Patents

Literature

33results about How to "Avoid the risk of human error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A malicious URL detection system and method based on automatic feature extraction

ActiveCN109005145ARapid responseImprove accuracy and coverageBiological neural network modelsPlatform integrity maintainanceParallel learningImaging Feature

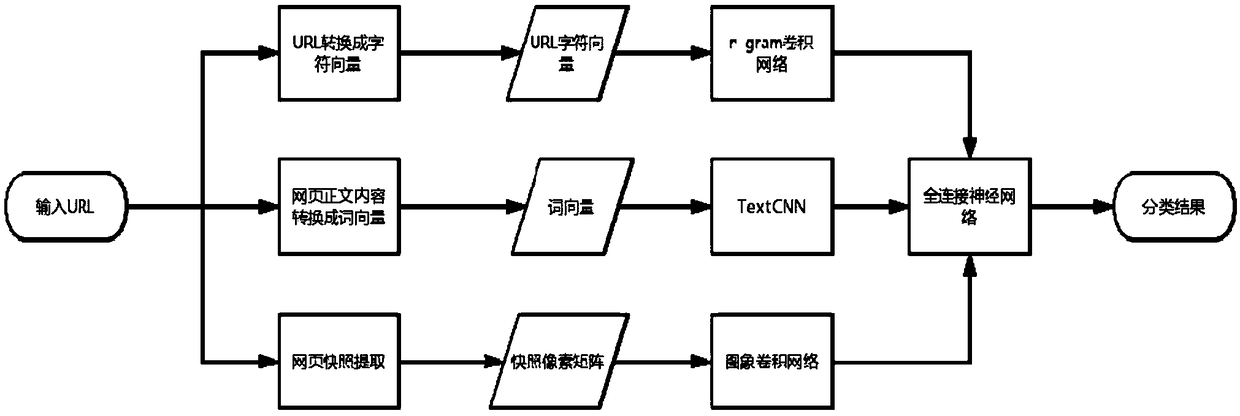

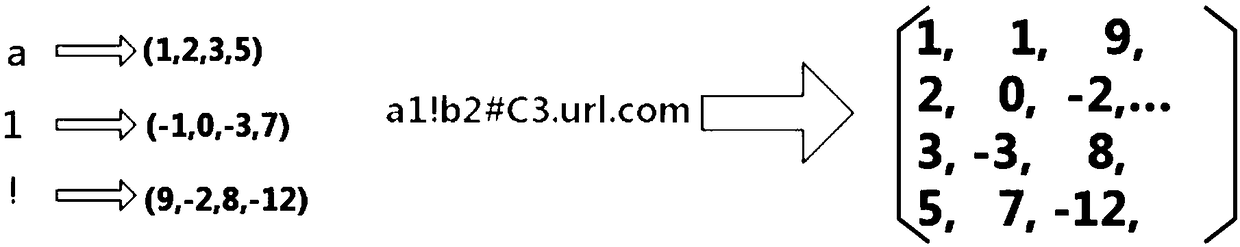

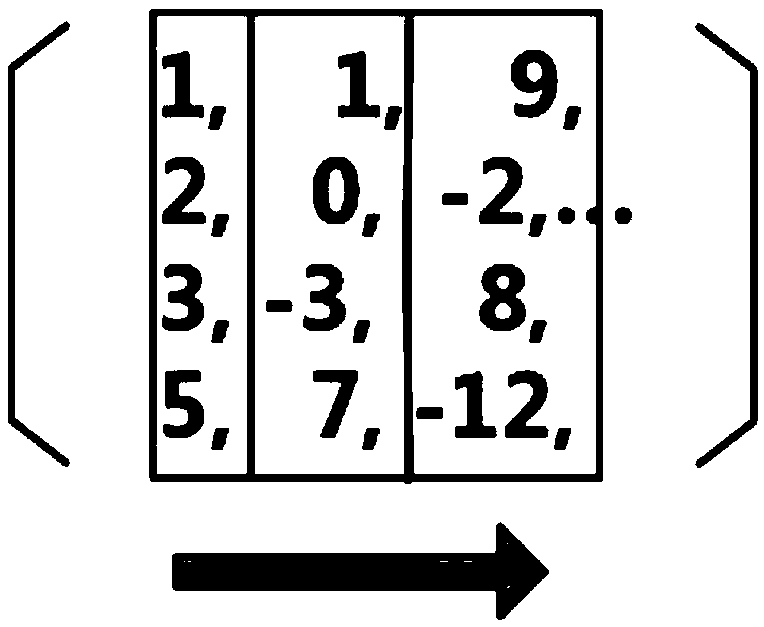

The invention discloses a malicious URL detection system and a malicious URL detection method based on automatic feature extraction, which relates to the malicious URL detection field. The malicious URL detection system comprises a preprocessing module, a parallel learning module and a detection classification module. The preprocessing module takes the URL of the web page as an input, and convertsthe URL structural features, the web page text content and structural features, and the image features extracted by the preprocessing into three digital matrices containing feature vectors respectively. The parallel learning module uses three independent depth learning networks of different algorithms to process the three digital matrices to obtain three probability matrices. The detection and classification module inputs the three probability matrices to a fully connected network for further processing to give a final classification result. The invention combines the depth learning model ofthe text and the image with the malicious URL detection, comprehensively extracts various information of the web page, and improves the application scope and accuracy of the detection method.

Owner:SHANGHAI JIAO TONG UNIV

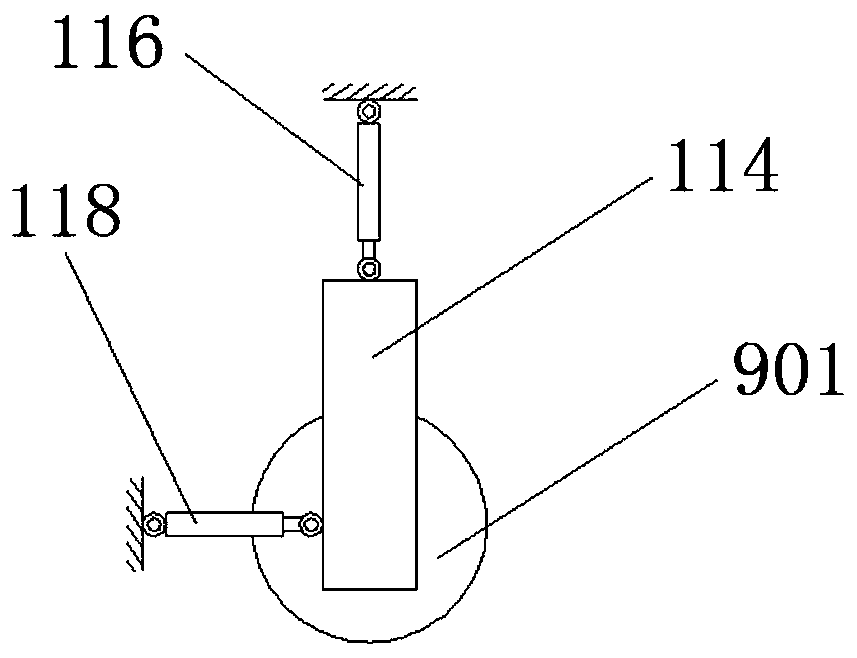

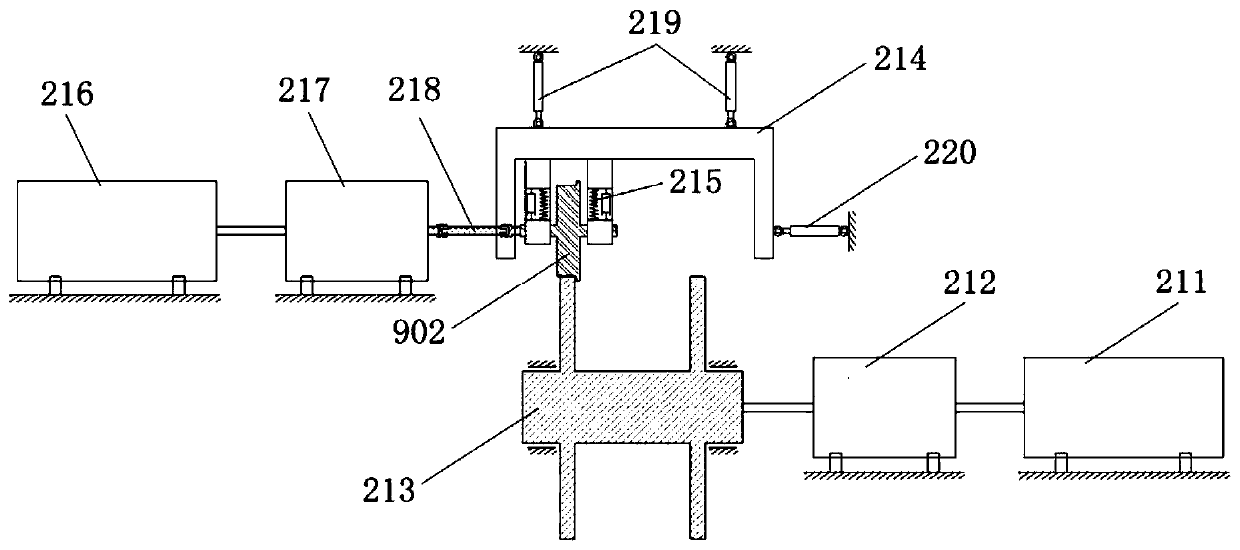

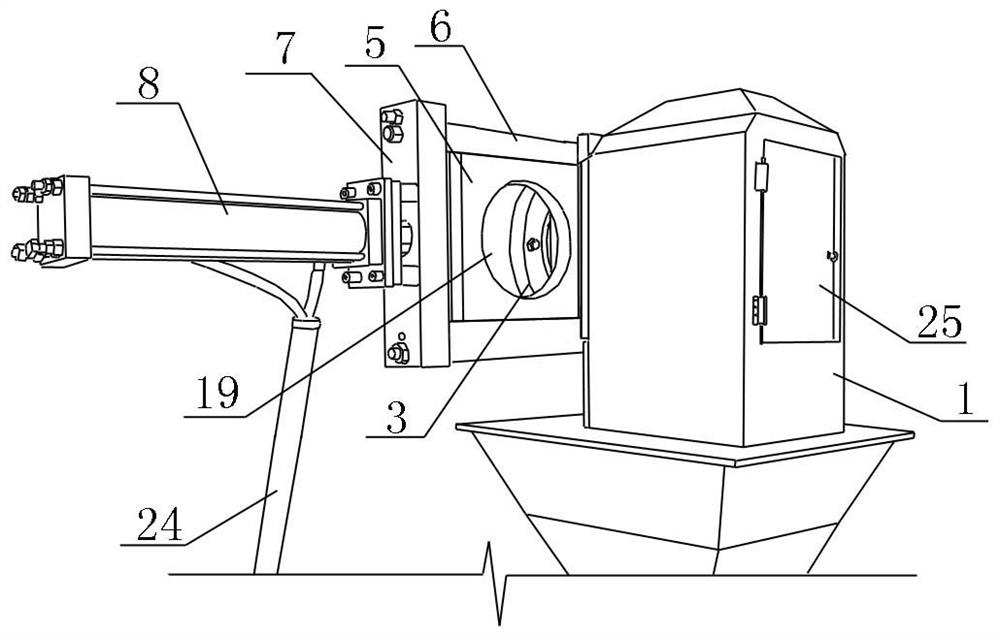

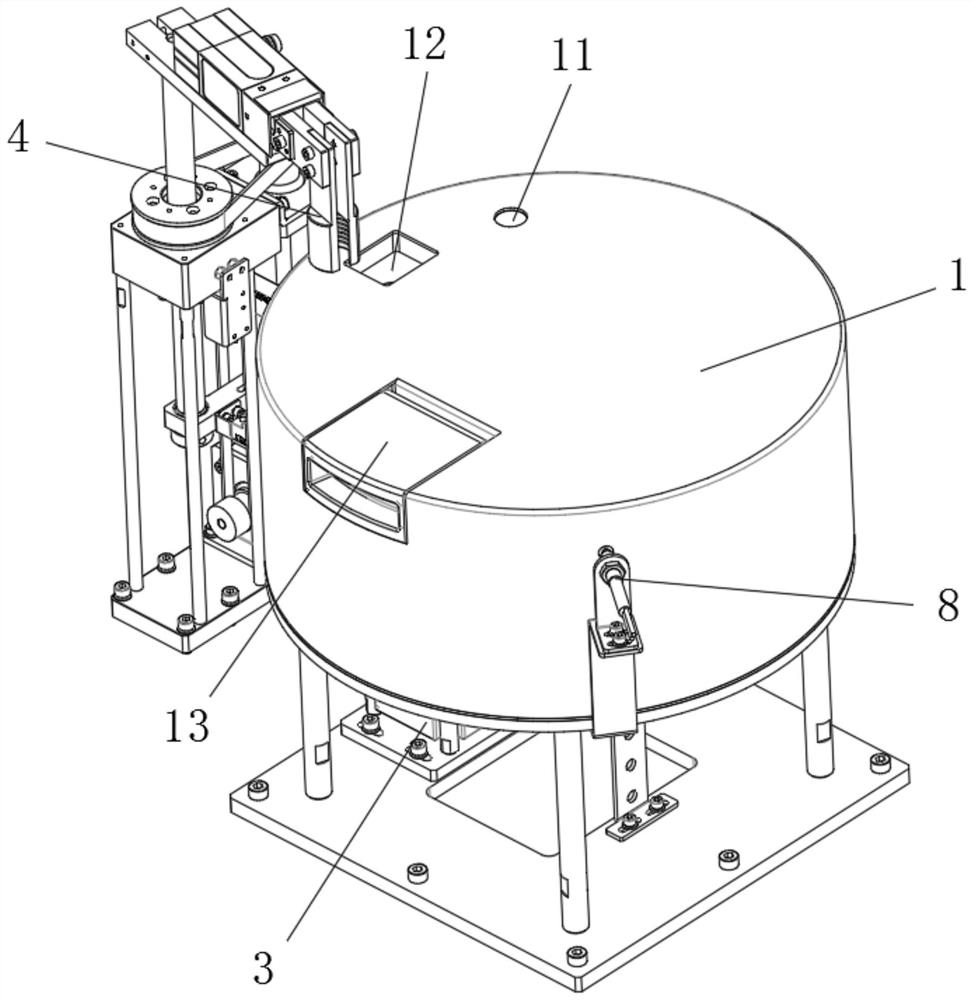

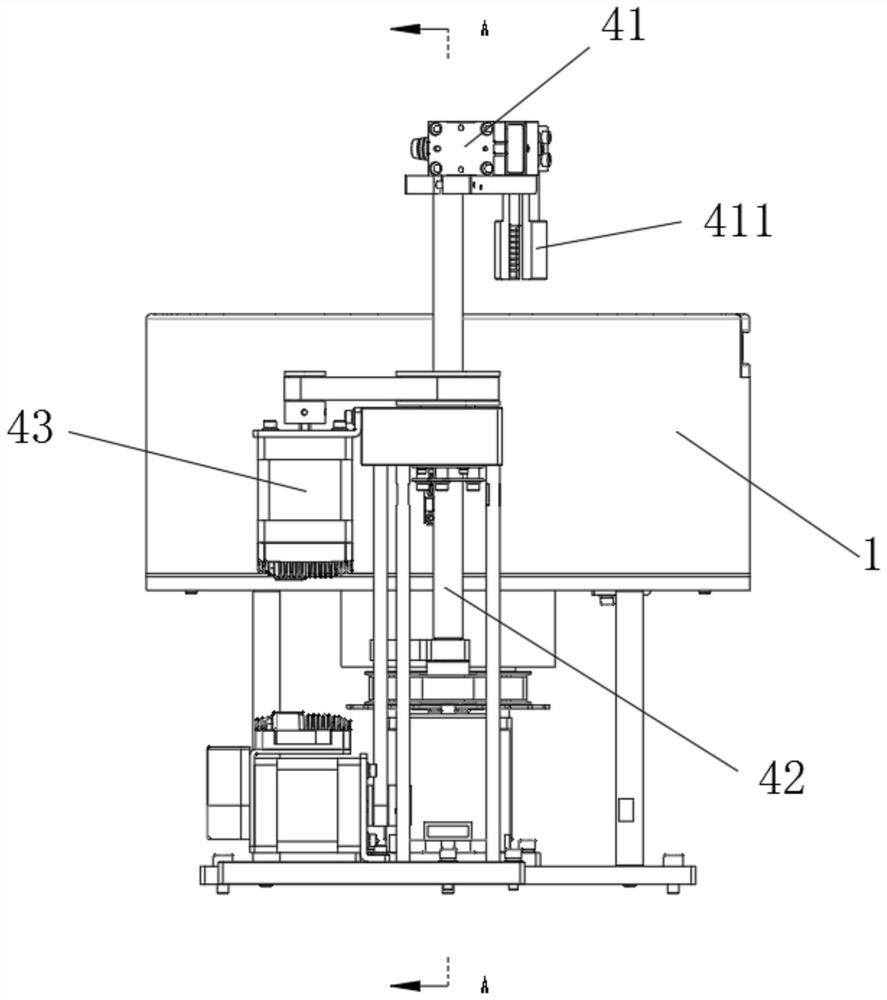

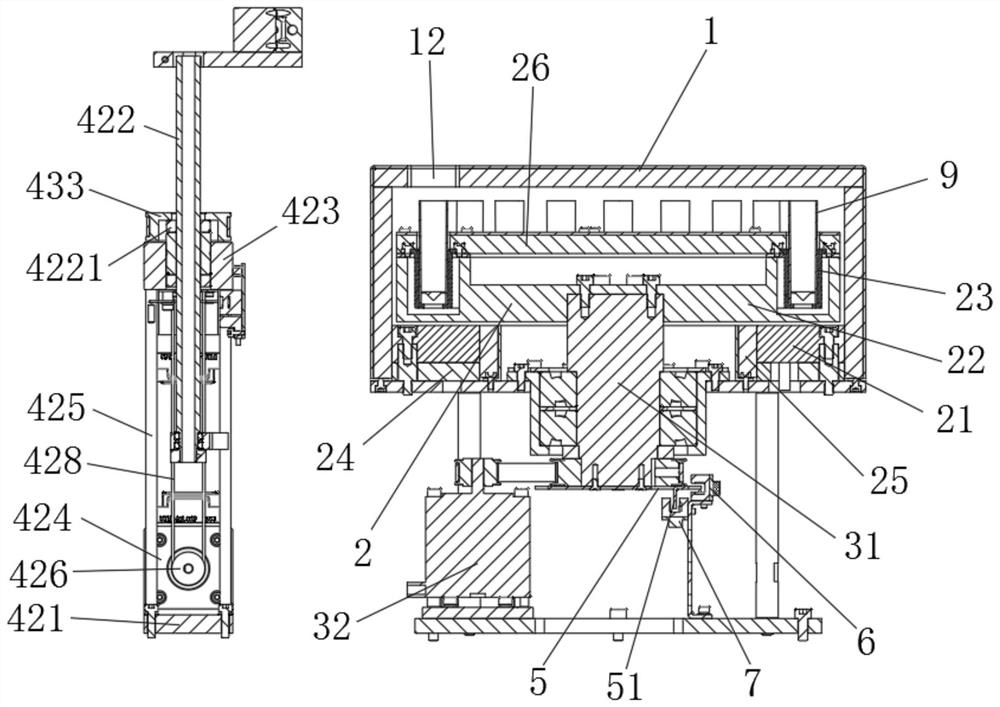

Rail vehicle wheeltrack relationship test bench and test method

InactiveCN110907204AAvoid human errorReduce test costsRailway vehicle testingSuspension (vehicle)Test bench

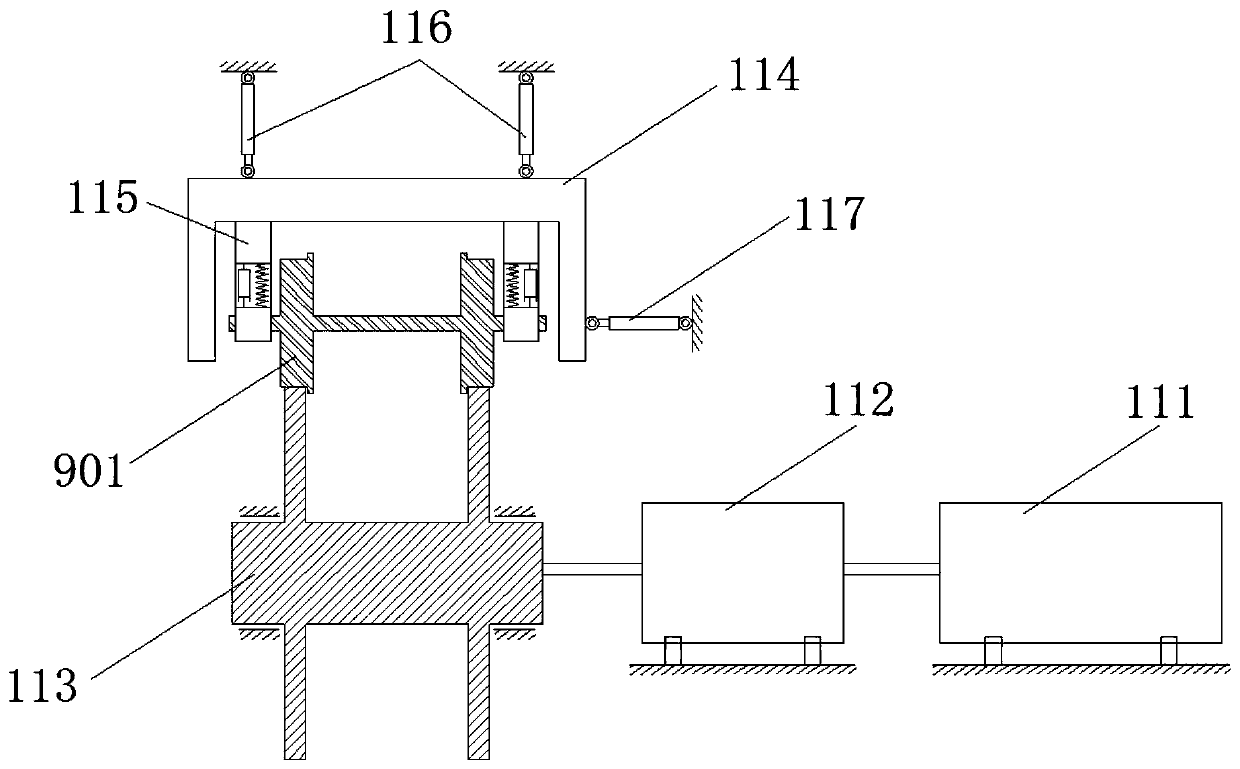

The invention discloses a rail vehicle wheeltrack relationship test bench. The bench comprises a rail wheel device, a wheel suspension device, a loading device, a measuring device and a control system, the rail wheel device simulates an actual steel rail; the loading device applies a load to the test wheel, the wheel suspension device transmits the load to the test wheel, the measuring device collects data of other devices and sends the data to the control system, the control system calculates the collected data and obtains a test result, automatic operation of the test is ensured, and the risk of manual control errors is avoided. The bench can be used for carrying out various tests in the wheel-rail relation field. Compared with the prior art, the test cost is reduced on the premise thatthe requirement for the highest test speed is met, in addition, the test bed can simulate line disturbance in the test process, the running state of wheels is close to the actual running state, the test result has higher reference value, and meanwhile the test requirements of various rail vehicles are met.

