Patents

Literature

32results about How to "Timely and effective removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

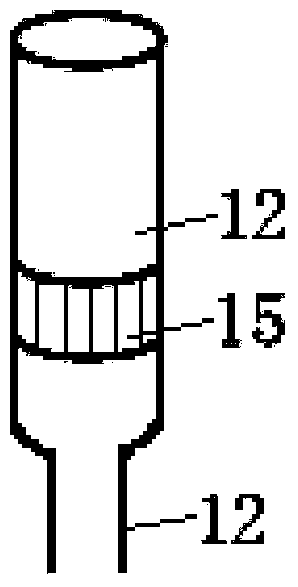

Surface microporous SiC ceramic material and preparation method thereof

ActiveCN102030532AIncrease chance of connectionEvenly distributedCeramicwareCarboxymethyl celluloseOxidation resistant

The invention discloses a surface microporous SiC ceramic material, which consists of main raw materials, polycarbosilane and carboxymethyl cellulose, wherein the main raw materials consist of the following components in percentage by weight: 85 to 90 percent of silicon carbide powder and 10 to 15 percent of yttrium aluminum garnet; the polycarbosilane is 5 to 10 percent of the total weight of the main raw materials; and the carboxymethyl cellulose is 2 to 8 percent of the total weight of the main raw materials. Meanwhile, the invention discloses a method for preparing the surface microporous SiC ceramic material, which comprises the following steps of: uniformly mixing the silicon carbide powder, the yttrium aluminum garnet and the polycarbosilane, and adding aqueous solution of the carboxymethyl cellulose and performing ball-milling mixing; drying the obtained size; and molding the obtained powder and performing vacuum sintering at high temperature so as to prepare the surface microporous SiC ceramic material. The surface microporous SiC ceramic material keeps high strength, high hardness, abrasion resistance, corrosion resistance and oxidation resistance, the self-lubricating property of the material is improved, and a cross section can be prevented from being bonded. Therefore, the service life of the material is prolonged.

Owner:ZHEJIANG UNIV

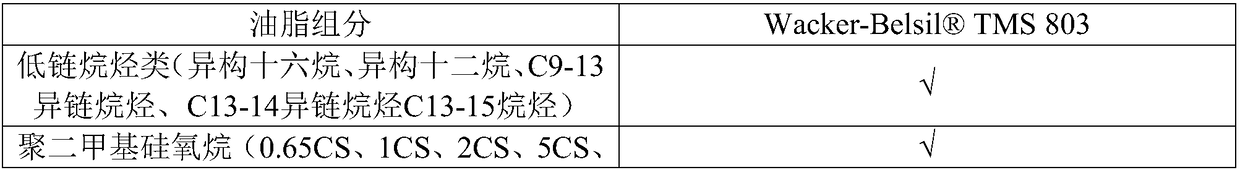

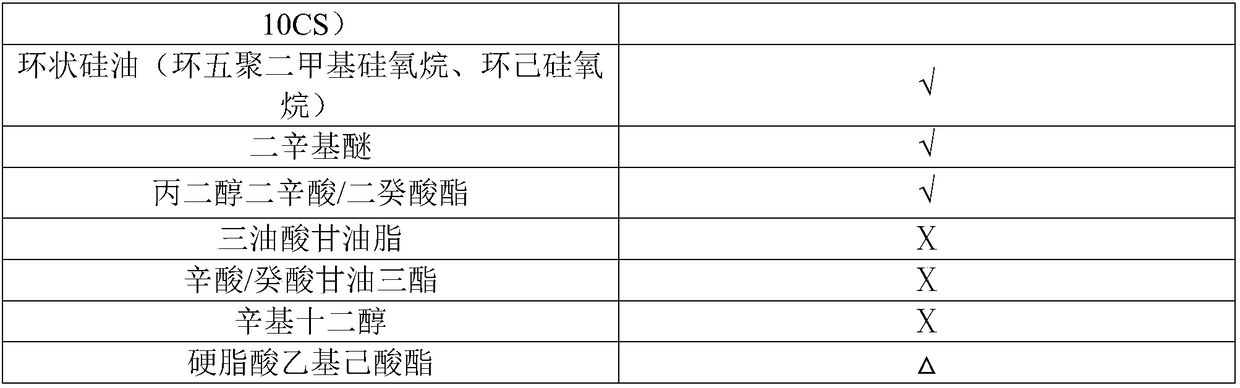

Preservative-free makeup removal dirt eliminating solution composition and preparation method thereof

InactiveCN108324679ATimely and effective detoxificationTimely and effective removalCosmetic preparationsMake-upForeign matterPreservative free

The invention discloses a preservative-free makeup removal dirt eliminating solution composition and a preparation method thereof. The composition is prepared from 5 to 50 percent of humectants, 10 to30 percent of hydrophilic surfactants, 1 to 10 percent of grease, 0.01 to 10 percent of skin conditioning agents and 5 to 60 percent of deionized water in percentage by mass. The preservative-free makeup removal turbid eliminating solution composition disclosed by the invention can be used for timely and effectively removing various cosmetics, and particularly has the good makeup removal capability on eye shadow, mascara cream and the like which generally cannot be easily removed; the contained skin conditioning agents can effectively eliminate toxin in the skin and foreign matters such as dirt, fat granules and blackheads in the pores; the effect of deeply eliminating dirt in the skin can be achieved; the skin quality is improved, so that the skin becomes clear.

Owner:上海彤颜实业有限公司

Method for preparing hydrogen sulfide

InactiveCN102502523AEasy temperature controlOvercome the defects in the direct synthesis of hydrogen sulfide technologyHydrogen sulfidesHydrogenEvaporation

The present invention relates to a method for preparing hydrogen sulfide. The method uses molten sulphur and hydrogen as starting materials, including a synthesizing stage of hydrogen sulfide and a refining stage of hydrogen sulfide. The synthesizing stage of hydrogen sulfide includes steps of evaporating and vaporizing the molten sulphur in an evaporator by utilizing an electric induction heating device on the periphery of the evaporator to obtain sulfuric vapors; putting the hydrogen into the evaporator, pre-heating, rising temperature, intensive mixing with the sulfuric vapors to obtain the gas mixture of hydrogen and sulfuric vapors; and putting the gas mixture of hydrogen and sulfuric vapors into a synthesizing tower, and synthesizing to obtain the gas mixture of hydrogen sulfide, hydrogen and sulfuric vapors. The refining stage includes steps of removing the sulfuric vapors from the gas mixture of hydrogen sulfide, hydrogen and sulfuric vapors, absorbing the hydrogen sulfide and regenerating to obtain the refined hydrogen sulfide gas. The molten sulphur is evaporated by utilizing the electric induction evaporator, which is easy to control the temperature and has high evaporation efficiency.

