Plastic pre-extrusion machine die structure and operation method thereof

A pre-extrusion and machine technology, applied in the field of plastic pre-extrusion machine mold structure, can solve the problems of low installation efficiency, safety production accidents of workers, etc., and achieve the effect of improving work efficiency, saving time, and improving work environment safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

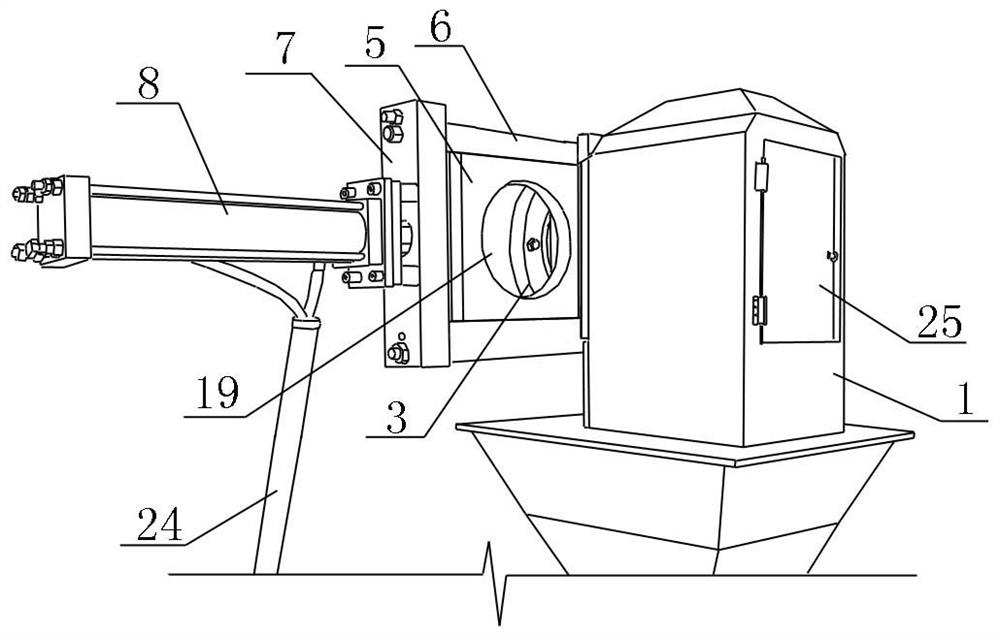

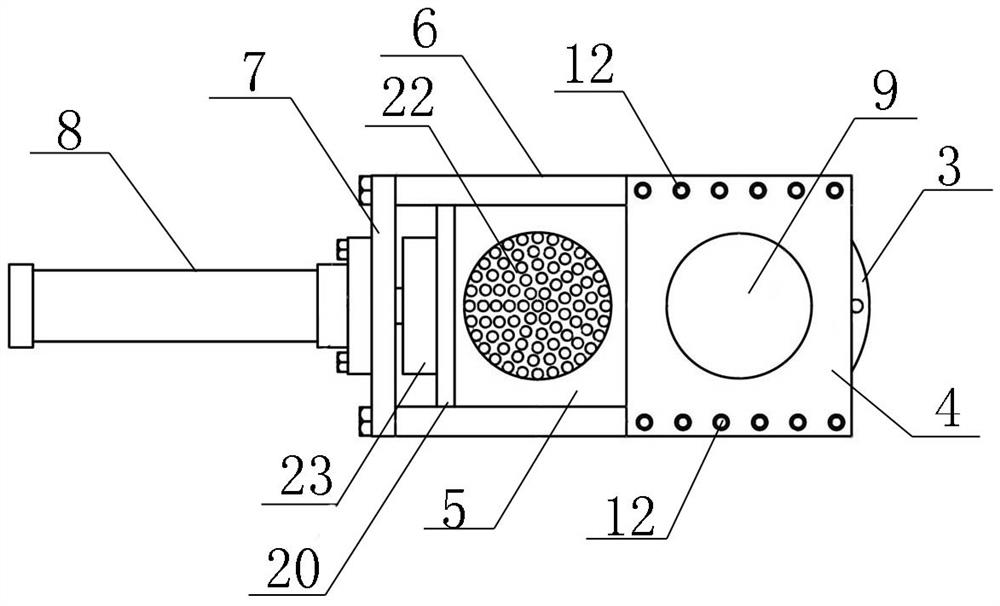

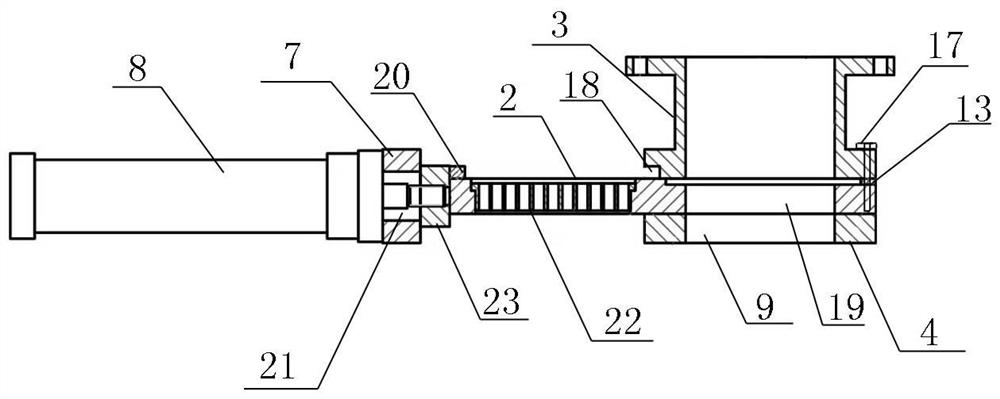

[0033] Such as Figure 1-8As shown, the plastic pre-extrusion machine mold structure is installed on the box body 1 of the plastic pre-extrusion machine; the front side plate of the box body 1 is provided with a rectangular opening; the plastic pre-extrusion machine mold The structure includes a terminal 3, a pressure plate 4, a two-station net seat 5, a tension column 6, a hydraulic cylinder base 7, and a hydraulic cylinder 8; the pressure plate 4 is installed on the inside of the front side plate of the box body 1, corresponding to the position, and a hole 9 is opened in the middle of the plate surface of the pressure plate 4, and the first connecting holes 10 are respectively spaced along the transverse direction on the upper and lower parts of the pressure plate 4; the terminal 3 is arranged on the front side of the box body 1 The outer side of the board is arranged in parallel with the pressing plate 4 at intervals, and the distance between the end 3 and the pressing plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com