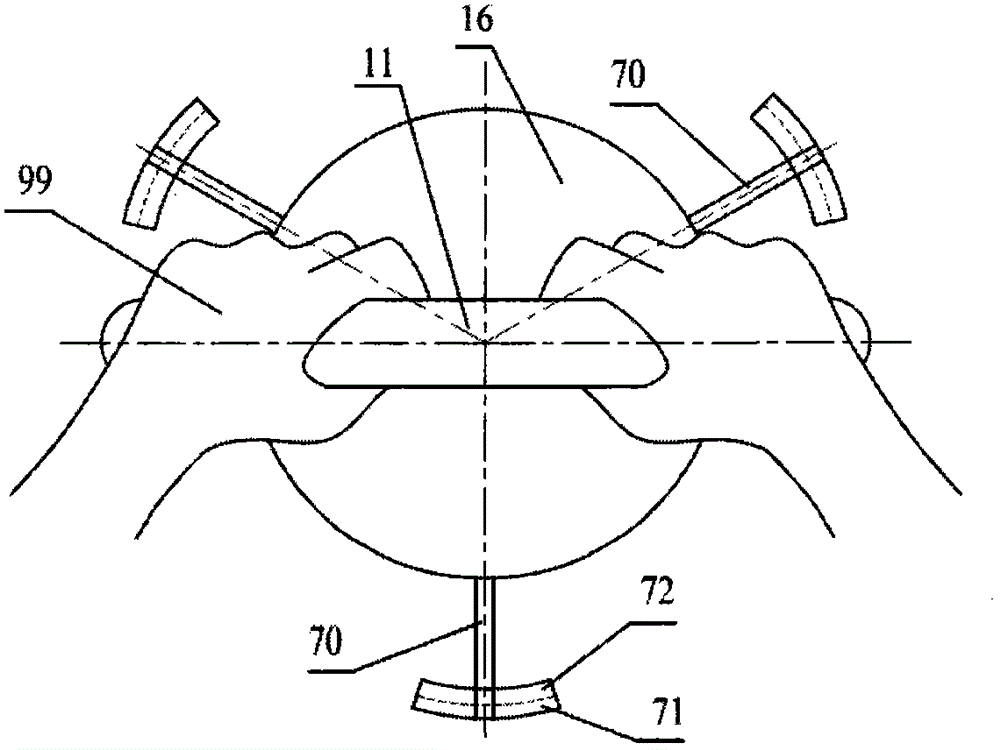

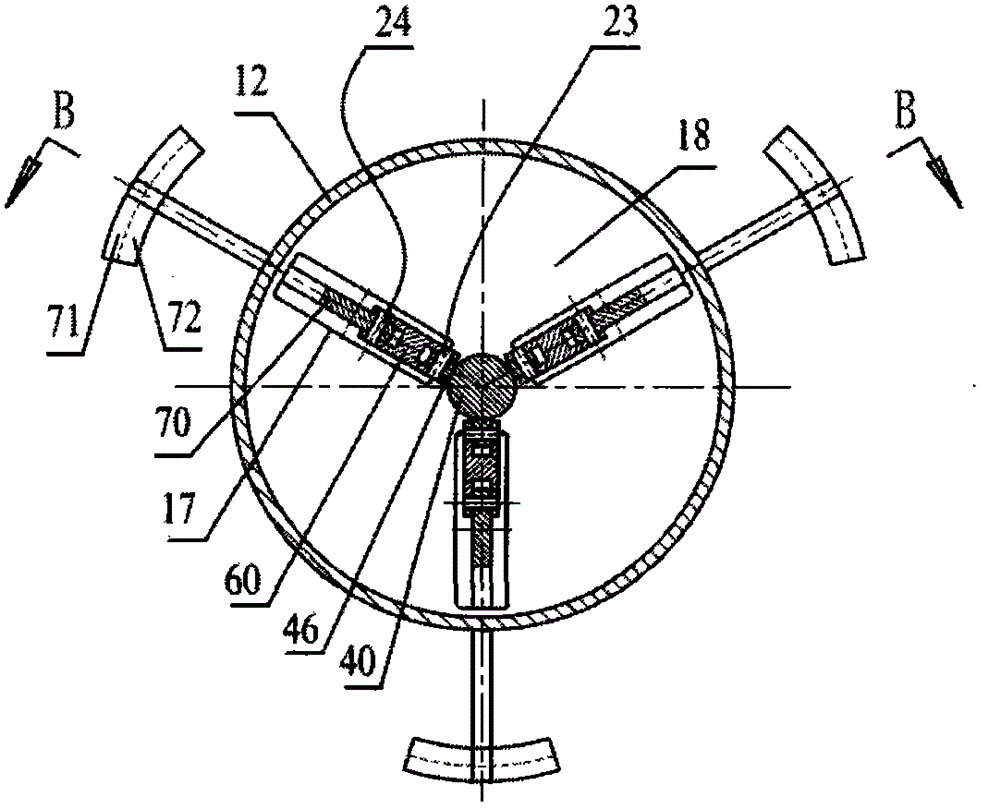

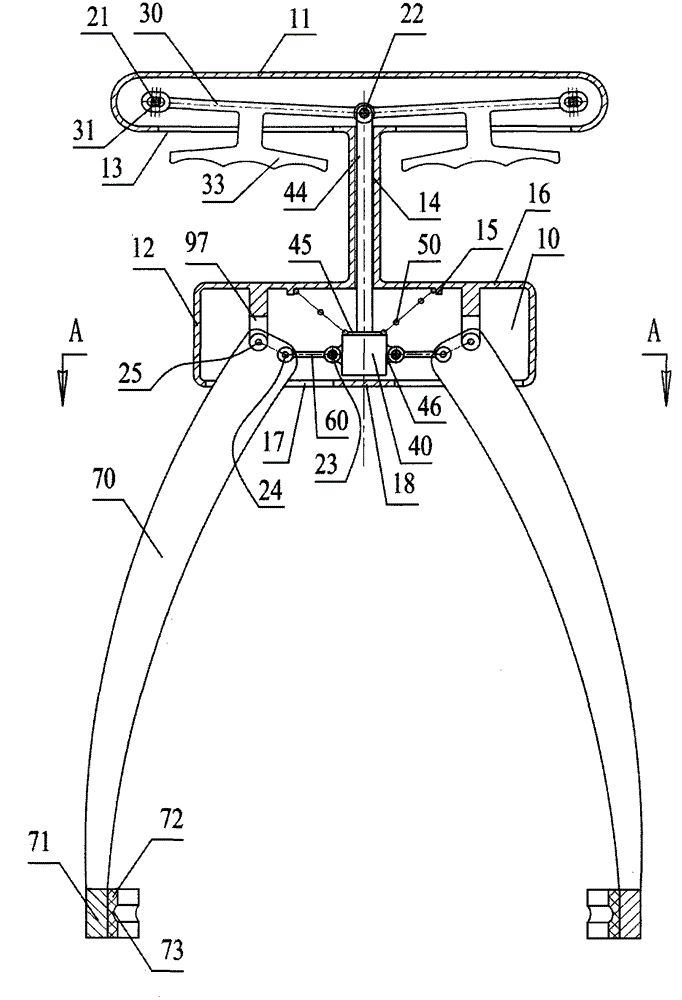

[0020] in figure 2 , image 3 In, a double-handle special three-jaw clamping pliers, including a housing 10 and an operation control component, as an improvement: the hollow handle 11 of the housing 10 has handle openings 13 under both sides, and the inner surfaces of the two outer ends of the hollow handle 11 Each has a pair of boss holes 91. The hollow handle 11 is connected to a circular pipe section 14 below the middle position. The lower end of the circular pipe section 14 is connected to the upper surface 16 of the control disc 12, and the inner surface of the upper surface 16 of the disc is provided with a spring. Fixed ring 15 and three suspension support feet 97. The three suspension support feet 97 are symmetrically arranged outside the fixed ring 15 on the spring. The lower surface 18 of the control disc 12 is also provided with three rectangles. The opening 17 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com