Owner:YANTAI UNIV

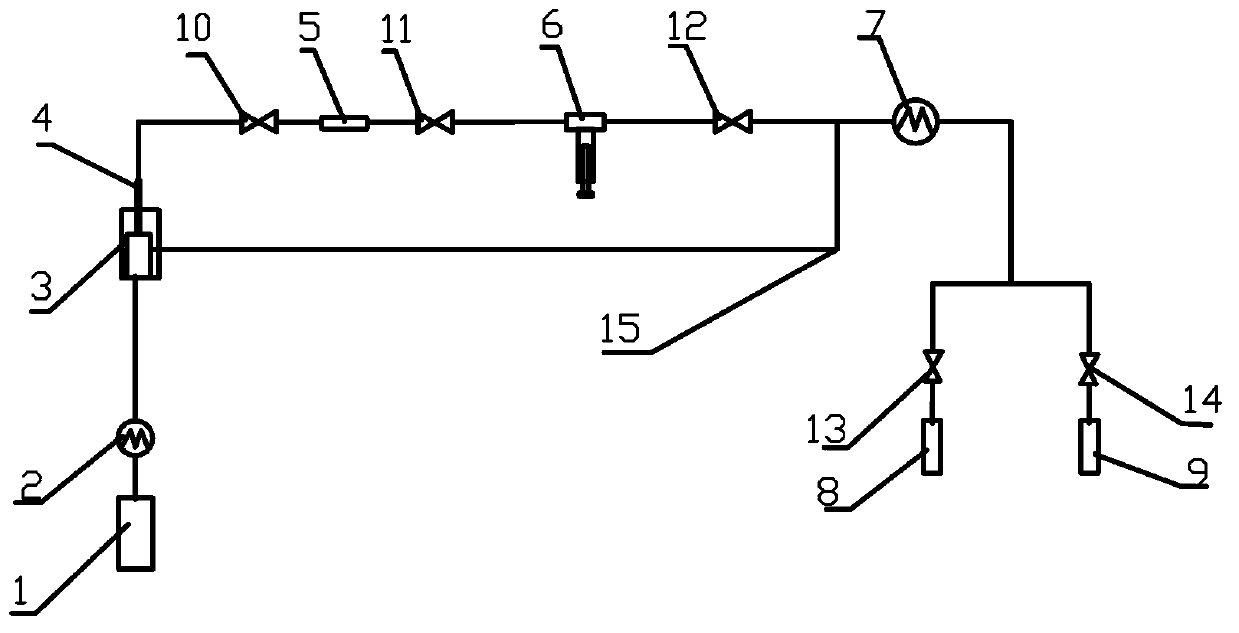

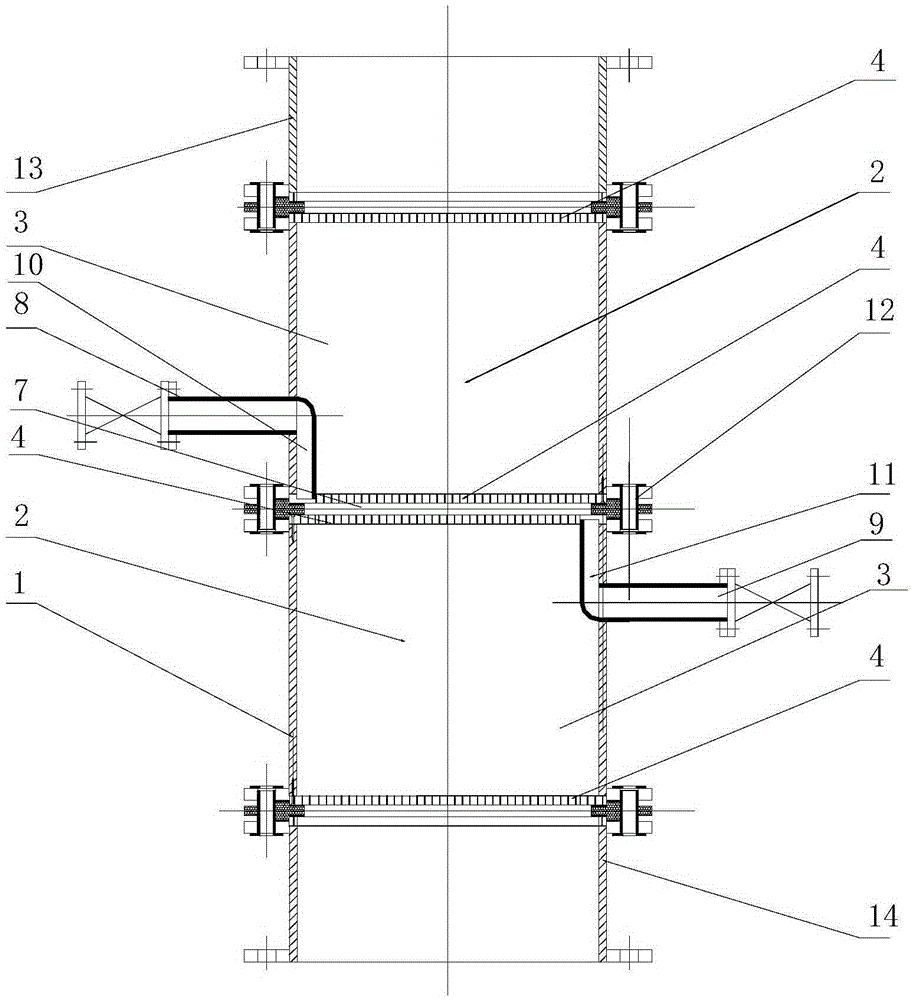

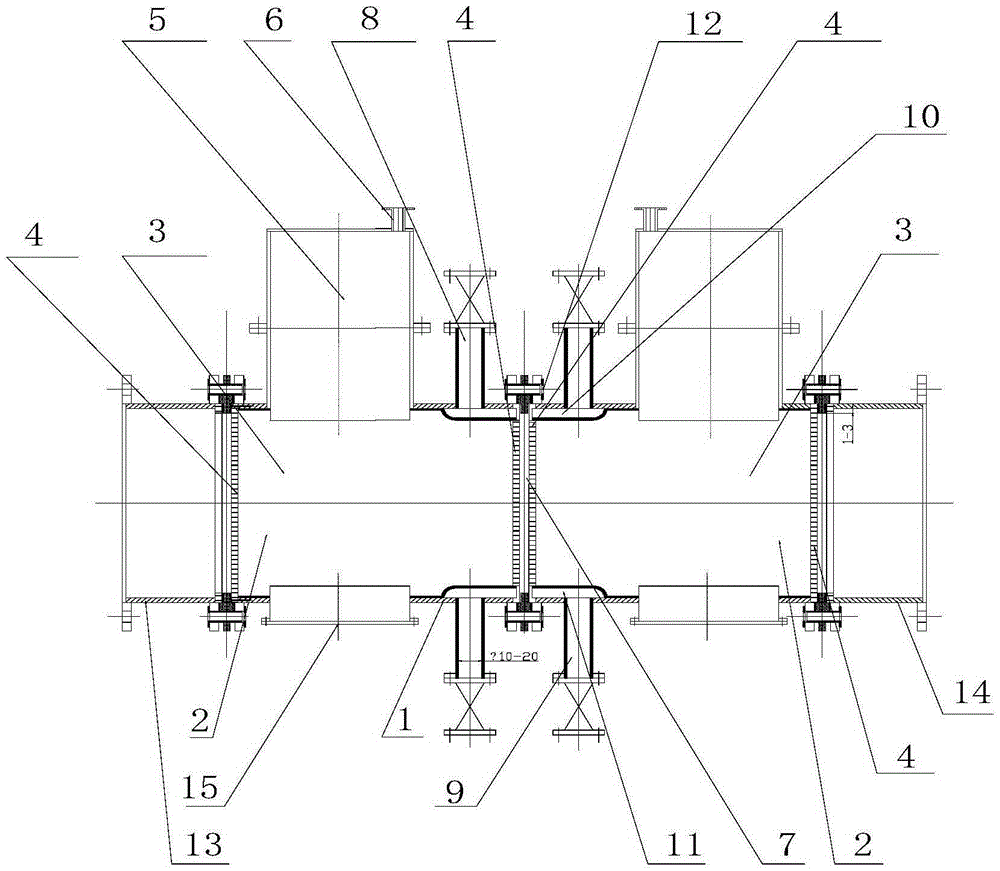

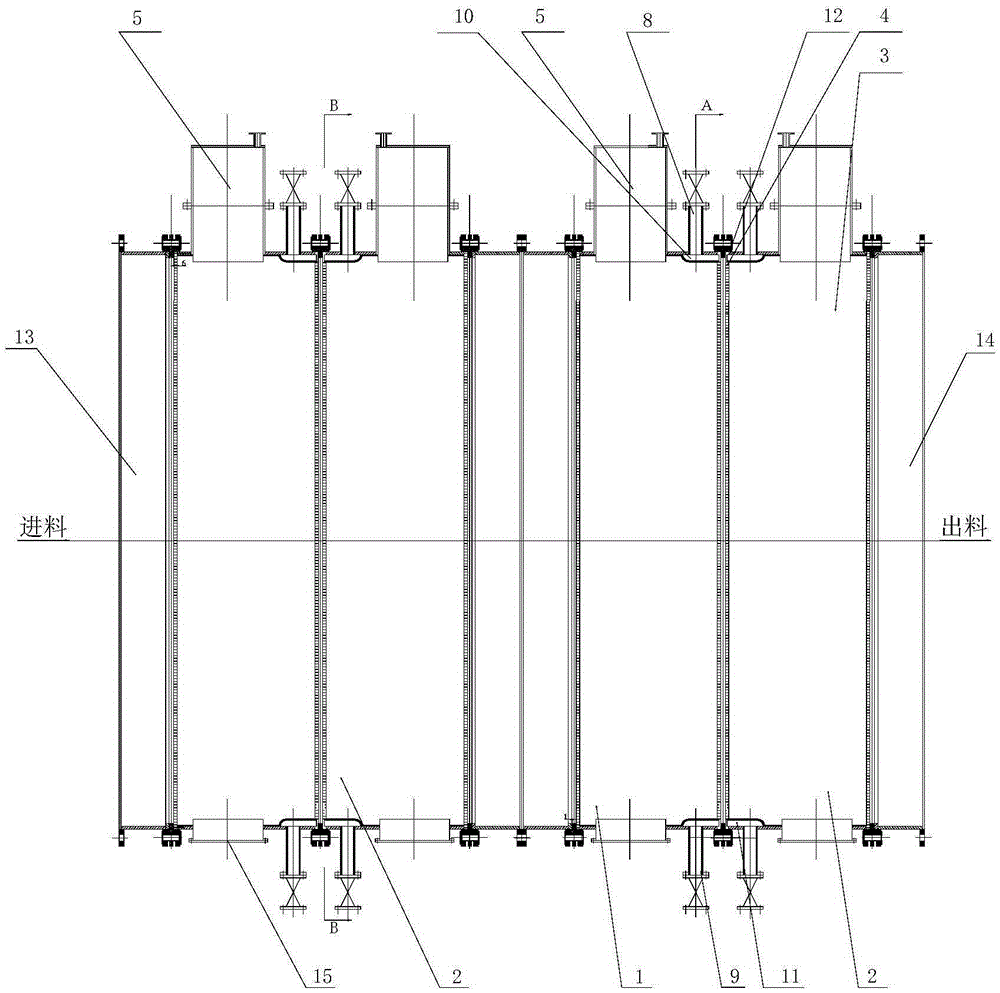

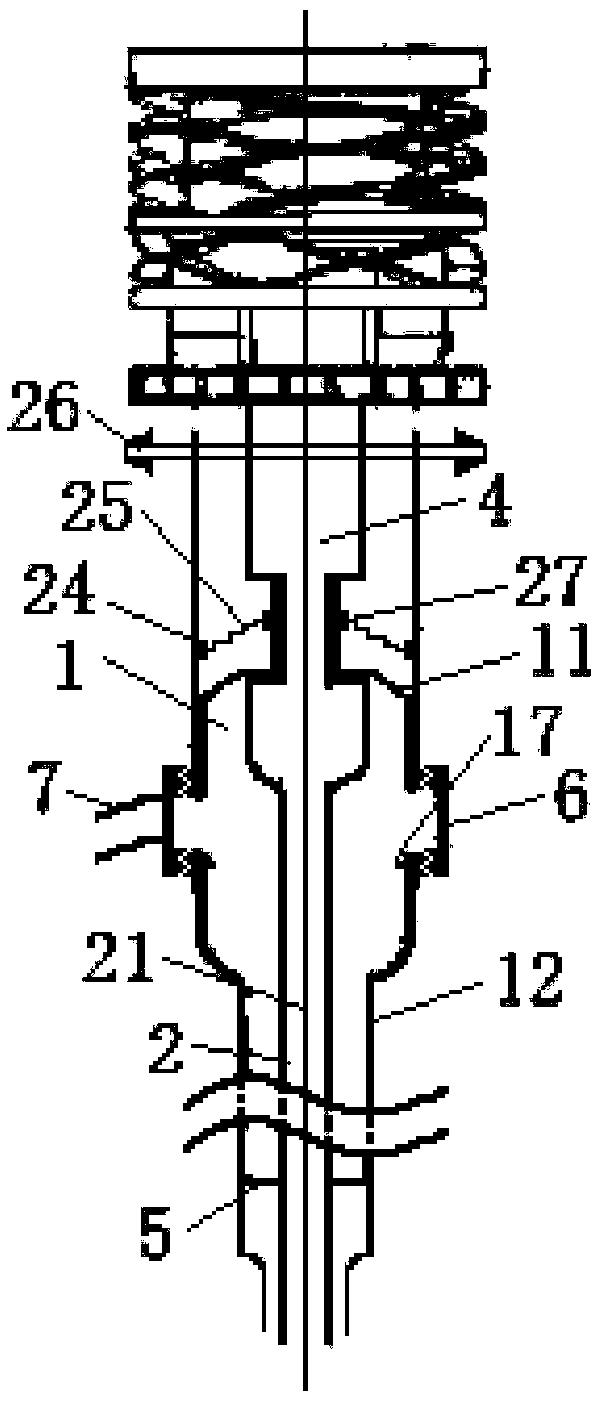

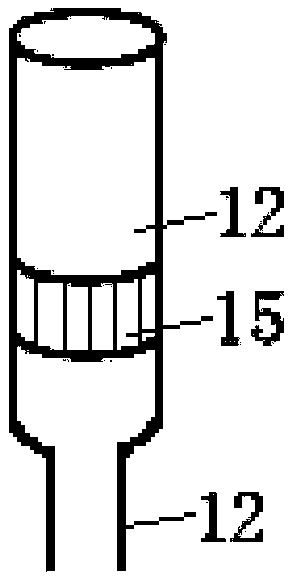

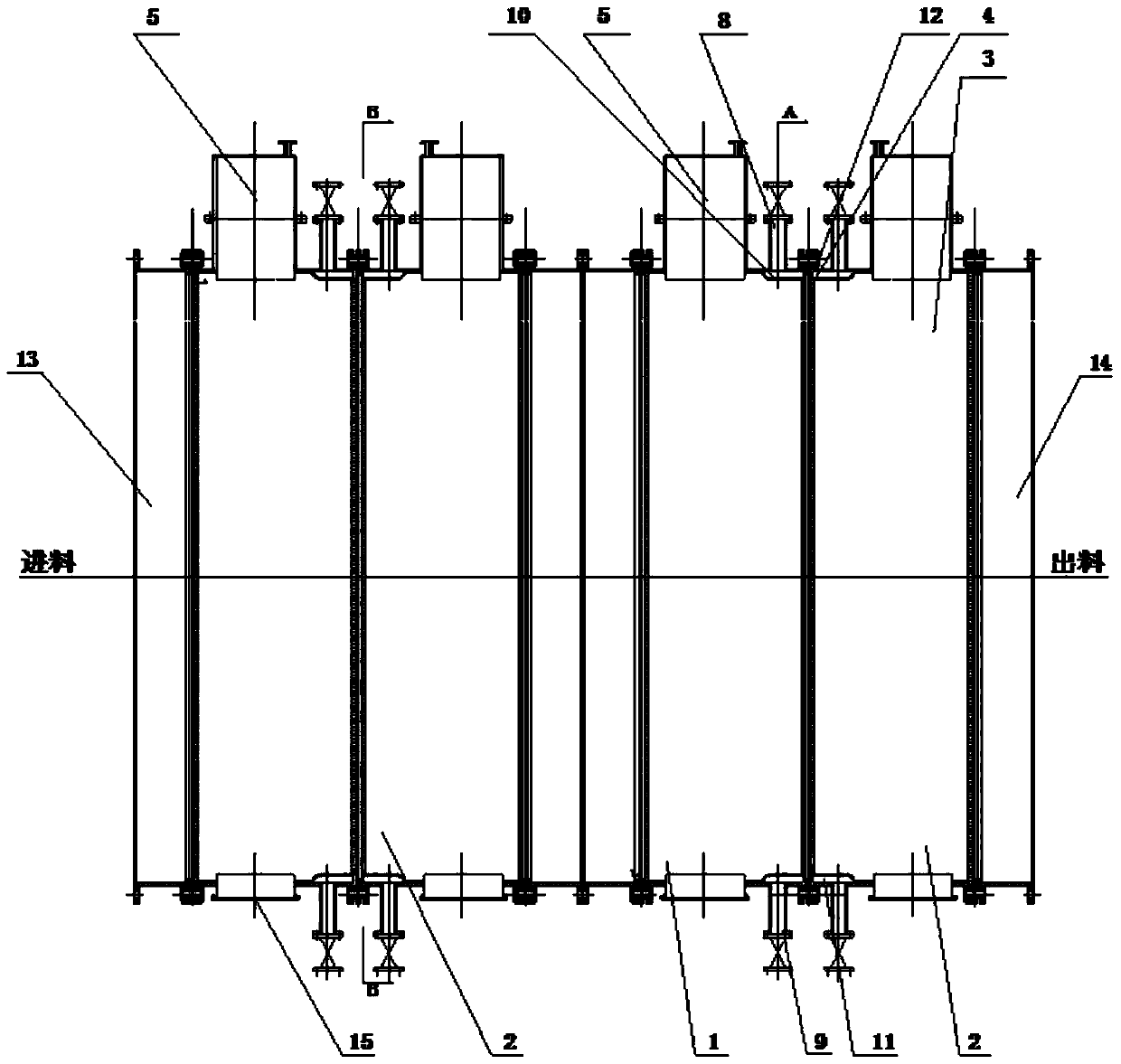

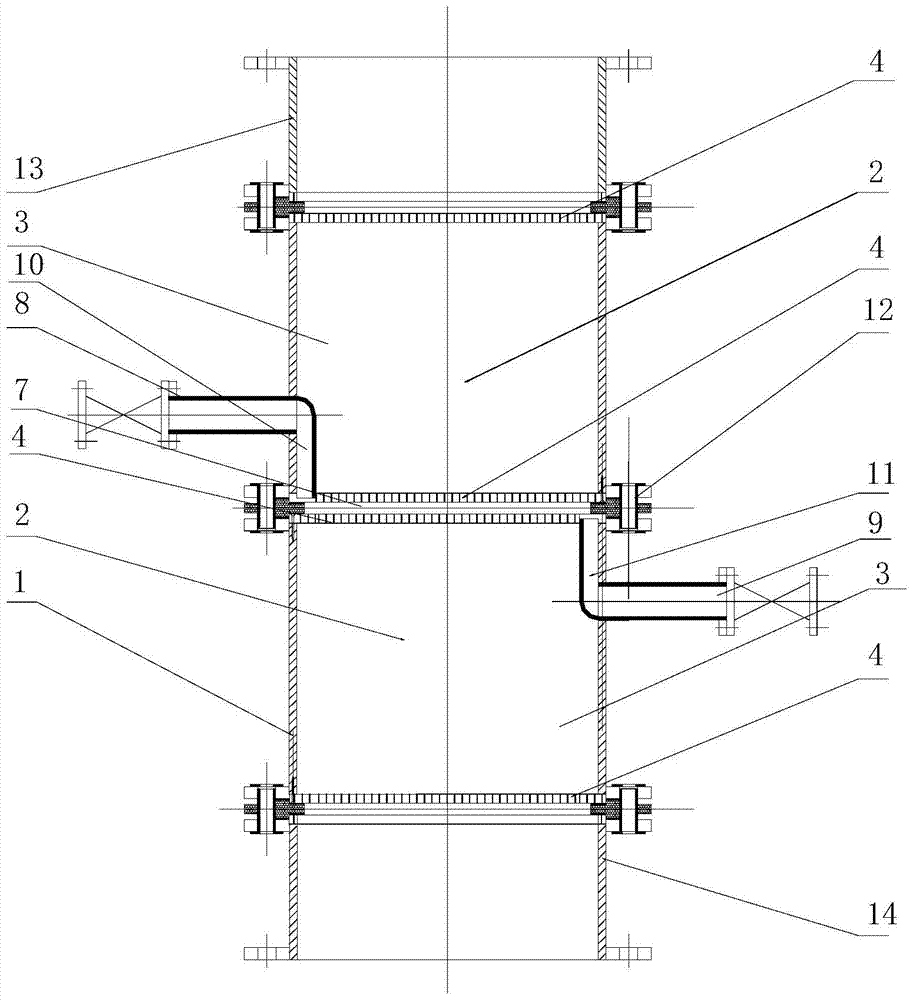

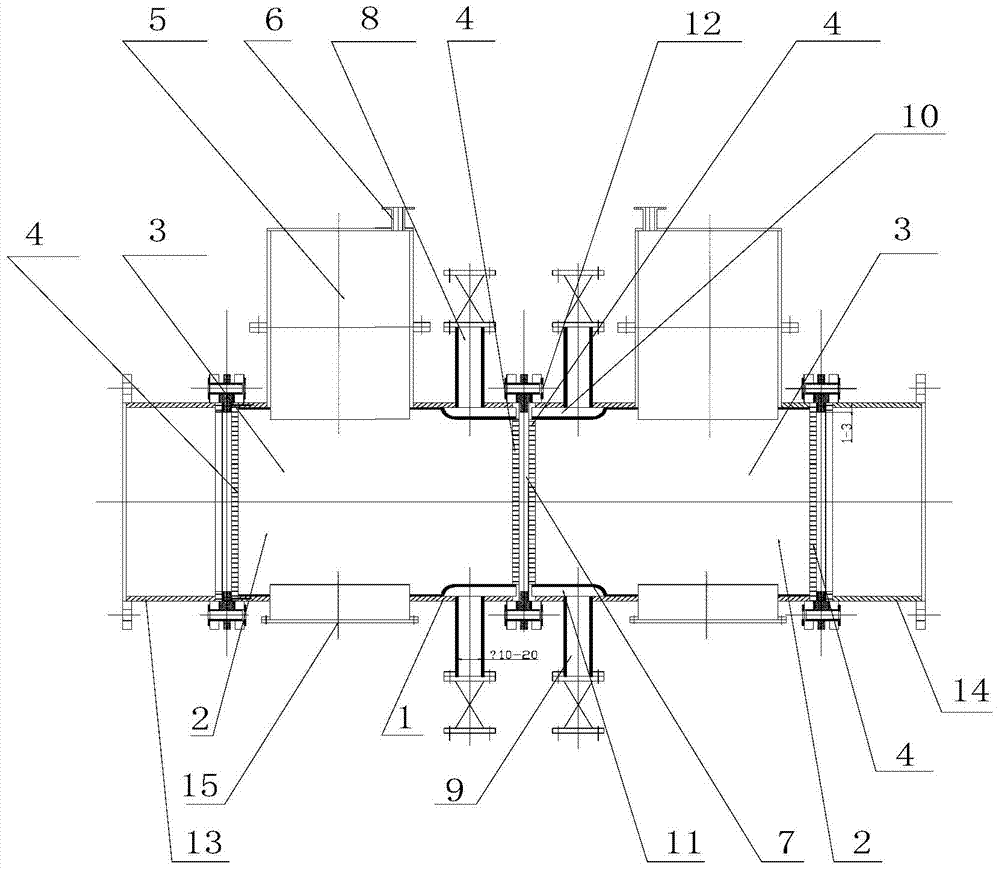

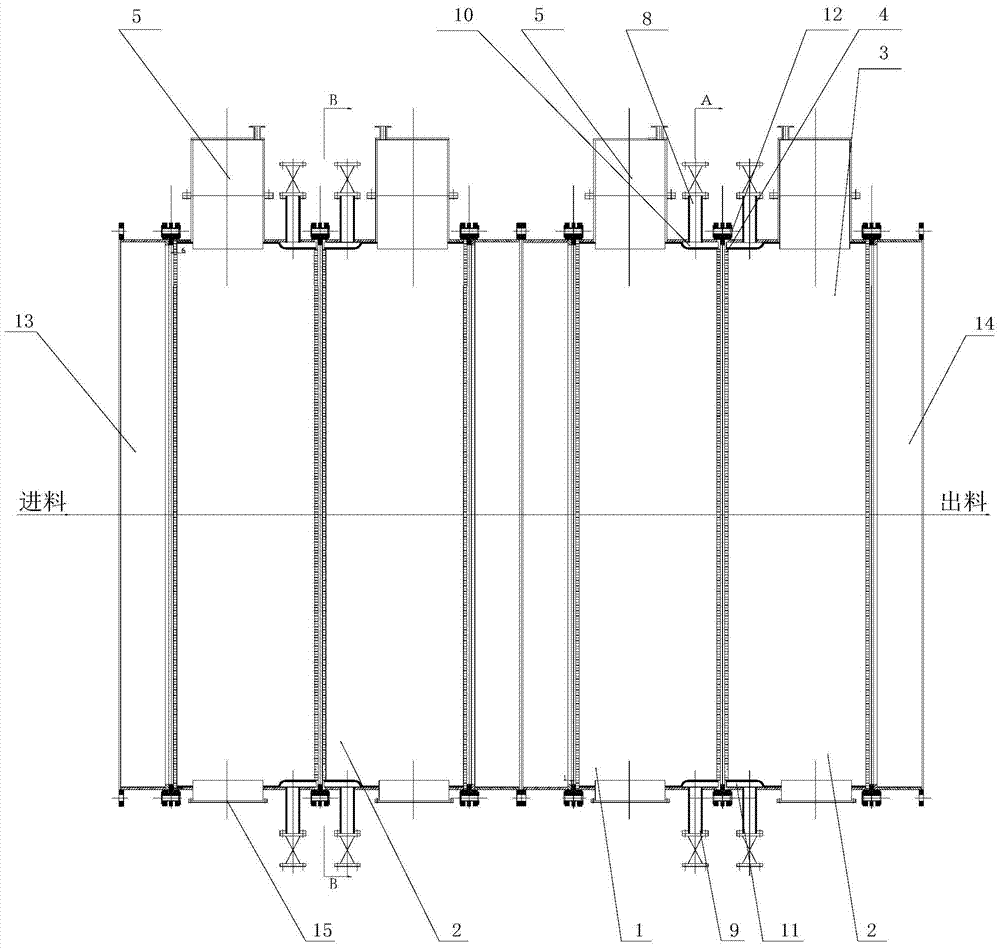

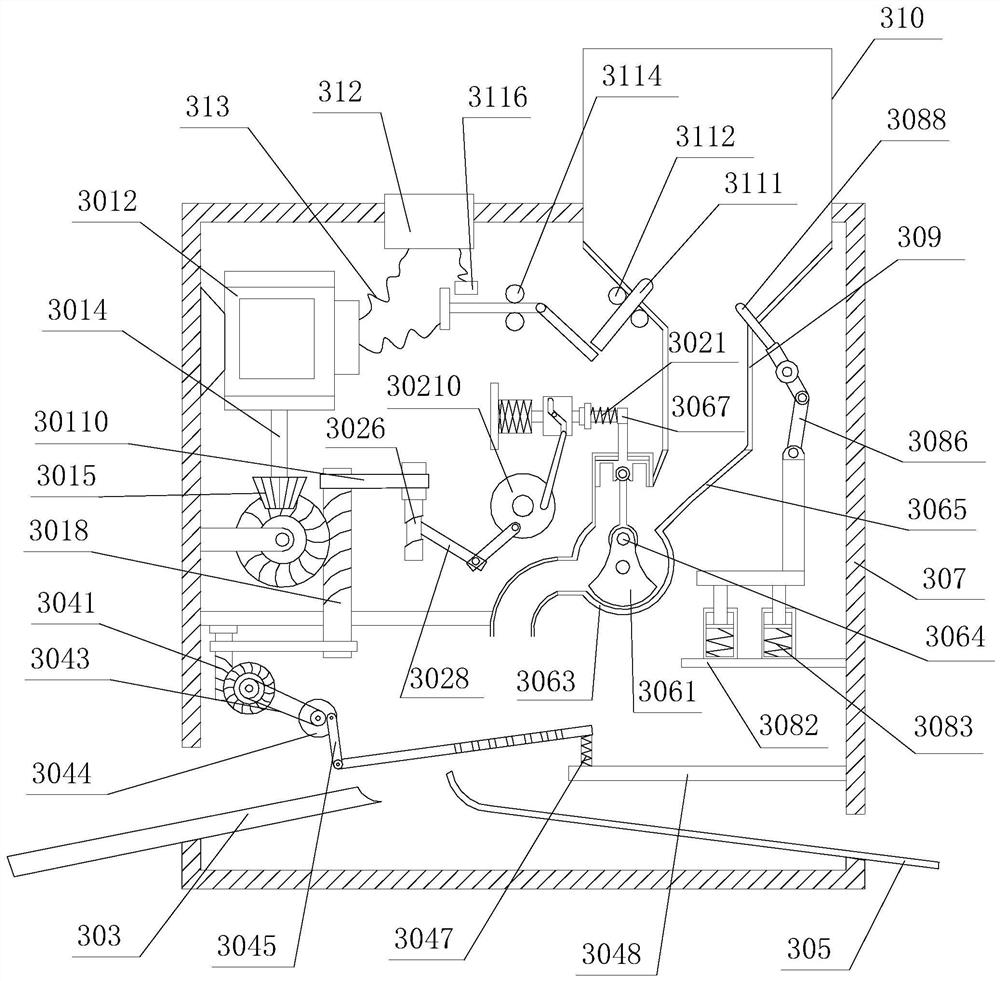

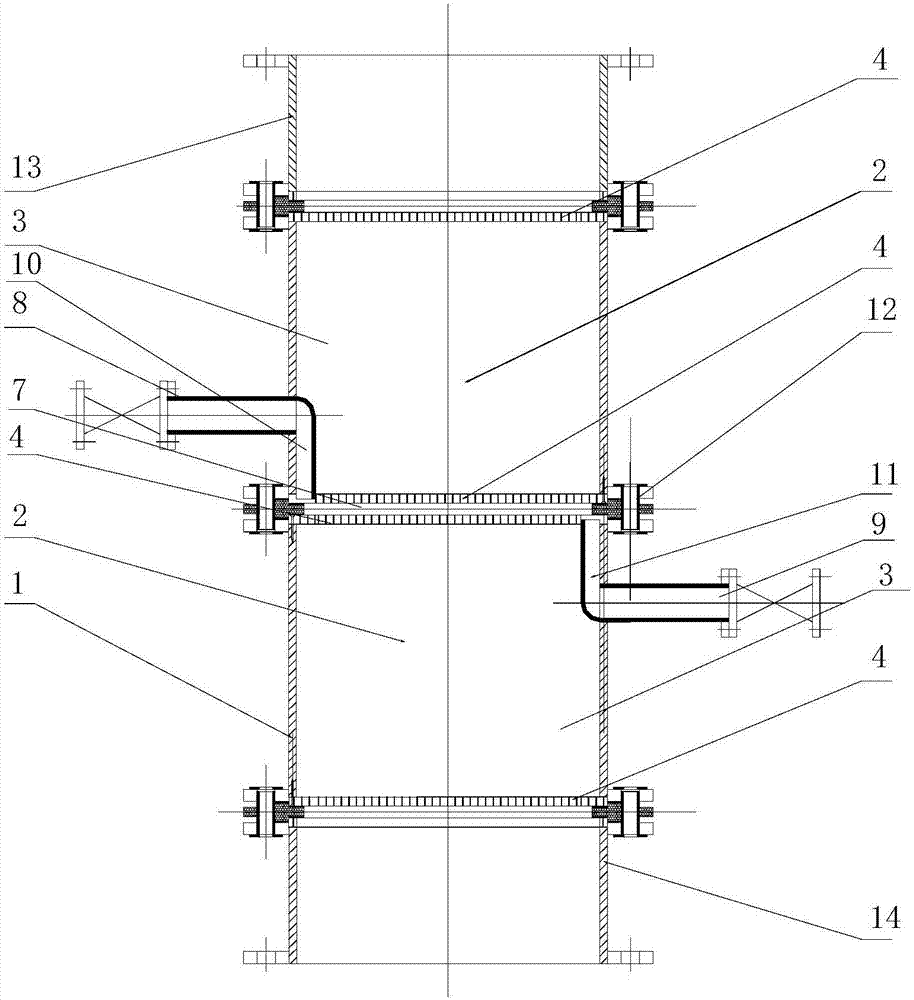

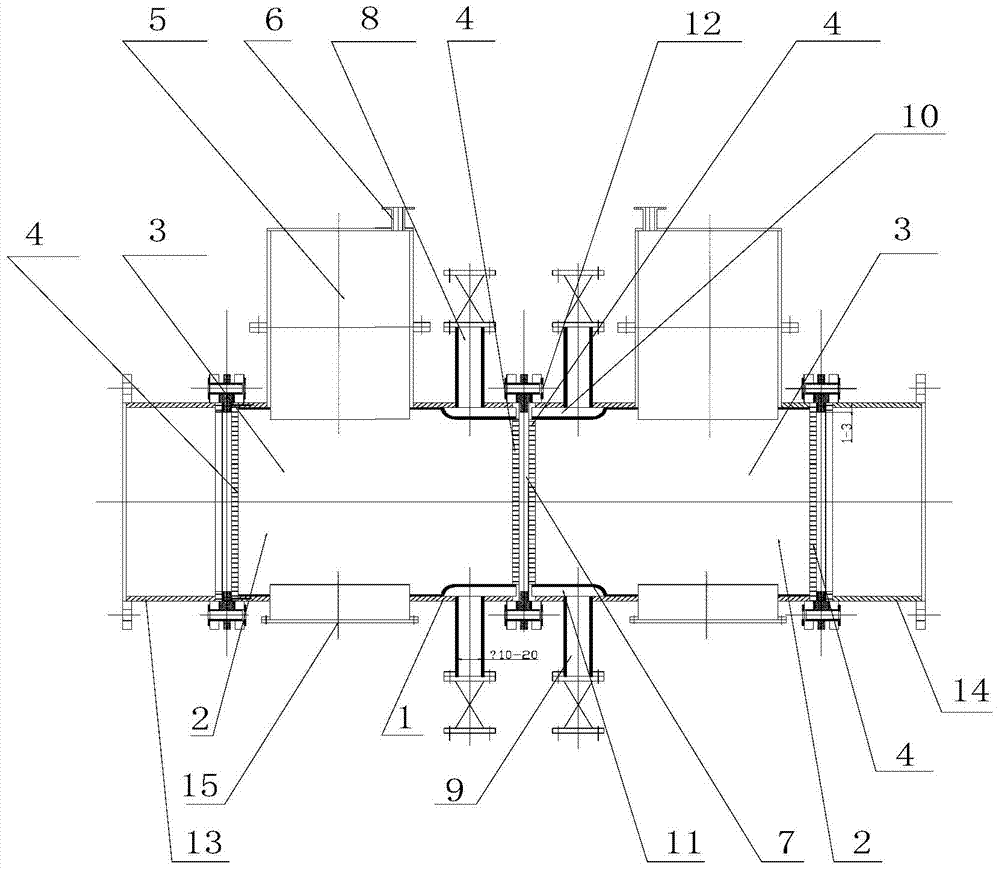

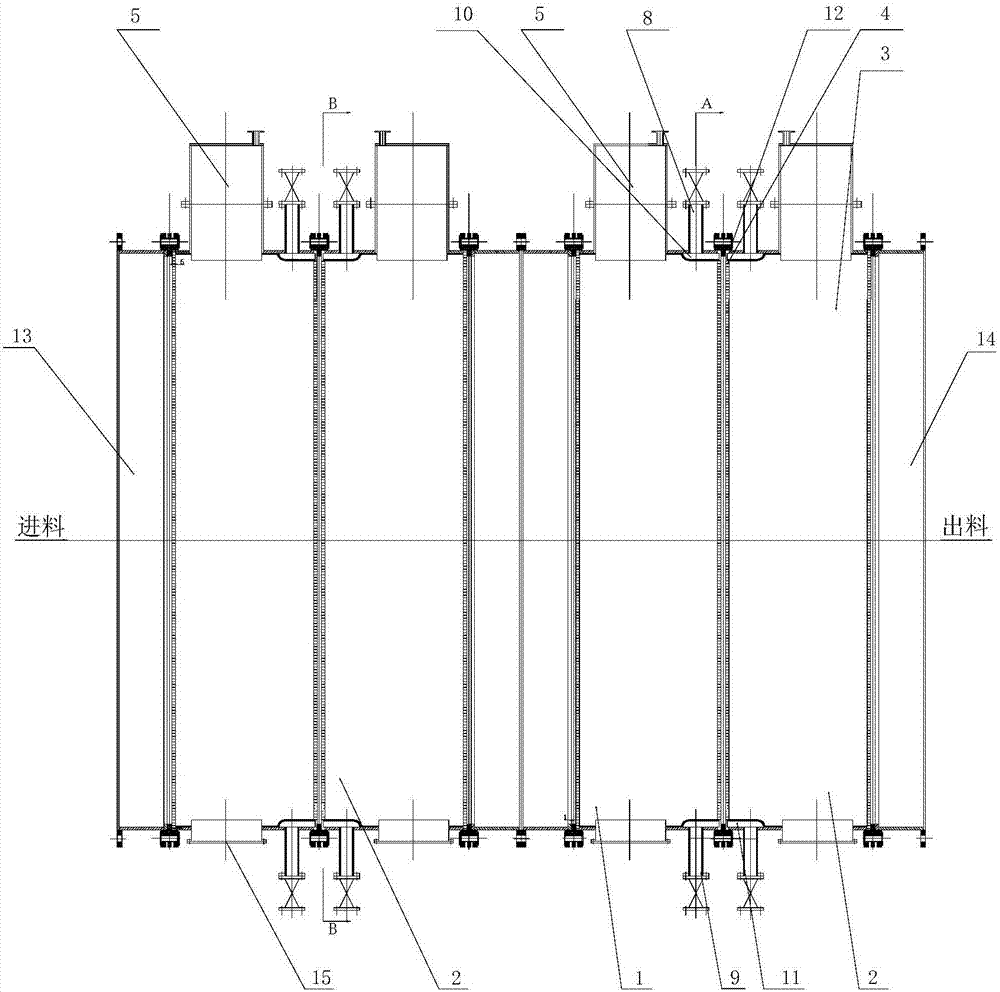

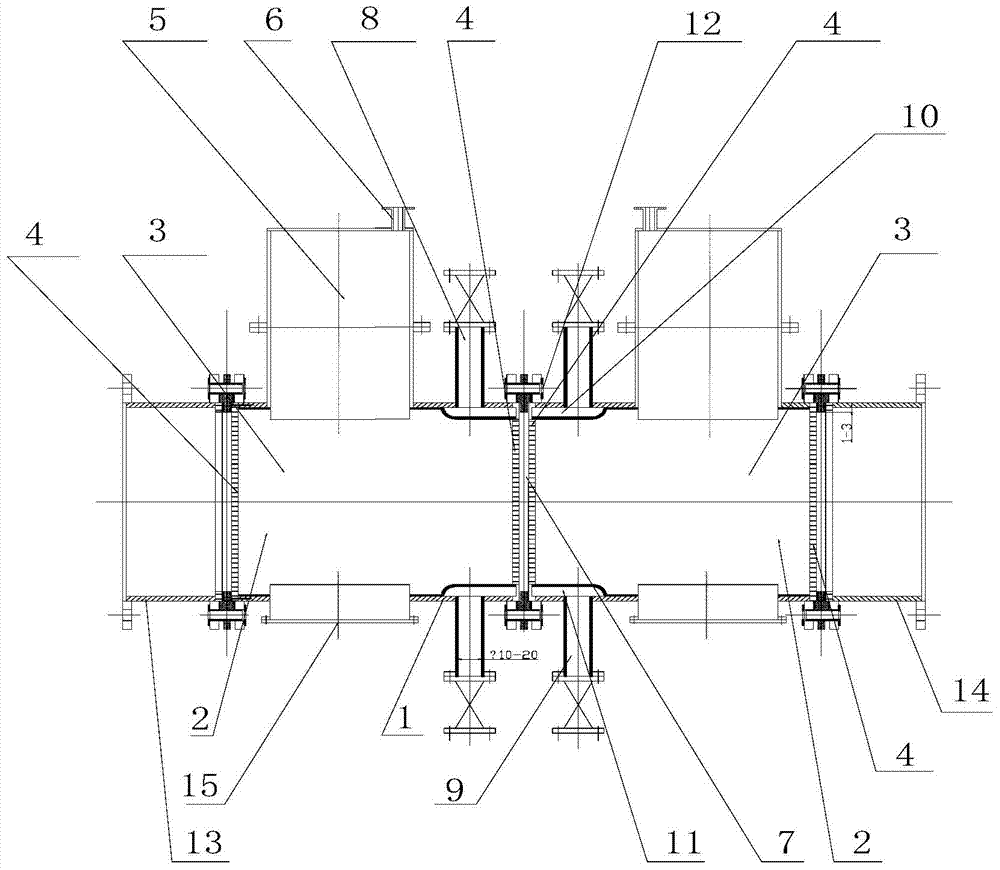

Sampling and washing system

InactiveCN103389265ATimely and effective removalEasy to operateHollow article cleaningMaterial analysis by optical meansDiaphragm pumpEngineering

The invention relates to a sampling and washing system, and belongs to the technical field of medical detection. The system comprises a waste liquid pool, a first diaphragm pump, a cleaning pool, a sampling needle, a counting pool, a diluter and a second diaphragm pump which are connected by a liquid path, wherein the second diaphragm pump is respectively connected with a cleanout fluid container containing a cleanout fluid and a preservation liquid container containing a preservation liquid through a washing pipeline, both ends of the counting pool are connected with a first electromagnetic valve and a second electromagnetic valve, a third electromagnetic valve is arranged between the diluter and the second diaphragm pump, a fourth electromagnetic valve is arranged between the second diaphragm pump and the cleanout fluid container, a fifth electromagnetic valve is arranged between the second diaphragm pump and the preservation liquid container, and a branch pipeline is further arranged on a pipeline between the third electromagnetic valve and the second diaphragm pump. The branch pipeline is communicated with an inner cavity of the cleaning pool. The system cannot only timely and effectively eliminate dirt attached to the cleaning pipeline, but also has the effect of preserving the pipeline, so that the system is convenient to use and operate.

