Process control method of methylallyl alcohol polyoxyethylene ether

A technology of methallyl alcohol polyoxyethylene ether and methallyl alcohol, which is applied in the field of polymer synthesis, can solve the problems of difficult stable control of process indicators, many by-products, complex synthesis process, etc., to ensure quality and Stability, fully automatic control, precise and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

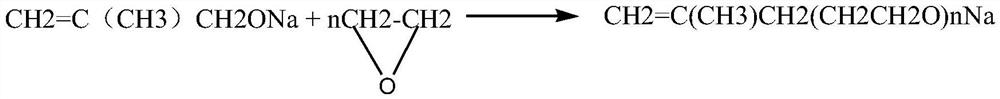

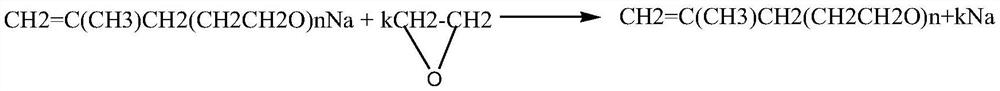

Method used

Image

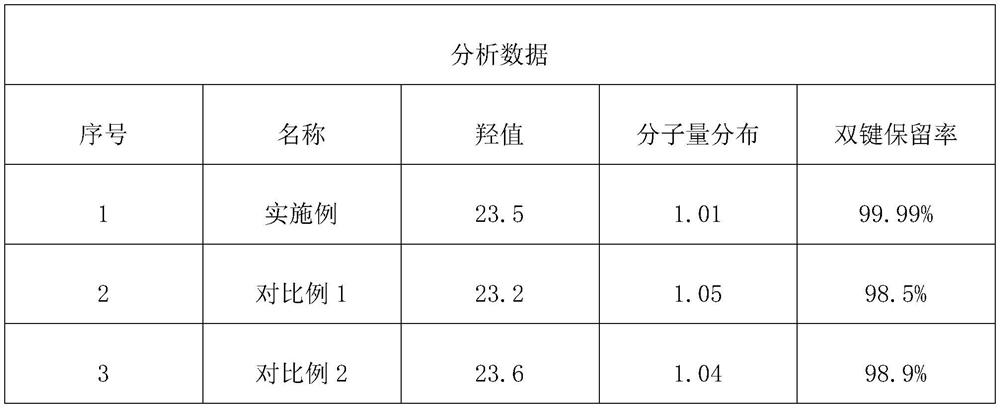

Examples

Embodiment 1

[0021] A process control method of methallyl alcohol polyoxyethylene ether, comprising the steps of:

[0022] 1) Add 70 parts by weight of methallyl alcohol to the reaction kettle, add 1 part by weight of liquid catalyst sodium metal within 30 minutes, control the reaction temperature to 60°C, and the reaction time is 15 minutes; after the reaction is completed, replace it with nitrogen and open the hot water valve Warm up to 75°C, then drop 400 parts by weight of ethylene oxide, and the feed rate of ethylene oxide is 140 parts by weight / hour. At this time, the temperature will drop slightly, and the pressure will rise slowly with a slight positive pressure. Gradually rise, when the temperature reaches 105°C, the hot water valve will open automatically, limiting the lower limit of the heat exchanger valve opening to 30%, and the upper limit to 80%; the material circulation temperature is set to 120°C, the set value According to the temperature change of the reactor, the flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com