Owner:RD CENT CHINA ACADEMY OF RAILWAY SCI

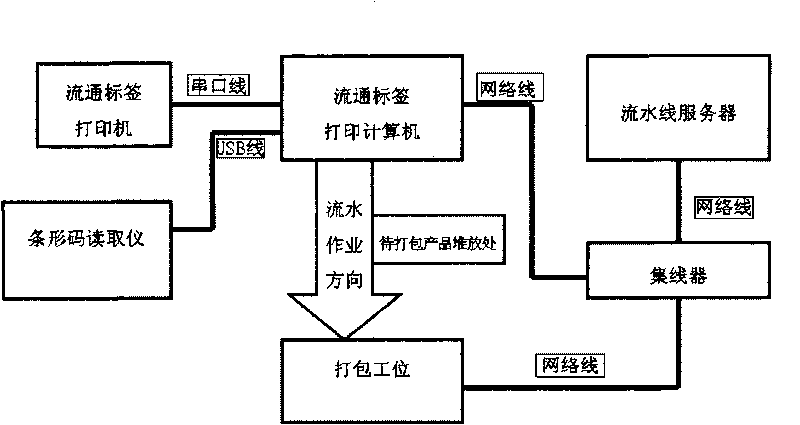

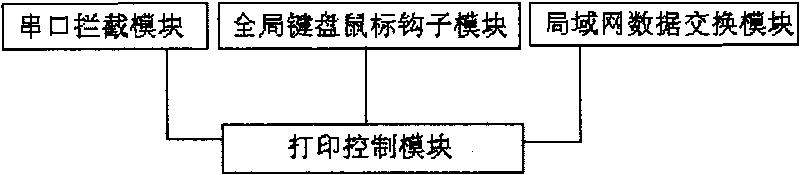

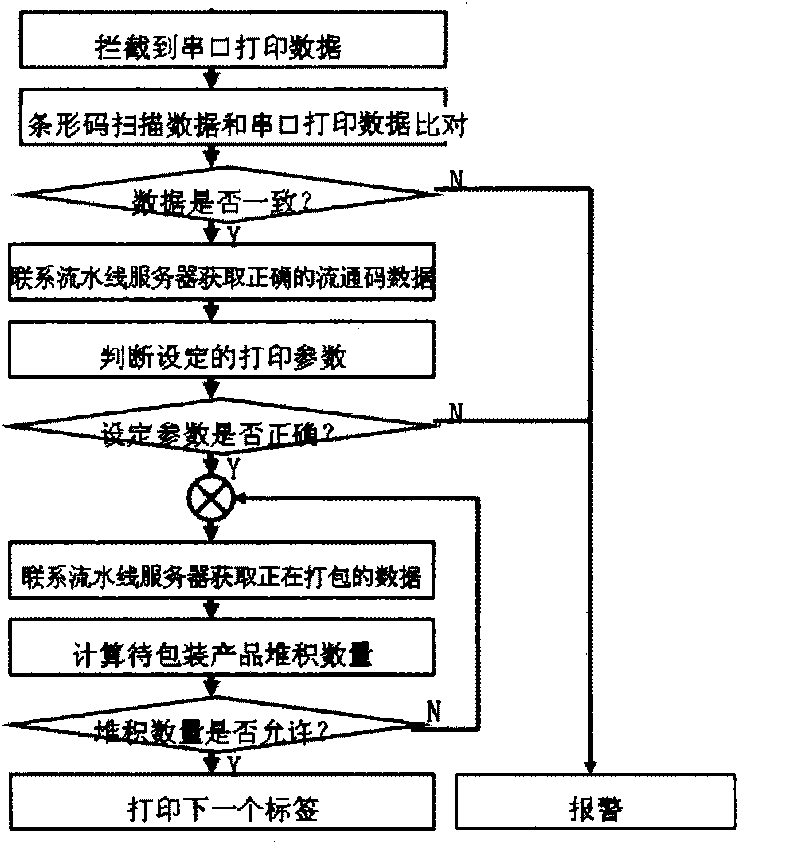

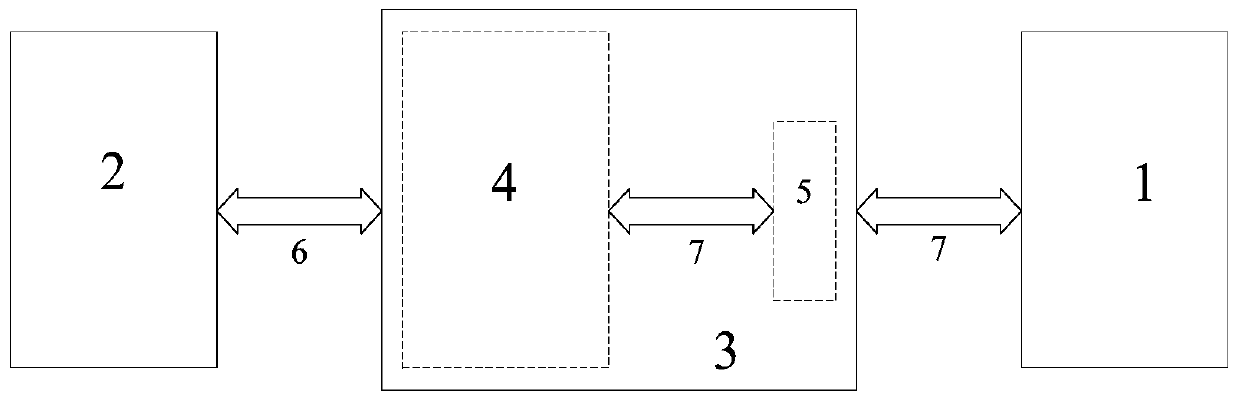

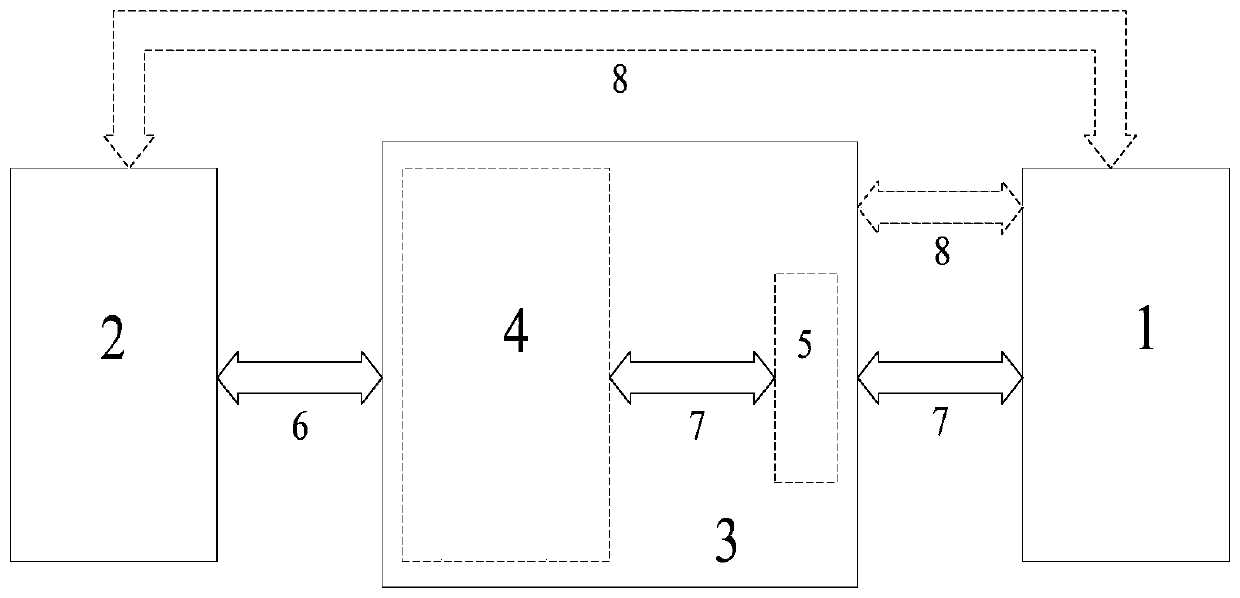

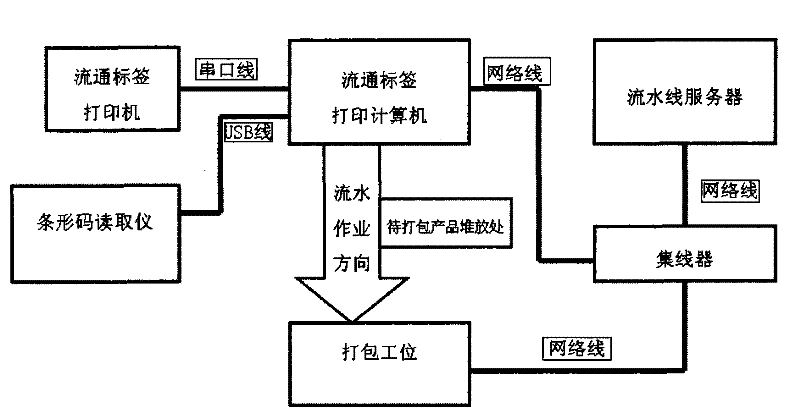

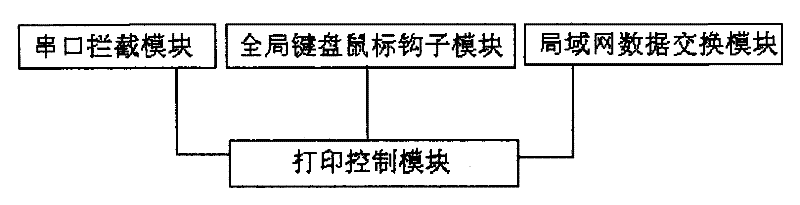

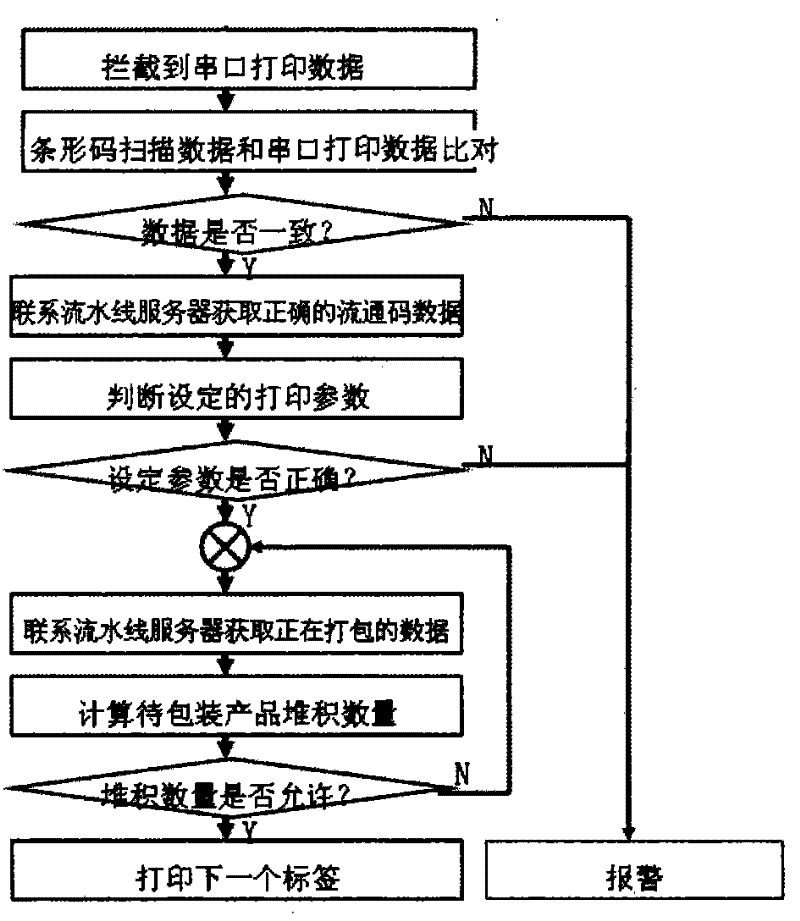

Device and method for printing and comparing circulating label bar codes

InactiveCN101697205AShielding effectAvoid the risk of human errorCo-operative working arrangementsDigital output to print unitsBarcodeData exchange

The invention provides a device and a method for printing and comparing circulating label bar codes, which belong to the technical field of bar code printing. The device for printing and comparing the circulating label bar codes is characterized by comprising a circulating label printing computer, wherein the circulating label printing computer is connected with a circulating label printer, a bar code reader and a concentrator through a serial port cable, a USB cable and a network cable respectively; the concentrator is connected with a pipelining server and a packing station through the network cable respectively; the circulating label printing computer is provided with a serial port blocking module, a global keyboard mouse hook module, a local area network data exchange module and a printing control module which are connected with one another in turn; and the printing control module is connected with the serial port blocking module. The device and the method have the advantages of being capable of determining the correctness of the printed bar codes and controlling the amount of products stacked on the packing station.

Owner:SHANGHAI SUOGUANG ELECTRONICS

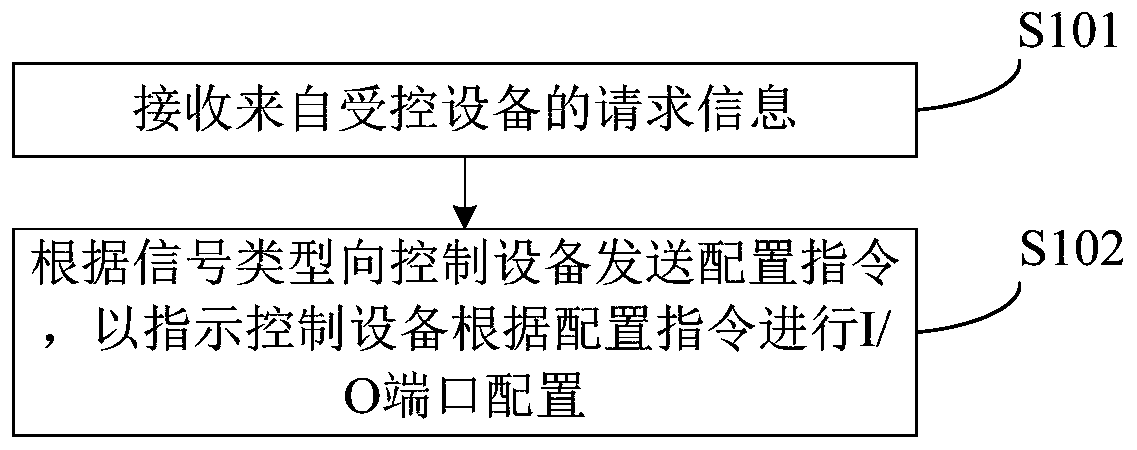

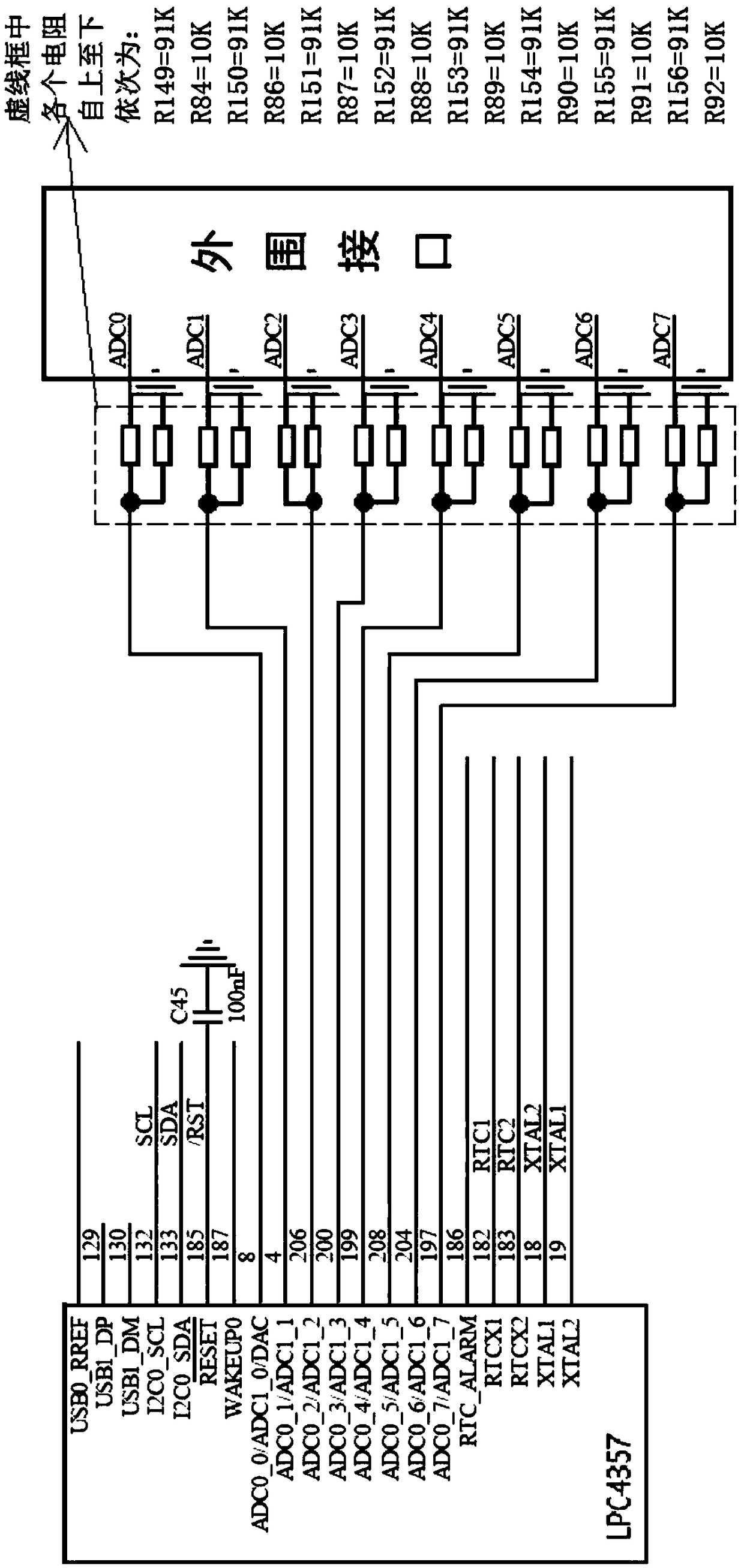

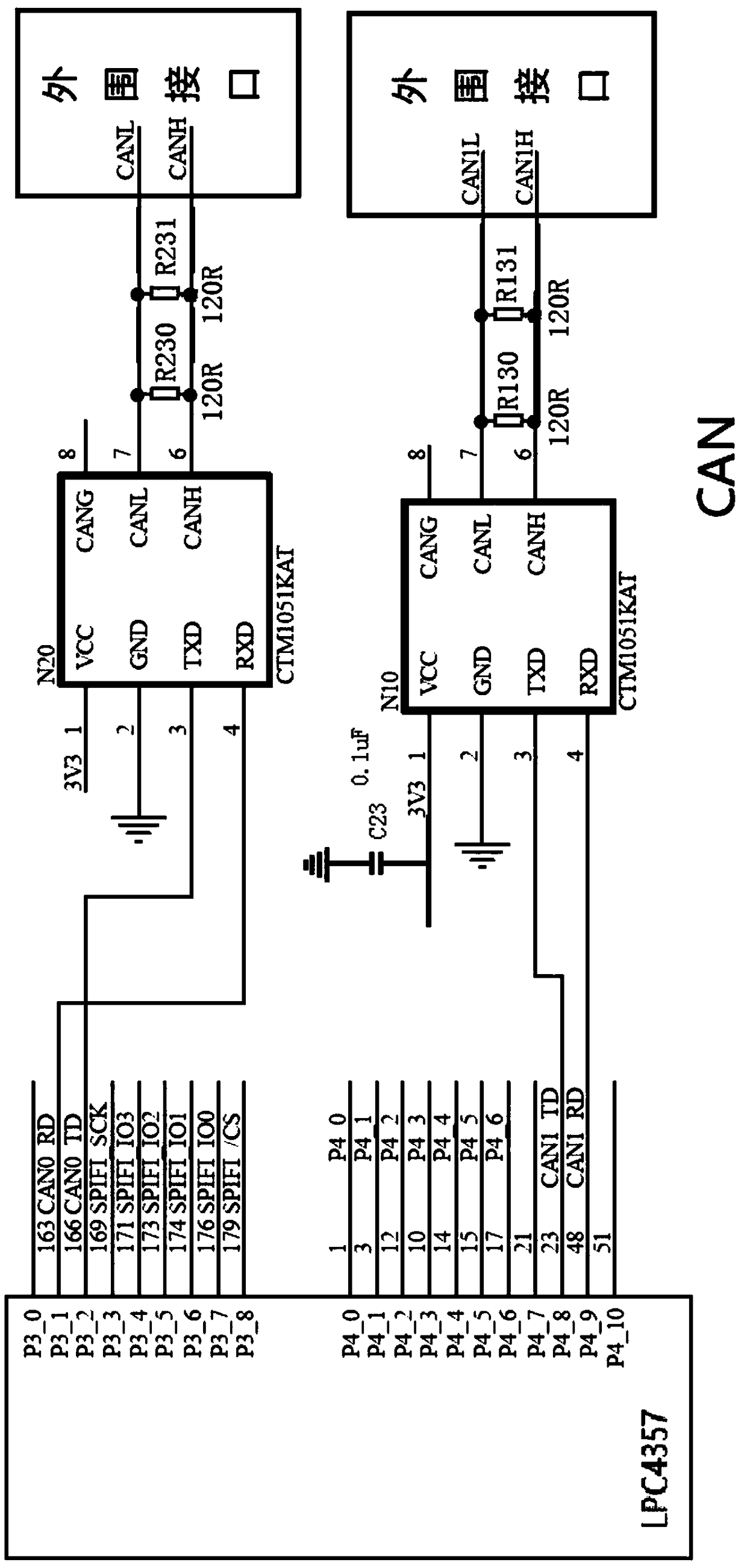

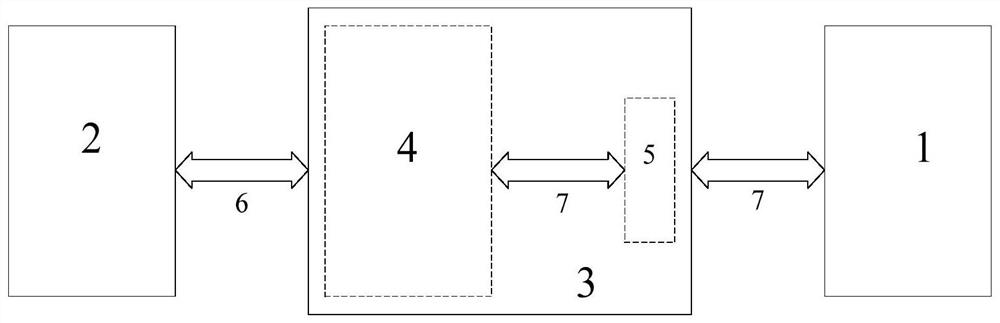

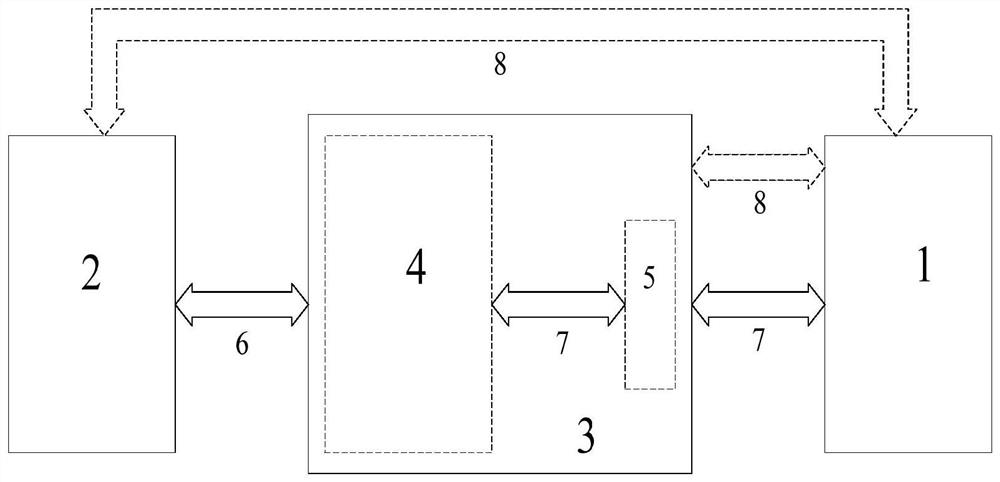

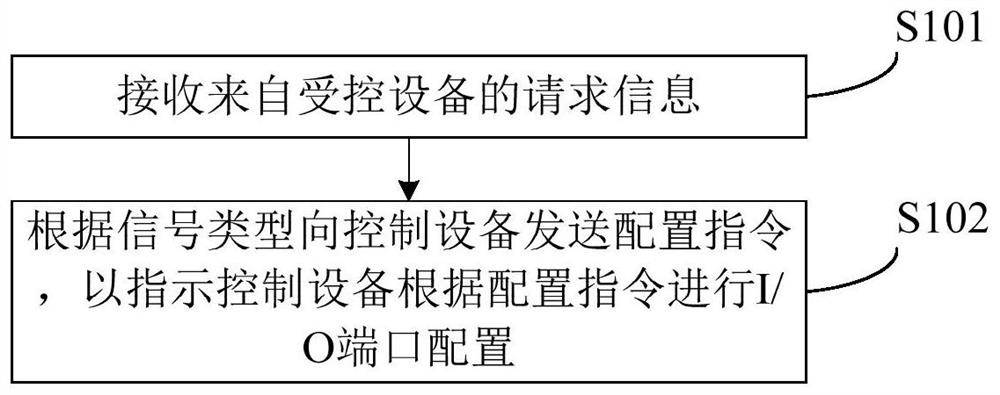

An automatic configuration method and system of an I/O port

ActiveCN109766291ARealize automatic configurationRealize unmanned operationProgramme controlTransmissionAuto-configurationEmbedded system

The invention discloses an automatic configuration method and system of an I / O port, and the method applied to a central processing unit comprises the steps of receiving the request information from acontrolled device, the request information carrying a signal type required by the controlled device; sending a configuration instruction to the control equipment according to the signal type so as toindicate the control equipment to perform I / O port configuration according to the configuration instruction, wherein the controlled device is directly connected with the central processing unit, or the controlled device is connected with the central processing unit through the control device. Therefore, the communication connection between the central processing unit and the controlled equipmentcan be established, the central processing unit can automatically generate the configuration instruction according to the signal type required by the controlled equipment to indicate the control equipment to carry out I / O port configuration, and accordingly the automatic configuration of the I / O port is realized, the unmanned operation is realized, and the risks caused by the manual misoperation are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