Owner:济南华天恒达科技有限公司

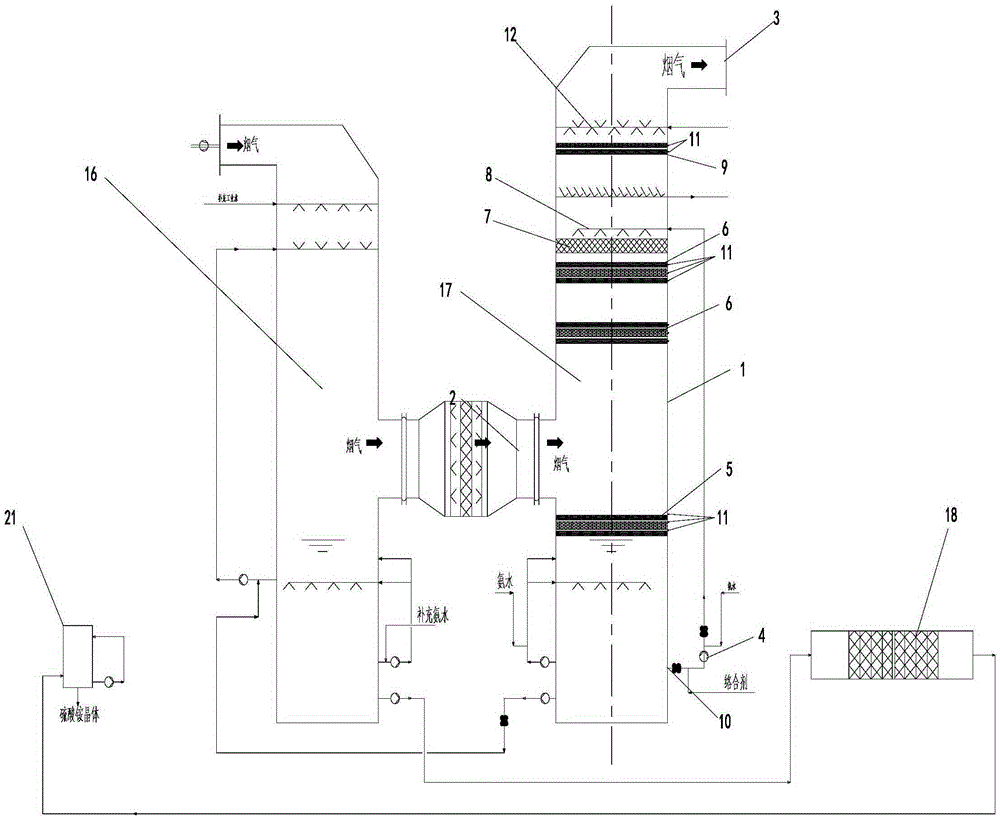

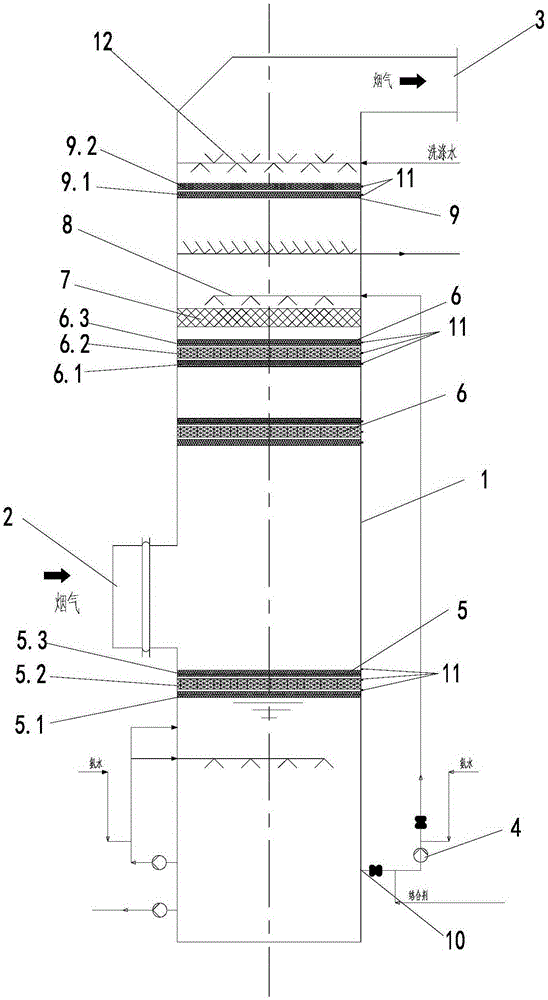

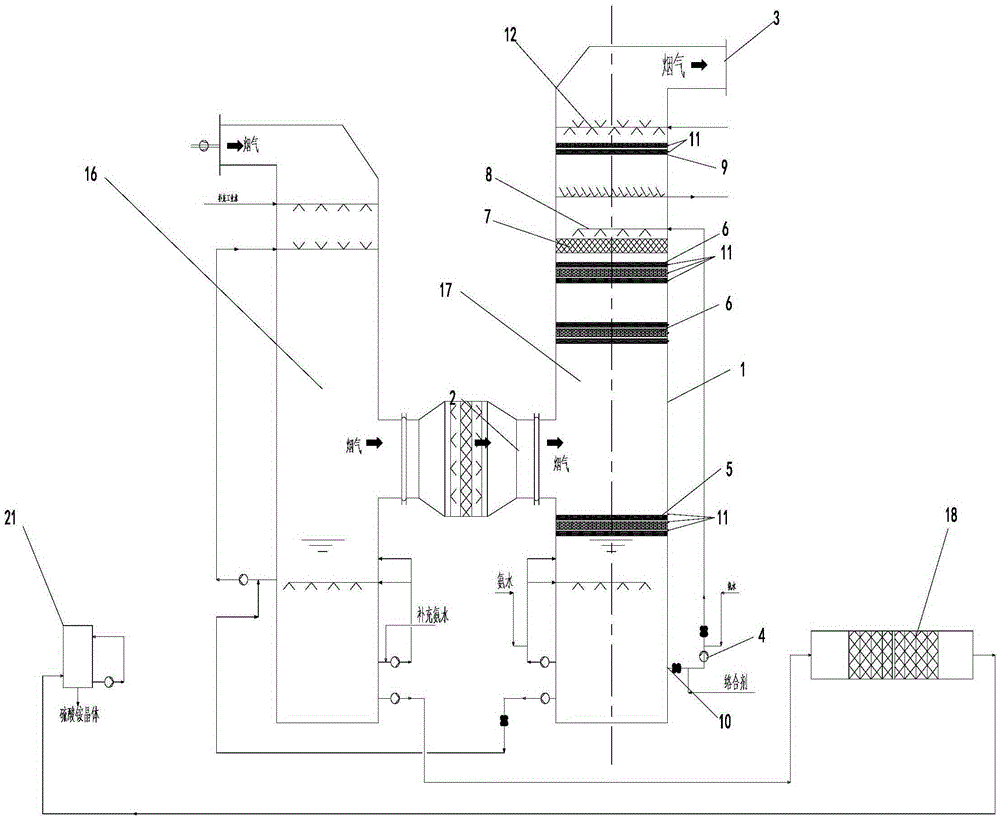

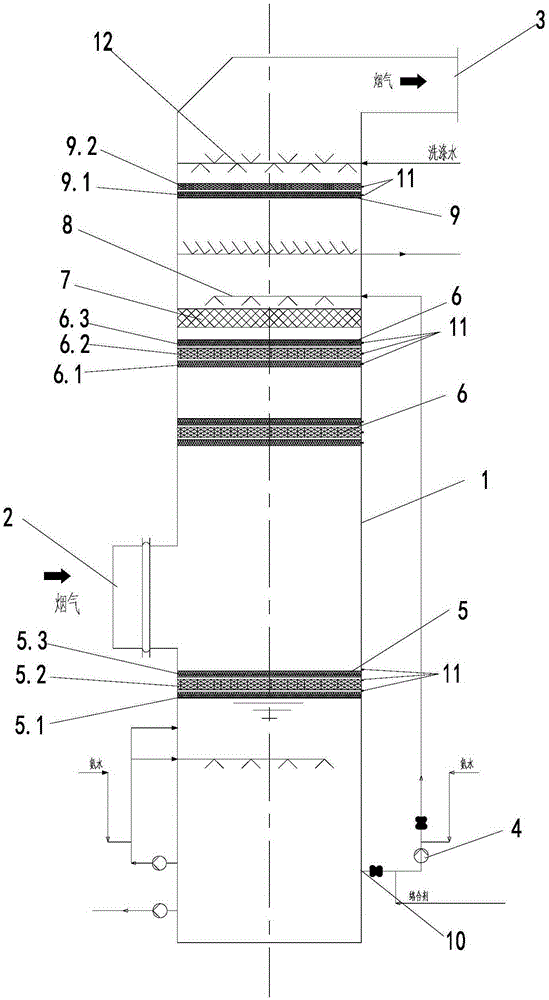

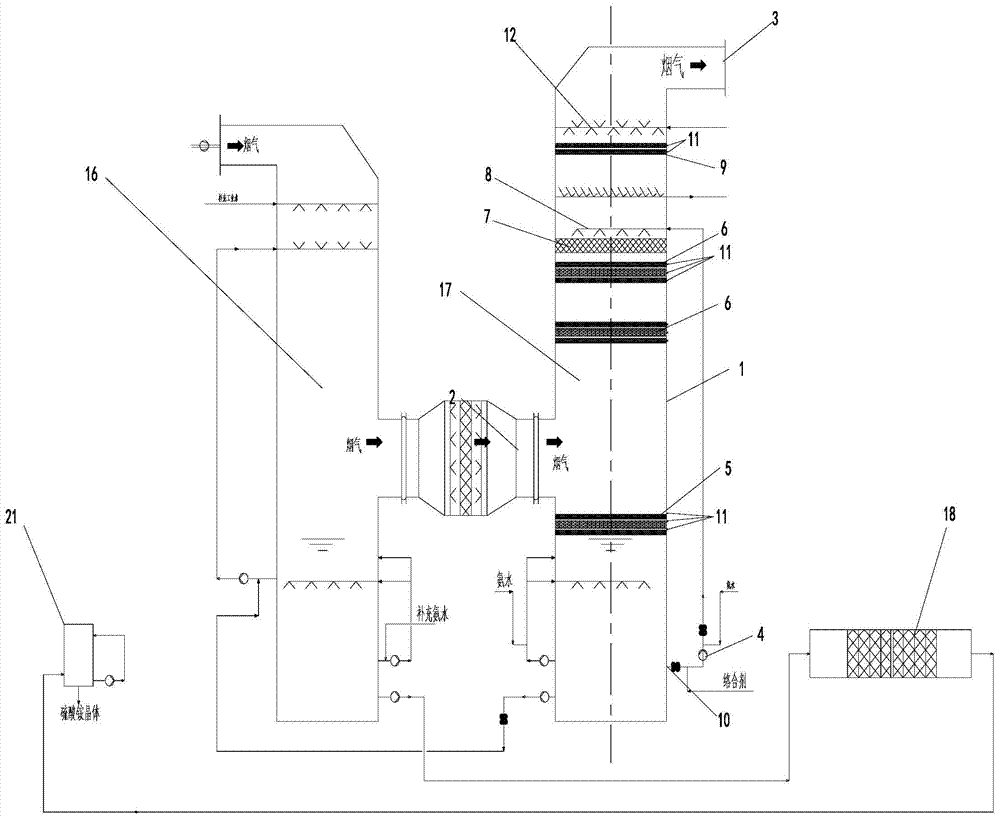

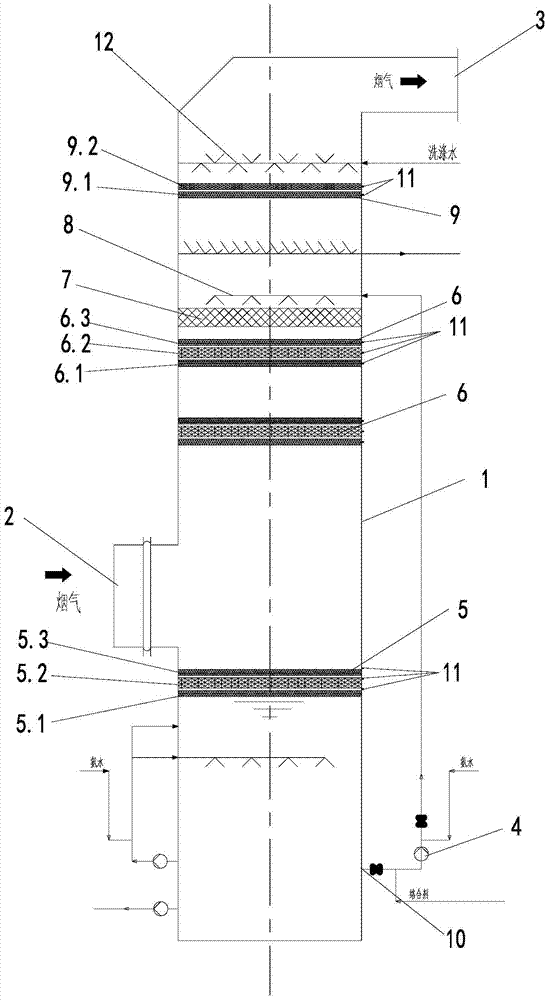

Ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration

ActiveCN105413422AEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationAmmonium sulfateFlue gas

