Automatic gas distribution device for mixed gas and method thereof

A mixed gas, automatic technology, applied in chemical instruments and methods, mixers, gas and gas/vapor mixing, etc., can solve the problem of uncontrollable gas flow rate at the end of gas filling, manual control operation errors, low mixed gas preparation accuracy, etc. problems, to avoid mistakes, improve accuracy, and improve control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation to the patent of the present invention.

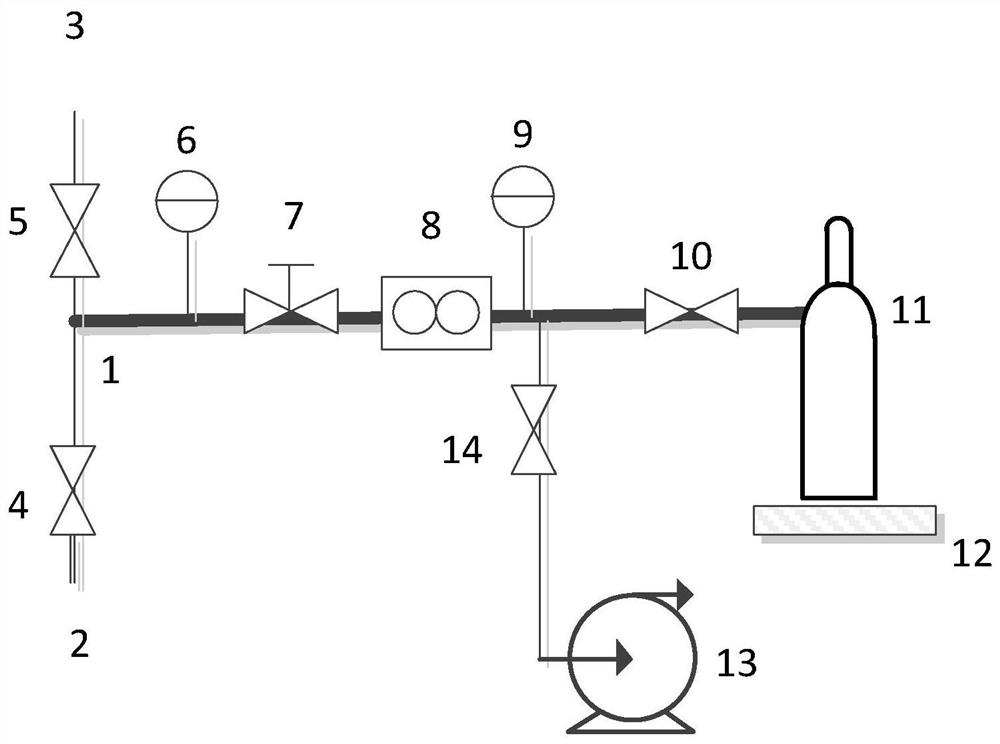

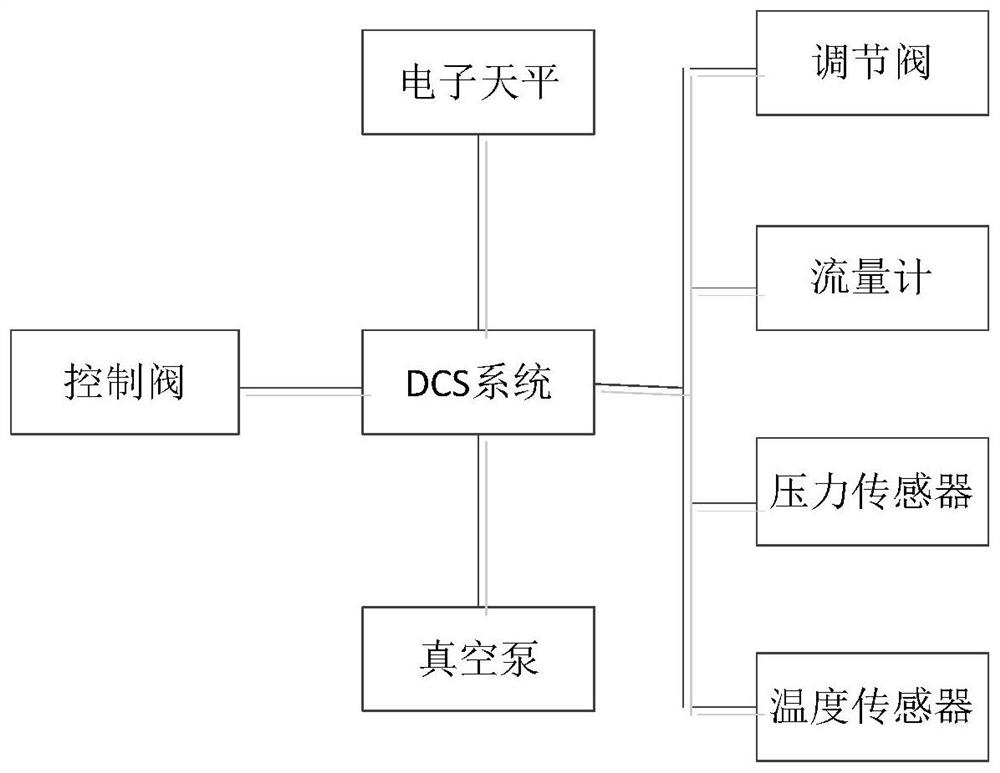

[0040] Such as figure 1 As shown, an automatic gas distribution device for mixed gas, the gas distribution device includes a filling pipeline 1, a second gas delivery pipeline 2, a first gas delivery pipeline 3, a second gas control valve 4, a first gas Control valve 5, pressure sensor before regulating valve 6, regulating valve 7, flow meter 8, pressure sensor after regulating valve 9, filling control valve 10, mixed gas container 11, electronic balance 12, vacuum pump pipeline, vacuum pump 13, vacuum control Valve 14 and temperature sensor.

[0041] The electronic balance 12 adopts a comparator-level ultra-high-precision electronic scale, and its typical parameter is 150kg ± 0.05g.

[0042] Vacuum pump 13 adopts vacuum degree to reach 1×10 -5 Two-stage vacuum pump for high v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com