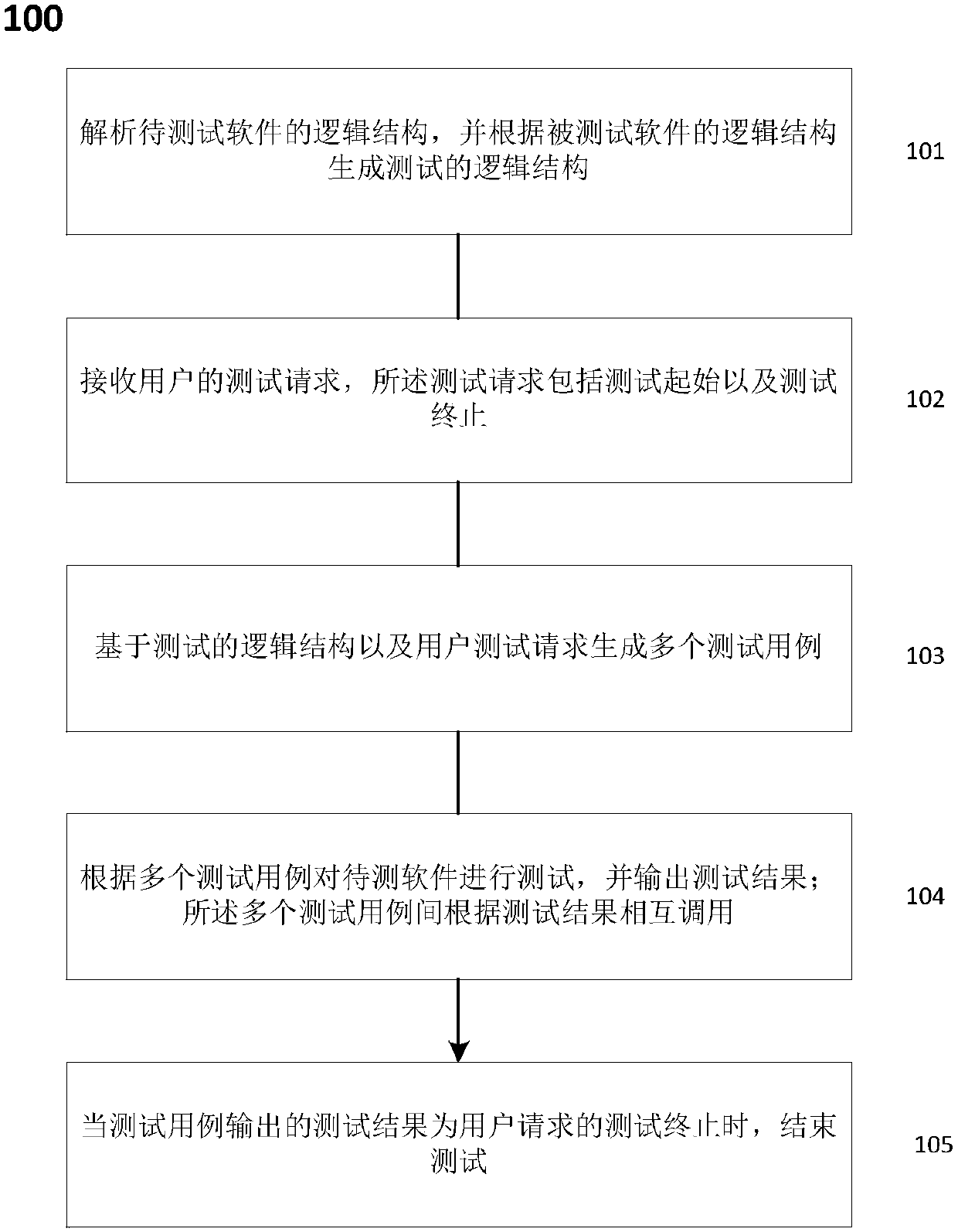

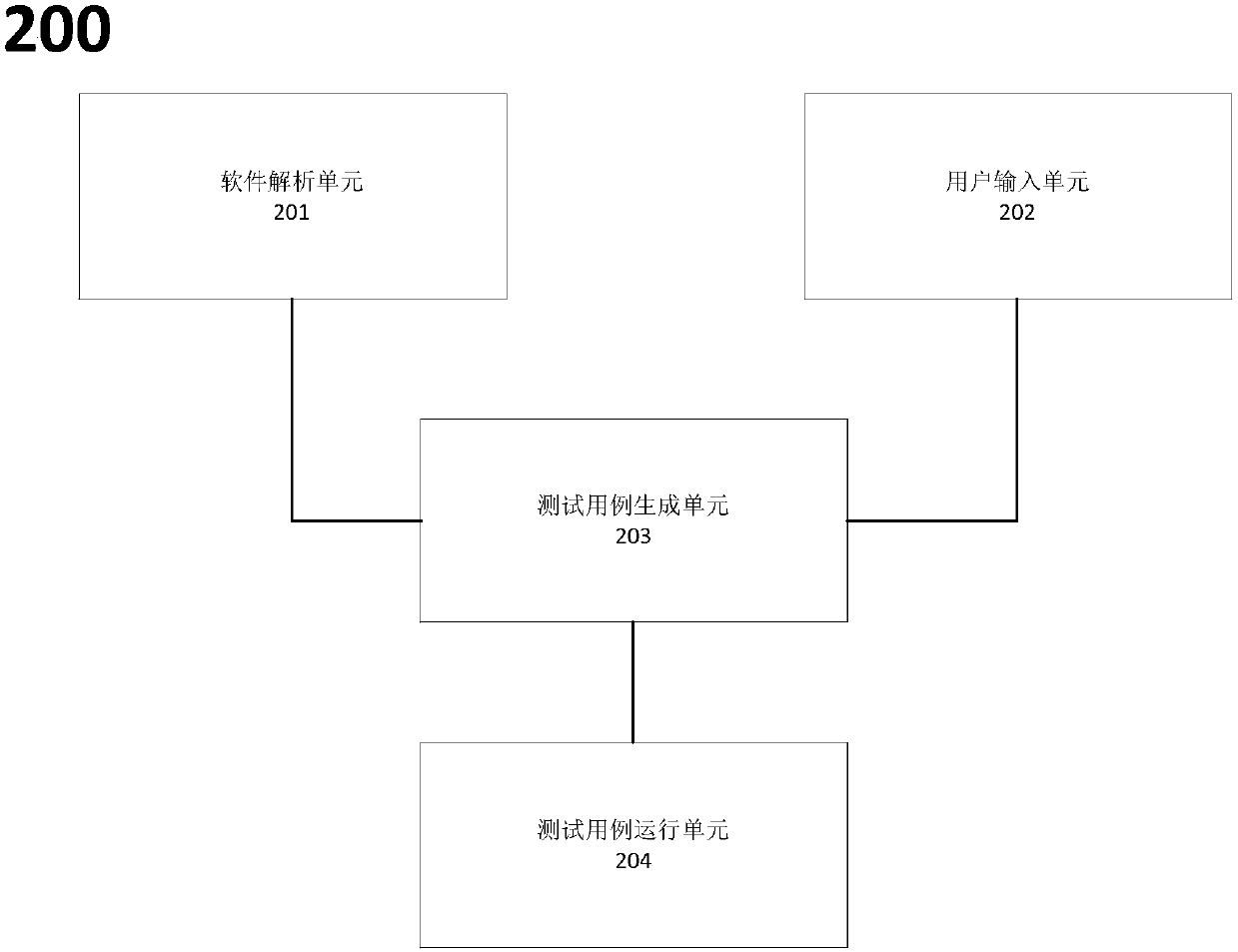

Software automation test method and system

PendingCN109976992AFree working hoursImprove work efficiencySoftware testing/debuggingTest requirementsSoftware automation

The invention discloses an automatic software testing method and system, and the method comprises the steps: analyzing a logic structure of to-be-tested software, and generating a tested logic structure according to the logic structure of the tested software; receiving a test request of a user, wherein the test request comprises a test start and a test end; generating a plurality of test cases based on the tested logic structure and the user test request; testing the to-be-tested software according to the plurality of test cases, and outputting a test result; wherein the plurality of test cases are mutually called according to a test result; when the test result output by the test case is that the test requested by the user is terminated, ending the test; wherein the test case comprises acase number, a command word, data, an instruction and a jump instruction; wherein the jump instruction is used for calling a corresponding test case or terminating a test according to a test result and test calling logic; according to the method and the system, the test case is automatically generated and tested according to the software logic structure, so that the test working efficiency is improved.

Owner:AEROSPACE INFORMATION

Operation and maintenance method for nuclear level digital instrument control system of pressurized water reactor nuclear power plant

ActiveCN108682467AAvoid experimental errorAvoid the risk of human errorNuclear energy generationComputer implemented nuclear controlControl systemPressurized water reactor

The invention belongs to the field of the operation and maintenance of a nuclear process control system and particularly relates to an operation and maintenance method for a nuclear level digital instrument control system of a pressurized water reactor nuclear power plant. The method comprises the steps of (1) determining an application system, and (2) determining a specific function and an implementation process of the method. The method is used for the operation and maintenance of the nuclear level digital instrument control system (KCS system) of the pressurized water reactor nuclear powerplant. The method has the advantages of high reliability and a high degree of automation, the reliability of the KCS, faults are detected and the performability of a protection system is checked, andthe safe and stable operation of a unit is ensured.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

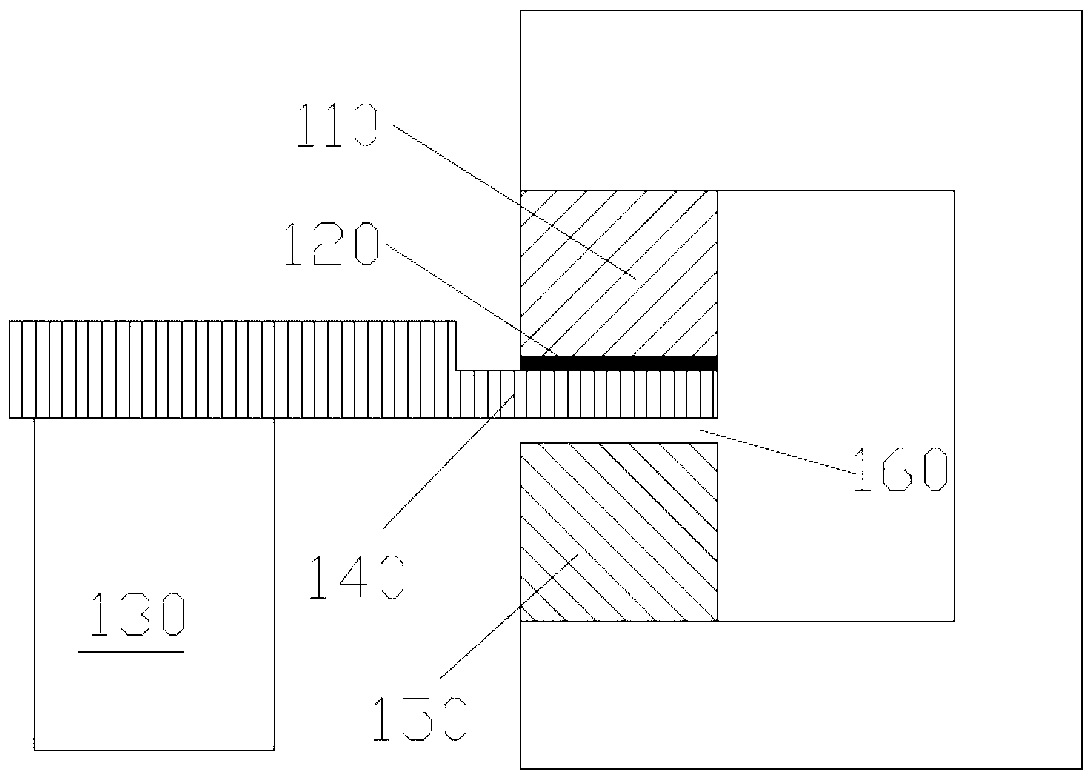

Device used for attaching chip-on-film to panel and using method thereof

InactiveCN103345086AReduce distanceReduce labor intensityPrinted circuit aspectsLaminating printed circuit boardsChip on filmEngineering

The invention relates to a device used for attaching a chip-on-film to a panel and a using method thereof. The device used for attaching the chip-on-film to the panel comprises a platform used for conveying the panel, a pressing head used for carrying the chip-on-film, a panel supporting mechanism which is matched with the pressing head for use, and a distance adjusting mechanism which is used for measuring and reducing the distance between the panel and the supporting mechanism after the panel is conveyed to a position between the pressing head and the supporting mechanism. The device used for attaching the chip-on-film to the panel has the advantages that the distance between the panel and the supporting mechanism can be reduced, attaching deviation of the chip-on-firm is avoided, and the quality of products is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

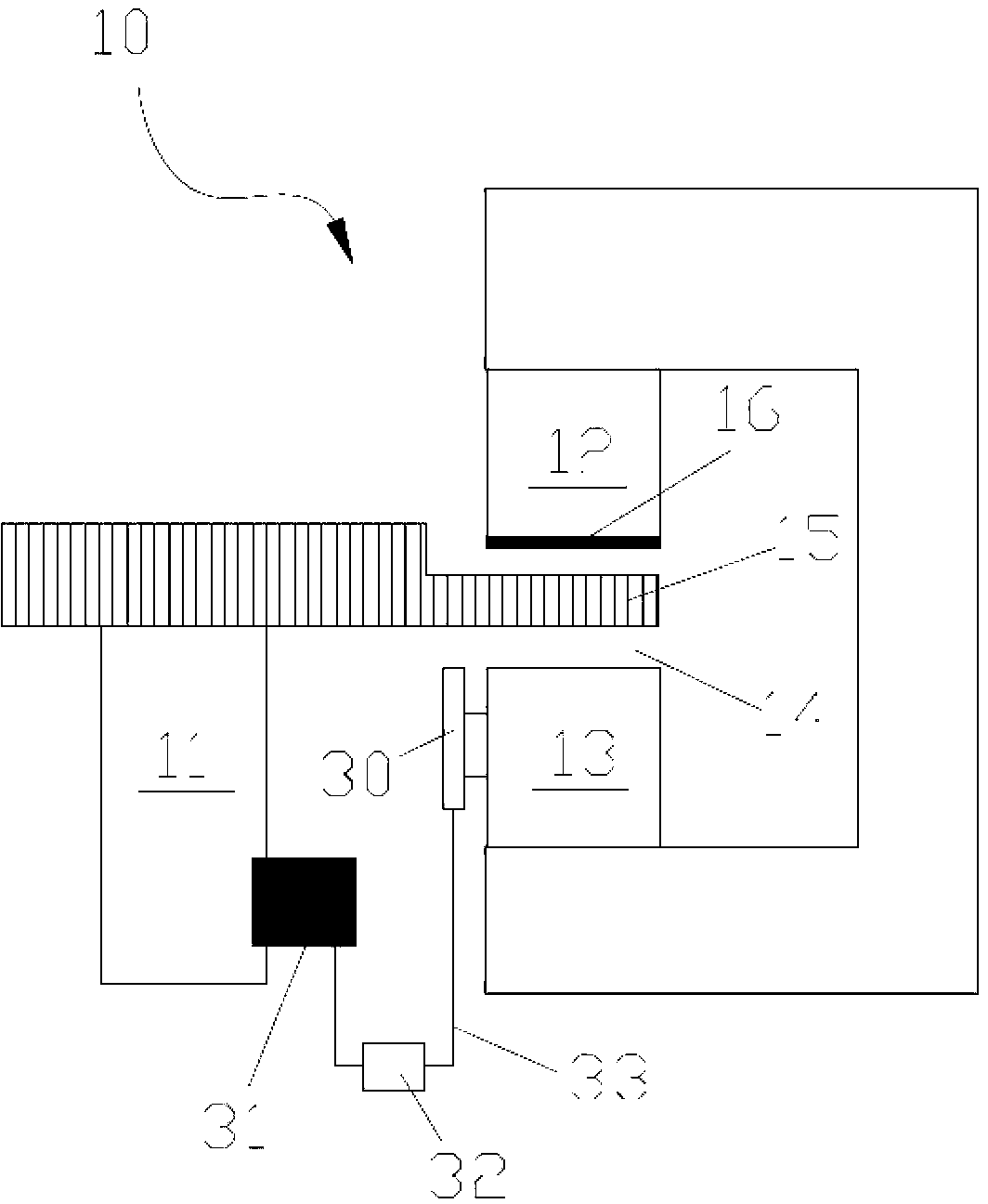

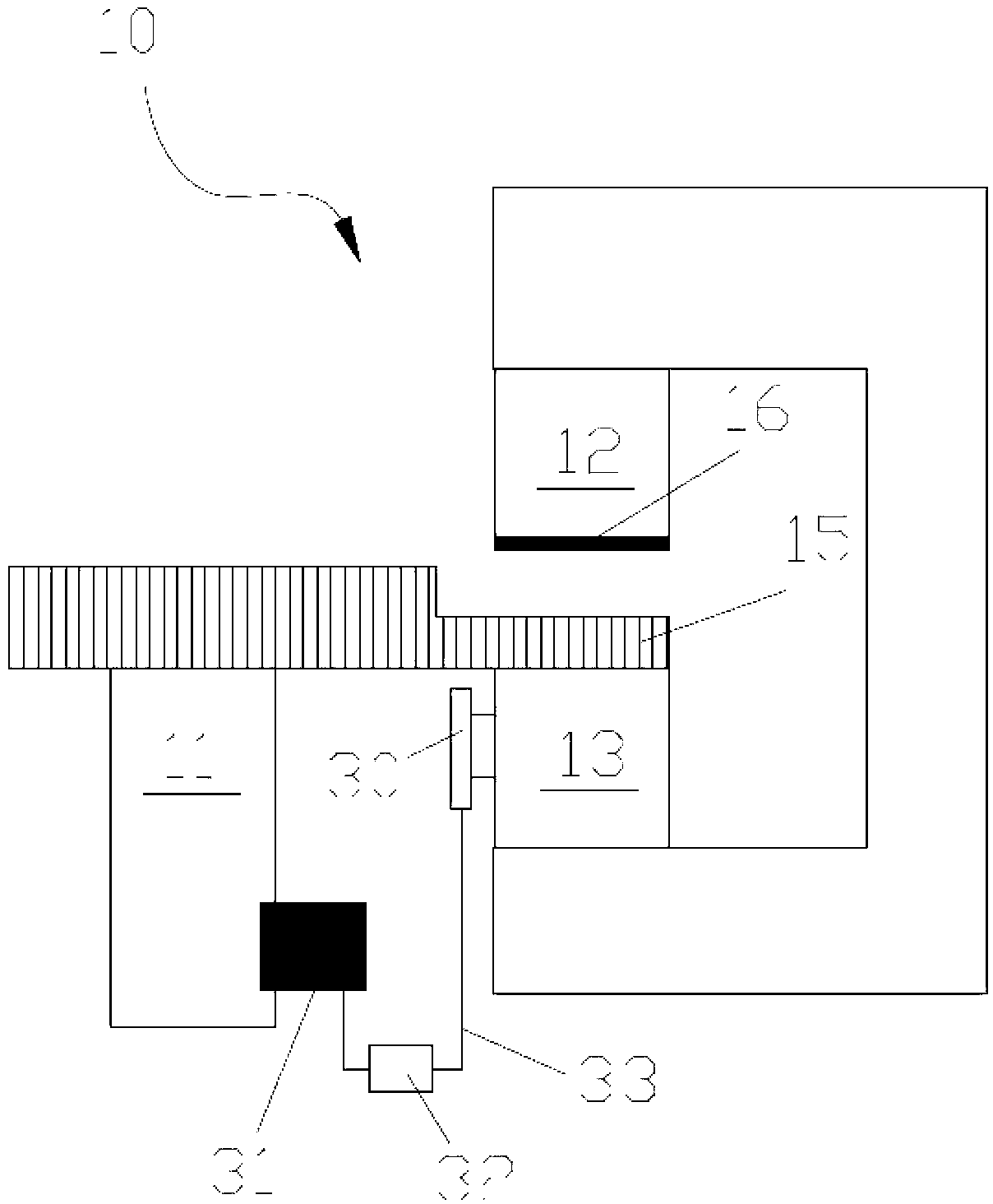

Automatic hardware test system

PendingCN108828426ASave human effortAvoid the risk of human errorAutomated test systemsEngineeringHuman error

The invention provides an automatic hardware test system and relates to the technical field of electronic device detection. The automation hardware test system comprises: a power source, a computer device, a test clamp and a test motherboard. The power source is connected to a tested motherboard. The computer device is connected to the test motherboard. The test clamp is connected to the test motherboard and the tested motherboard. The test clamp is a structure clamp customized according to the tested motherboard, and connects a hardware resource provided by the test motherboard to a functional module required to be tested on the tested motherboard by a wire and / or a probe. A variety of hardware test interfaces and related circuits are integrated into the test motherboard. A test process requires almost no manual intervention. The integrated circuit module replaces a complicated instrument to simplify the test model. Test results are determined and recorded by the computer and the processor, thereby avoiding a risk caused by human error while saving a lot of manpower.

Owner:天津华泽瑞威信息技术有限公司

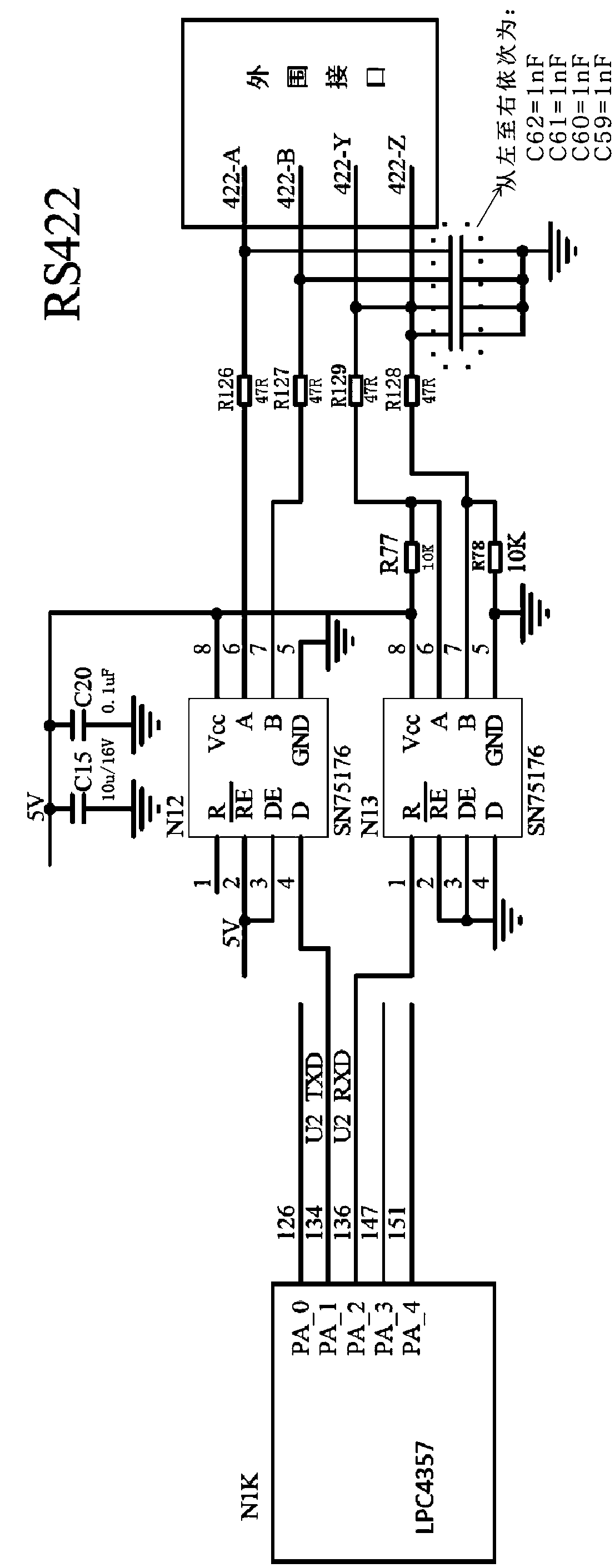

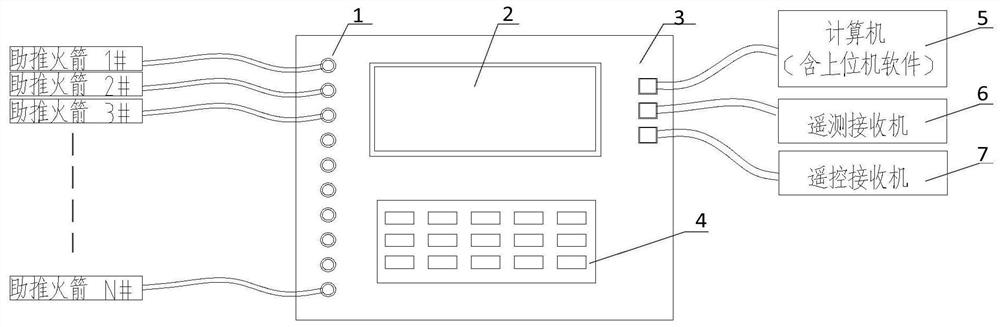

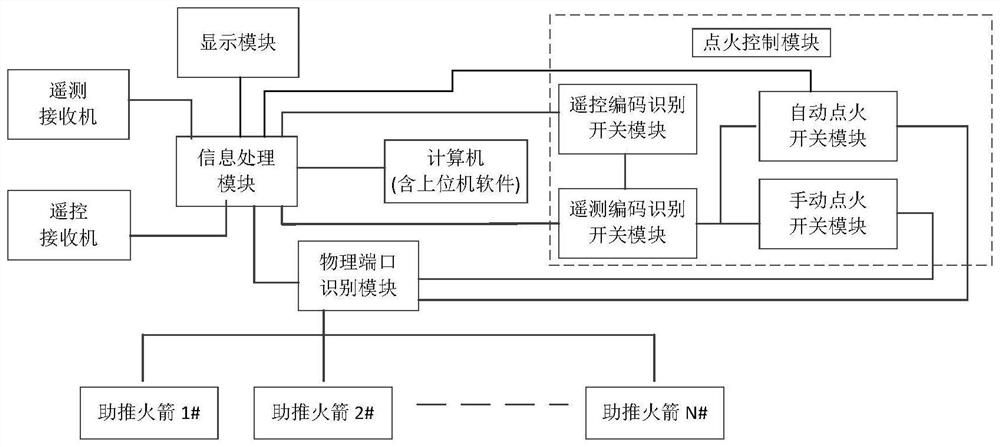

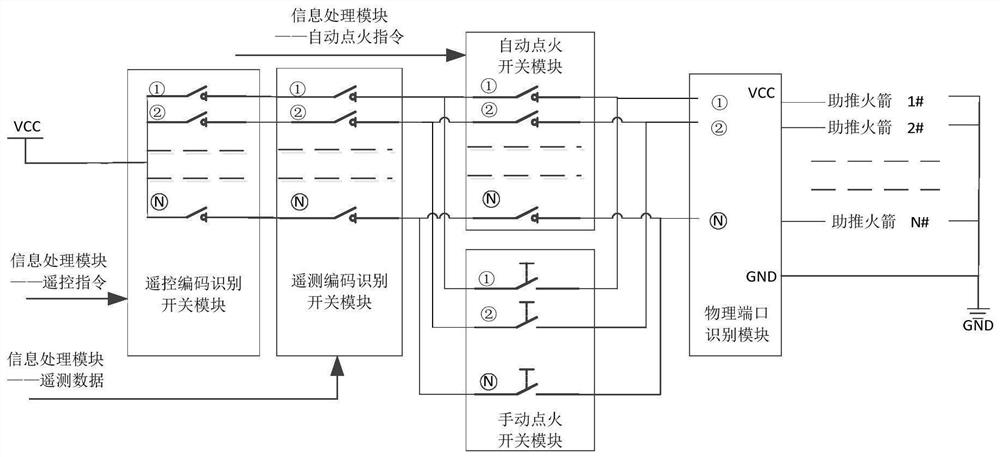

Unmanned aerial vehicle cluster booster rocket ignition control system and working method thereof