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

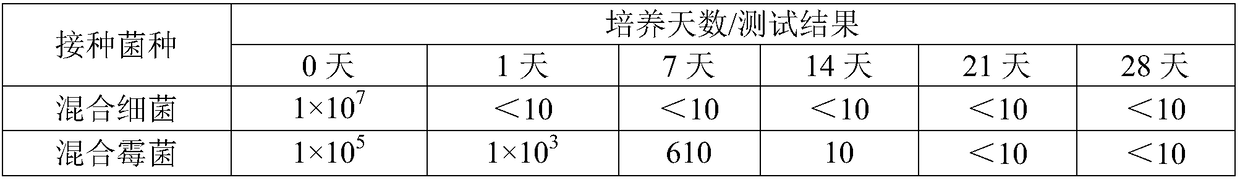

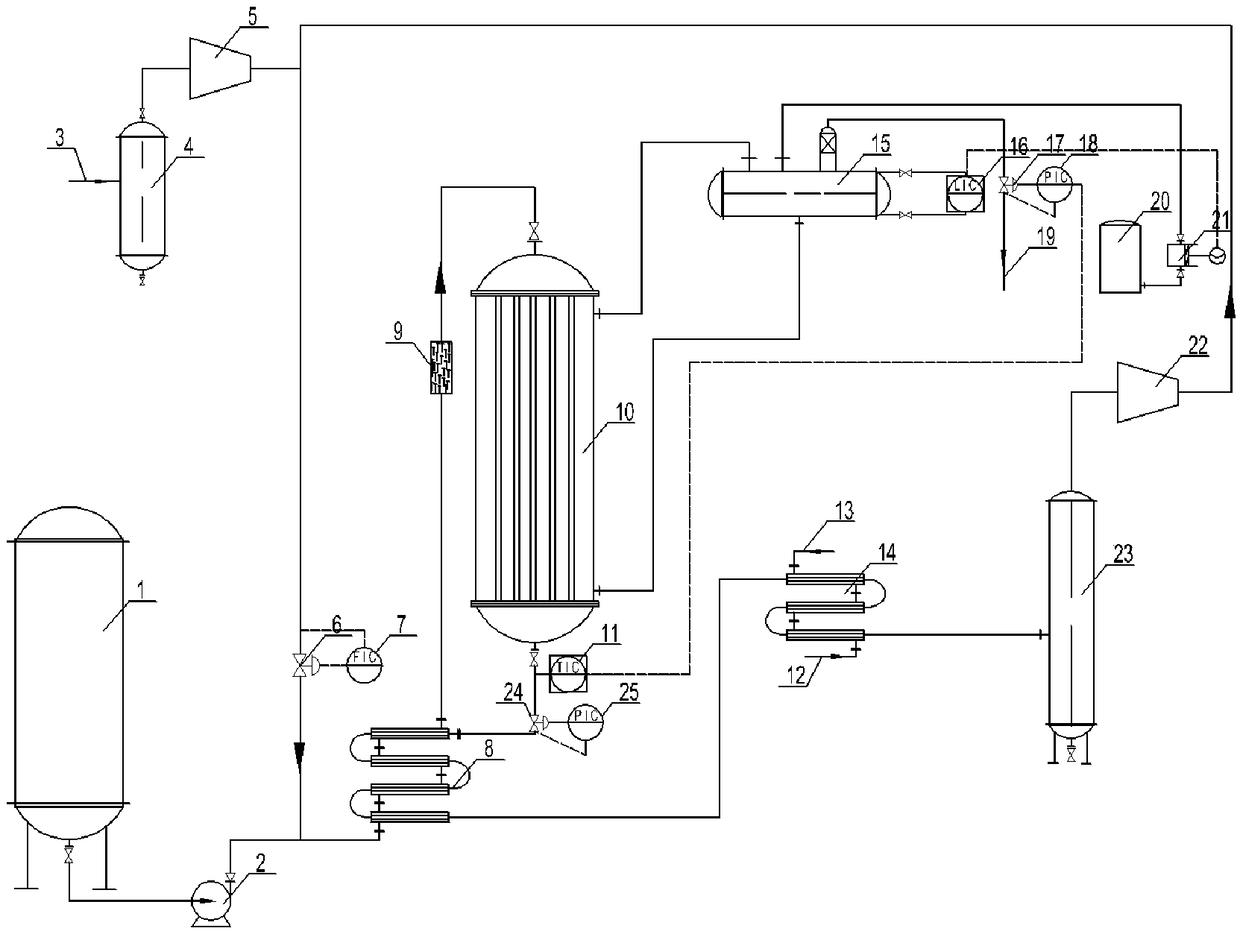

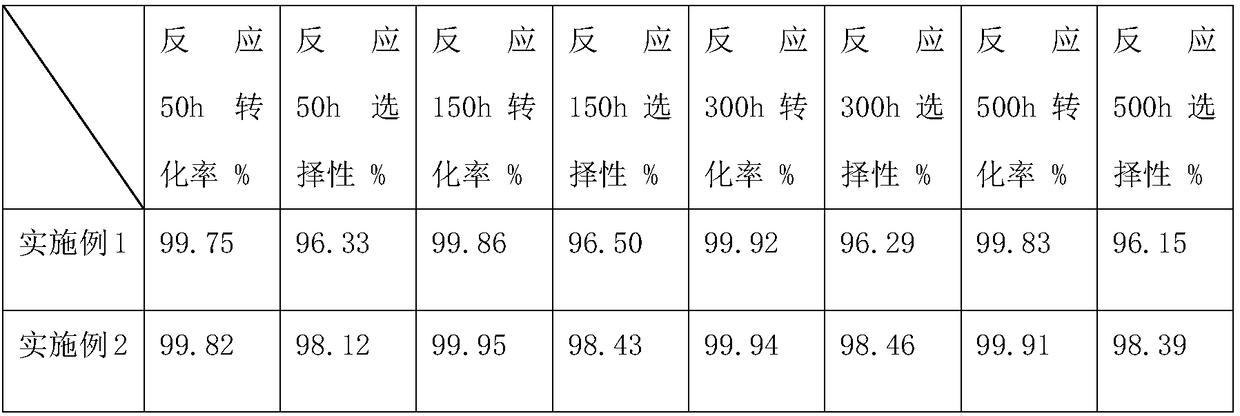

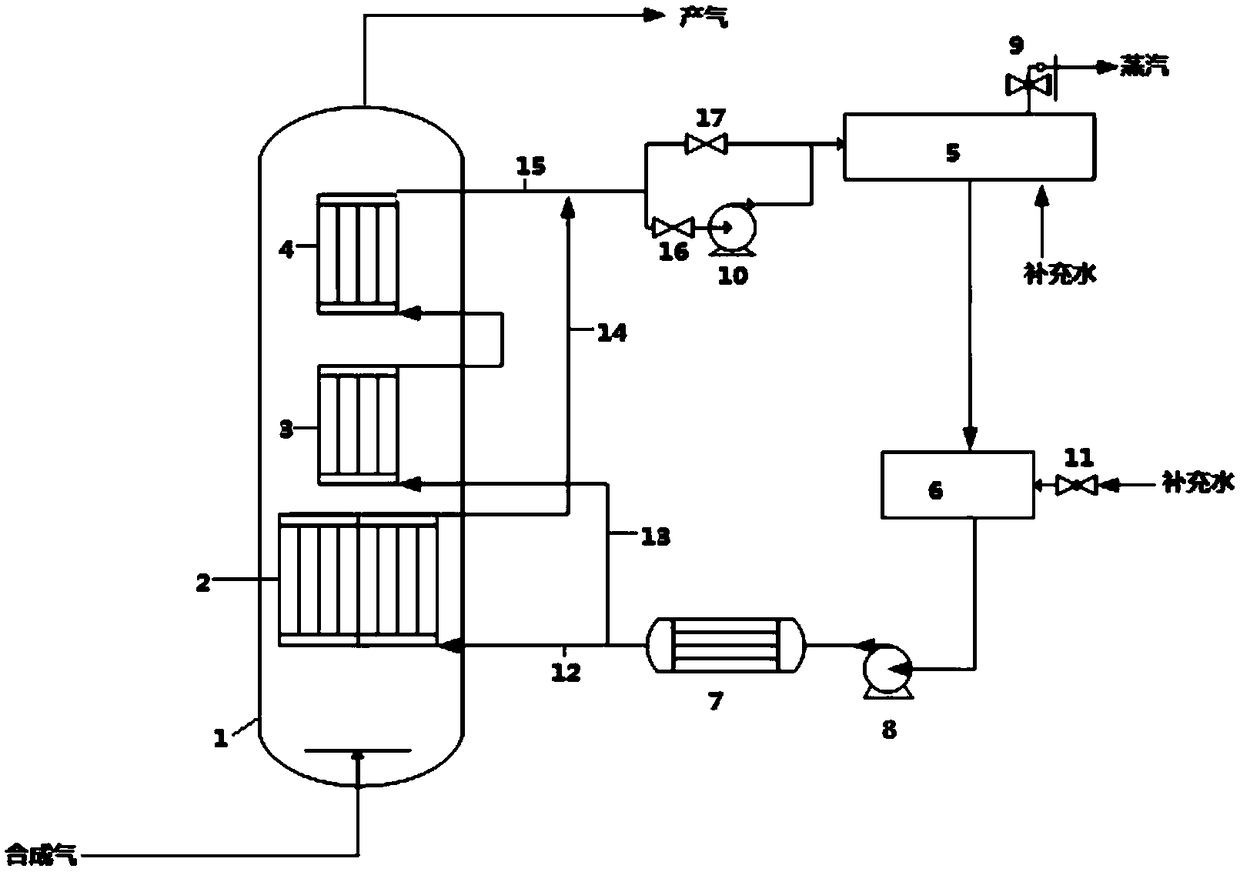

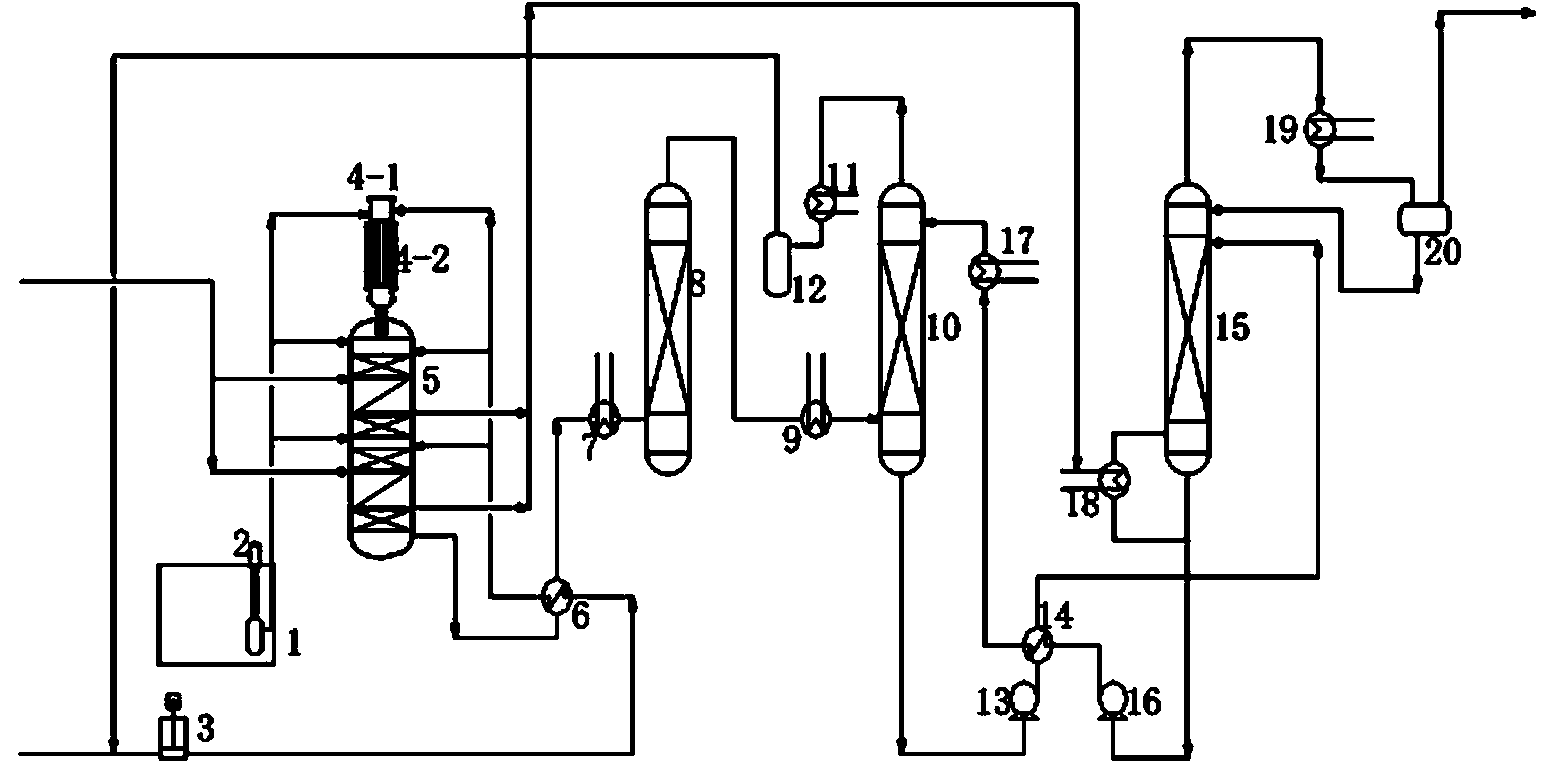

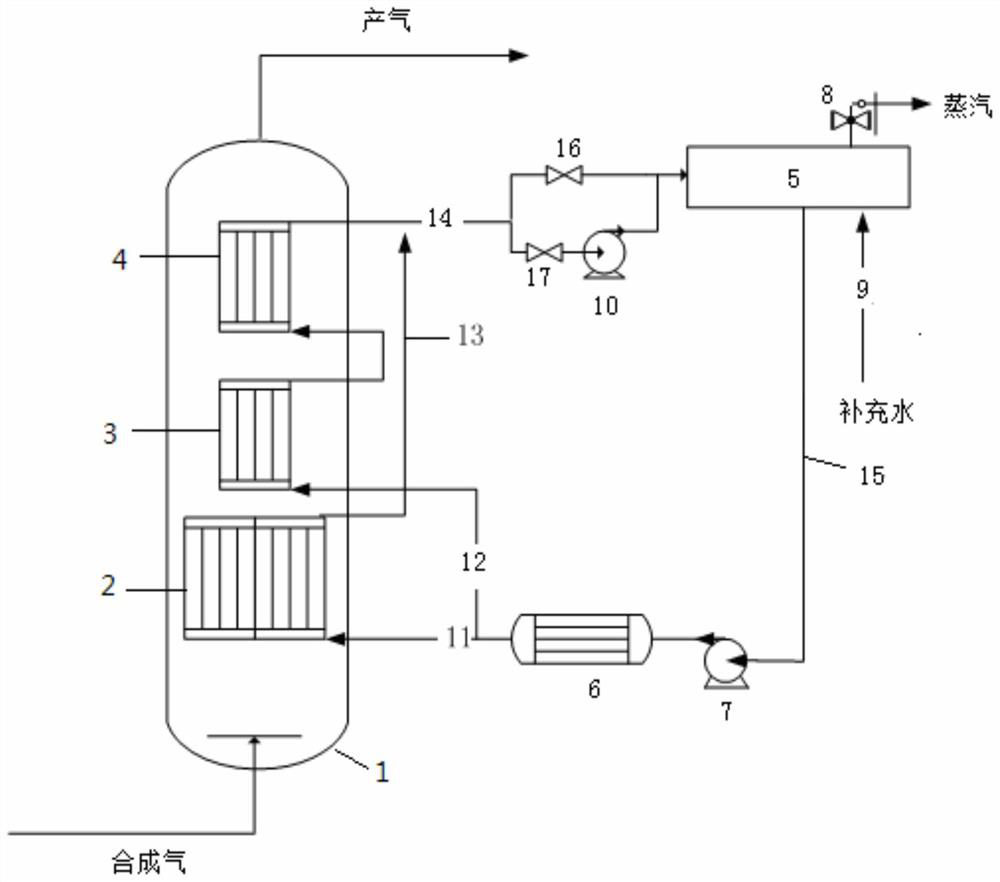

Device and method for preparing ethylene glycol through dimethyl oxalate hydrogenation

PendingCN109400443AAchieve recyclingTimely and effective removalOrganic compound preparationHydroxy compound preparationThermal energySteam pressure

The invention discloses a device and method for preparing ethylene glycol through dimethyl oxalate hydrogenation. The device is composed of a gas feeding system, a liquid feeding system, a preheatingfiltration system, a reaction system and a condensation separation system. The gas feeding system comprises a fresh hydrogen compressor, a recycle hydrogen compressor, a flow adjusting valve and a flow transmitter; the liquid feeding system comprises a dimethyl oxalate feeding tank and a metering pump; the preheating filtration system mainly comprises a feeding heat exchanger and a precision filter; the reaction system comprises a tubular reactor and a steam pocket; the condensation separation system comprises a product cooler and a gas-liquid separation tank. Accordingly, full utilization ofheat energy and hydrogen recycling are achieved, the system temperature, pressure, flow and liquid level are all automatically controlled, the tubular reactor is adopted, in the shell side, high pressure hot water coming from the steam pocket passes, reaction heat is absorbed to become high pressure steam, by adjusting the steam pressure, the reaction temperature can be strictly controlled, the reaction heat is effectively removed in time, the product stability is improved, and the service life of a catalyst is prolonged.

Owner:CHINA CATALYST HLDG CO LTD

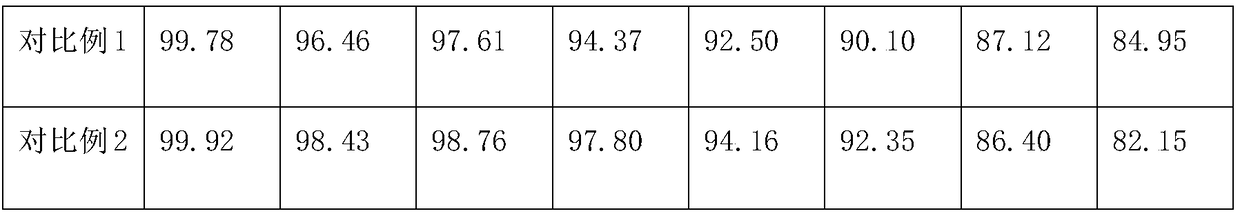

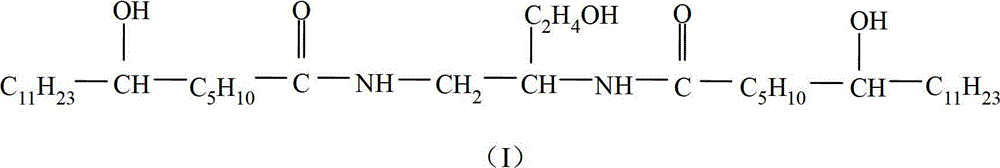

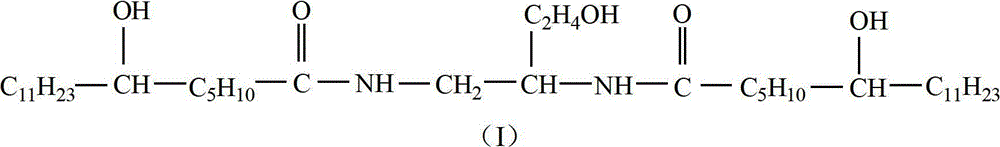

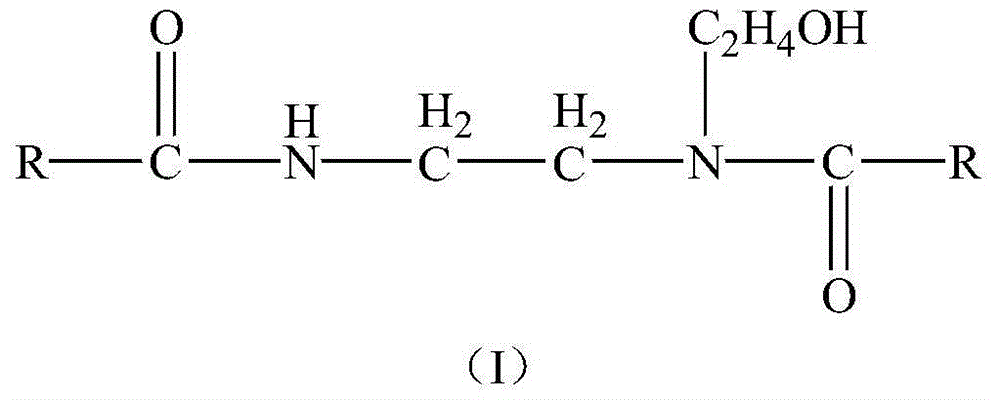

Preparation method for hydroxyethyl dual fatty acid amide

ActiveCN102746180AGood colorLow melting pointOrganic compound preparationCarboxylic acid amides preparationEthylenediaminePotassium borohydride

The invention discloses a preparation method for hydroxyethyl dual fatty acid amide. The method specifically includes steps: (1) salification reaction: reacting hydroxy higher fatty acid with hydroxyethyl ethylenediamine under the protection of nitrogen, heating a complex antioxidant of sodium bisulfite and sodium borohydride and a complex catalyst of phosphoric acid, magnesium sulfate and calcium sulfate for salification reaction; (2) dehydration reaction: increasing temperature for continuing reaction after adding hydroxyethyl ethylenediamine for reaction; and (3) enabling the temperature of materials to be decreased to 80 DEG C to 100 DEG C, the amine value to be less than or equal to 5 mgKOH / g and the acid value to be less than or equal to 10 mgKOH / g for discharging to obtain the hydroxyethyl dual fatty acid amide. The sodium bisulfite and the sodium borohydride are taken as the complex antioxidant during the reaction process and the process conditions are adopted, so that products are colory and have low melting point.

Owner:常州可赛成功塑胶材料有限公司

Flue gas pollutant cooperation removal technology based on electrolysis

InactiveCN105344215AImprove conversion rateSimple structureCombination devicesGas treatmentAmmonium sulfateElectrochemical response

The invention discloses a flue gas pollutant cooperation removal technology based on electrolysis. The problems are solved that technologies are complex, the pollutant treatment efficiency is low, investment and operation cost are high in present flue gas treatment. The technology comprises steps: flue gas is pressurized and sent to a concentration tower, a reaction is carried out, the flue gas going out from the concentration tower is sent to an absorbing tower and contacts and reacts with a circulating absorption solution sprayed from a spray layer at the upper part of the tower in a reverse manner, and the flue gas after reaction is discharged from the top of the absorbing tower; part of the concentrate at the tower bottom of the concentration tower is subjected to iron removal, then is sent to a ammonium sulfate crystallization system, the flue gas goes into the absorbing tower from a flue gas inlet at the middle part of the absorbing tower, goes through at least one absorbing and electrochemical reaction layer arranged at the upper part of the tower firstly, then contacts and reacts with a circulating absorption solution in a reverse manner, then goes through a filler layer and a spraying layer, and is discharged from a flue gas outlet. The technology is simple, the reaction efficiency is high, the operation and investment cost are low, the system land occupation area is small, and the technology is especially suitable for cooperation treatment of multiple pollutants of sulfur dioxide, nitrogen oxides, fine particles, dioxin and the like.

Owner:WUHAN WUTUO TECH +1

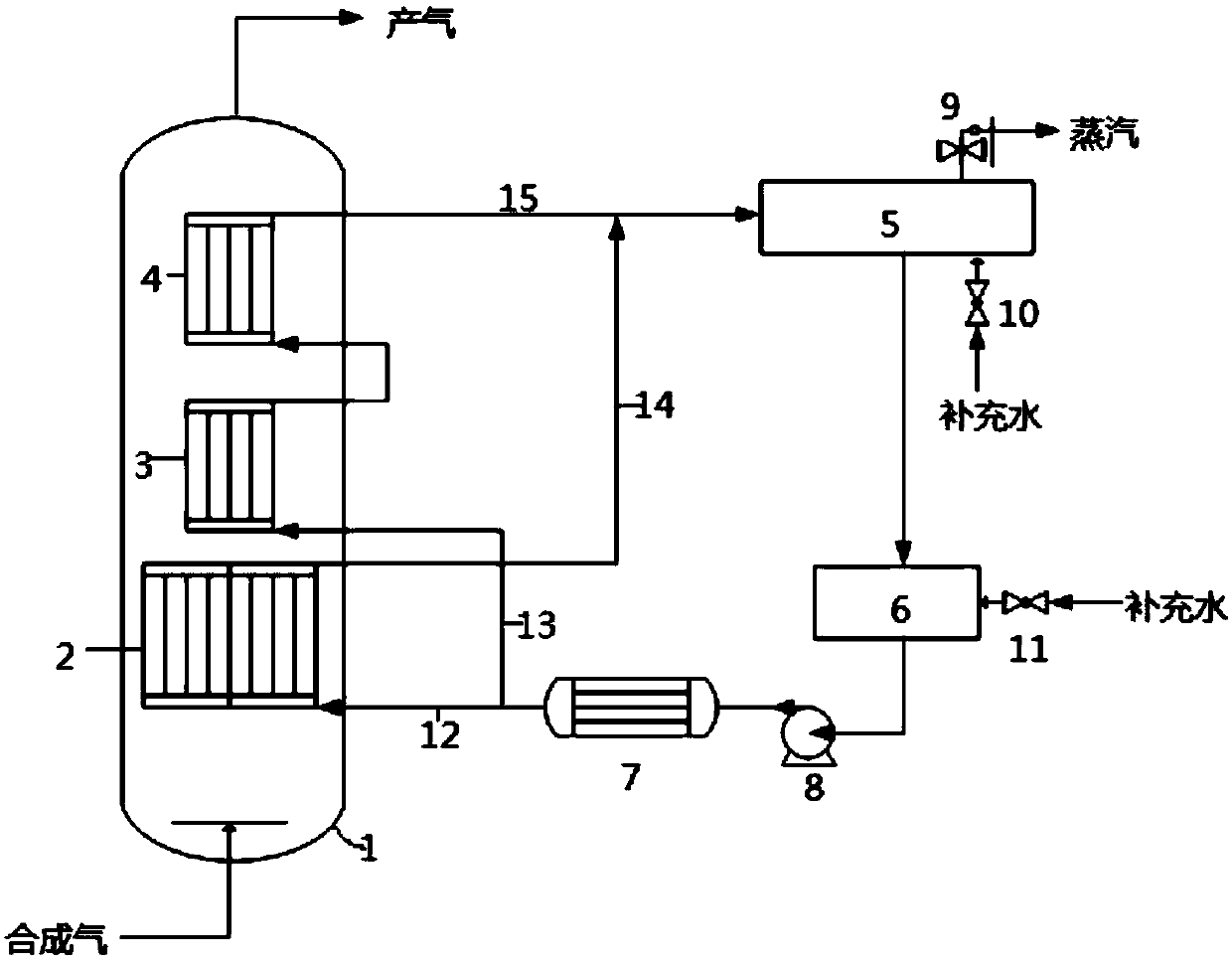

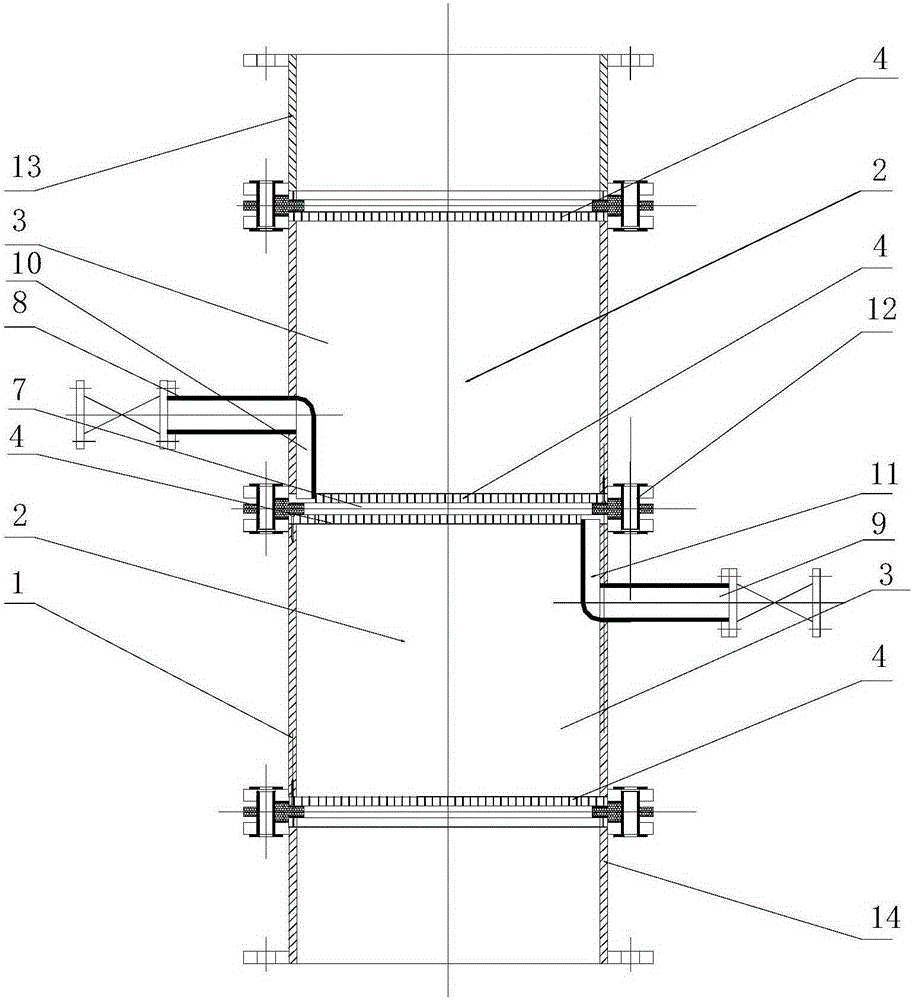

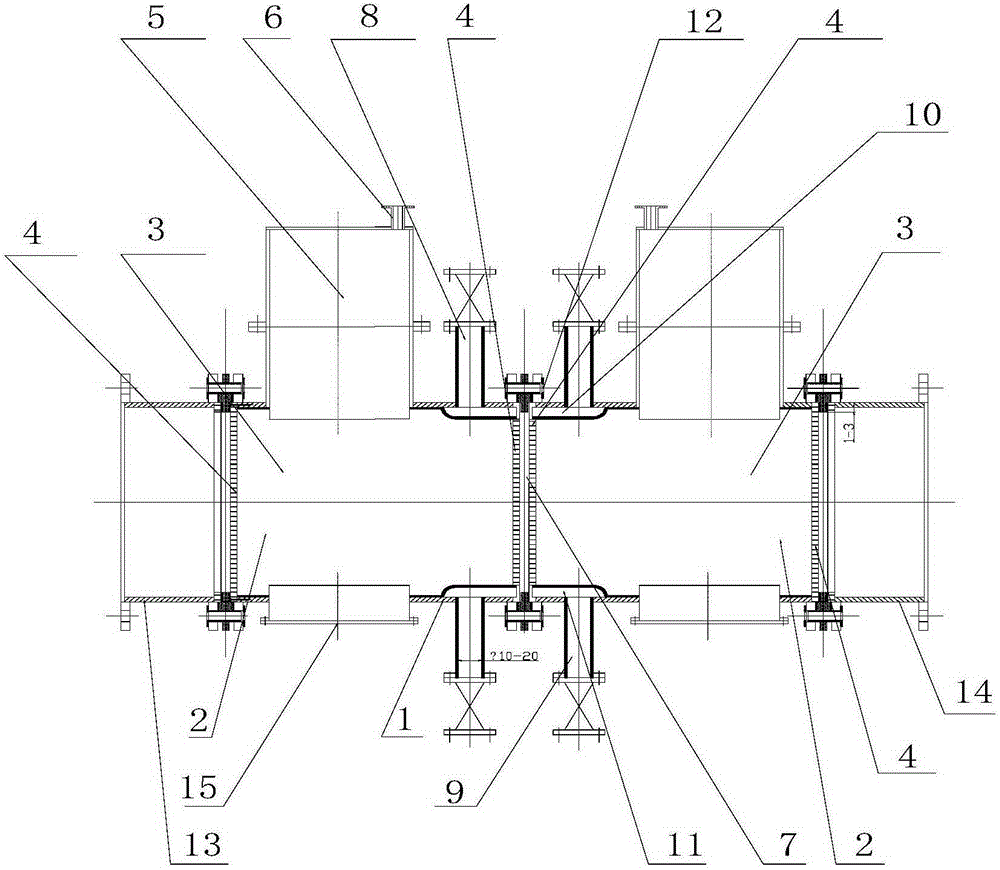

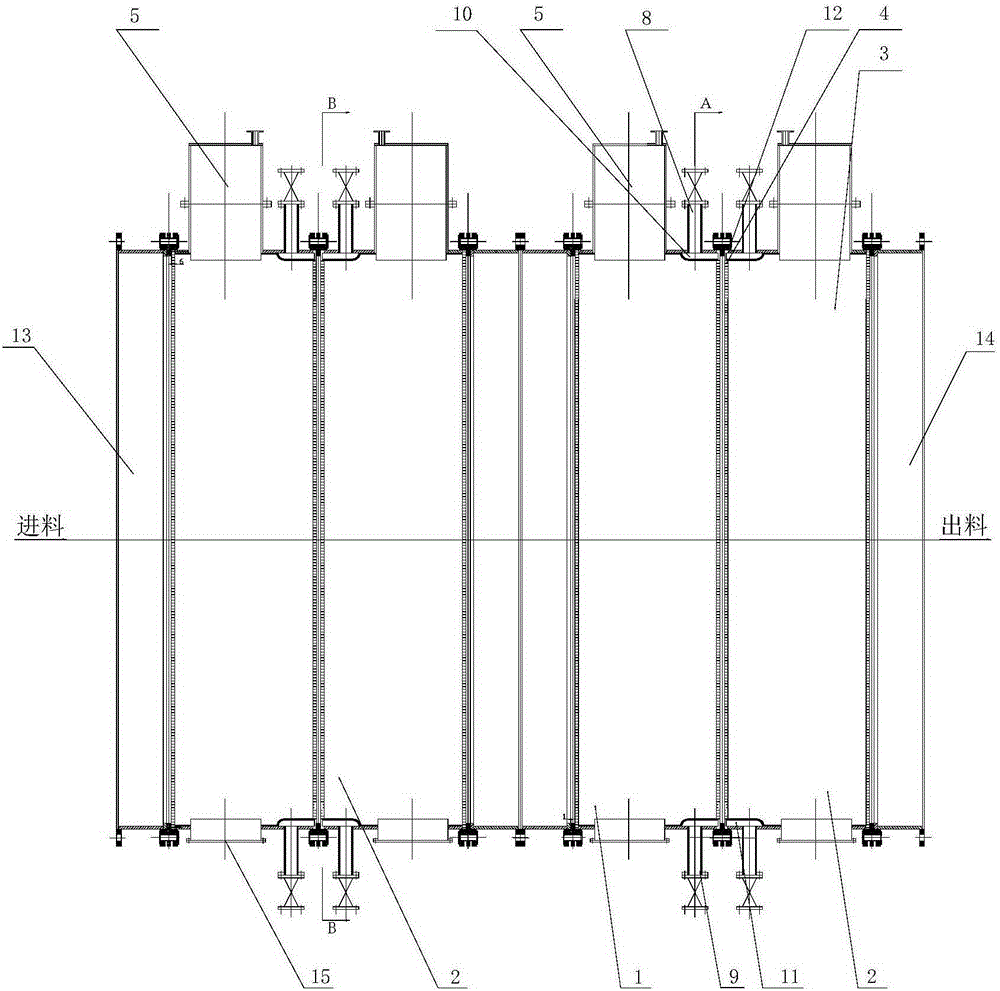

Fischer-Tropsch slurry bed reaction system and Fischer-Tropsch synthesis reaction method

InactiveCN107790072ATimely and effective removalLiquid hydrocarbon mixture productionChemical/physical processesBuffer tankEngineering

The invention relates to the field of Fischer-Tropsch synthesis, and discloses a Fischer-Tropsch synthesis slurry bed reaction system and a Fischer-Tropsch synthesis reaction method. The slurry bed reaction system comprises a slurry bed reactor, a heat exchanger, an external heat exchange device and a part for supplementing cooling water; the heat exchanger is arranged inside the slurry bed reactor; the external heat exchange device is arranged outside the slurry bed reactor; the external heat exchange device comprises a steam pocket, a buffer tank and a heater which are sequentially connectedin series; the heater communicates with a lower water inlet of the heat exchanger; the steam pocket communicates with an upper water outlet of the heat exchanger; and the part for supplementing the cooling water is used for providing the cooling water to the external heat exchange device. The system can timely and effectively remove excessive heat brought by temperature runaway when the local temperature runaway of the catalyst is generated, so that the yield of a target product is ensured, and the operation safety of a device is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Process for synergic removal of flue gas pollutants through complexing absorption synchronous electrolytic reduction

InactiveCN105289254ASimple processing methodImprove controllabilityDispersed particle separationExternal electric electrostatic seperatorComing outElectrolysis

The invention discloses a process for synergic removal of flue gas pollutants through complexing absorption synchronous electrolytic reduction. The technical scheme is that the process comprises the steps that flue gas is pressurized and then fed into a concentrating tower to react; the flue gas coming out of the concentrating tower is fed into an absorption tower to be in reverse contact reaction with circulating absorption liquid sprayed out of a spraying layer on the upper portion of the tower and then is discharged out of the top of the absorption tower; part of concentrated solution at the bottom of the concentrating tower undergoes iron removal and then is fed into an ammonium sulfate crystallization system; the circulating absorption liquid sprayed out of the spraying layer is in reverse contact reaction with the flue gas downwards and then enters the bottom of the absorption tower through an electrolytic regeneration layer below a flue gas inlet, and a cathode layer, an anode layer and a cathode layer are sequentially arranged on the electrolytic regeneration layer from top to bottom. Each electrode layer is of a net structure made of a conductive material, every two adjacent electrode layers are insulated from each other, and the electrolytic regeneration layer is connected with a power supply through a binding post installed on the tower wall. The process is simple, high in reaction efficiency, low in running and investment cost, small in occupied space and particularly suitable for coordinating management of multiple flue gas pollutants.

Owner:WUHAN UNIV OF SCI & TECH +1

Technology of synchronous desulfurization and denitration through flue gas ammonia method based on electrolytic regeneration iron removal

ActiveCN105251330AEasy to fillGuaranteed reliabilityDispersed particle separationAmmonium sulfatesComing outCrystal system

The invention discloses a technology of synchronous desulfurization and denitration through a flue gas ammonia method based on electrolytic regeneration iron removal. The problem that for an existing desulfurization and denitration technology, the regeneration efficiency of an absorption solution is not high is solved. According to the technical scheme, the technology comprises the steps that pressurizing is conducted on flue gas, the flue gas is sent to a concentration tower to be reacted with a concentrated solution in the tower in a contacting mode, the flue gas coming out of the concentration tower is sent to an absorption tower to be reacted with the circulation absorption solution in the tower in a contacting mode, the concentrated solution reacted at the tower bottom part of the concentration tower is sent into an ammonium sulfate crystal system after iron is removed through a first electrolytic reactor, the absorption solution reacted at the tower bottom part of the absorption tower is sent back to the upper portion of the absorption tower to serve as the circulation absorption solution through regeneration, and the concentration solution enters an anode chamber in a reaction unit of the first electrolytic reactor to conduct an oxidation reaction and then enters a cathode chamber to conduct a reduction reaction; a reacted electrolyte is discharged from an outlet connection short pipe and sent into the ammonium sulfate crystal system. The technology of synchronous desulfurization and denitration through the flue gas ammonia method based on electrolytic regeneration iron removal has the advantages of being simple in method, low in investment cost and operating cost, high in conversion efficiency, good in iron removing effect and good in desulfurization and denitration effect.

Owner:武汉武钢绿色城市技术发展有限公司

Slurry reactor reaction system and method for Fischer-Tropsch synthesis reaction

ActiveCN109126640AImprove heat transfer efficiencyHigh yieldChemical industryLiquid hydrocarbon mixture productionSlurry reactorBuffer tank

The invention relates to the field of Fischer-Tropsch, and discloses a slurry reactor reaction system and a method for a Fischer-Tropsch synthesis reaction. The reaction system comprises a slurry reactor, an internal heat exchange unit and an external heat exchange unit; the internal heat exchange unit is arranged inside the slurry reactor, the external heat exchange unit is arranged outside the slurry reactor, the external heat exchange unit comprises a steam pocket, a buffer tank and a heater which are sequentially connected in series, the heater is communicated with a lower water inlet in the internal heat exchange unit, and the steam pocket is communicated with an upper water outlet of the internal heat exchange unit; the internal heat exchange unit comprises a heat exchange pipe witha baffle. The heat exchange efficiency of the heat exchange unit inside the slurry reactor can be improved, the uniform and stable temperature inside the slurry reactor is ensured, when local temperature runaway of a catalyst happens, surplus heat brought by temperature runaway can be effectively removed in time, and then the yield of a target product is ensured.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

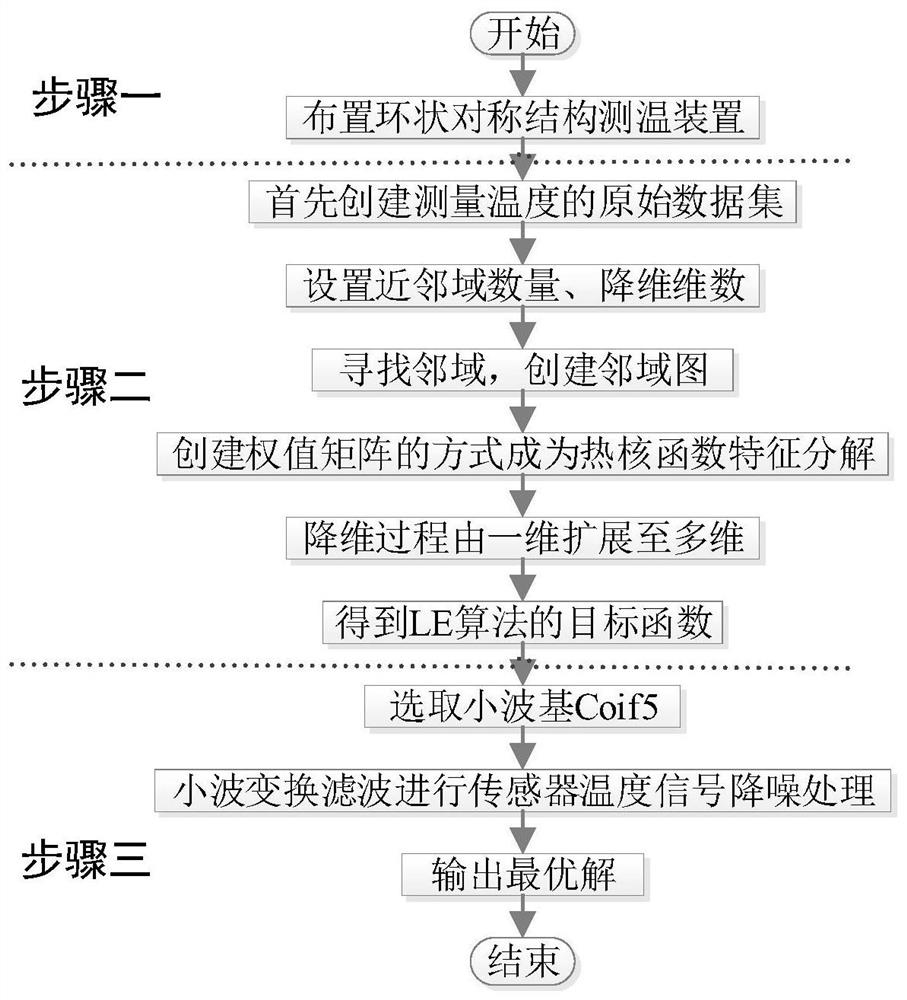

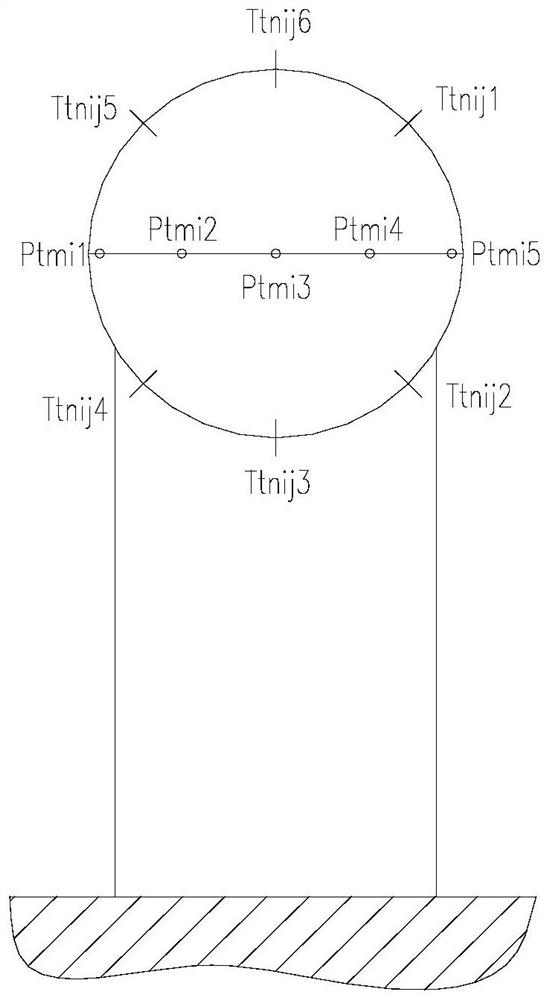

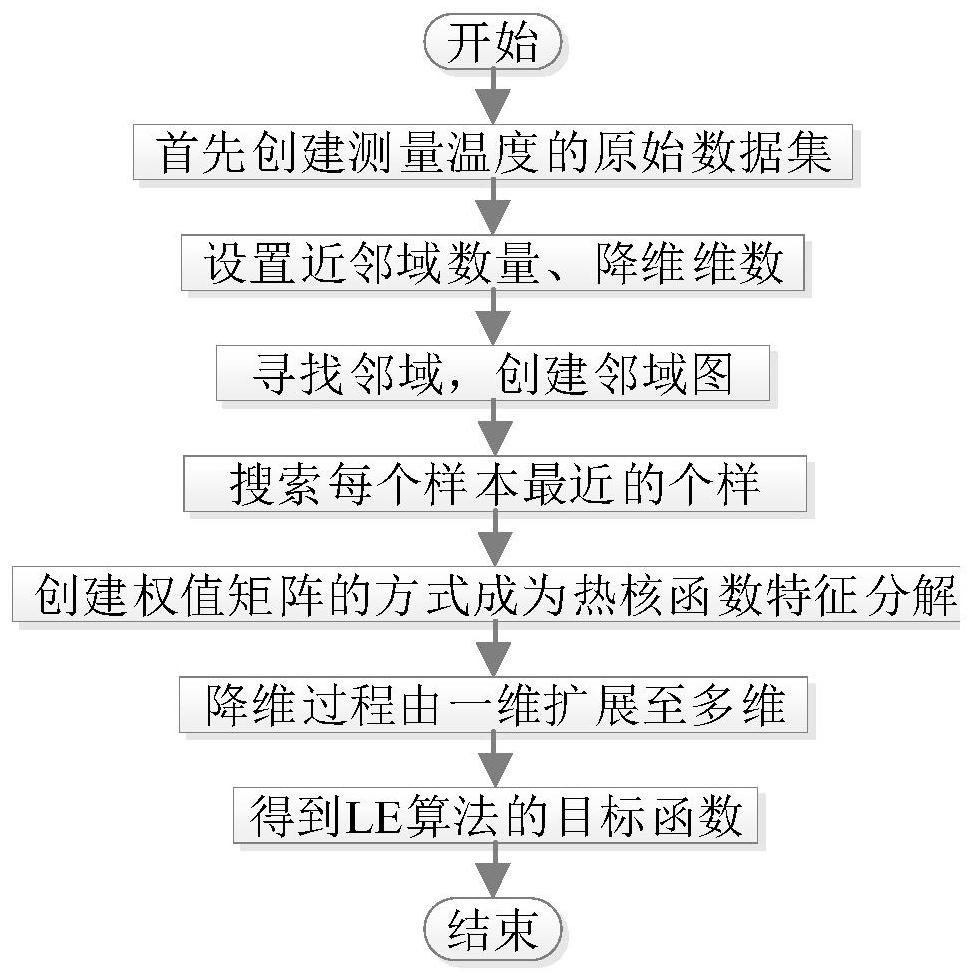

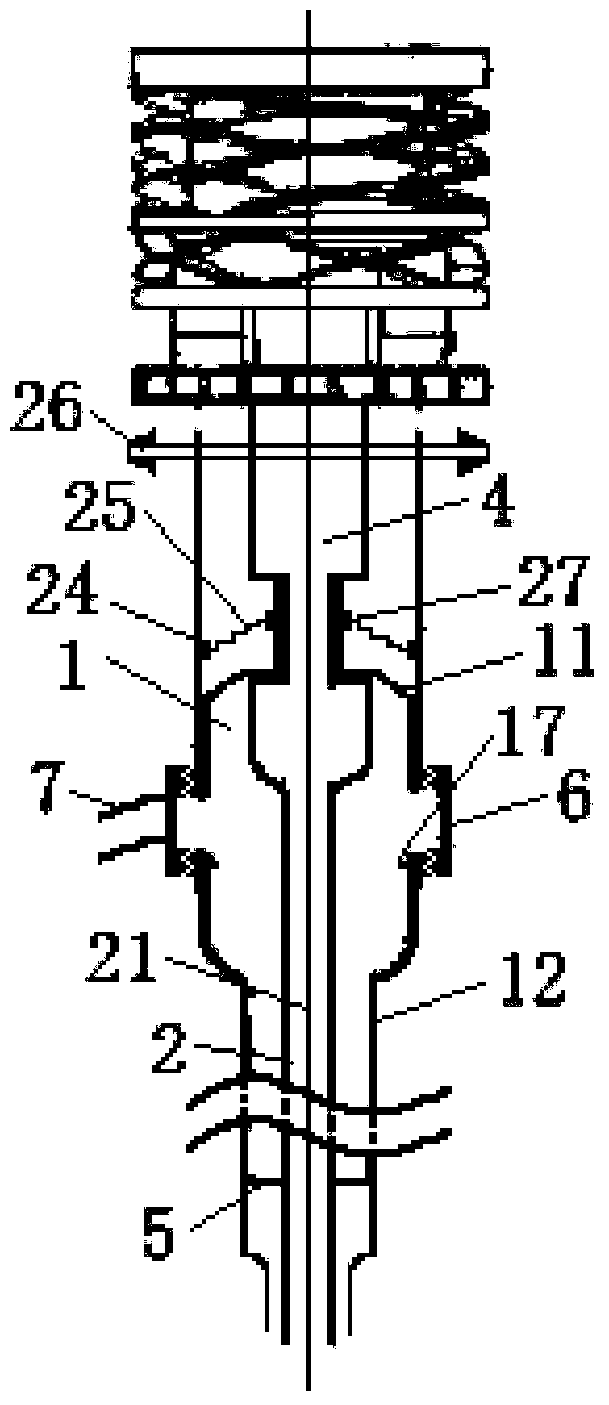

Sensor error identification and elimination method based on Laplacian eigenmapping algorithm

ActiveCN112763225AEvenly distributedAccurate measurementInternal-combustion engine testingThermometers using electric/magnetic elementsCombustion chamberEngine testing

The invention discloses a sensor error identification and elimination method based on a Laplacian eigenmapping algorithm, and relates to the field of engine testing. An annular symmetrical temperature measurement structure, Laplacian eigenmapping and a wavelet basis noise reduction algorithm to complete continuous and accurate measurement of the temperature of an engine are adopted. The method comprises the following steps: 1, in order to cope with airflow disturbance generated by deflection of tail flame of an engine, arranging an engine combustion chamber annular symmetrical structure measuring device; 2, in order to timely and effectively weaken and remove measurement interference, further obtaining a target temperature value through dimension reduction processing of a Laplacian feature mapping algorithm; and 3, performing sensor temperature signal noise reduction processing through wavelet transform filtering, and selecting a wavelet basis Coif5 to perform temperature signal noise reduction processing so as to eliminate a measurement error caused by a complex engine tail flame temperature change rule. According to the invention, the problems of poor temperature measurement accuracy caused by complex temperature change rules and difficulty in timely and effective removal of measurement interference can be effectively solved.

Owner:HARBIN INST OF TECH

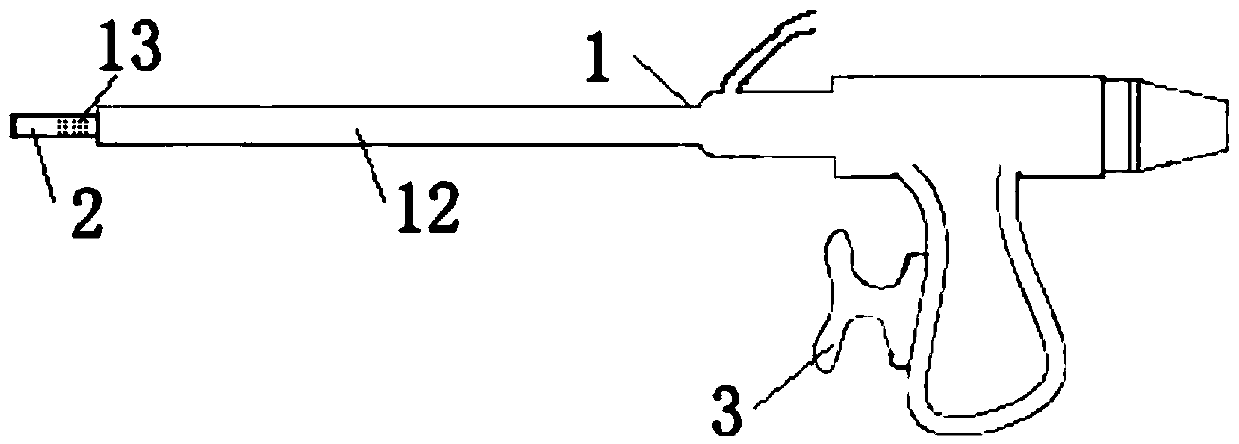

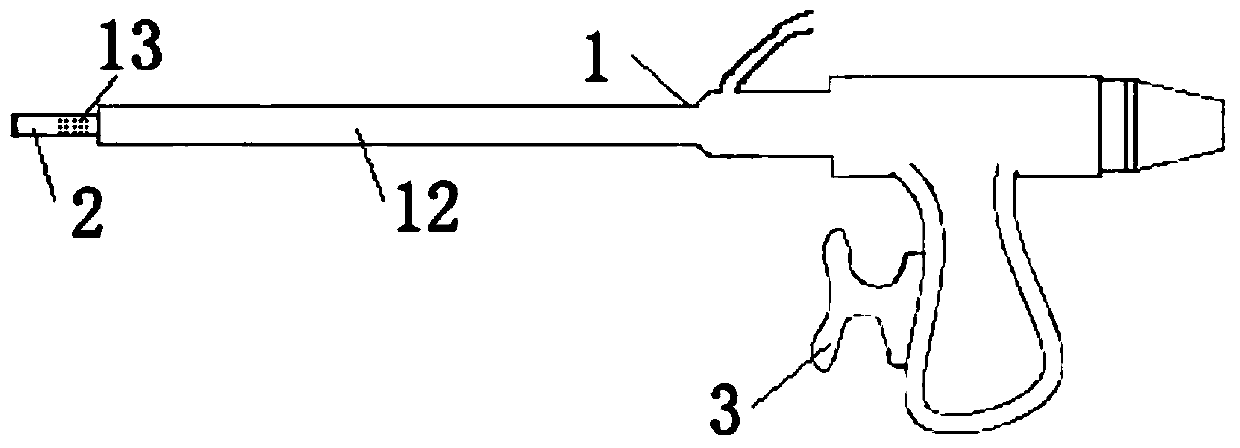

Smog-free ultrasound knife

The invention discloses a smog-free ultrasound knife. The smog-free ultrasound knife comprises a control device, a suction device, a housing and an ultrasonic knife body. The control device comprises a switch, a power unit and a transmission unit, the power unit is connected with the transmission unit, the switch is electrically connected with the power unit and a negative pressure generator, the suction device comprises the negative pressure generator and a suction part, the negative pressure generator is electrically connected with the control device, the suction device coincides with the axis of the knife bar of the ultrasonic knife body, the inner diameter of the pipe of the suction device is larger than the largest diameter of the outer pipe of the ultrasonic knife body, the suction device is communicated with the negative pressure generator in a sealing manner, one end of the suction device is in transmission connection with the transmission unit to form the seal, the other end of the suction device is in transmission connection with the housing to form the seal, and the suction device is arranged in the housing. During the cutting process of the ultrasonic knife body, the suction device can play a role in cleaning the operation visual field, and the safety and fluency of operations can be improved.

Owner:郜永顺

Method for preparing hydrogen sulfide

InactiveCN102502523BEffective temperature controlTemperature controlHydrogen sulfidesHydrogenEvaporation

The present invention relates to a method for preparing hydrogen sulfide. The method uses molten sulphur and hydrogen as starting materials, including a synthesizing stage of hydrogen sulfide and a refining stage of hydrogen sulfide. The synthesizing stage of hydrogen sulfide includes steps of evaporating and vaporizing the molten sulphur in an evaporator by utilizing an electric induction heating device on the periphery of the evaporator to obtain sulfuric vapors; putting the hydrogen into the evaporator, pre-heating, rising temperature, intensive mixing with the sulfuric vapors to obtain the gas mixture of hydrogen and sulfuric vapors; and putting the gas mixture of hydrogen and sulfuric vapors into a synthesizing tower, and synthesizing to obtain the gas mixture of hydrogen sulfide, hydrogen and sulfuric vapors. The refining stage includes steps of removing the sulfuric vapors from the gas mixture of hydrogen sulfide, hydrogen and sulfuric vapors, absorbing the hydrogen sulfide and regenerating to obtain the refined hydrogen sulfide gas. The molten sulphur is evaporated by utilizing the electric induction evaporator, which is easy to control the temperature and has high evaporation efficiency.