PendingCN112012851AAvoid the risk of human errorRealize wireless remote ignition controlLaunching/towing gearRocket engine plantsAutomotive engineeringIgnition control

The invention discloses an unmanned aerial vehicle cluster booster rocket ignition control system and a working method thereof. The system comprises a display module, an information processing module,a physical port recognition module, a computer (including upper computer software), an ignition control module, a remote-control receiver and a telemetering receiver. Ignition triggering conditions are judged through the computer (including the upper computer software), remote control code recognition logic and telemetering code recognition logic, and manual or automatic triggering of multi-channel booster rocket ignition is achieved. According to the unmanned aerial vehicle cluster booster rocket ignition control system and the working method thereof, multi-aircraft ignition launching is supported in an unmanned aerial vehicle cluster scene, automatic or manual ignition launching of different types of unmanned aerial vehicle booster rockets can be adapted to, and the problem that a booster rocket ignition control device is numerous in type, tedious in operation and high in error risk during unmanned aerial vehicle cluster launching is solved.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

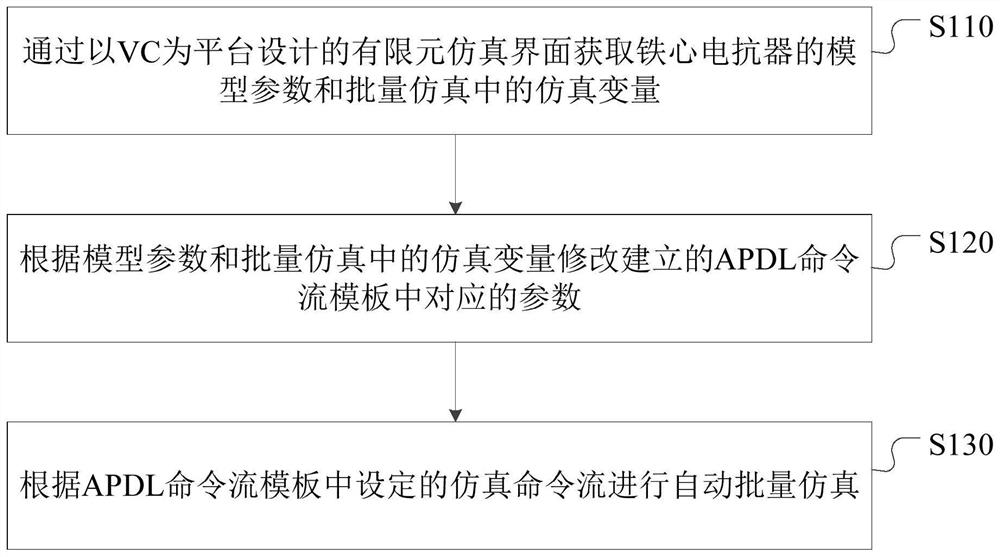

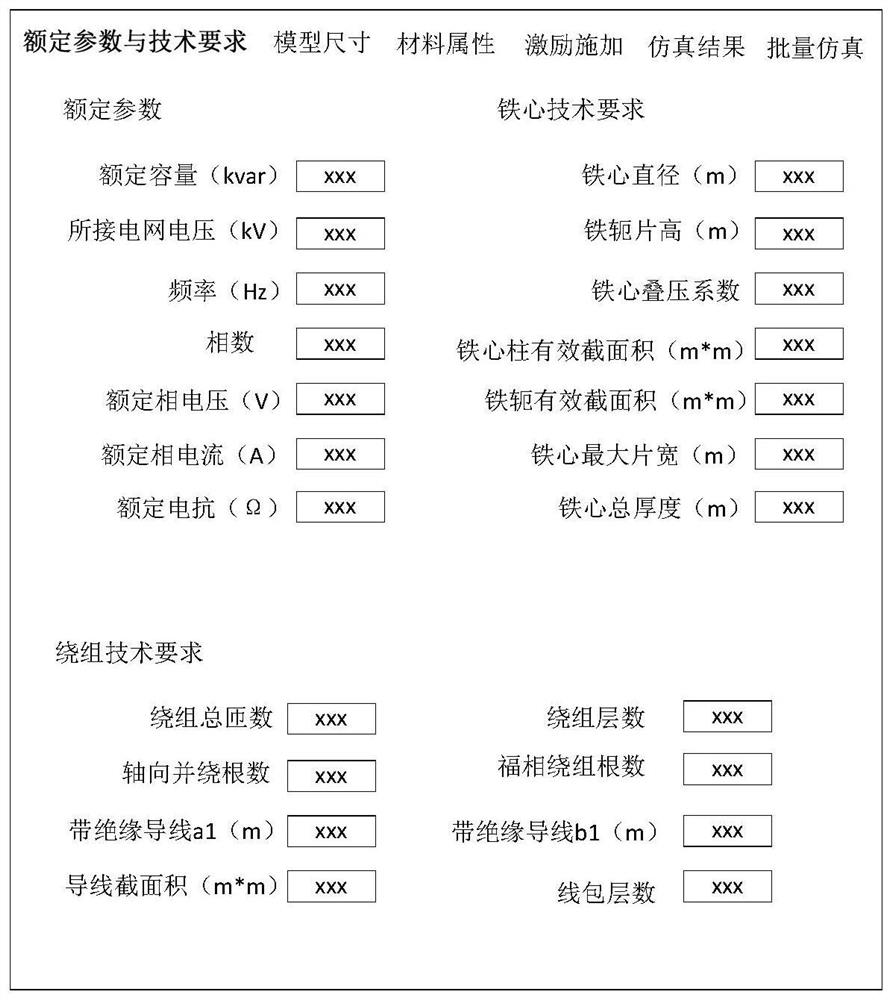

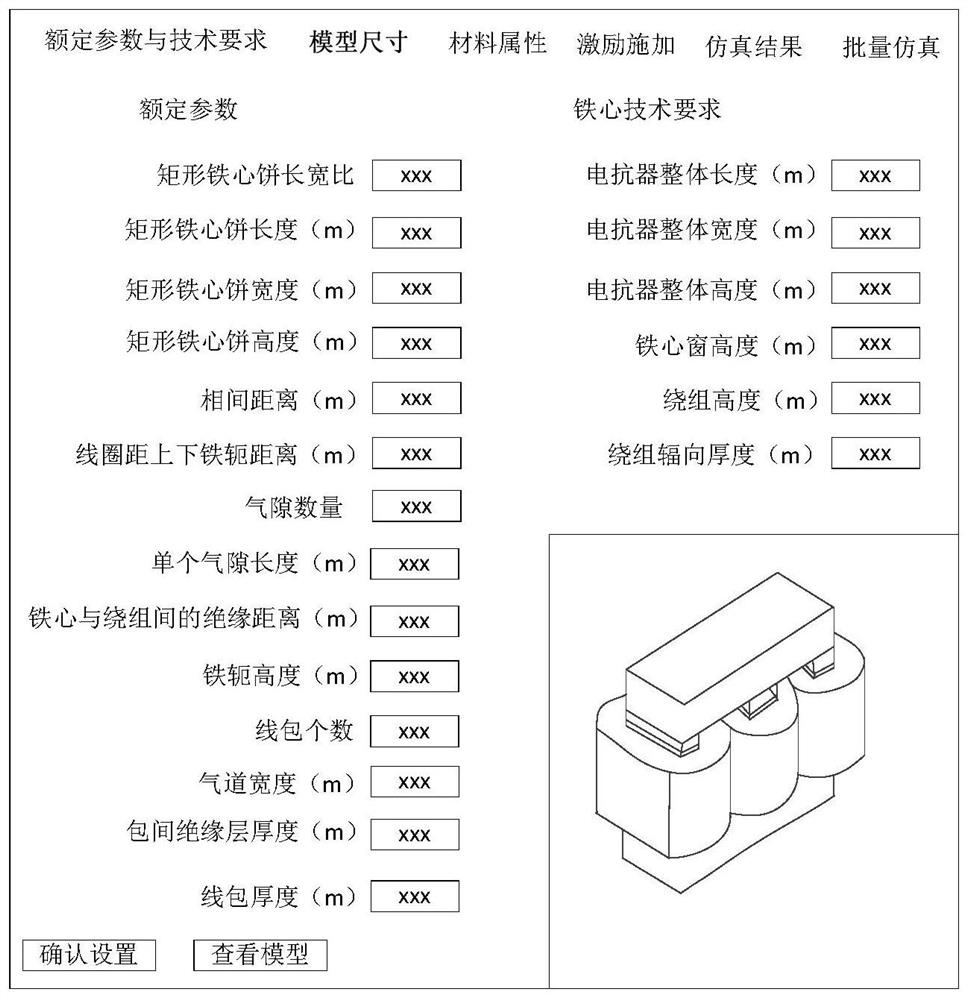

Iron core reactor batch simulation method

PendingCN112182937AConvenient large-scale simulationEasy to operateDesign optimisation/simulationSpecial data processing applicationsModelSimProcess engineering

The embodiment of the invention discloses an iron core reactor batch simulation method, which comprises the steps: acquiring model parameters of an iron core reactor and simulation variables in batchsimulation through a finite element simulation interface designed with VC as a platform; modifying corresponding parameters in an established APDL command stream template according to the model parameters and simulation variables in batch simulation; and performing automatic batch simulation according to the simulation command stream set in the APDL command stream template. According to the method, the operation steps of a designer during calculation and analysis of the magnetic field performance of the iron core reactor are simplified, the risk of personal errors in the repeated modeling process is avoided, the efficiency and accuracy of batch simulation are improved, and large-scale simulation of the iron core reactor is completed conveniently.

Owner:GUANGDONG POWER GRID CO LTD +1

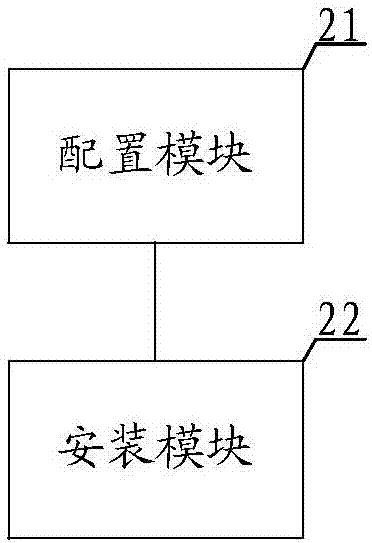

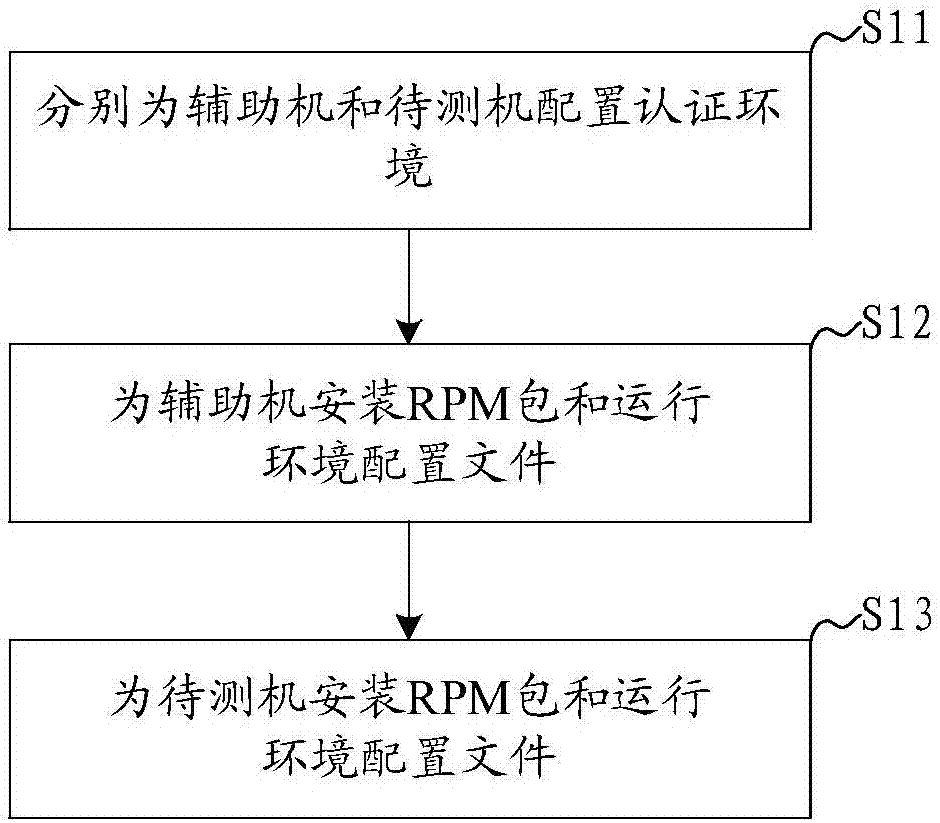

Test system and method for auxiliary machine, to-be-tested machine and terminal

InactiveCN107229496AImplement automatic deploymentAvoid the risk of human errorProgram loading/initiatingData switching networksSoftware engineeringComputer terminal

The invention discloses a test system and method for an auxiliary machine, a to-be-tested machine and a terminal, and is applied to the certification environment of NeoKylin. The system and method comprises a configuration module for configuring the certification environment and an installation module for installing a RPM package and running files of the environment configuration. According to the test system and method for an auxiliary machine, a to-be-tested machine and a terminal, the auxiliary machine utilizes the configuration module to configure the certification environment in the certification environment of NeoKylin, and uses the installation module to install the RPM package which is required for a certification test and run the files of the environment configuration; above all, automatic assignment of the certification environment of the auxiliary machine is achieved, and risks of man mistakes brought by manual installation and environment configuration are avoided, so that the certification test can be conducted quickly and smoothly.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

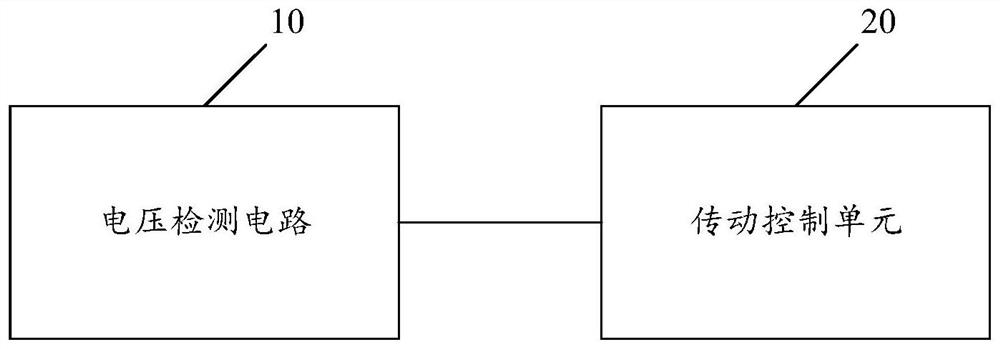

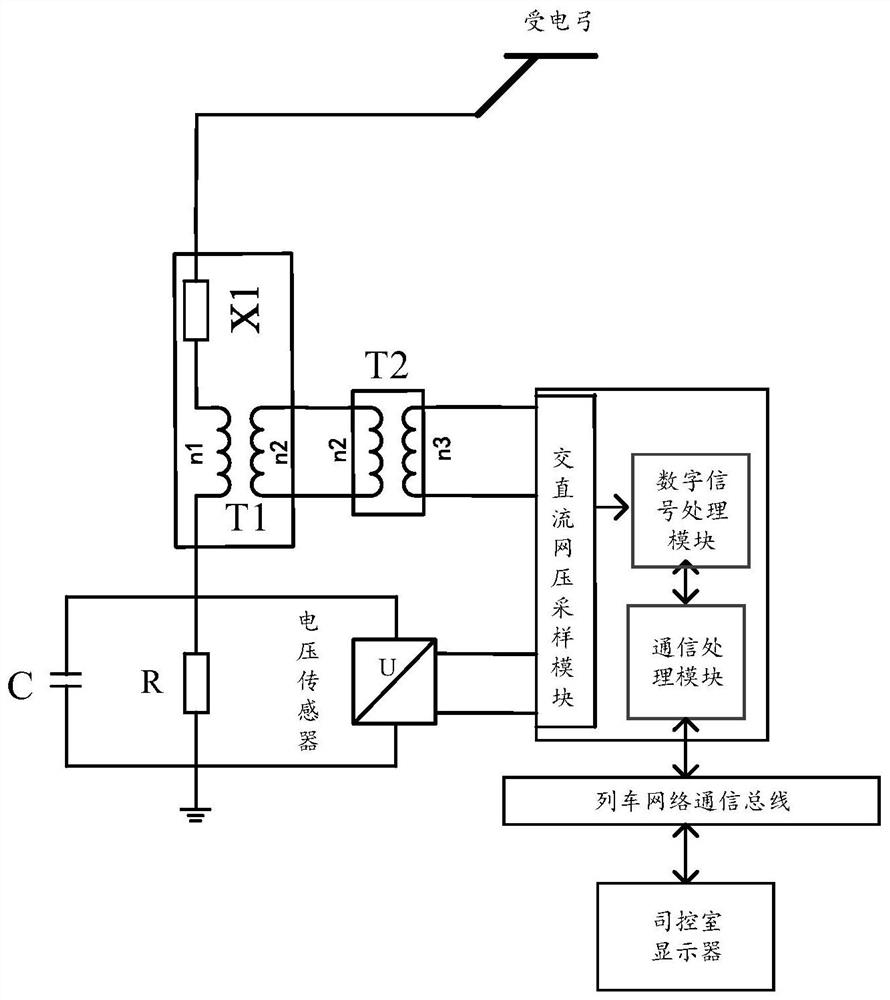

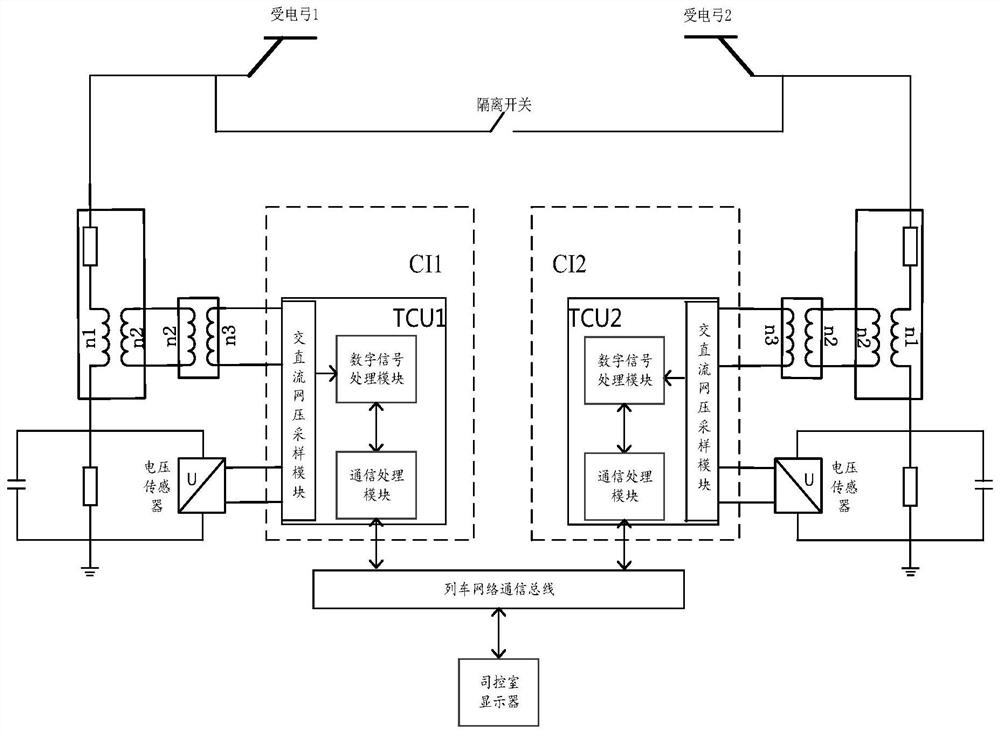

Control device and method of traction converter

ActiveCN113644813AImprove securityAvoid the risk of human errorSelective ac load connection arrangementsPower supply linesControl engineeringPower grid

The invention discloses a control device of a traction converter. The control device comprises a voltage detection circuit and a transmission control unit, the voltage detection circuit is used for detecting the voltage of a power grid and outputting a voltage signal; and the transmission control unit is used for determining a power supply system of a line according to the voltage signal, calculating the power grid voltage according to the voltage signal, and controlling an operation mode of a main circuit of the traction converter according to the power supply system and the power grid voltage. The control device can automatically detect the power supply system and control the operation mode of the main circuit of the traction converter, the risk of manual misoperation is avoided, and the operation safety of the railway vehicle is improved. The invention further discloses a control method of the traction converter, and the control method also has the above technical effects.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