Owner:YANTAI UNIV

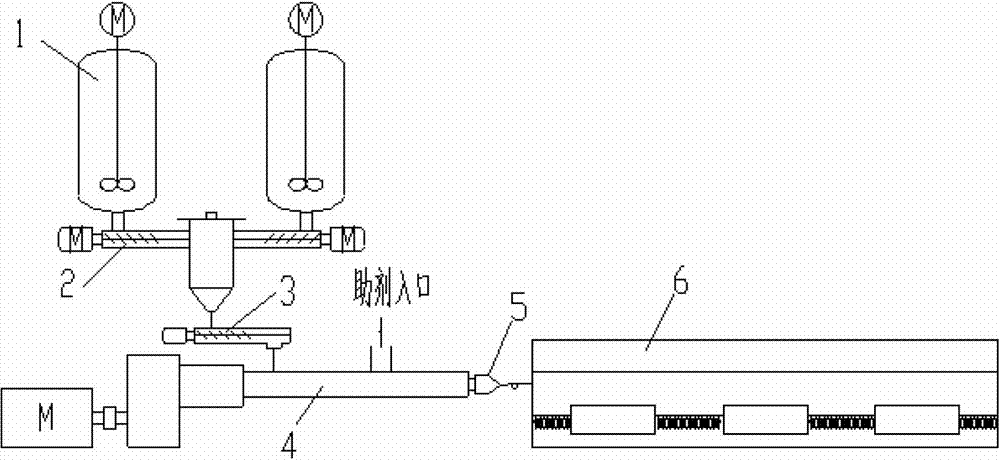

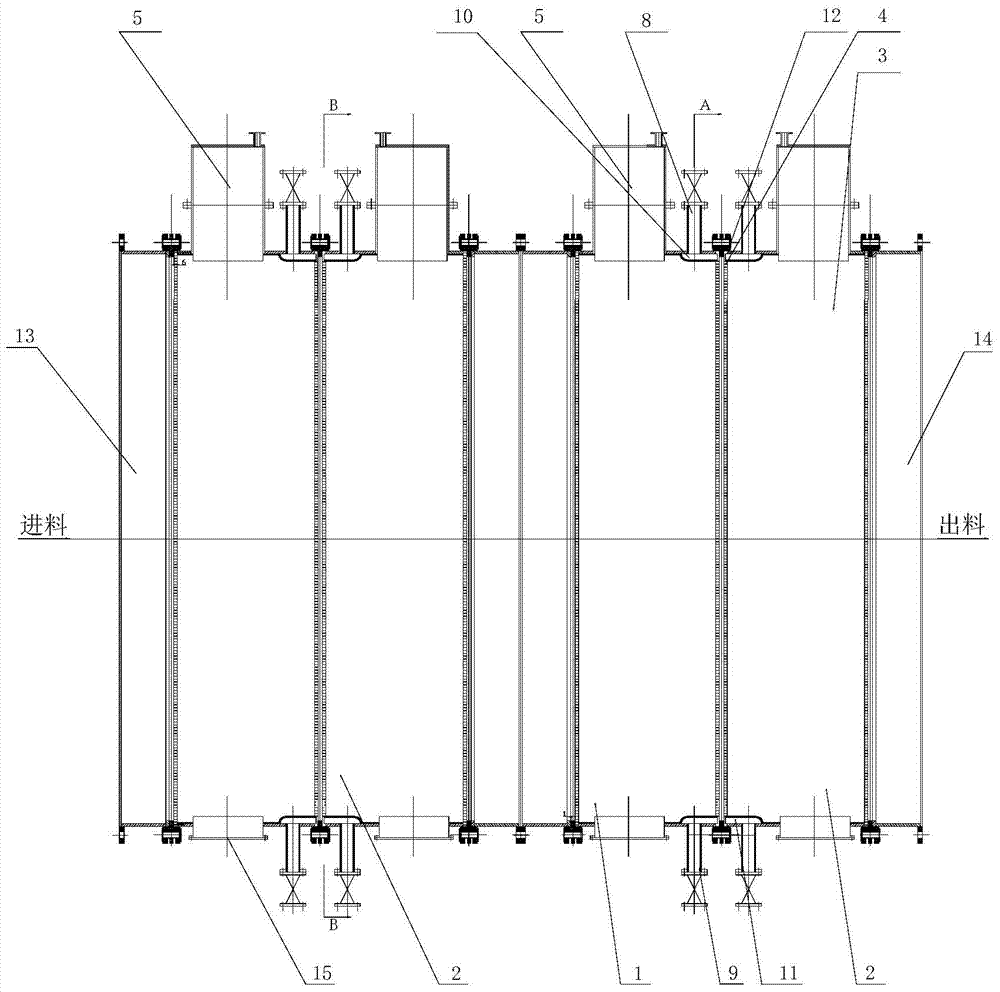

Device and process for preparation of melamine formaldehyde foam

InactiveCN104325648ATimely and effective removalContinuous productionDomestic articlesMelamine formaldehydeEngineering

The invention discloses a device and process for preparation of melamine formaldehyde foam, the device comprises melamine reactors, a single screw extruder, a metering feeder, a reaction type twin-screw extruder, a sheet machine head and a microwave foaming device, which are connected in sequence, the number of the melamine reactors is two, and the melamine reactors are arranged in parallel. The device can effectively and timely remove a large amount of heat of reaction when melamine and formaldehyde react, so that the reaction is performed in a smooth and controlled manner, and a melamine formaldehyde foam product with stable quality can be continuously produced.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

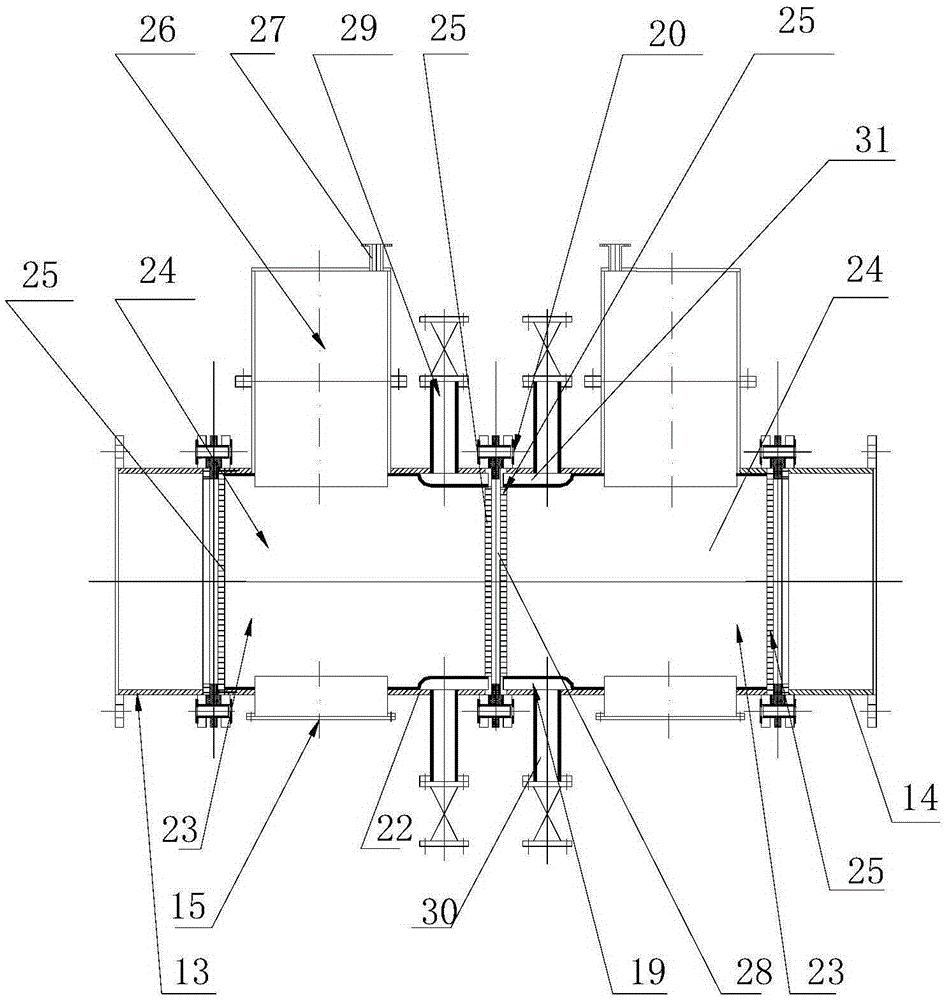

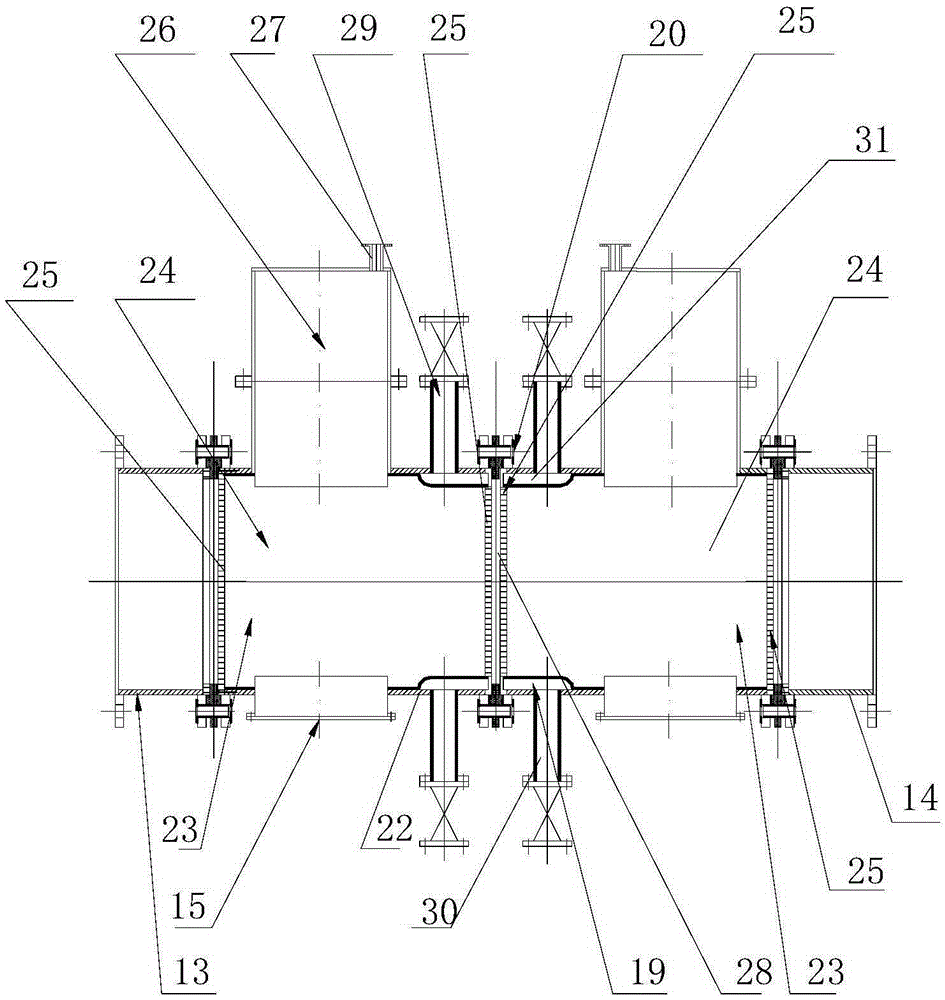

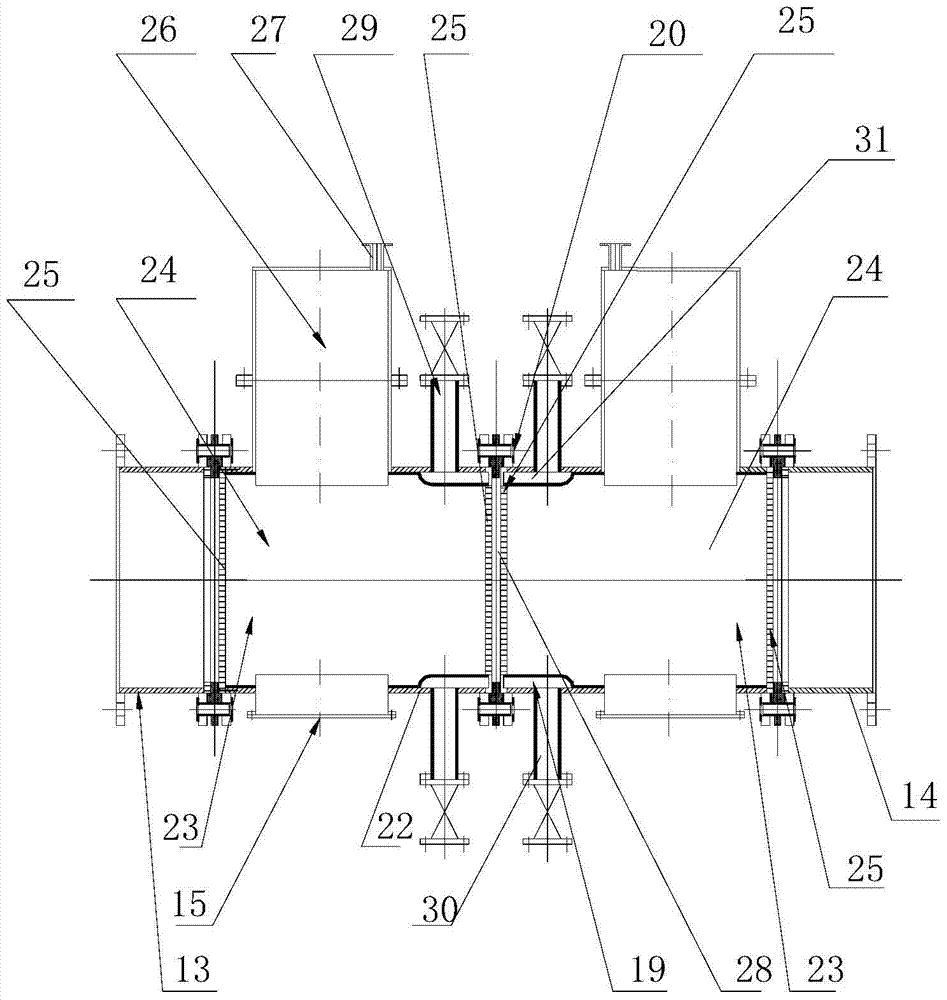

A packed directional flow electrochemical reactor

ActiveCN105420752BWith uniform effectIncreased turbulent forceCellsElectrolytic organic productionElectrochemical responseProcess engineering

The invention discloses a packed directional flow electrochemical reactor, which solves the problems of low reaction conversion efficiency, high energy consumption, complex structure, high operation cost, poor adaptability and the like existing in the existing electrochemical reactor. The technical solution includes a cylinder body, the two ends of the cylinder body are short inlet connection pipes and outlet connection short pipes respectively, and at least one reaction unit is arranged in the cylinder body, and the reaction unit is composed of two electrodes with opposite poles and insulated from each other. The chamber is composed of a cathode chamber and an anode chamber respectively, and the inlet connection short pipe of the cylindrical body communicates with the outlet connection short pipe through the two electrode chambers of the reaction unit in turn. The invention has the advantages of simple structure, low investment cost and operation cost, high conversion efficiency, and is suitable for electrolytes with various properties.