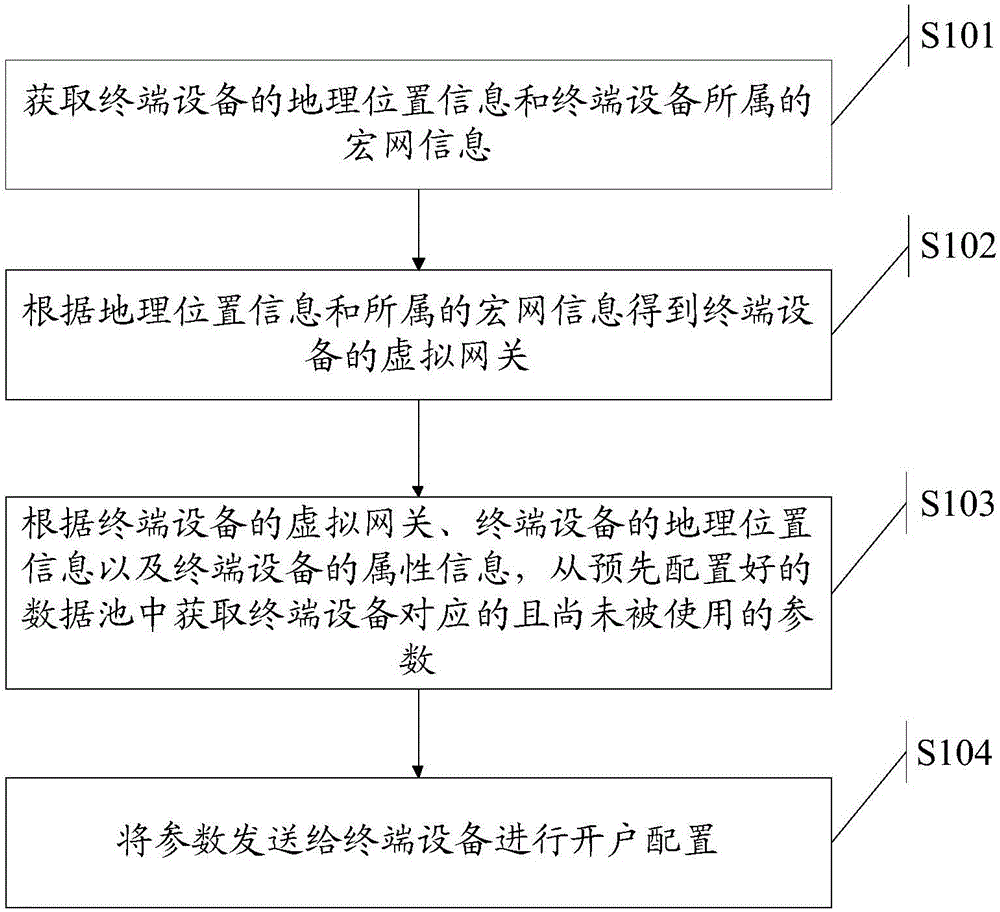

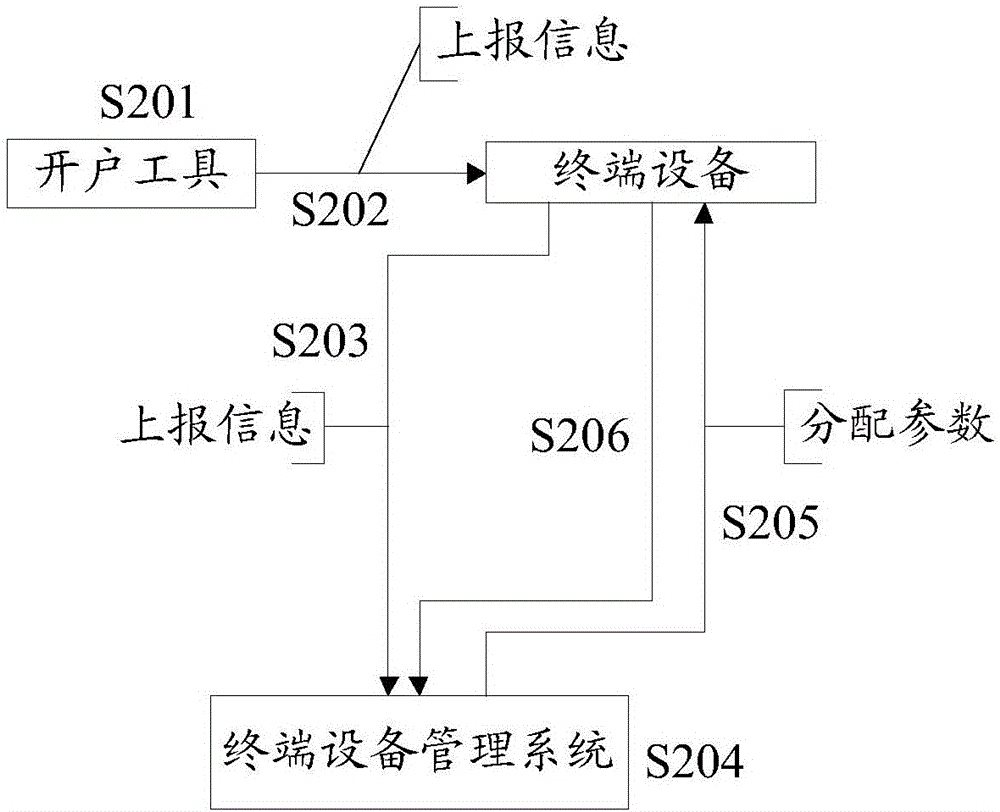

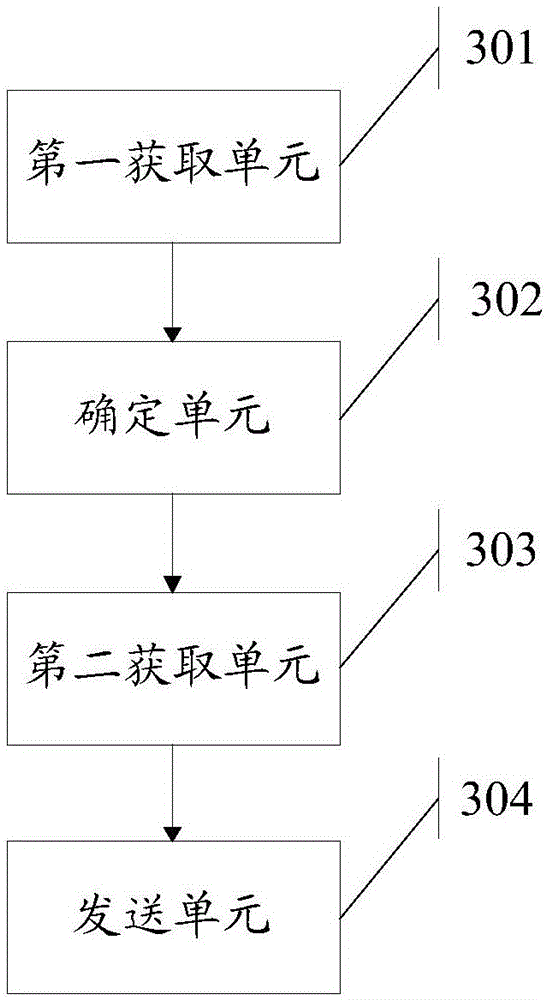

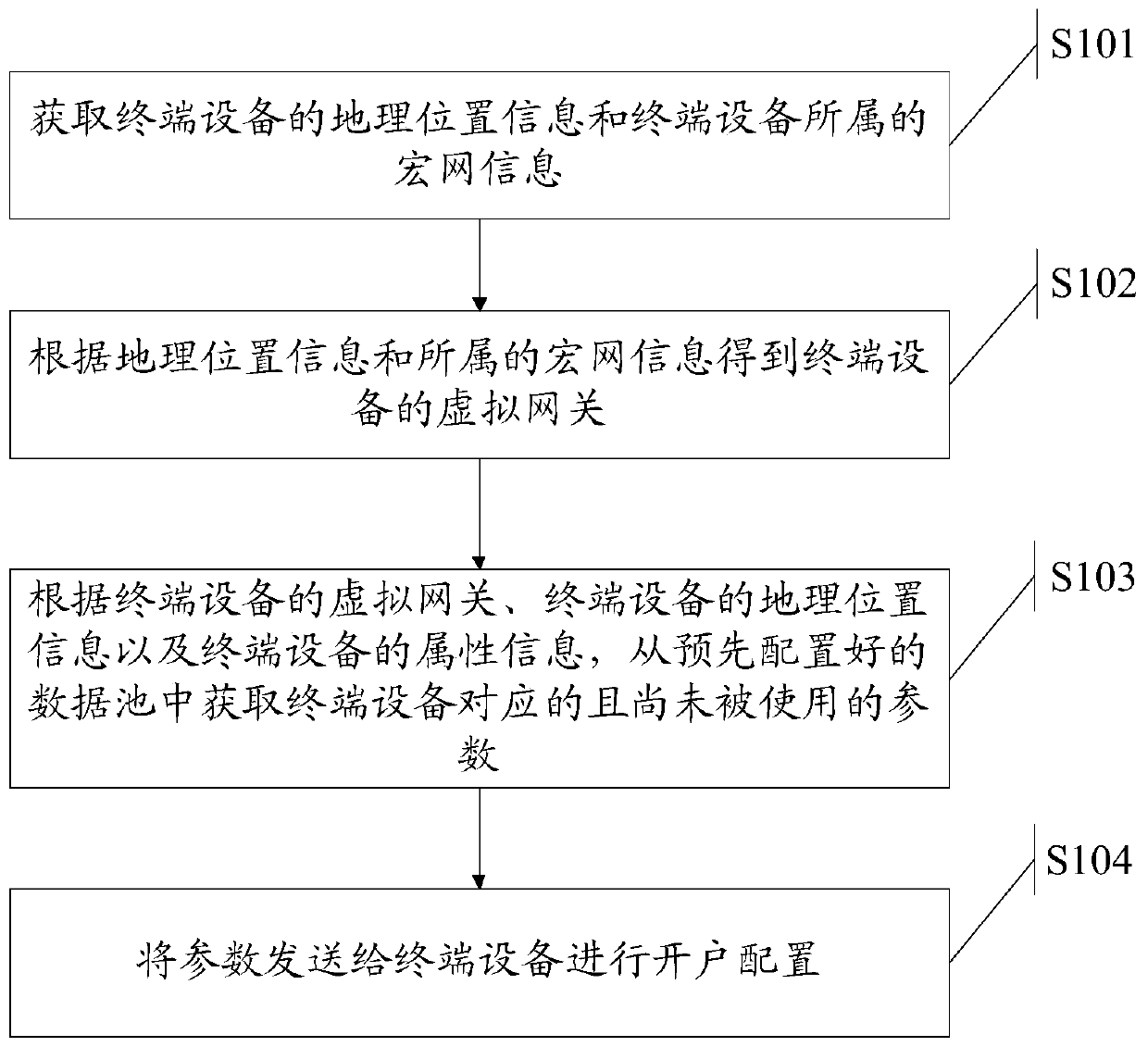

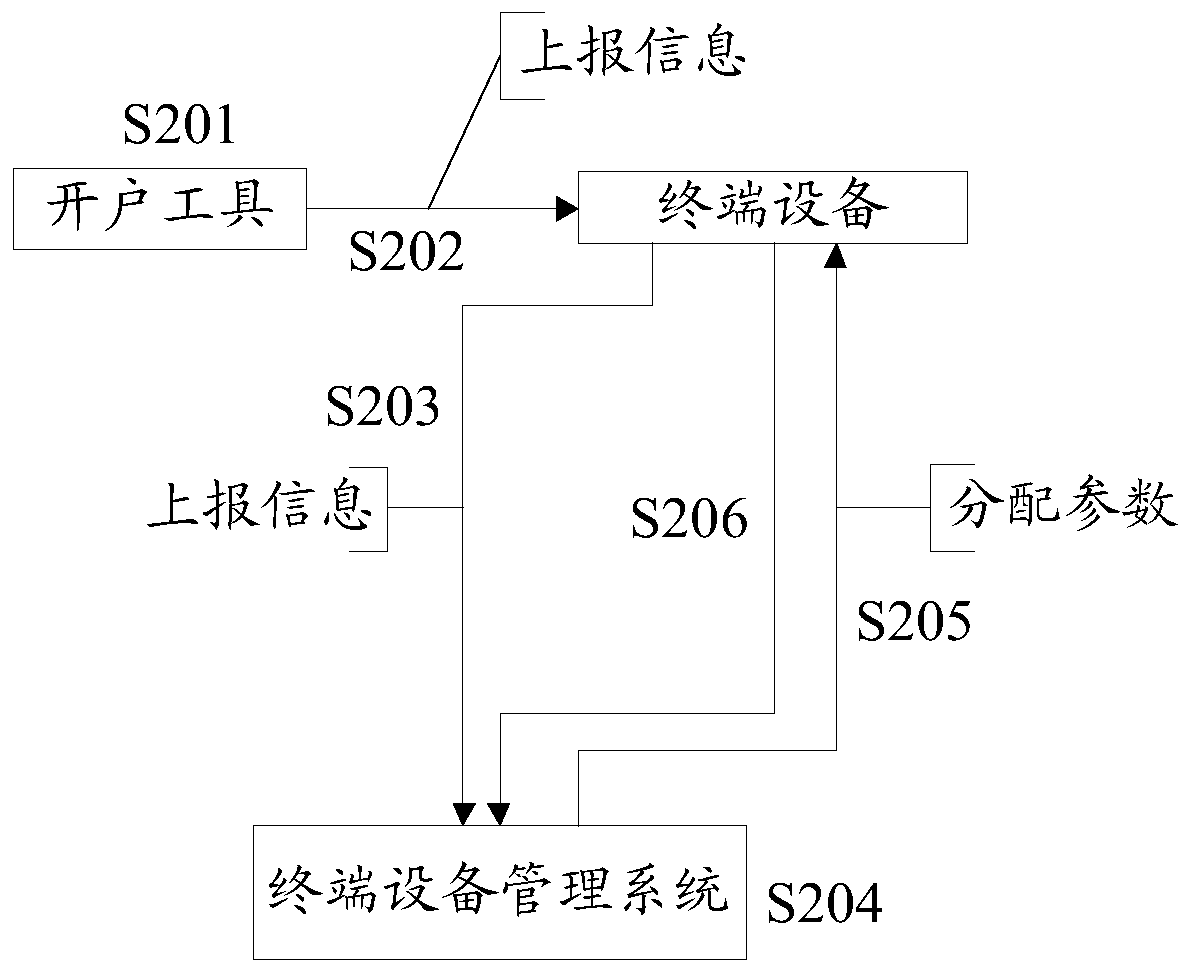

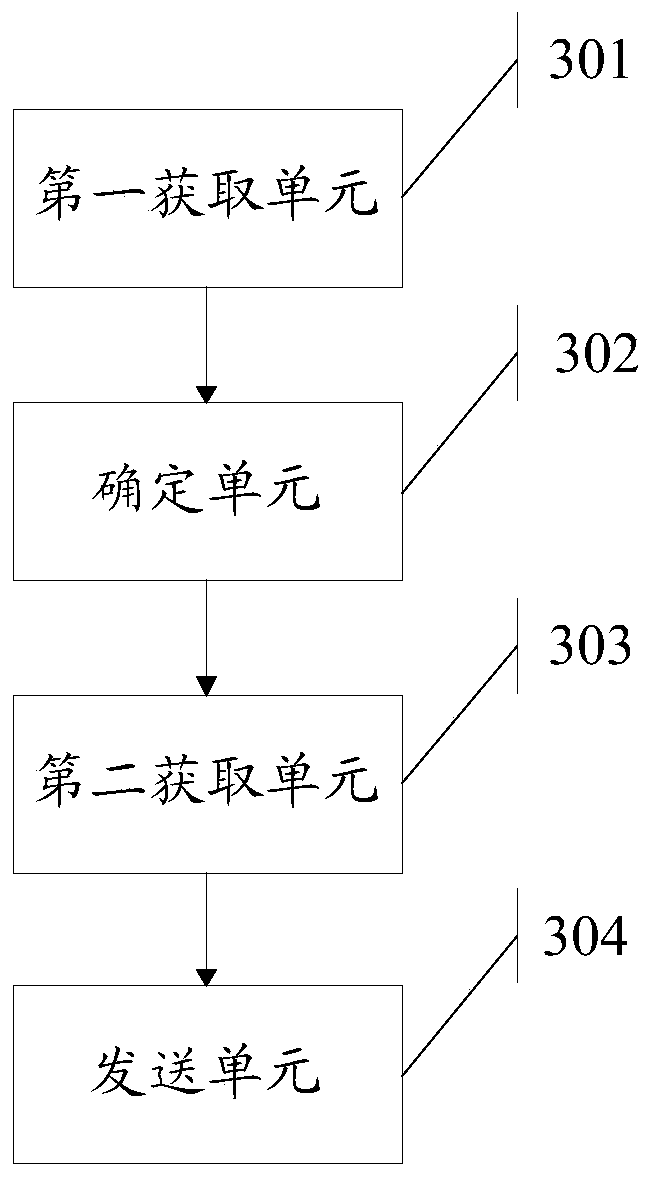

Method and apparatus for opening account for terminal device

ActiveCN106411573AGuaranteed success rateGuaranteed efficiencyData switching networksNetwork data managementComputer hardwareGeolocation

The embodiment of the invention relates to the field of communication, and particularly relates to a method and apparatus for opening an account for a terminal device, used for configuring the account opening of the terminal device. In the embodiment of the invention, the method comprises the following steps: acquiring geographical location information of the terminal device and macro network information to which the terminal device belongs; acquiring a virtual gateway of the terminal device according to the geographical location information and the macro network information to which the terminal device belongs; acquiring unused parameters corresponding to the terminal device form a pre-configured data pool according to the virtual gateway of the terminal device, the geographical location information of the terminal device and attribute information of the terminal device; and sending the parameters to the terminal device to perform account opening configuration, so that a terminal device management system performs the account opening configuration according to the parameters of the terminal device.

Owner:COMBA TELECOM SYST CHINA LTD

A connector with locking device

Owner:胡连电子(南京)有限公司

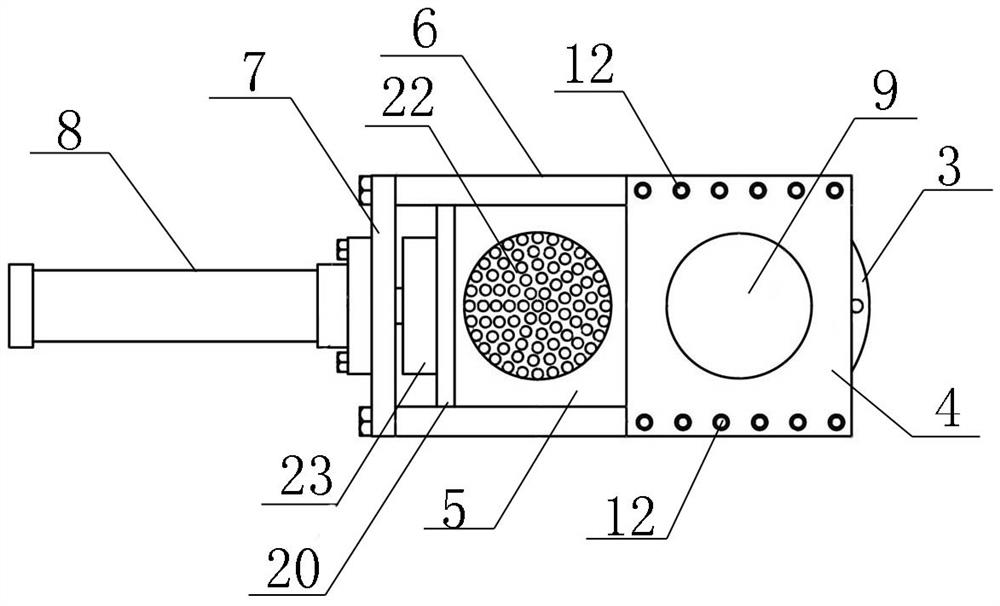

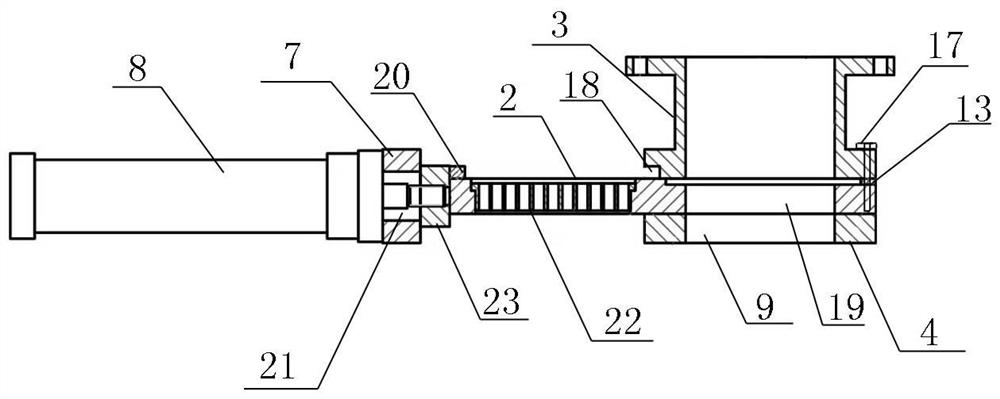

Plastic pre-extrusion machine die structure and operation method thereof

The invention discloses a plastic pre-extrusion machine die structure and an operation method thereof. The plastic pre-extrusion machine die structure comprises an end, a pressing plate, a two-stationnet base, tension columns, a hydraulic oil cylinder base and a hydraulic oil cylinder. The pressing plate is installed at the inner side of a front side plate of a box body. The end is arranged at the outer side of the front side plate of the box body and is parallel to the pressing plate at an interval. The end and the pressing plate are tied through a tie bolt; the two-station net base is inserted into a gap between the end and the pressing plate and can be adjusted in the transverse direction; two installation openings are formed in the plate face of the two-station net base in the transverse direction in a spaced manner; the two tension columns are located at the top and the bottom of the two-station net base respectively; the hydraulic oil cylinder base is connected between the leftends of the two tension columns; and the hydraulic oil cylinder is horizontally connected to the left side face of the hydraulic oil cylinder base, and the hydraulic oil cylinder pushes and pulls thetwo-station net base to move in the transverse direction. The technical problems that the traditional manual die loading and unloading installation efficiency is low, a certain risk exists for the safety of workers, and production accidents are easily caused are solved.

Owner:JIANGSU LONGYUAN CATALYST CO LTD +1

Device and method for printing and comparing circulating label bar codes

InactiveCN101697205BShielding effectAvoid the risk of human errorCo-operative working arrangementsDigital output to print unitsData exchangeBarcode reader

The invention provides a device and a method for printing and comparing circulating label bar codes, which belong to the technical field of bar code printing. The device for printing and comparing the circulating label bar codes is characterized by comprising a circulating label printing computer, wherein the circulating label printing computer is connected with a circulating label printer, a barcode reader and a concentrator through a serial port cable, a USB cable and a network cable respectively; the concentrator is connected with a pipelining server and a packing station through the network cable respectively; the circulating label printing computer is provided with a serial port blocking module, a global keyboard mouse hook module, a local area network data exchange module and a printing control module which are connected with one another in turn; and the printing control module is connected with the serial port blocking module. The device and the method have the advantages of being capable of determining the correctness of the printed bar codes and controlling the amount of products stacked on the packing station.

Owner:SHANGHAI SUOGUANG ELECTRONICS

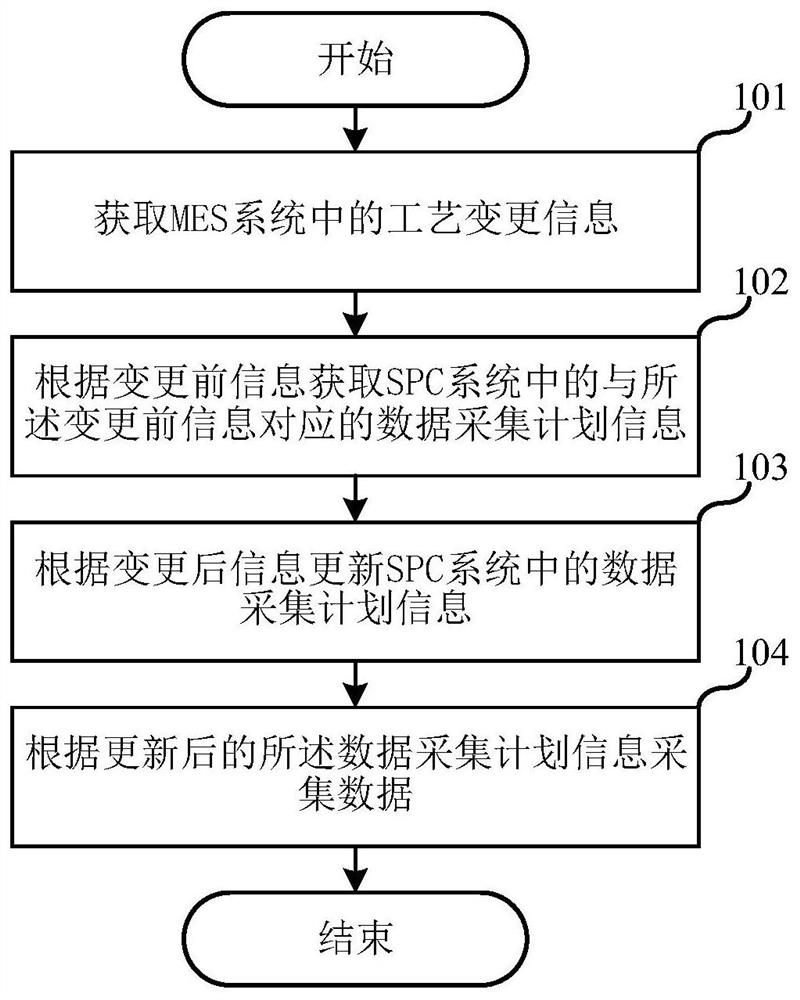

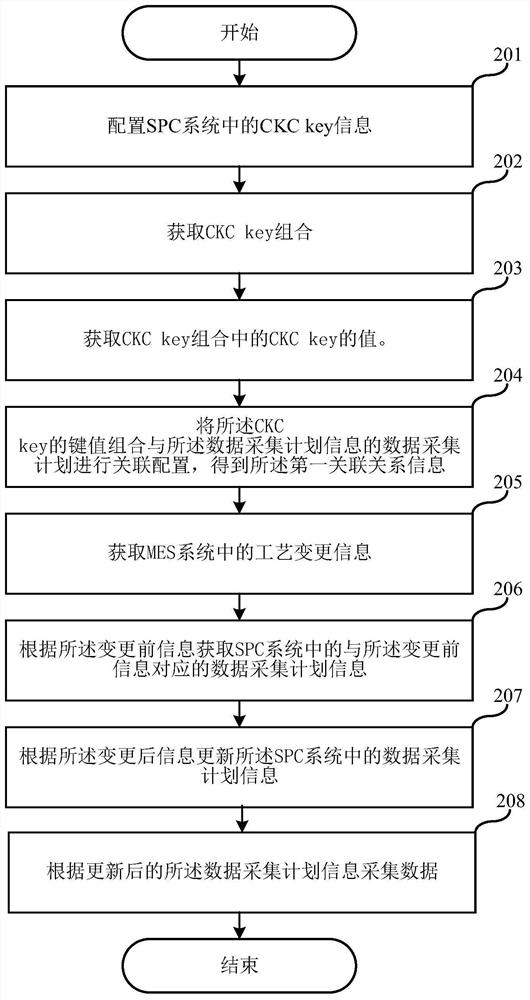

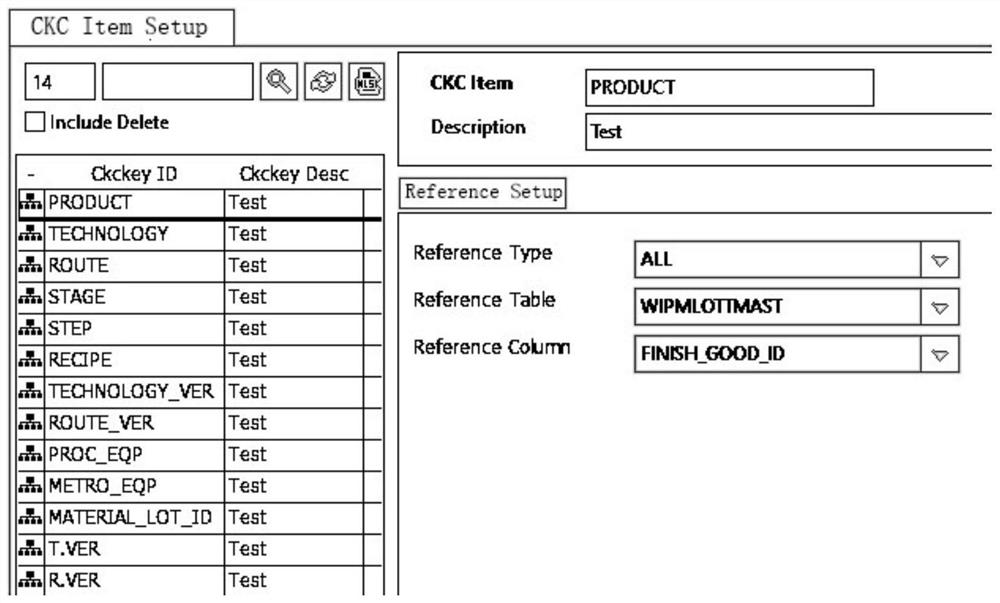

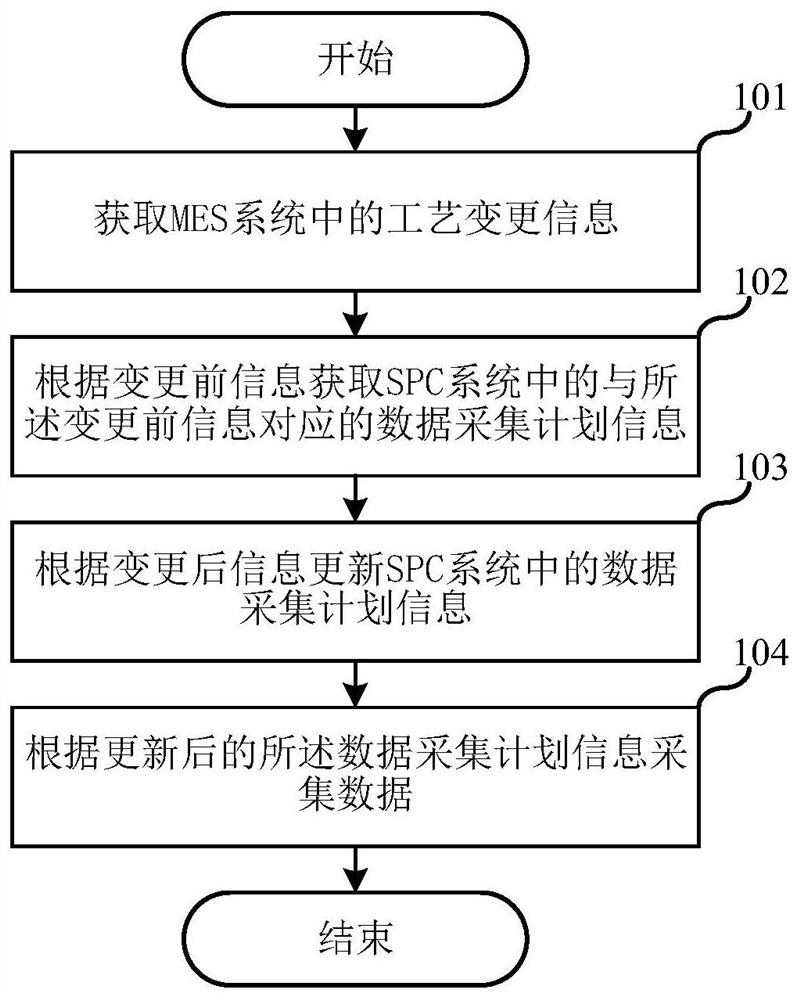

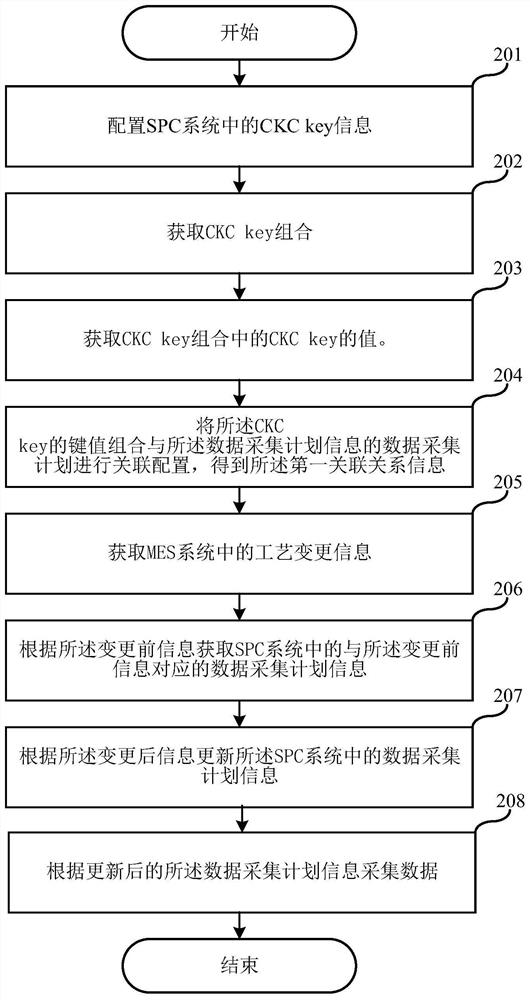

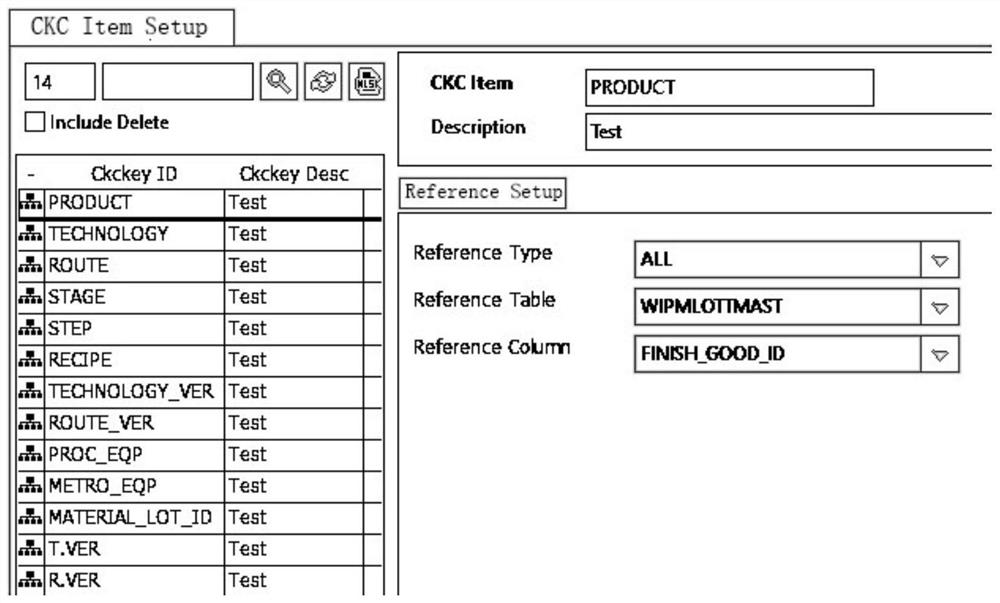

Data acquisition method, device, electronic device, storage medium

ActiveCN112612255BImprove data collection efficiencyAvoid the risk of human errorTotal factory controlProgramme total factory controlData acquisitionEngineering

The embodiment of the invention relates to the field of control, and discloses a data acquisition method, device, electronic equipment, and storage medium. In the present invention, the process change information in the MES system is obtained, and the process change information includes the information before the change and the information after the change; according to the information before the change, the data acquisition plan information corresponding to the information before the change in the SPC system is obtained; according to the information after the change Information acquisition and change information CKC key key value combination corresponding to the change information; add the change information CKC key value combination to the association relationship information of the data collection plan to obtain the updated data collection plan, collect data according to the updated data collection plan information, In this way, the information of the data collection plan can be automatically updated without adding a new data collection plan, so that the data monitored by the version before the change and the version added according to the information after the change are automatically collected according to the data collection plan, avoiding human errors caused by a large amount of setting work risks and reduce labor costs.

Owner:上海赛美特软件科技有限公司

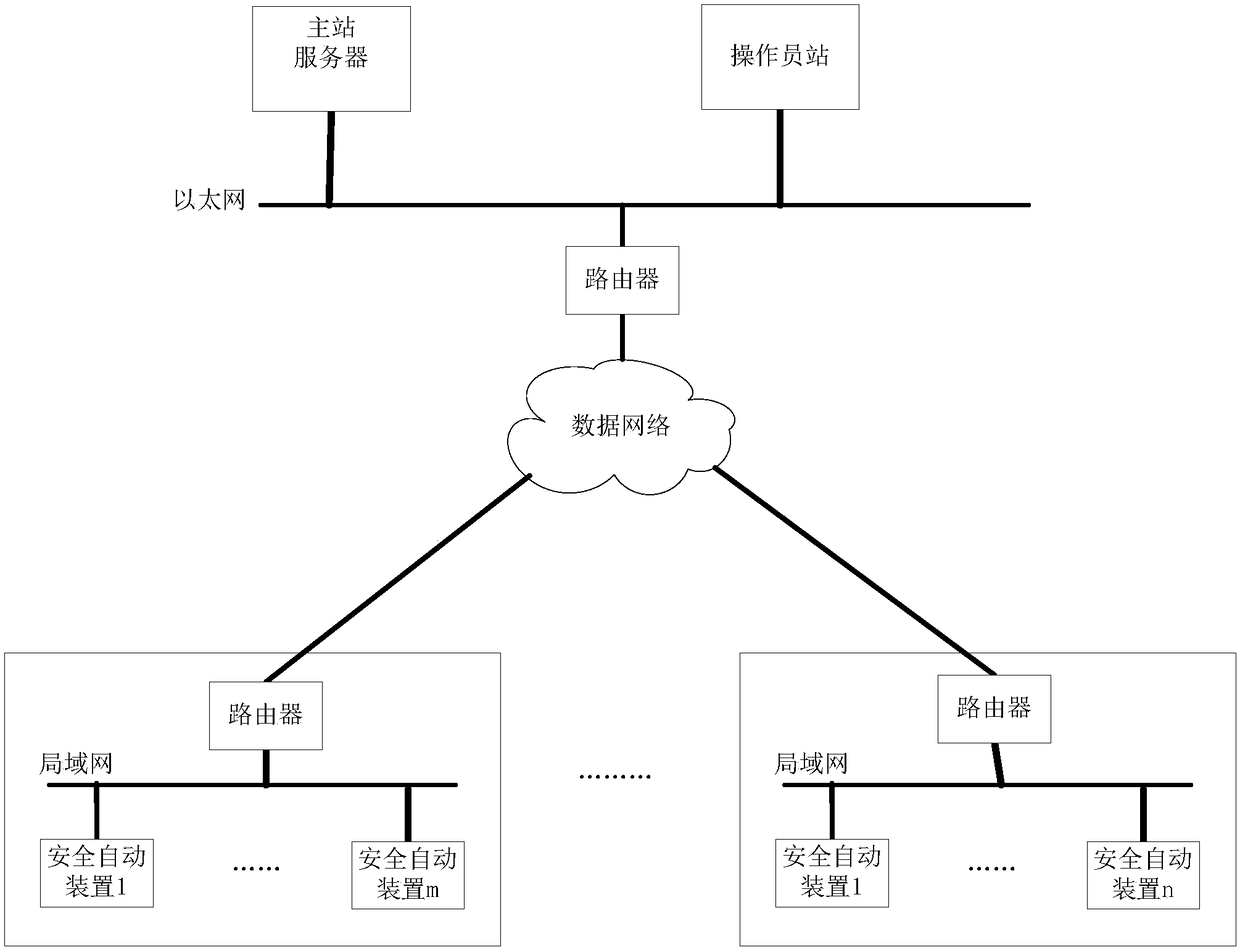

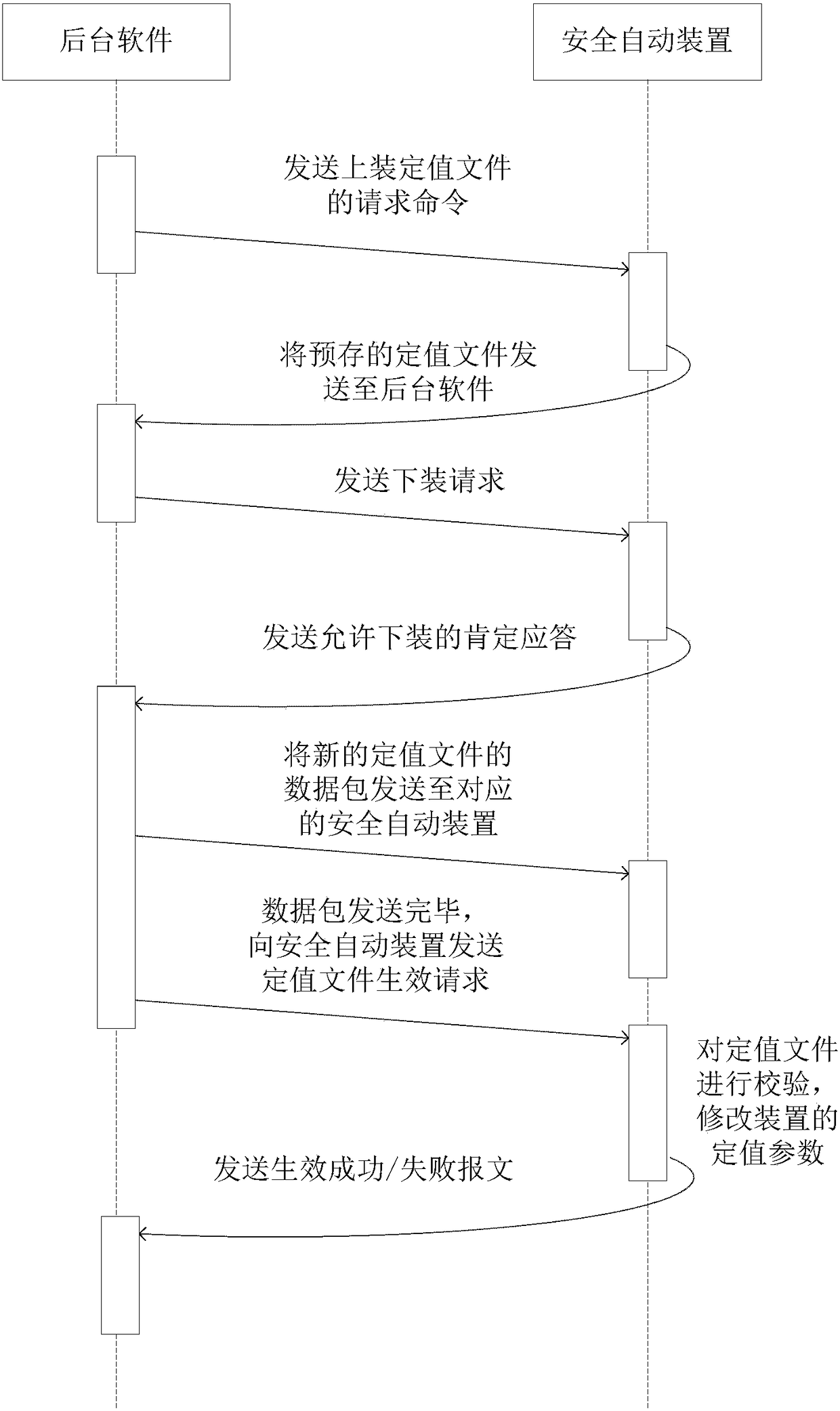

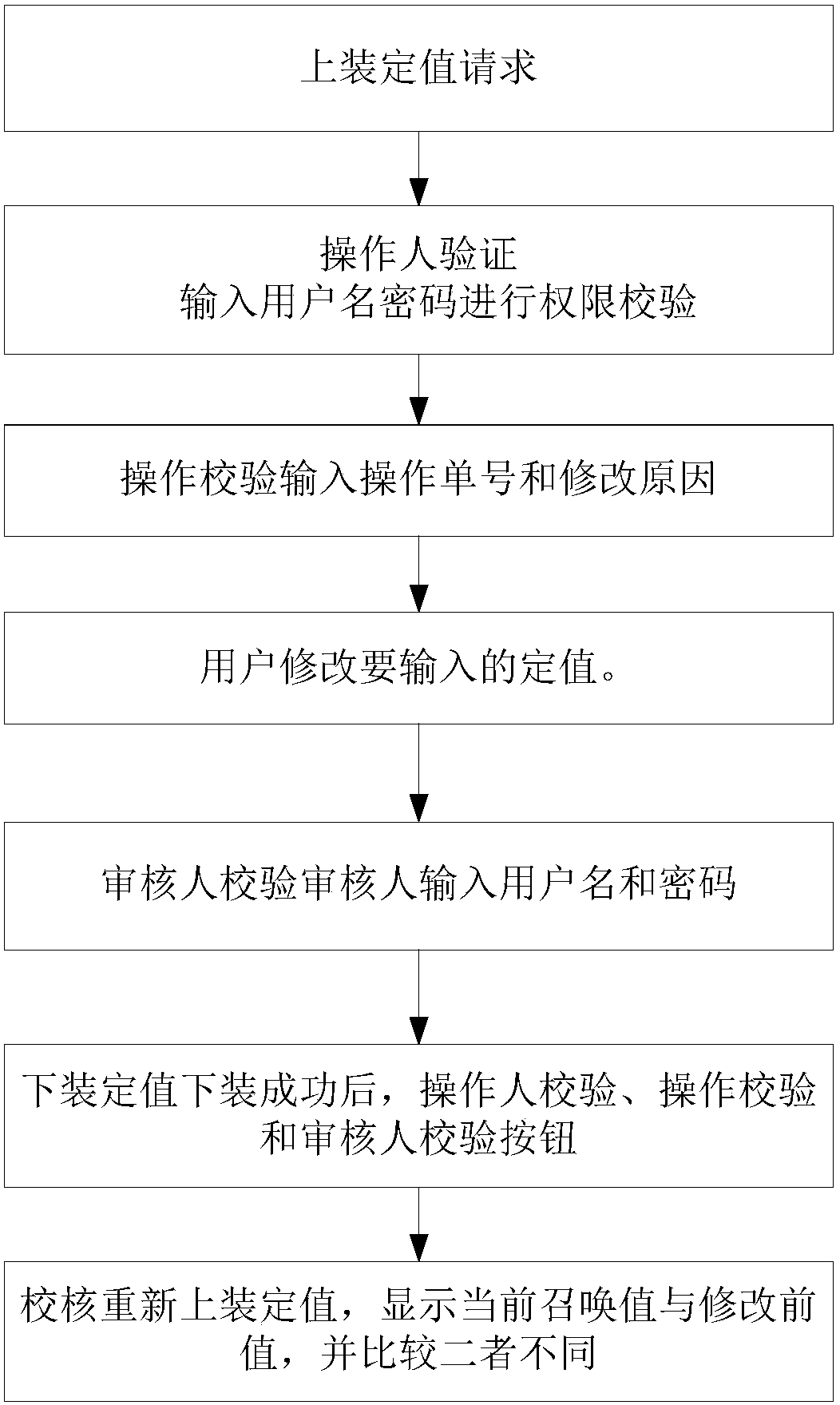

Remote setting value modification system of safety automatic device based on file interaction

ActiveCN105978147BImprove work efficiencyImprove reliabilityCircuit arrangementsTransmissionData packPower grid