Owner:武汉钢铁有限公司

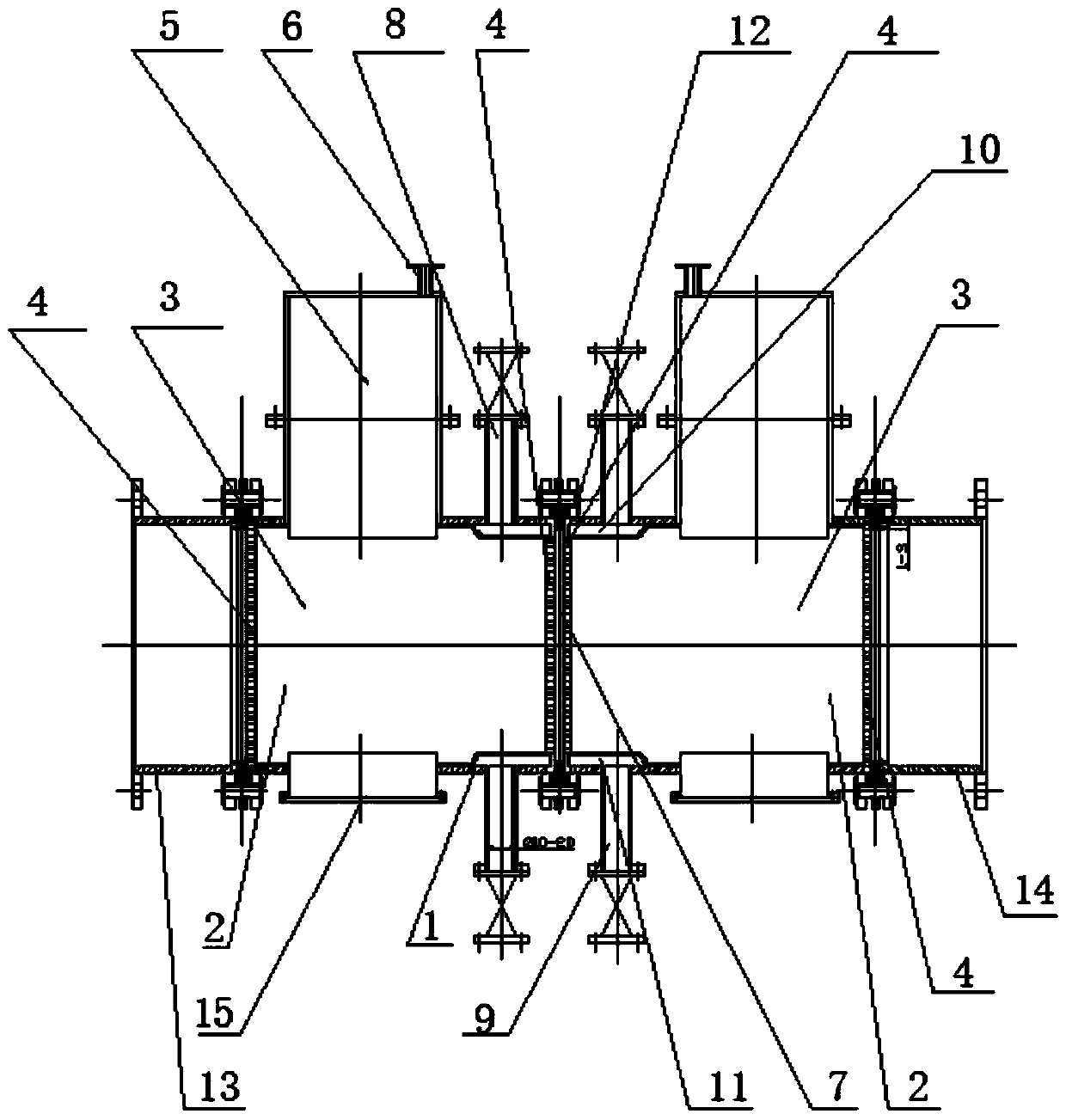

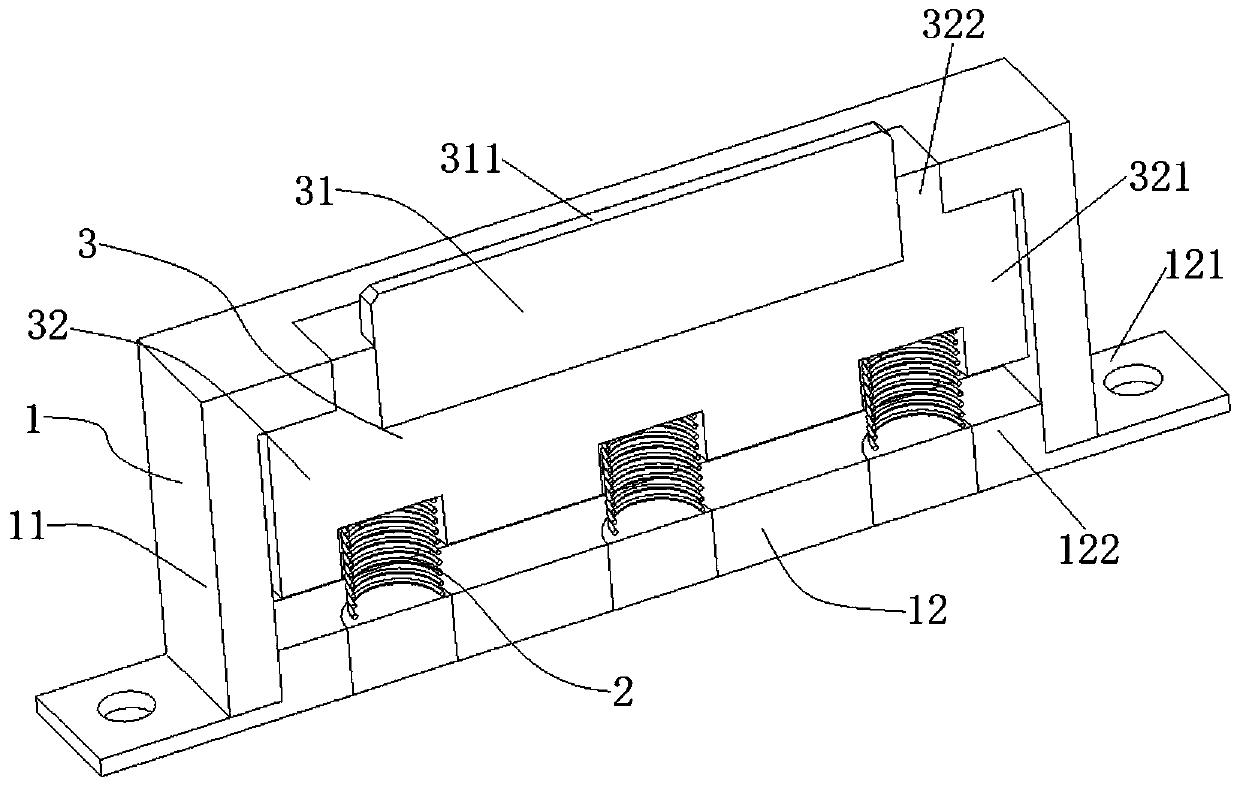

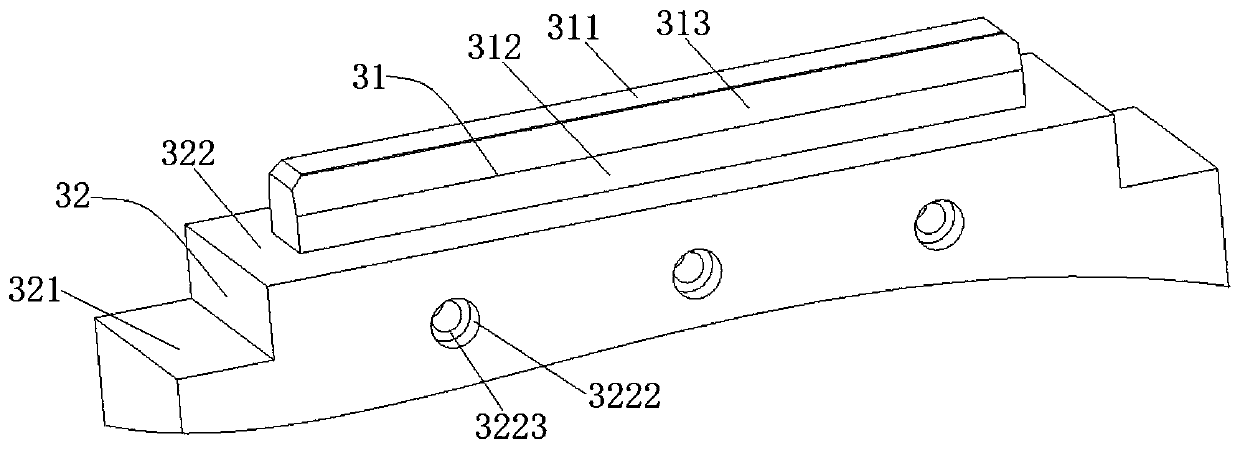

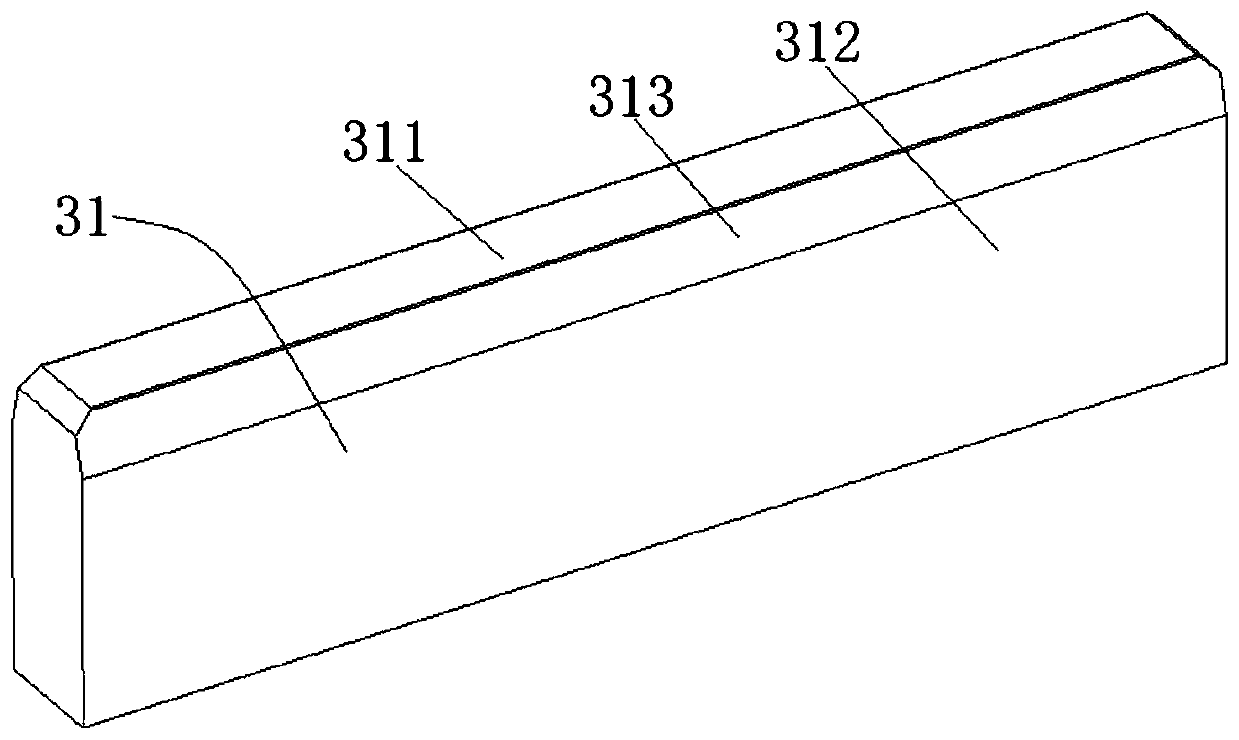

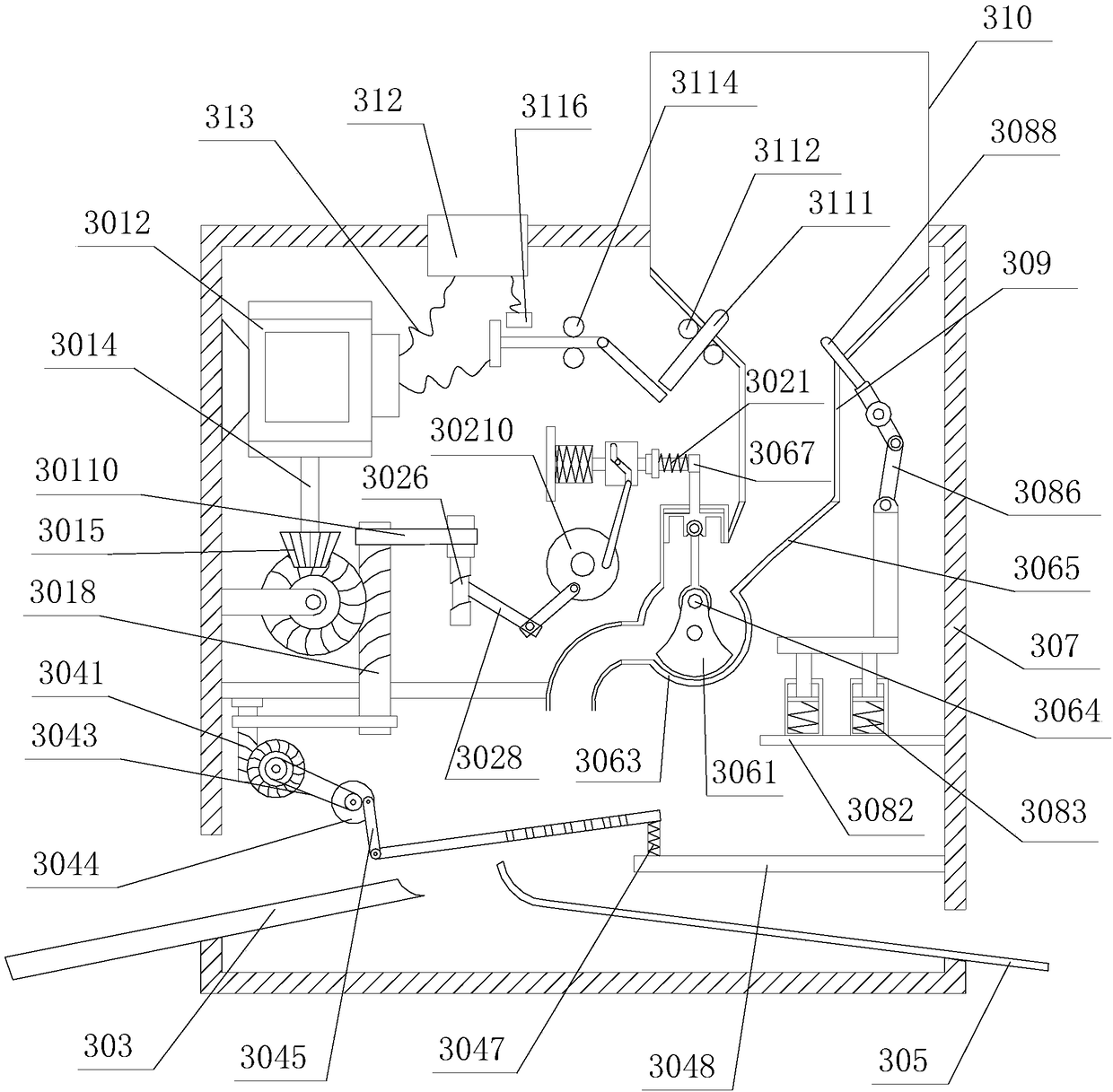

Clearing device, and wind power generator set and yaw system thereof

ActiveCN110206696AImprove stabilityReduced risk of wear and tearWind motor controlMachines/enginesWind forceYaw system

The application provides a clearing device, and a wind power generator set and a yaw system thereof. The clearing device is used for clearing attachments on a first component, and comprises a base seat, at least one pressure applying part and at least one clearing assembly, wherein the at least one clearing assembly is in sliding fit with the base seat, the at least one pressure applying part haselasticity, one end of each pressure applying part is arranged on the base seat, one end of each clearing assembly is butted against or connected with the other end of each corresponding pressure applying part, and the other end of each clearing assembly exceeds the base seat, and used for butting against the first component under elasticity effect of each pressure applying part. The clearing device can timely and effectively remove attachments on a brake disc and / or a friction plate, guarantees that the yaw system in the wind power generator set can stably run in a good state, improves executing stability of yaw maneuver for the wind power generator set, and simultaneously reduces worn risk of the friction plate and the brake disc, and prolongs use life of the frication plate and the brake disc. The clearing device does not need to additionally arrange energy dissipation units, reduces design cost, and improves reliability.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

A directional flow electrolysis process

InactiveCN105274556BWith uniform effectSimple processElectrolysis componentsElectrolytic organic productionHigh energyPhysical chemistry

The invention discloses a directional flow electrolysis process, which solves the problems of low conversion rate of reactants, high energy consumption, poor adaptability and the like existing in the existing electrolysis process. The technical solution includes sending the electrolyte solution into the electrolysis reactor to carry out the electrolysis reaction. The electrolyte solution first enters one of the electrode chambers in the electrolysis reactor, and after completing the electrochemical oxidation or reduction reaction, flows through the gap between the two electrode chambers and then Enter the next electrode chamber with opposite polarity to carry out electrochemical reduction or oxidation reaction, and the reacted electrolyte flows out of the electrolytic reactor. The invention has the advantages of simple process, low investment cost and operation cost, high conversion efficiency, and is suitable for electrolytes with various properties.

Owner:WUHAN UNIV OF SCI & TECH +1

A Cooperative Removal Process of Flue Gas Pollutants Based on Electrolysis

InactiveCN105344215BSimple processing methodImprove controllabilityCombination devicesGas treatmentReaction layerElectrochemical response

The invention discloses a flue gas pollutant cooperation removal technology based on electrolysis. The problems are solved that technologies are complex, the pollutant treatment efficiency is low, investment and operation cost are high in present flue gas treatment. The technology comprises steps: flue gas is pressurized and sent to a concentration tower, a reaction is carried out, the flue gas going out from the concentration tower is sent to an absorbing tower and contacts and reacts with a circulating absorption solution sprayed from a spray layer at the upper part of the tower in a reverse manner, and the flue gas after reaction is discharged from the top of the absorbing tower; part of the concentrate at the tower bottom of the concentration tower is subjected to iron removal, then is sent to a ammonium sulfate crystallization system, the flue gas goes into the absorbing tower from a flue gas inlet at the middle part of the absorbing tower, goes through at least one absorbing and electrochemical reaction layer arranged at the upper part of the tower firstly, then contacts and reacts with a circulating absorption solution in a reverse manner, then goes through a filler layer and a spraying layer, and is discharged from a flue gas outlet. The technology is simple, the reaction efficiency is high, the operation and investment cost are low, the system land occupation area is small, and the technology is especially suitable for cooperation treatment of multiple pollutants of sulfur dioxide, nitrogen oxides, fine particles, dioxin and the like.

Owner:WUHAN WUTUO TECH +1

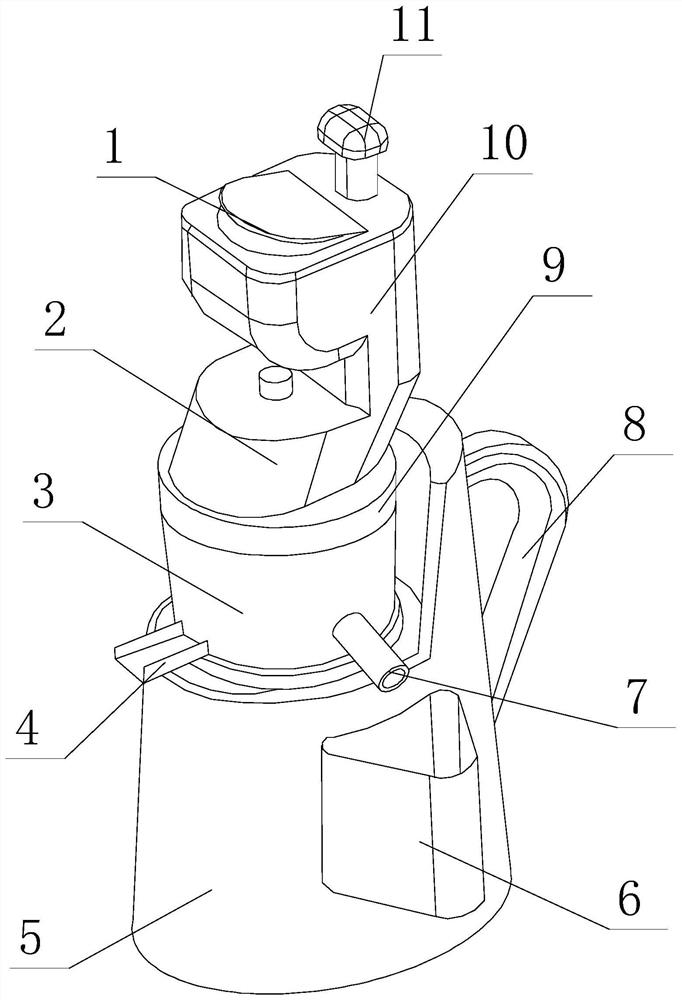

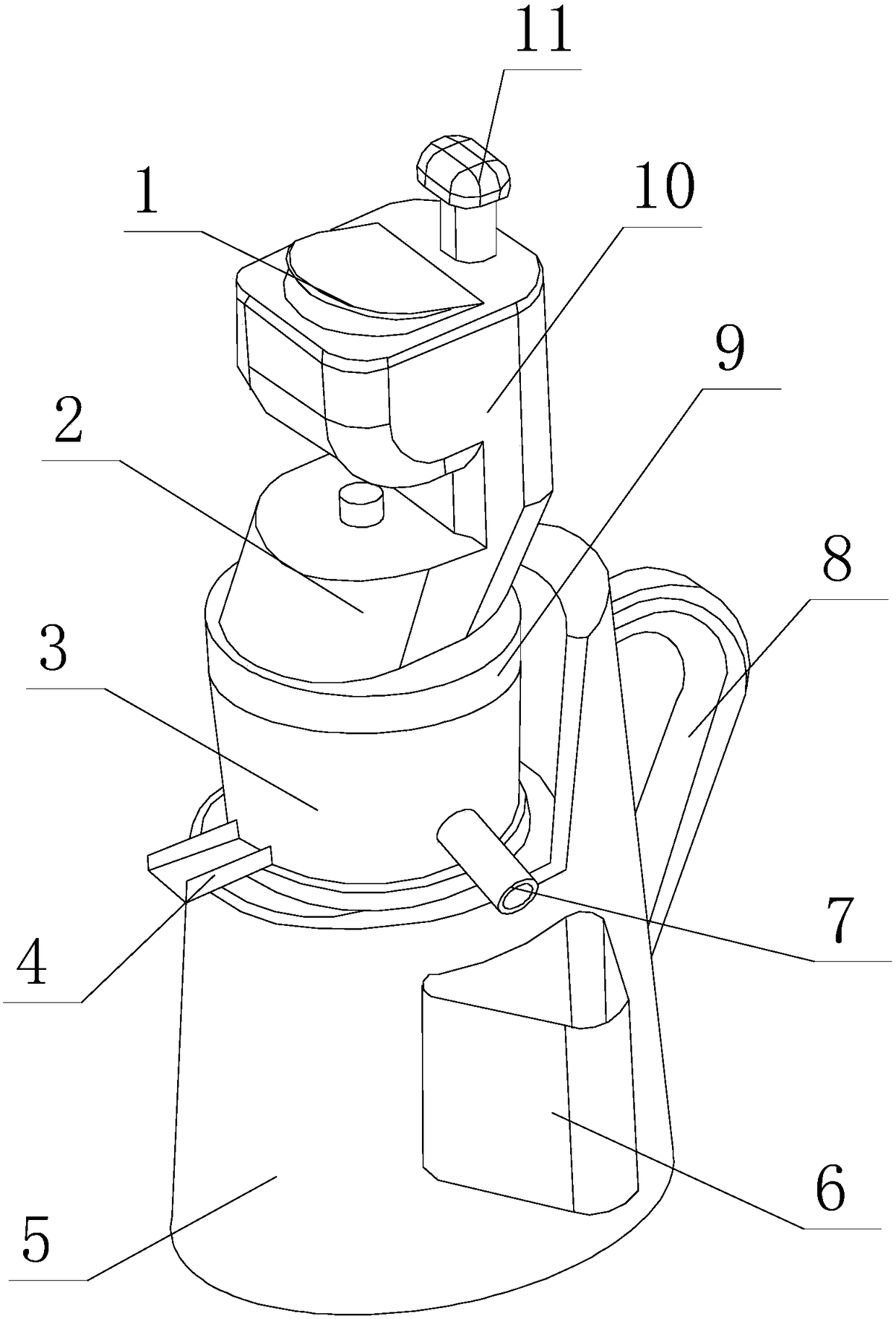

A new high-efficiency fruit juicer

The invention discloses a novel efficient fruit juicing device which structurally comprises a feeding cover hole, a connection protective outer frame, a juicing separation device, a pollution discharge platform, a supporting buffer base, a placement cup groove, a juice outlet pipe orifice, a safety handle grip, an isolation buffer layer, a fruit placement bottle and a safety pressure grip; the front side of the outer surface of the supporting buffer base is welded to the back end of the placement cup groove; the upper end of the supporting buffer base is installed at the lower end of the juicing separation device; and the lower side of the front end of the juicing separation device is mechanically connected to the back end of the juice outlet pipe orifice. The novel efficient fruit juicingdevice has the beneficial effects that by adding the juicing separation device on the equipment, when the equipment performs fruit juicing operation, fruit dregs and residues in a fruit juice can betimely and effectively eliminated, so that the efficiency of the novel efficient fruit juicing device in juicing the fruit juice is improved, the workload of a worker is lightened, the working efficiency of the equipment is greatly improved, and the novel efficient fruit juicing device is more practical.

Owner:江苏速冰洋饮料有限公司

A smoke-free ultrasonic knife

The invention discloses a smog-free ultrasound knife. The smog-free ultrasound knife comprises a control device, a suction device, a housing and an ultrasonic knife body. The control device comprises a switch, a power unit and a transmission unit, the power unit is connected with the transmission unit, the switch is electrically connected with the power unit and a negative pressure generator, the suction device comprises the negative pressure generator and a suction part, the negative pressure generator is electrically connected with the control device, the suction device coincides with the axis of the knife bar of the ultrasonic knife body, the inner diameter of the pipe of the suction device is larger than the largest diameter of the outer pipe of the ultrasonic knife body, the suction device is communicated with the negative pressure generator in a sealing manner, one end of the suction device is in transmission connection with the transmission unit to form the seal, the other end of the suction device is in transmission connection with the housing to form the seal, and the suction device is arranged in the housing. During the cutting process of the ultrasonic knife body, the suction device can play a role in cleaning the operation visual field, and the safety and fluency of operations can be improved.

Owner:郜永顺

A Simultaneous Desulfurization and Denitrification Process Based on Electrolytic Regeneration for Iron Removal in Flue Gas and Ammonia

ActiveCN105251330BWith uniform effectWith updateDispersed particle separationAmmonium sulfatesElectrolysisAbsorption column

The invention discloses a flue gas ammonia synchronous desulfurization and denitrification process based on electrolytic regeneration to remove iron, which solves the problem of low regeneration efficiency of absorption liquid in the existing desulfurization and denitrification process. The technical scheme includes that after the flue gas is pressurized, it is sent to the concentration tower to contact and react with the concentrated liquid in the tower. After iron removal by the first electrolytic reactor, it is sent to the ammonium sulfate crystallization system. The absorbed liquid after partial reaction at the bottom of the absorption tower is regenerated and returned to the upper part of the absorption tower as a circulating absorption liquid. The concentrated liquid first enters the first electrolytic reactor The anode chamber in the reaction unit undergoes an oxidation reaction, and then enters the cathode chamber to undergo a reduction reaction; the reacted electrolyte is discharged from the short outlet pipe of the reactor and sent to the ammonium sulfate crystallization system. The invention has the advantages of simple method, low investment cost and operation cost, high conversion efficiency, good iron removal effect, and good desulfurization and denitrification effect.

Owner:武汉武钢绿色城市技术发展有限公司

Preparation method for hydroxyethyl dual fatty acid amide

ActiveCN102746180BGood colorLow melting pointOrganic compound preparationCarboxylic acid amides preparationEthylenediamineO-Phosphoric Acid

The invention discloses a preparation method for hydroxyethyl dual fatty acid amide. The method specifically includes steps: (1) salification reaction: reacting hydroxy higher fatty acid with hydroxyethyl ethylenediamine under the protection of nitrogen, heating a complex antioxidant of sodium bisulfite and sodium borohydride and a complex catalyst of phosphoric acid, magnesium sulfate and calcium sulfate for salification reaction; (2) dehydration reaction: increasing temperature for continuing reaction after adding hydroxyethyl ethylenediamine for reaction; and (3) enabling the temperature of materials to be decreased to 80 DEG C to 100 DEG C, the amine value to be less than or equal to 5 mgKOH / g and the acid value to be less than or equal to 10 mgKOH / g for discharging to obtain the hydroxyethyl dual fatty acid amide. The sodium bisulfite and the sodium borohydride are taken as the complex antioxidant during the reaction process and the process conditions are adopted, so that products are colory and have low melting point.