Owner:POWER DISPATCHING CONTROL CENT OF GUANGDONG POWER GRID CO LTD

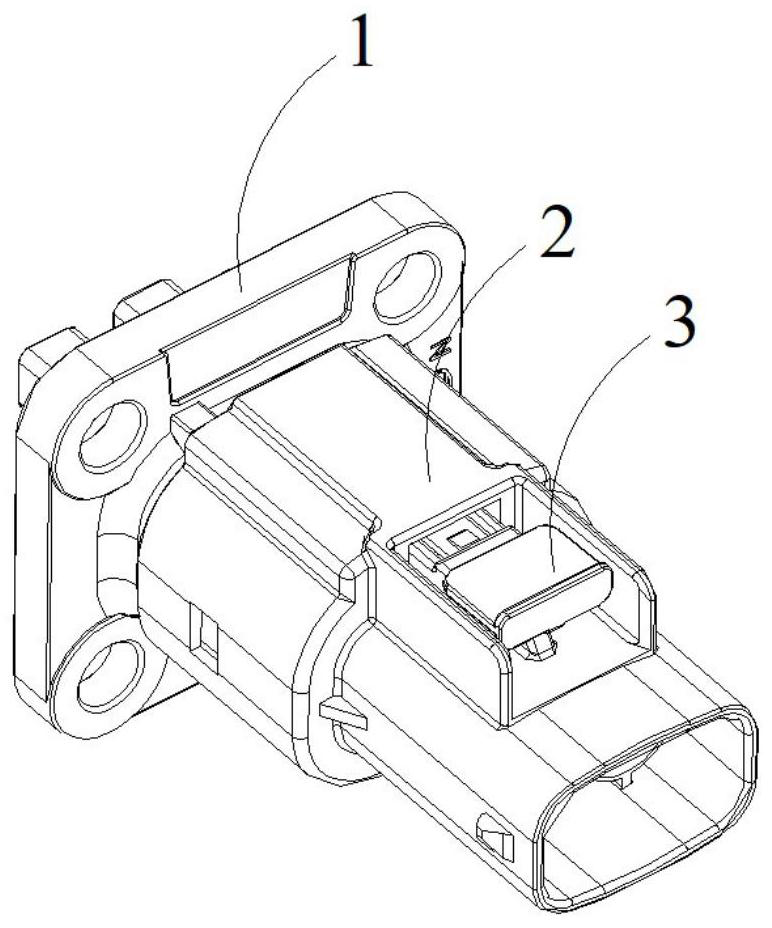

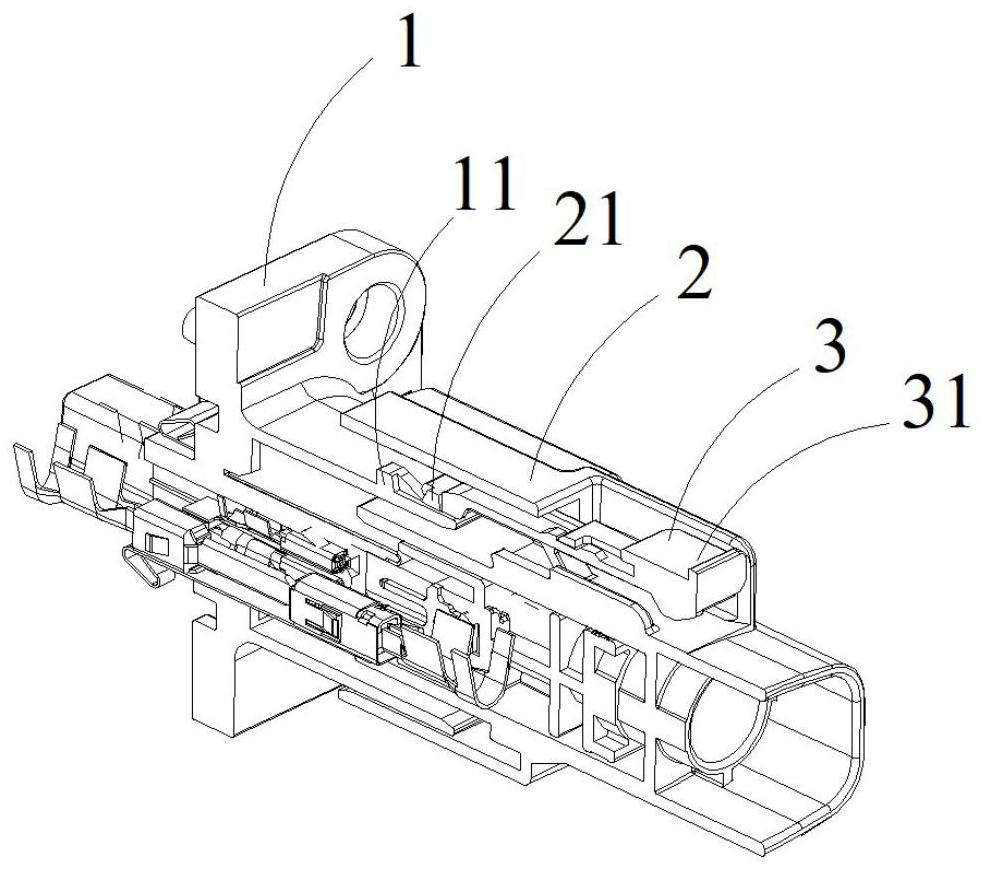

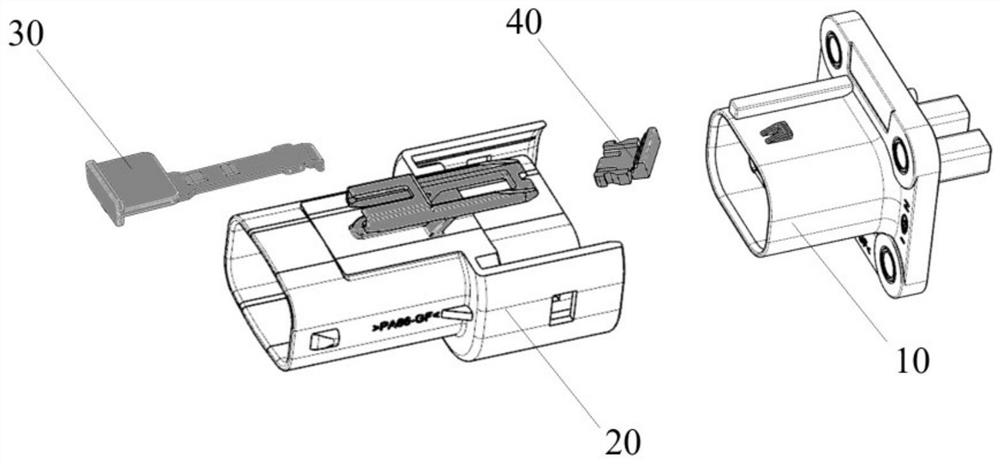

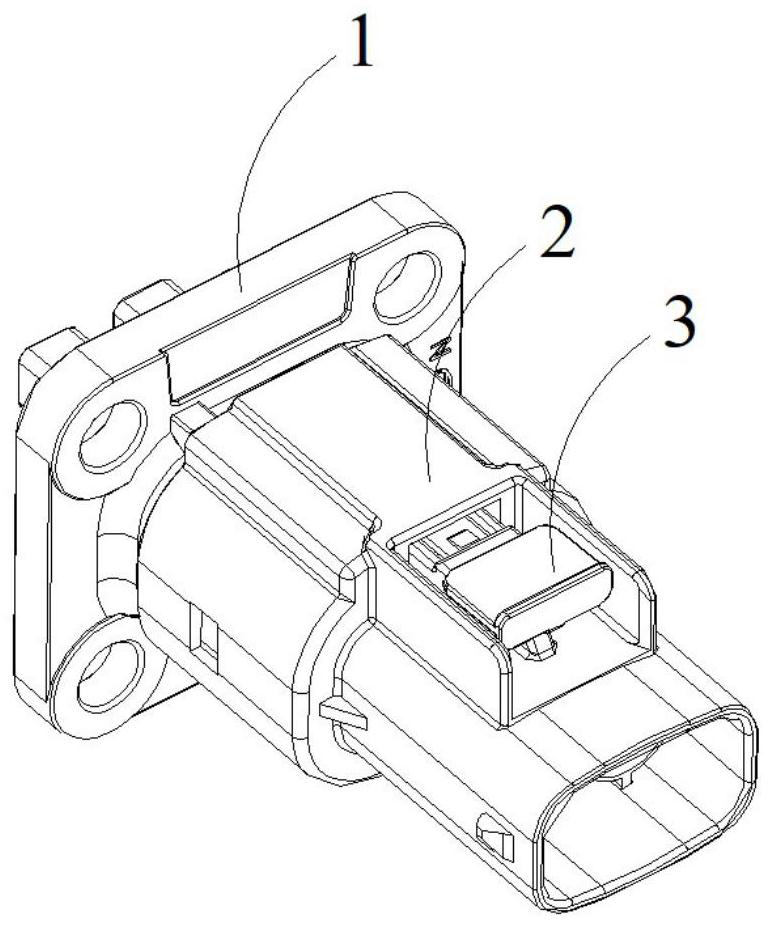

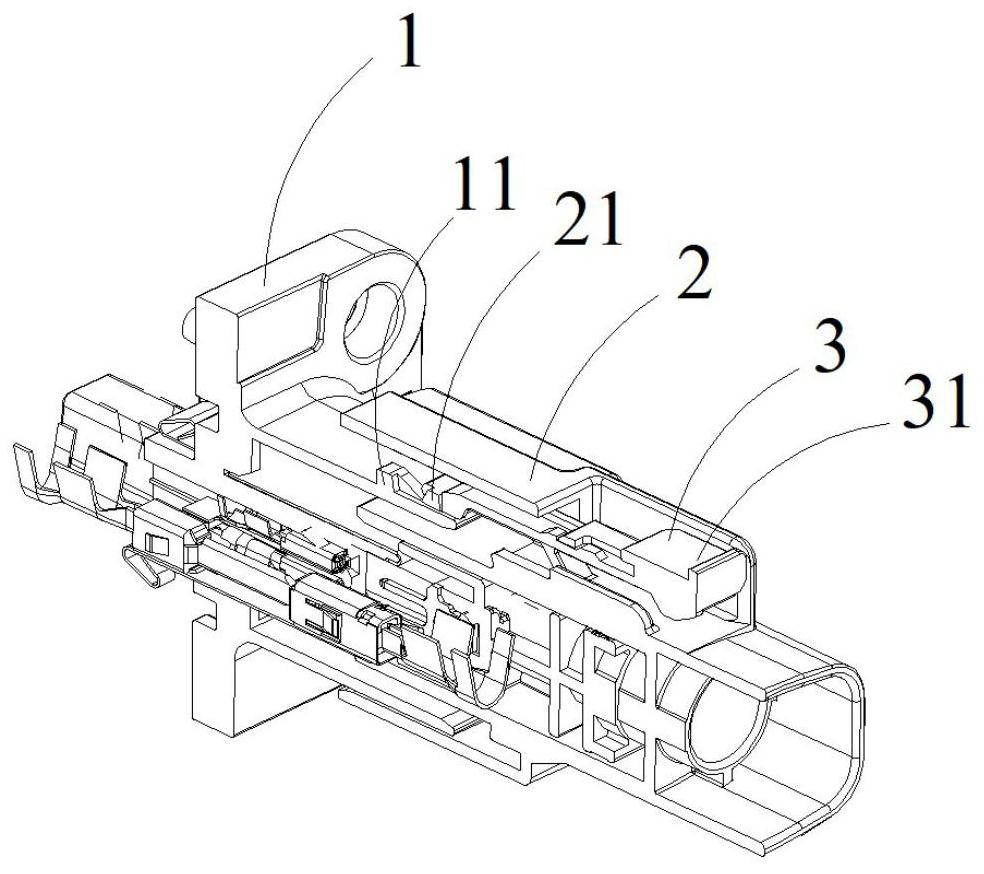

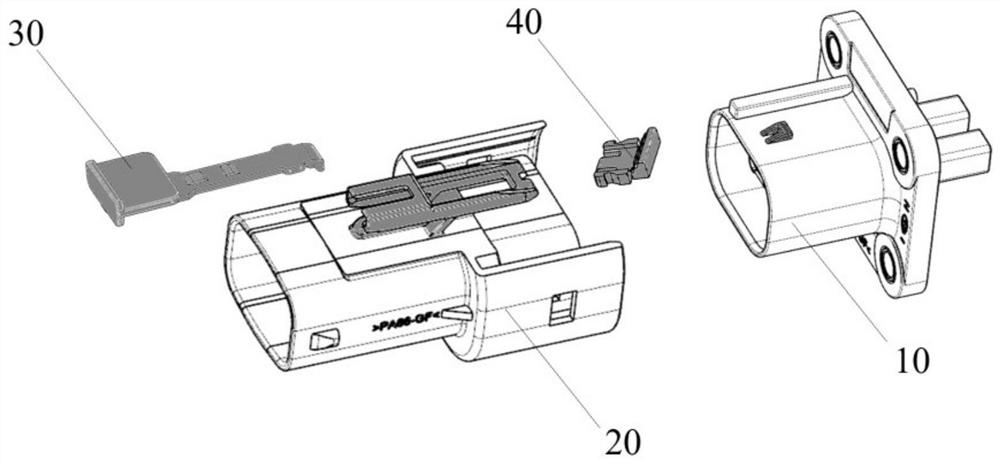

Connector with locking device

ActiveCN112531410AAvoid the risk of human errorCoupling device detailsStructural engineeringMechanical engineering

The invention discloses a connector with a locking device. The connector comprises a first connecting device, a second connecting device, a first locking device and a second locking device, wherein the second connecting device is used for fixing and protecting a power supply terminal and a signal terminal in the second connecting device, and the first connecting device is matched with the second connecting device; a first connecting structure is arranged on the upper surface of the first connecting device, and the first connecting structure is clamped with the first locking device; the secondconnecting structure is detachably connected with the first locking device, a second connecting structure is arranged on the upper surface of the second connecting device, and the second connecting structure is clamped with the second locking device. According to the high-voltage interlocking structure of the connector, a low-voltage monitoring loop in the connector can be disconnected earlier than a high-voltage loop, and a function of keeping a certain advance can be realized.

Owner:胡连电子(南京)有限公司

Method and device for opening account of terminal equipment

ActiveCN106411573BGuaranteed success rateGuaranteed efficiencyData switching networksNetwork data managementGeolocationTerminal equipment

Owner:COMBA TELECOM SYST CHINA LTD

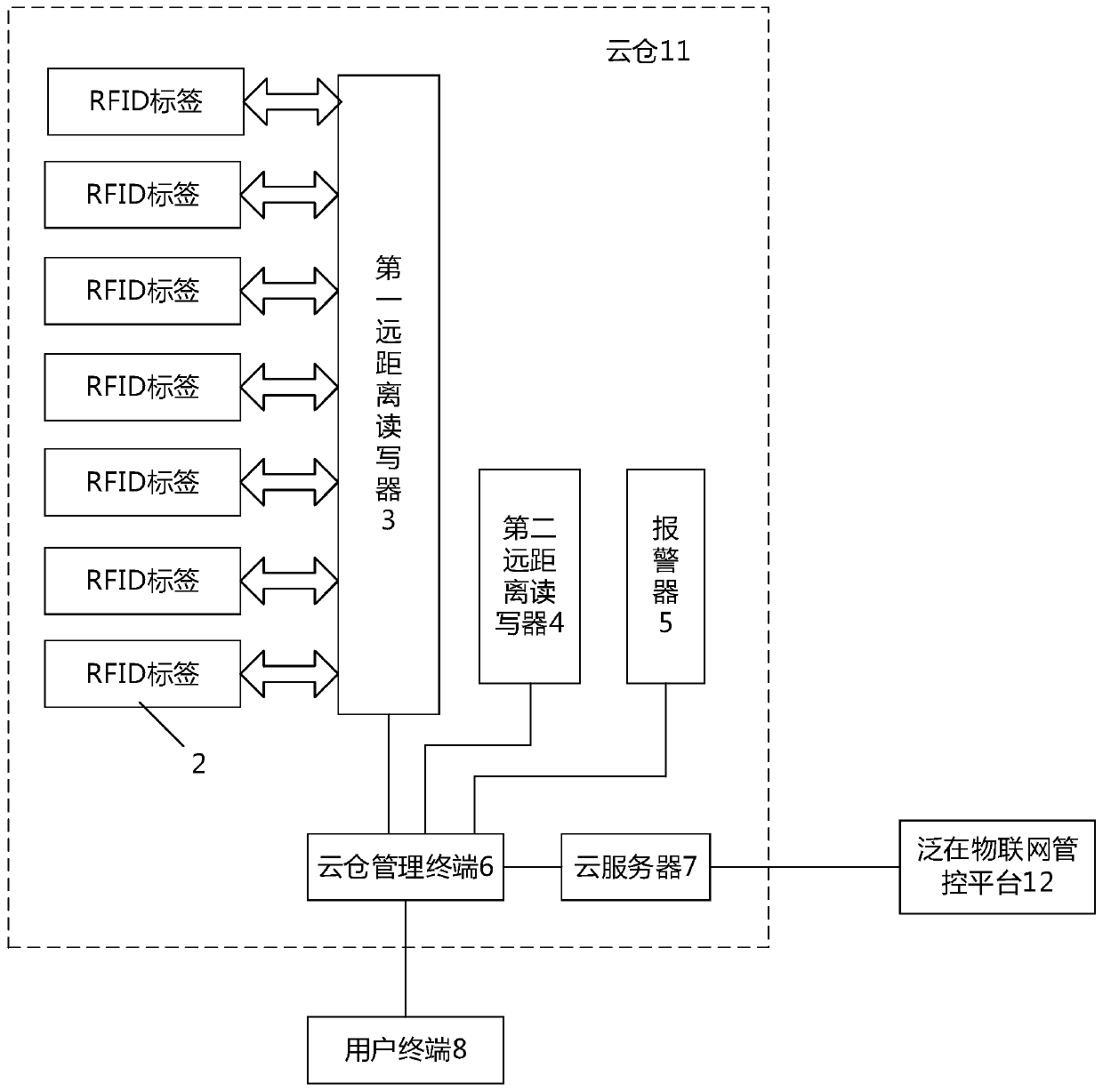

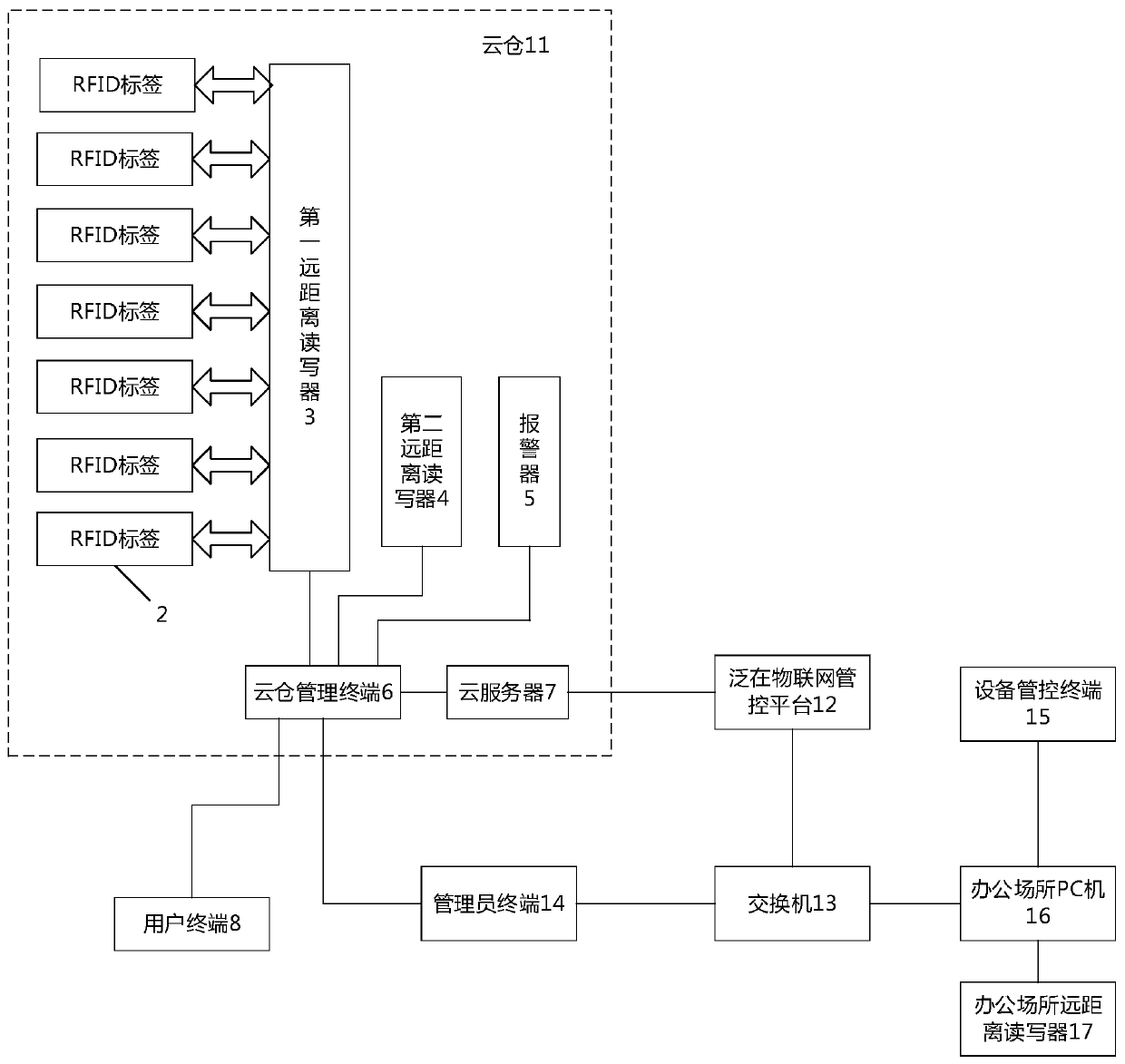

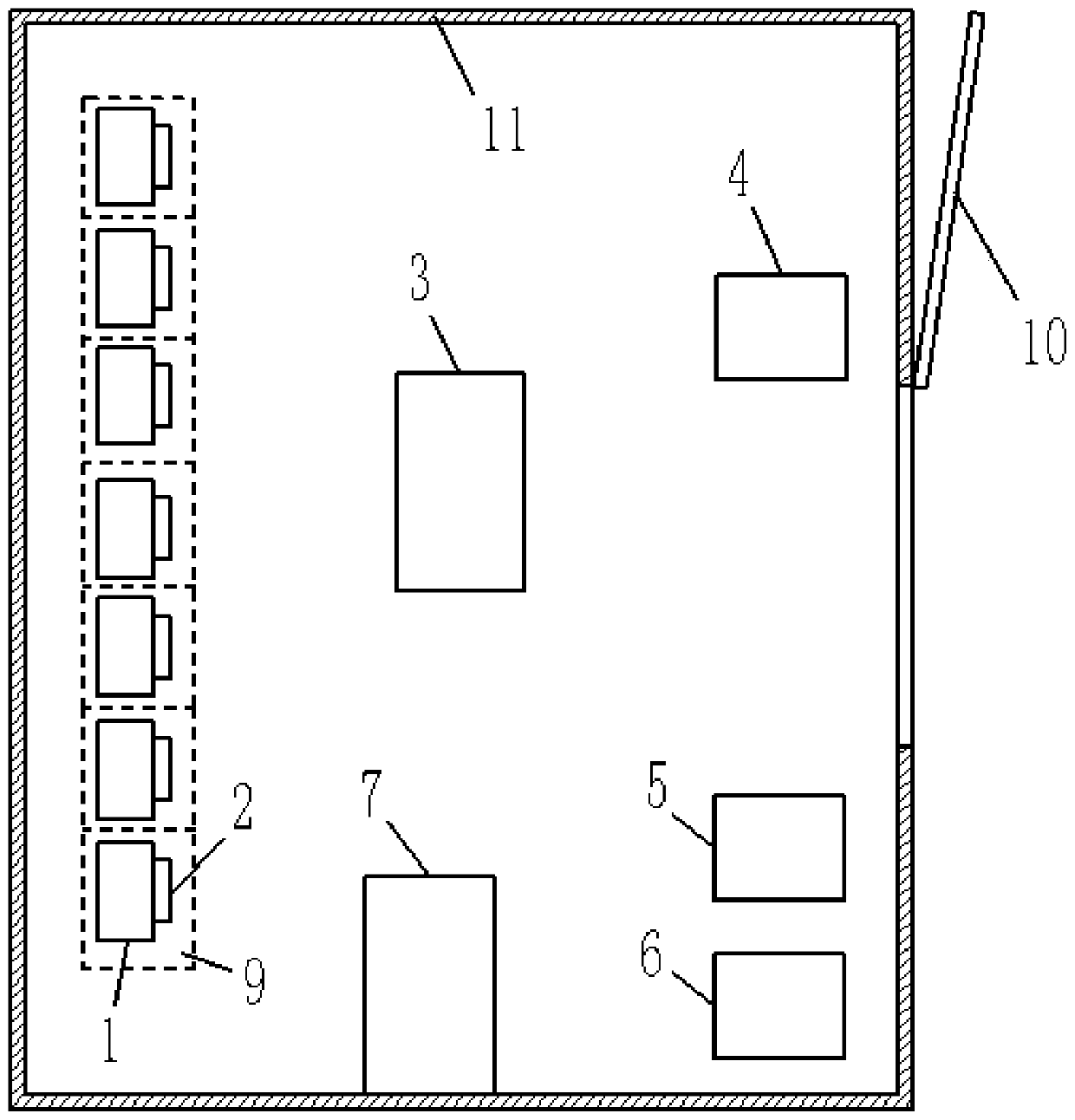

Power asset equipment management and control system under ubiquitous Internet of Things

ActiveCN111126524APut an end to the phenomenonImprove work efficiencyCo-operative working arrangementsResourcesControl systemServer

The invention provides a power asset equipment management and control system under the ubiquitous Internet of Things. The system comprises a cloud warehouse, a user terminal and a ubiquitous Internetof Things management and control platform, the cloud warehouse comprises a cloud warehouse management terminal, a cloud server, a first remote reader-writer and managed and controlled electric power asset equipment placed on a warehouse position, and each managed and controlled electric power asset equipment is provided with an RFID tag; the user terminal is used for submitting a receiving application of the target controlled power asset equipment to the cloud warehouse management terminal; the cloud warehouse management terminal is used for approving the received receiving application; the cloud server is used for information storage of the system; the cloud warehouse management terminal is connected with the first remote reader-writer; the ubiquitous Internet of Things management and control platform is connected with the cloud server; the cloud bin further comprises an alarm and a second remote reader-writer; and the cloud warehouse management terminal is respectively connected withthe second remote reader-writer and the alarm. The invention is used for improving the information input efficiency of the power system fixed asset equipment, and is also used for improving the powersystem fixed asset management safety.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

Drug trace analyzer

The invention provides a drug trace analyzer, which comprises: a heat insulation housing, which is provided with a sampling hole and a tube taking port; a heating device which is arranged in the heat insulation shell, wherein a plurality of placing grooves for placing test tubes are formed in the heating device; a driving device which is connected with the heating device and is used for driving the heating device to rotate so as to enable a certain placing groove to correspond to the sampling hole or the pipe taking opening; a clamping device which is used for clamping the test tube from the interior of the heat insulation shell to the outer side of the heat insulation shell through the tube taking opening; and a sampling device which is used for extracting a sample in the test tube through the sampling hole and loading the sample onto the reagent card. Compared with the prior art, manual operation is reduced, the detection efficiency is improved, and the risk of manual errors is avoided.

Owner:GUANGZHOU LABSIM BIOTECH CO LTD

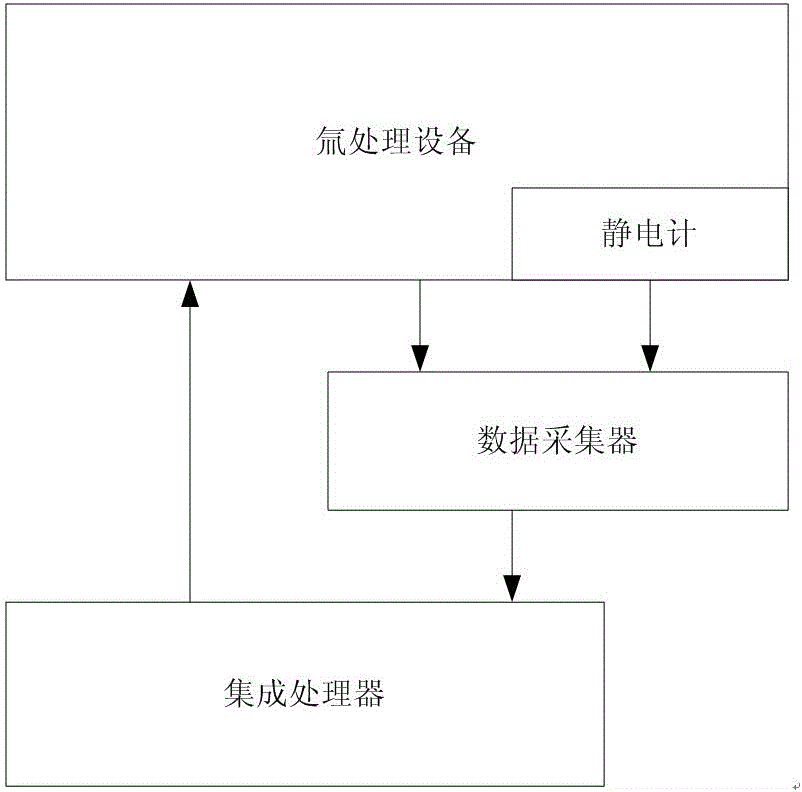

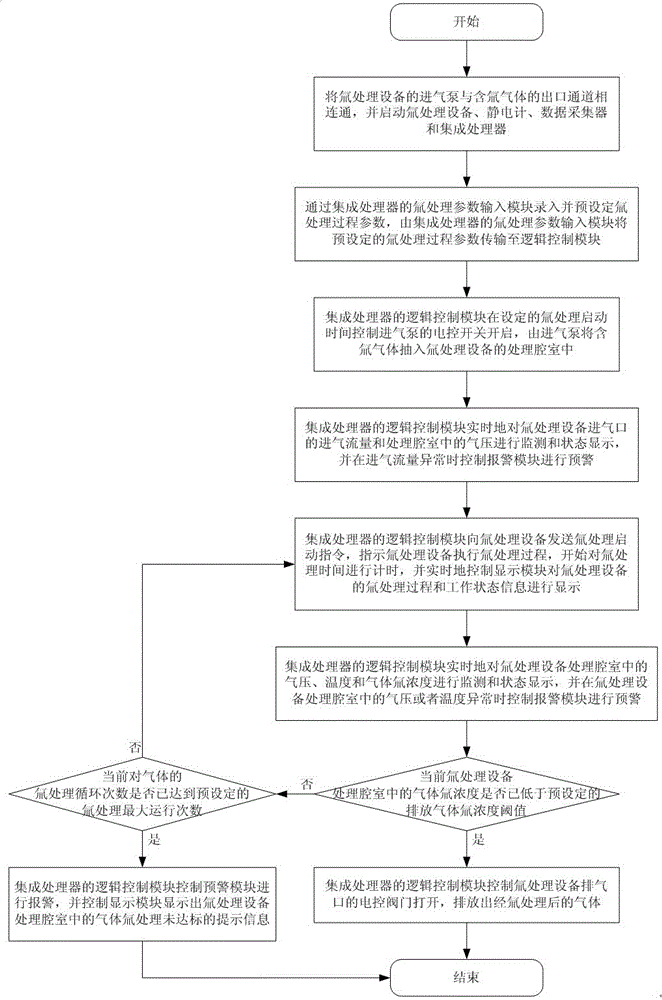

A monitoring and early warning method for tritium treatment process

ActiveCN104460601BRealize tracking and monitoringAvoid the risk of human errorTotal factory controlProgramme total factory controlEarly warning systemAutomatic control

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

A method and system for automatic configuration of I/O ports

ActiveCN109766291BRealize automatic configurationRealize unmanned operationProgramme controlTransmissionAuto-configurationEngineering

The invention discloses a method and system for automatic configuration of an I / O port, wherein the method applied to a central processing unit includes: receiving request information from a controlled device, wherein the request information carries information required by the controlled device The signal type; according to the signal type, send configuration instructions to the control device to instruct the control device to configure the I / O port according to the configuration command; where the controlled device is directly connected to the central processing unit, or the controlled device is connected to the central processing unit through the control device Processor connection. Thus, a communication link between the central processor and the controlled device can be established, so that the central processor can automatically generate configuration instructions according to the signal type required by the controlled device to instruct the control device to configure the I / O port. In this way, the automatic configuration of I / O ports can be realized, unmanned operation can be realized, and the risk caused by human misoperation can be avoided.

Owner:GREE ELECTRIC APPLIANCES INC

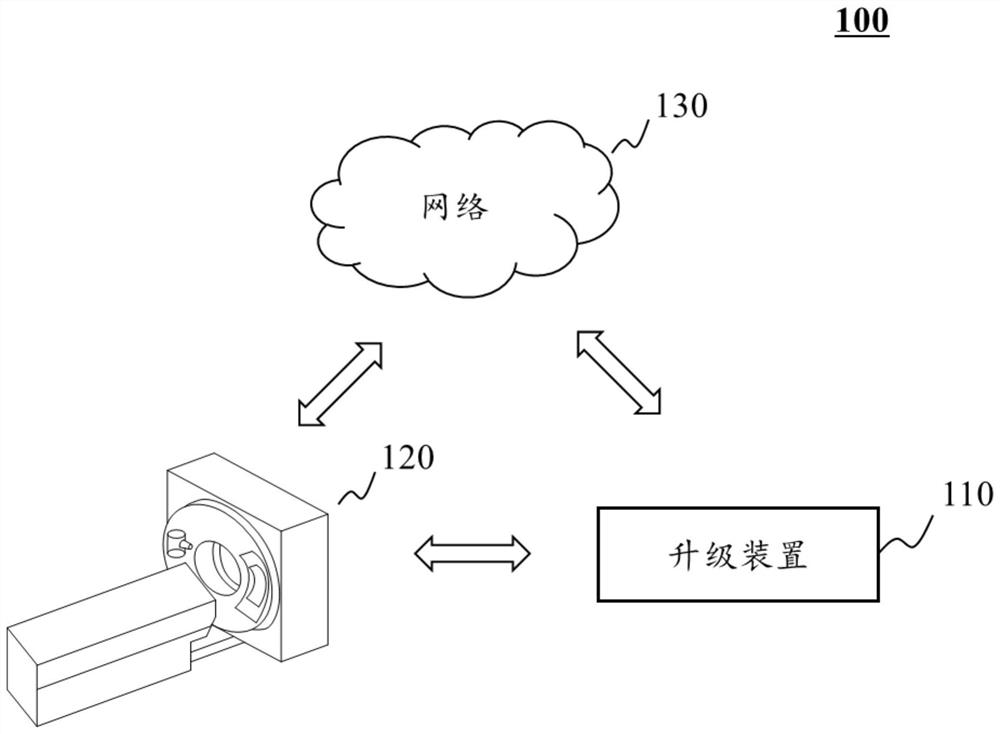

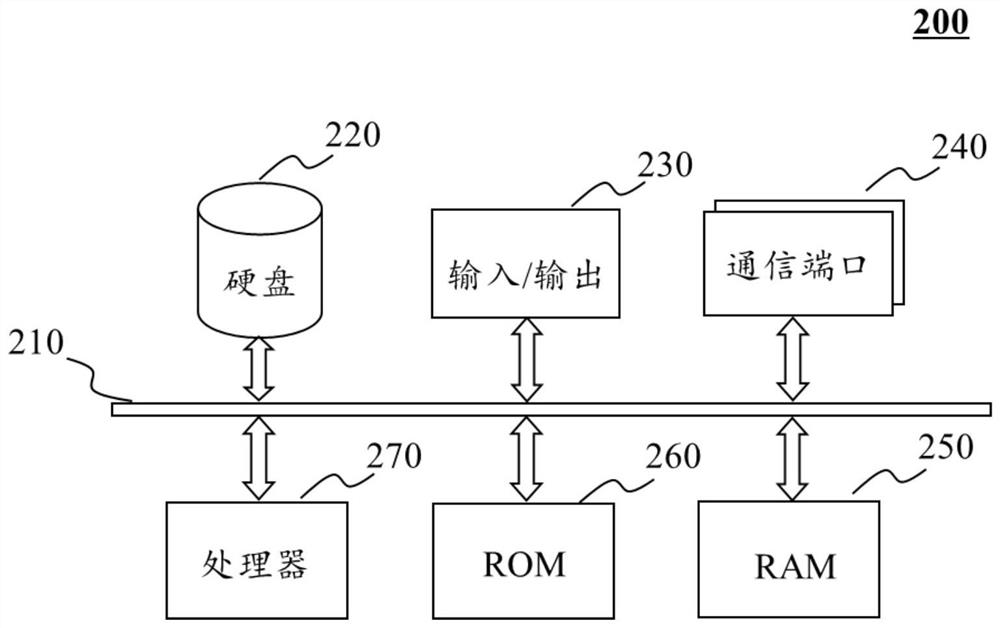

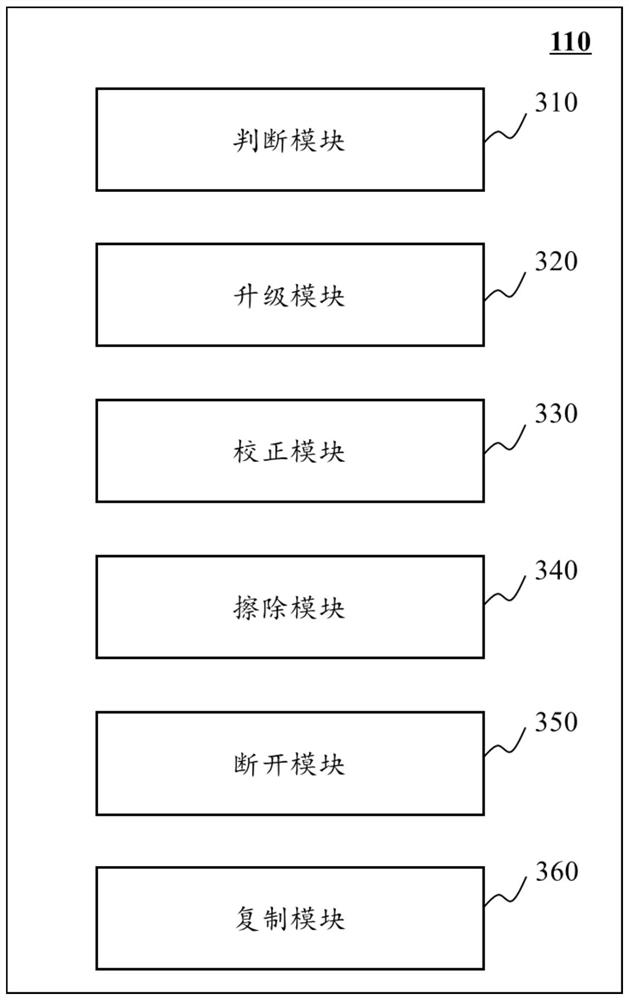

A medical equipment system upgrade method and device

ActiveCN107491659BReduce dependenceOccupied usage timeMedical equipmentService engineerComputer science

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Data acquisition method and device, electronic equipment and storage medium

ActiveCN112612255AImprove data collection efficiencyAvoid the risk of human errorTotal factory controlProgramme total factory controlData acquisitionData mining

The embodiment of the invention relates to the field of control, and discloses a data acquisition method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining process change information in an MES system, the process change information comprising pre-change information and post-change information; acquiring data acquisition plan information corresponding to the pre-change information in the SPC system according to the pre-change information; obtaining a change information CKC key value combination corresponding to the change information according to the changed information; and adding the change information CKC key value combination into the association relationship information of the data acquisition plan to obtain an updated data acquisition plan, and acquiring data according to the updated data acquisition plan information, thereby realizing automatic updating of the data acquisition plan information without adding a new data acquisition plan. Therefore, the version before change and the version monitoring data newly added according to the changed information are automatically collected according to the data collection plan, the risk of human errors caused by a large amount of setting work is avoided, and the labor cost is reduced.

Owner:上海赛美特软件科技有限公司

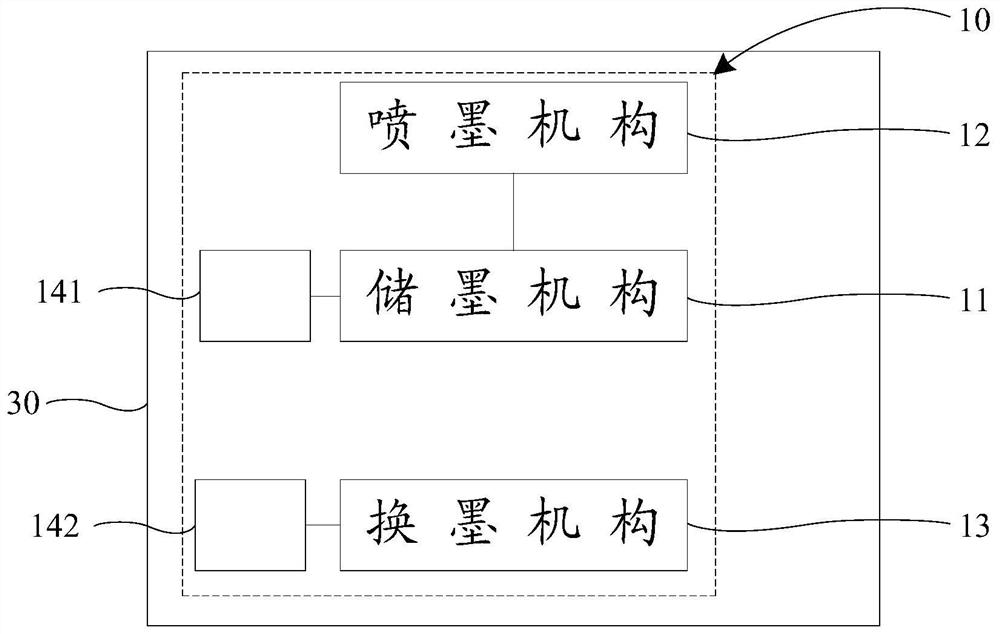

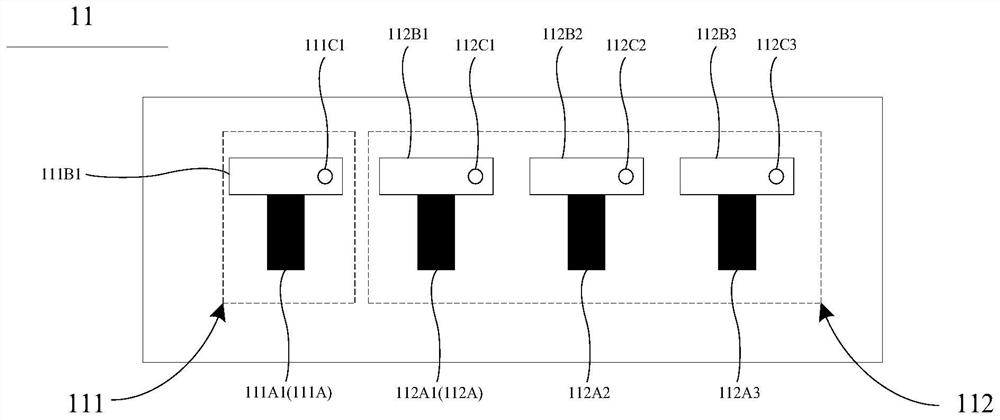

Inkjet printing system

PendingCN114789608AShorten the timeAvoid the risk of human errorOther printing apparatusPhysicsInkjet printing

The invention provides an ink-jet printing system which comprises an ink-jet printing device and a control mechanism interacting with the ink-jet printing device, and the ink-jet printing device comprises an ink storage mechanism, an ink jet mechanism and an ink changing mechanism; the ink storage mechanism comprises an ink supply assembly and an ink storage assembly. The ink supply assembly and the ink storage assembly are both used for storing a certain amount of ink. The ink jetting mechanism is connected with the ink storage mechanism and used for jetting ink from the ink supply assembly. The ink changing mechanism is located on the side, away from the ink jetting mechanism, of the ink storage mechanism and used for adding or changing ink in the ink storage assembly into the ink supply assembly. Wherein a preset control signal is arranged in the control mechanism, and the control mechanism is in wireless connection with the ink changing mechanism and is used for sending the preset control signal to the ink changing mechanism; the ink changing mechanism comprises a controller, and the controller is used for receiving a preset control signal and controlling the ink changing mechanism to move in the direction of the ink supply assembly or the direction of the ink storage assembly according to the preset control signal.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

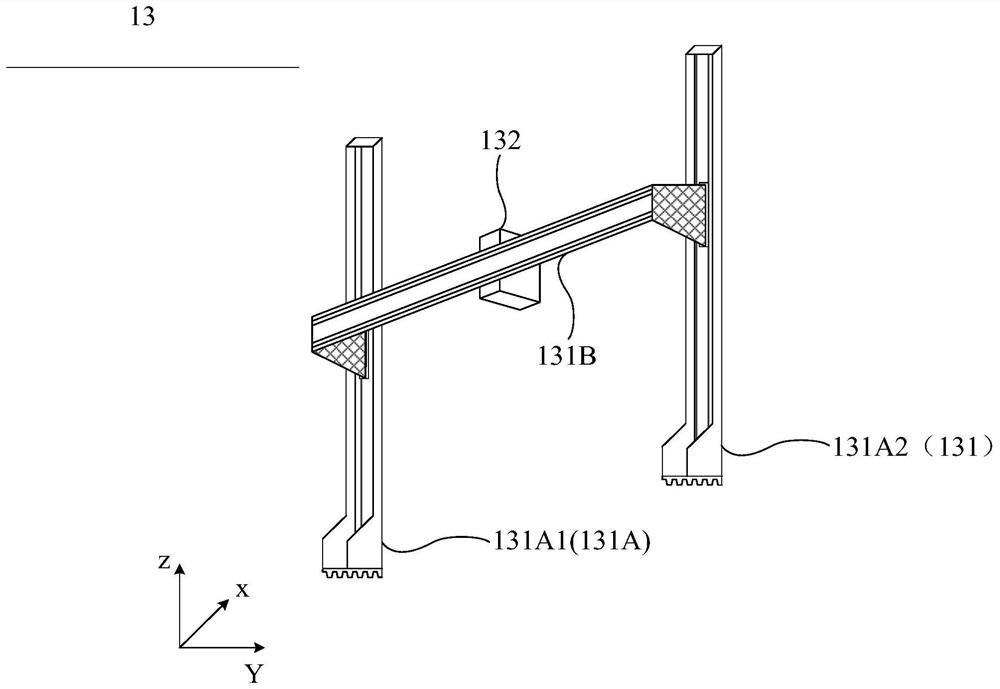

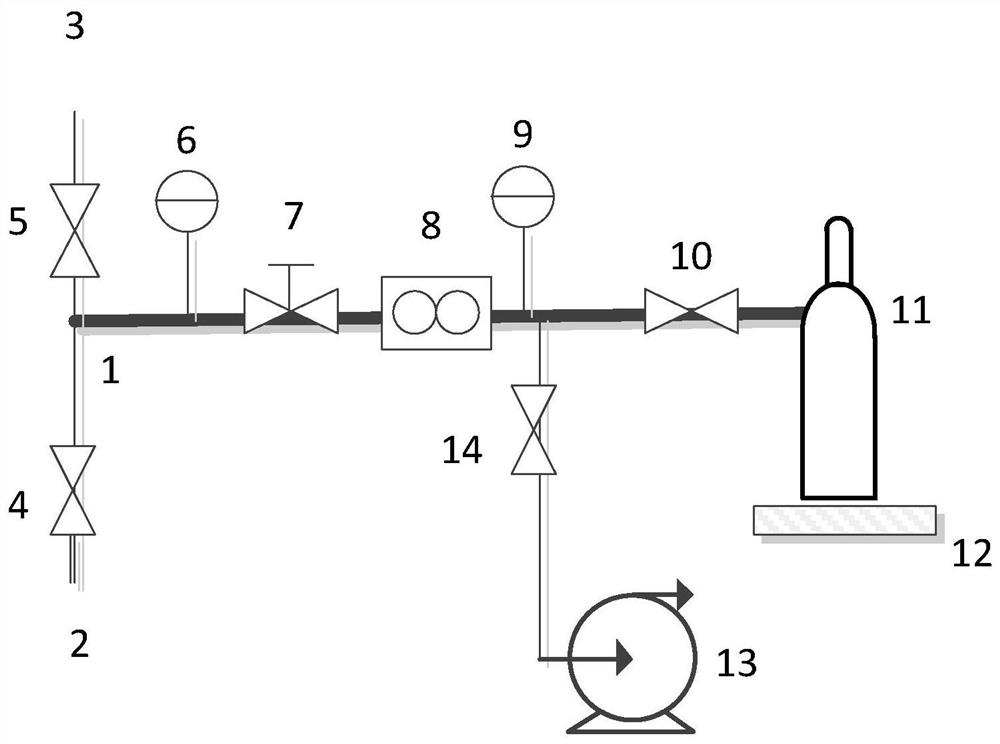

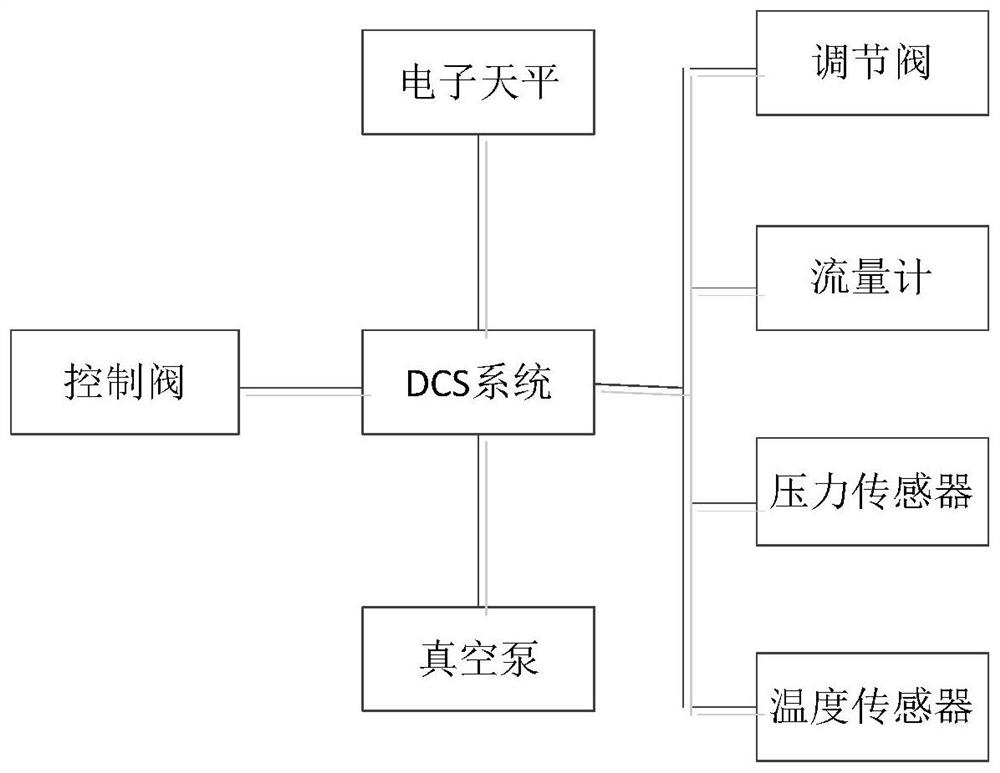

Automatic gas distribution device for mixed gas and method thereof

PendingCN114082362AHigh control precisionImprove accuracyTransportation and packagingMixer accessoriesEngineeringStress sensors

The invention relates to an automatic gas distribution device for mixed gas and a method thereof, and belongs to the technical field of electronic mixed gas. The gas distribution device comprises a filling pipeline, a second gas conveying pipeline, a first gas conveying pipeline, a second gas control valve, a first gas control valve, a pressure sensor in front of a regulating valve, the regulating valve, a flow meter, a pressure sensor behind the regulating valve, a filling control valve, a mixed gas container, an electronic balance, a vacuum pump pipeline, a vacuum pump, a vacuum control valve and a temperature sensor; the gas distribution method is completed by adopting the gas distribution device. Flow control is carried out on gas introduced into a filling pipeline, and the gas flow is adjusted to the set flow according to specific requirements through a DCS according to the front pressure and the rear pressure of the regulating valve, so that the accuracy of the content of each gas in the configured mixed gas can be improved; according to the gas distribution device and method, the mixed gas can be completely and automatically prepared, and the content of each gas component in the mixed gas is accurately controlled.

Owner:PERIC SPECIAL GASES CO LTD

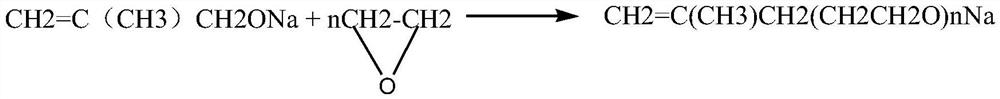

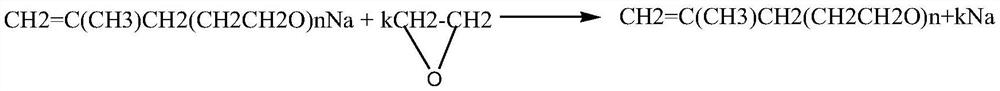

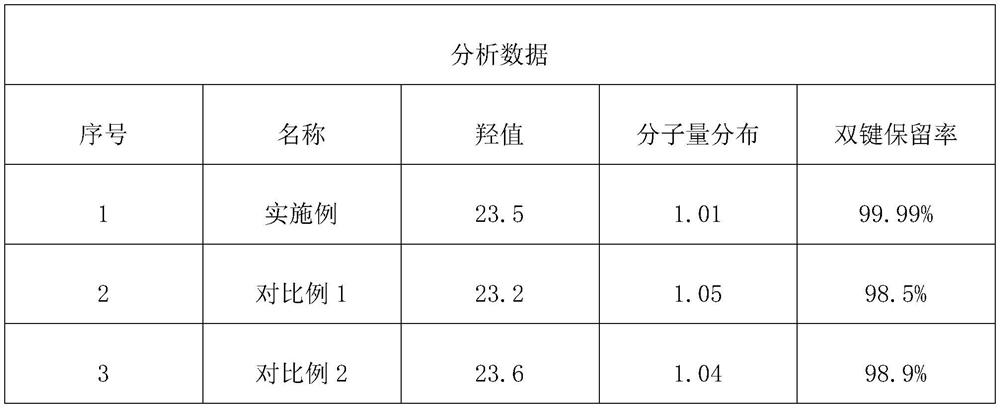

Process control method of methylallyl alcohol polyoxyethylene ether

A process control method of methylallyl alcohol polyoxyethylene ether belongs to the technical field of polymer synthesis, and comprises the following steps: 1) adding methylallyl alcohol as an initiator and a catalyst into a reaction kettle for reaction, then dropwise adding ethylene oxide, controlling the temperature of the reaction kettle to be stabilized at 135 DEG C, cooling the reaction kettle to a certain temperature after the reaction is finished, and then adding a catalyst for reaction; discharging to obtain a methylallyl alcohol polyoxyethylene ether oligomer; and (2) adding ethylene oxide into the methallyl alcohol oligomer obtained in the step (1) again to carry out anionic polymerization reaction, and after the reaction is finished, cooling and discharging to obtain the methallyl alcohol polyoxyethylene ether, thereby solving the technical problem of unstable molecular weight distribution of the methallyl alcohol polyoxyethylene ether caused by stable process condition control in the production process of the existing process. The method is mainly applied to the production technology of the methylallyl alcohol polyoxyethylene ether.

Owner:连云港石化有限公司

A method for operation and maintenance of a nuclear-level digital instrumentation and control system in a pressurized water reactor nuclear power plant

ActiveCN108682467BAvoid experimental errorAvoid the risk of human errorNuclear energy generationComputer implemented nuclear controlNuclear plantPressurized water reactor

The invention belongs to the field of operation and maintenance of nuclear process control systems, and in particular relates to a method for operation and maintenance of nuclear-level digital instrument control systems in pressurized water reactor nuclear power plants. The method includes the following steps: 1. Determining the application system; 2. Determining the specific function and realization process of the method. This method is used in the operation and maintenance of nuclear-level digital instrumentation and control system (KCS system) in pressurized water reactor nuclear power plant. To ensure the safe and stable operation of the unit.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com