Owner:常州可赛成功塑胶材料有限公司

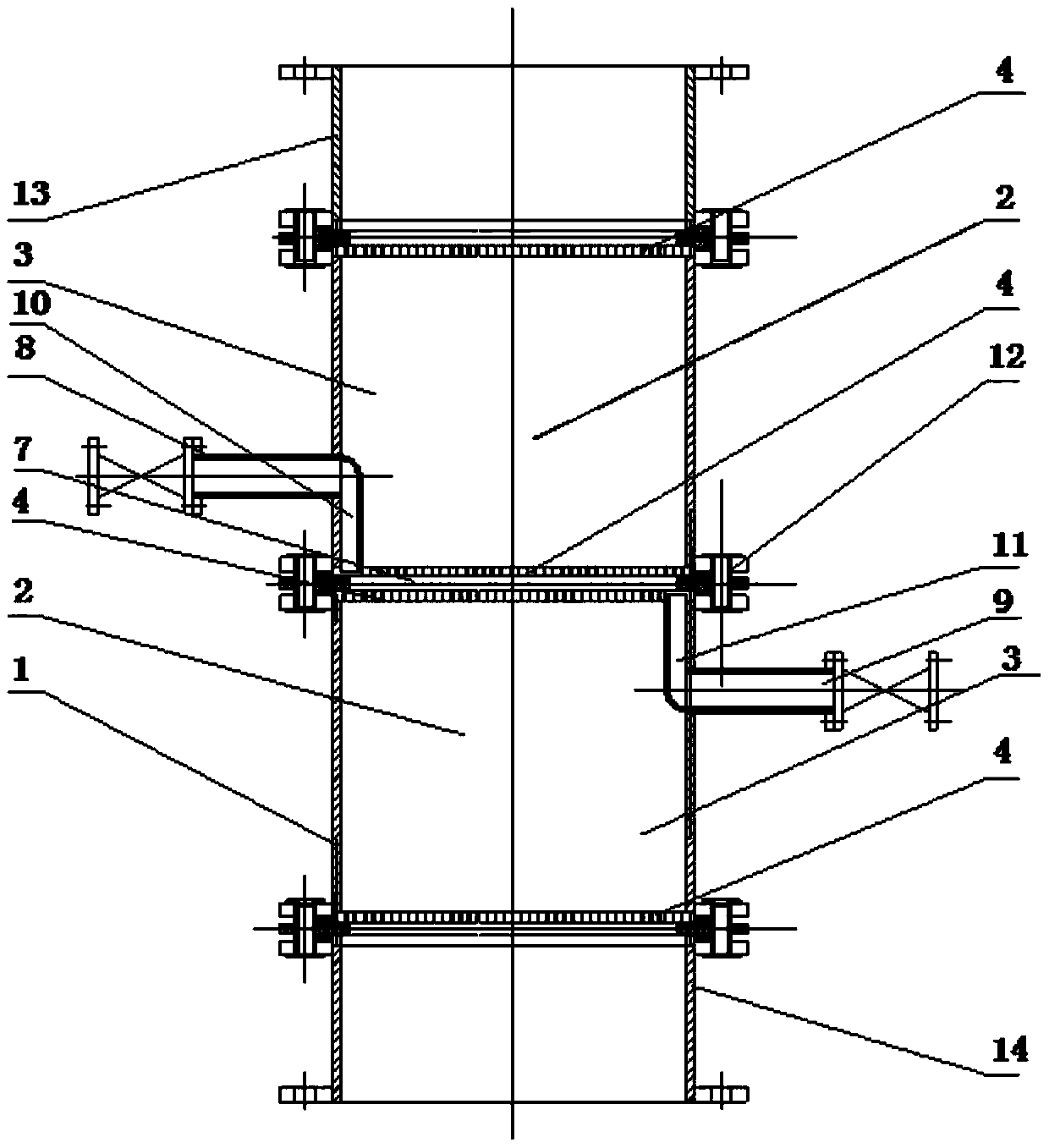

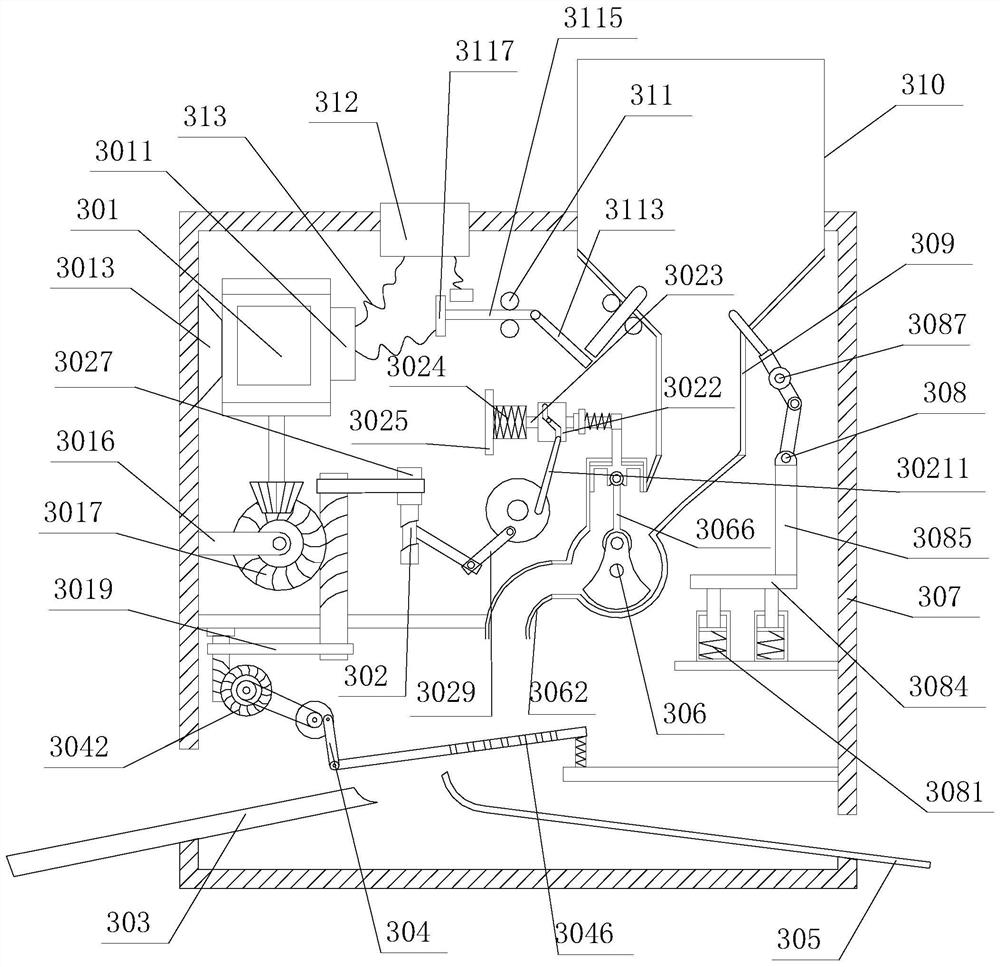

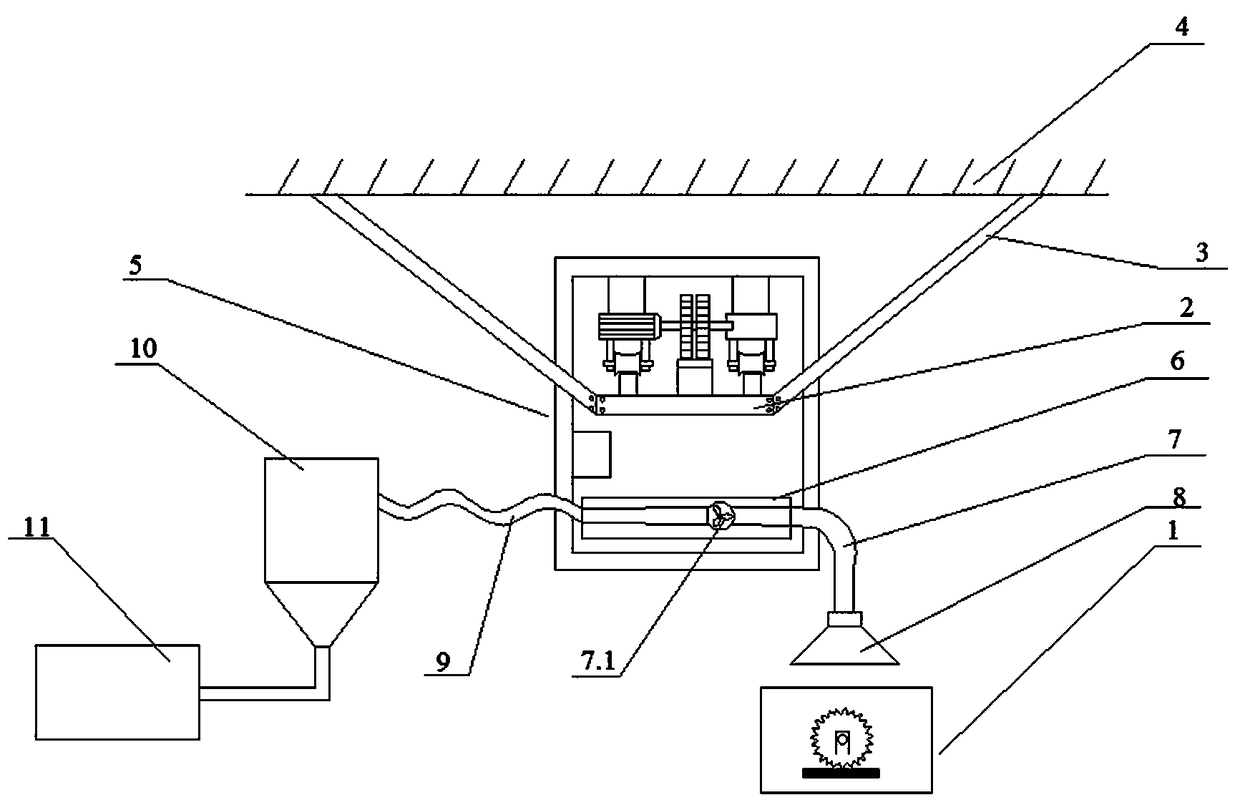

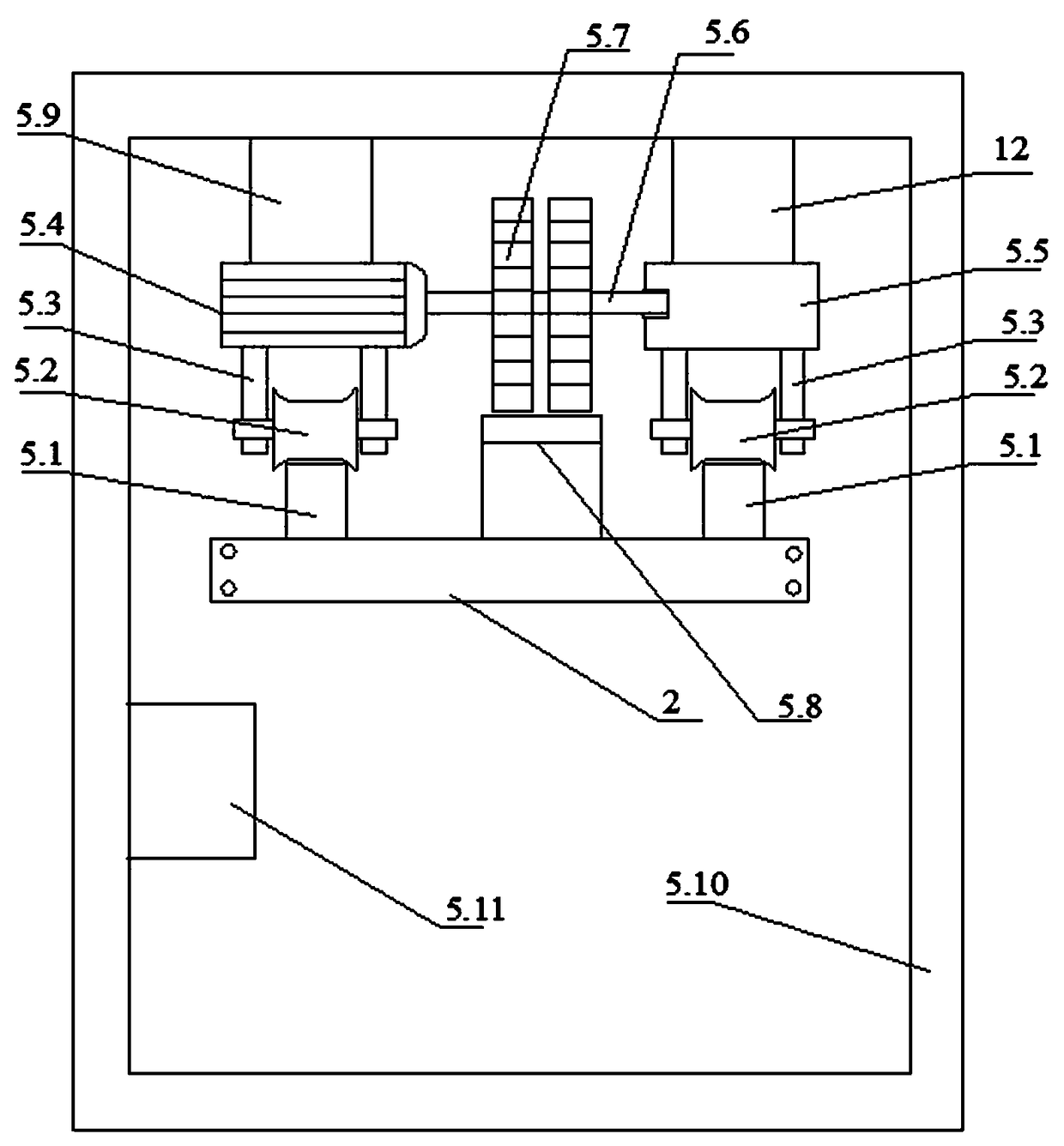

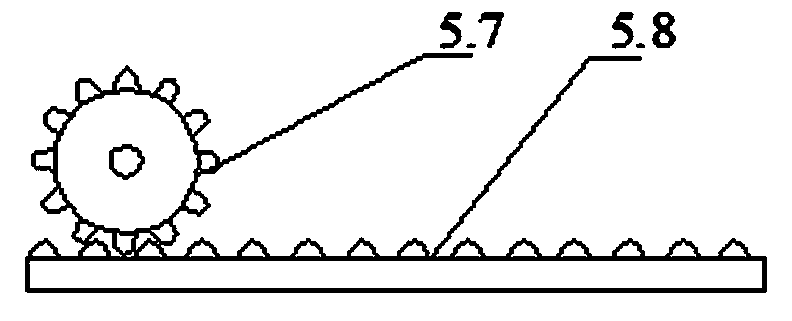

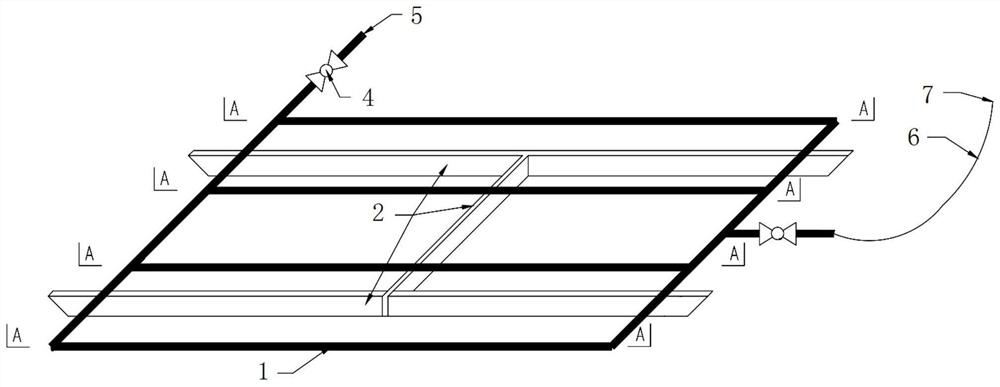

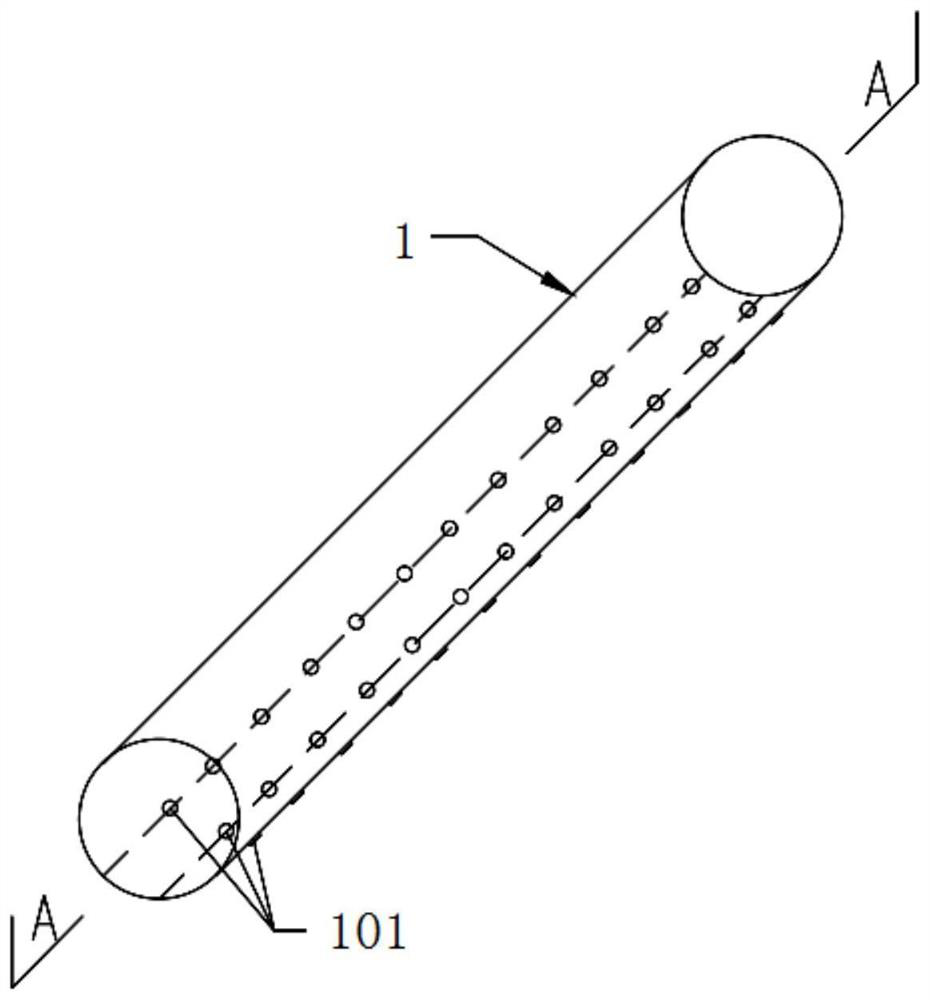

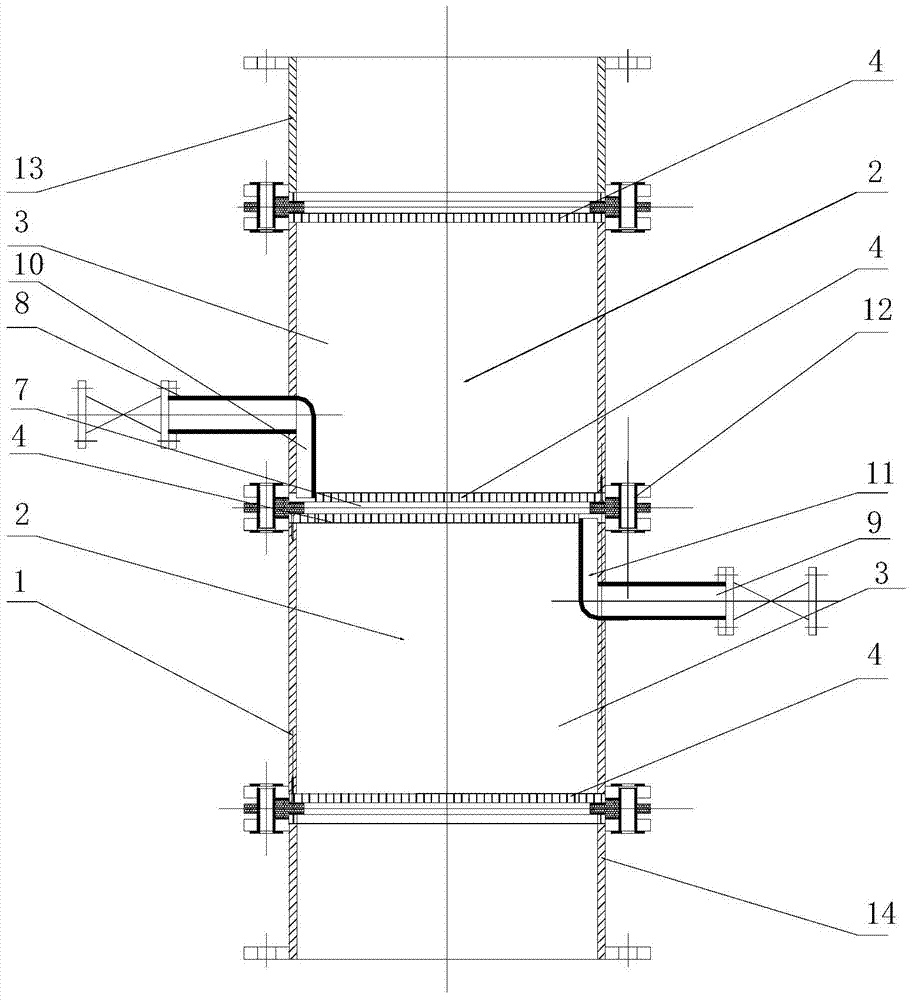

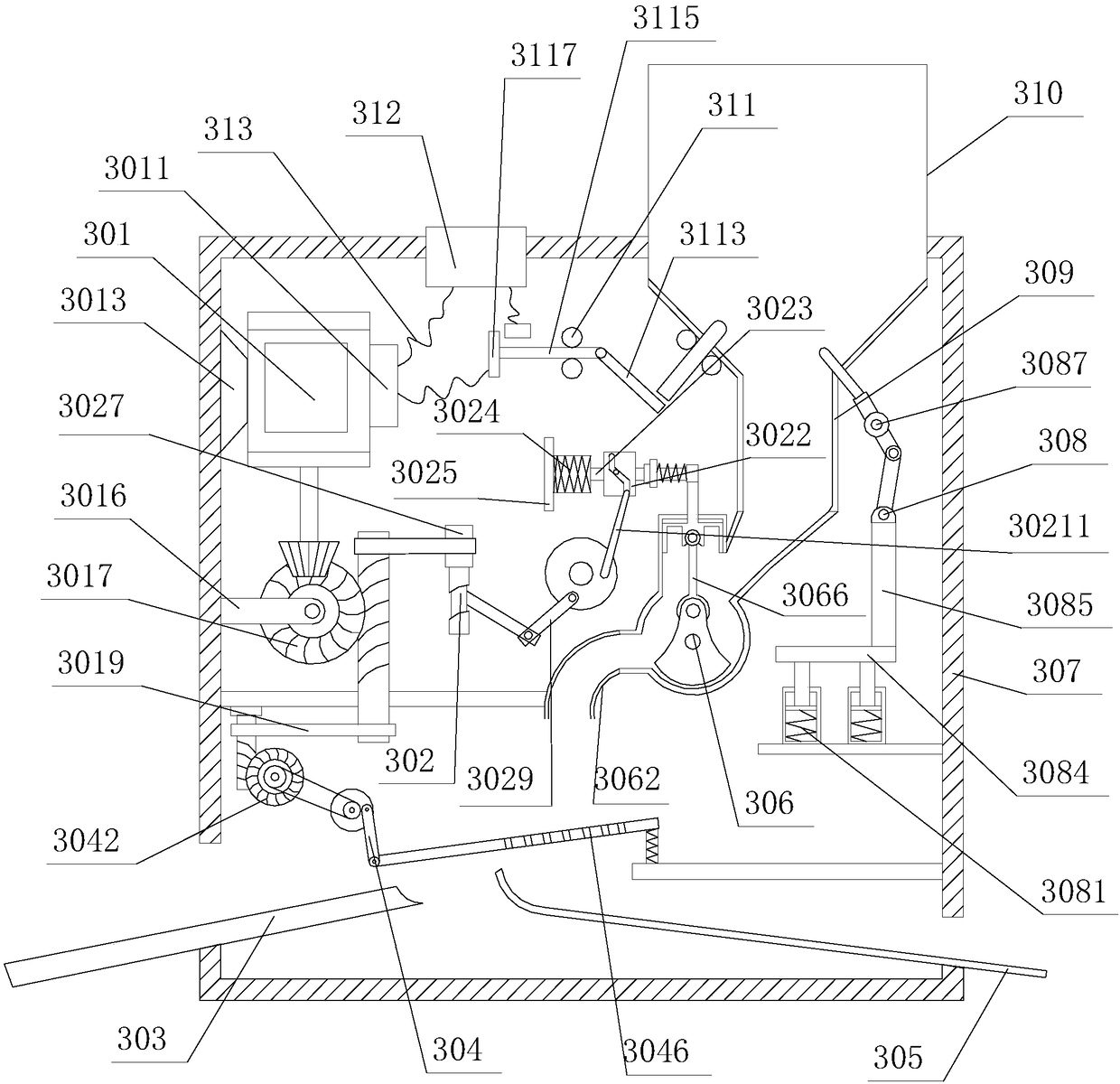

Dedusting system used in fiberboard production process

InactiveCN109421118ASafeguard the production environment and the health of workersTimely and effective removalBark-zones/chip/dust/waste removalWorker healthEngineering

The invention discloses a dedusting system used in the fiberboard production process. The dedusting system comprises a supporting board which is horizontally arranged above a fiberboard cutting machine and is rectangular, the four corners of the supporting board are fixed to a floor through four supporting rods correspondingly, and the supporting board and the floor are parallel to each other; a moving mechanism capable of moving horizontally is arranged on the supporting board and provided with a shell, and an air pumping pipeline is arranged in the shell; one end of the air pumping pipelineis connected with a suction hood, and the other end of the air pumping pipeline is connected with one end of a retractable flexible pipe; and the other end of the retractable flexible pipe is connected with a deduster air inlet, the suction hood faces the top of the fiberboard cutting machine, and an air pump is arranged in the air pumping pipeline. Dust generated in the fiberboard production process can be effectively cleared, and the plant production environment and worker health can be guaranteed.

Owner:宜昌洪亚科技有限公司

Surface microporous SiC ceramic material and preparation method thereof

ActiveCN102030532BIncrease chance of connectionEvenly distributedCeramicwareCarboxymethyl celluloseMethyl cellulose

The invention discloses a surface microporous SiC ceramic material, which consists of main raw materials, polycarbosilane and carboxymethyl cellulose, wherein the main raw materials consist of the following components in percentage by weight: 85 to 90 percent of silicon carbide powder and 10 to 15 percent of yttrium aluminum garnet; the polycarbosilane is 5 to 10 percent of the total weight of the main raw materials; and the carboxymethyl cellulose is 2 to 8 percent of the total weight of the main raw materials. Meanwhile, the invention discloses a method for preparing the surface microporousSiC ceramic material, which comprises the following steps of: uniformly mixing the silicon carbide powder, the yttrium aluminum garnet and the polycarbosilane, and adding aqueous solution of the carboxymethyl cellulose and performing ball-milling mixing; drying the obtained size; and molding the obtained powder and performing vacuum sintering at high temperature so as to prepare the surface microporous SiC ceramic material. The surface microporous SiC ceramic material keeps high strength, high hardness, abrasion resistance, corrosion resistance and oxidation resistance, the self-lubricating property of the material is improved, and a cross section can be prevented from being bonded. Therefore, the service life of the material is prolonged.

Owner:ZHEJIANG UNIV

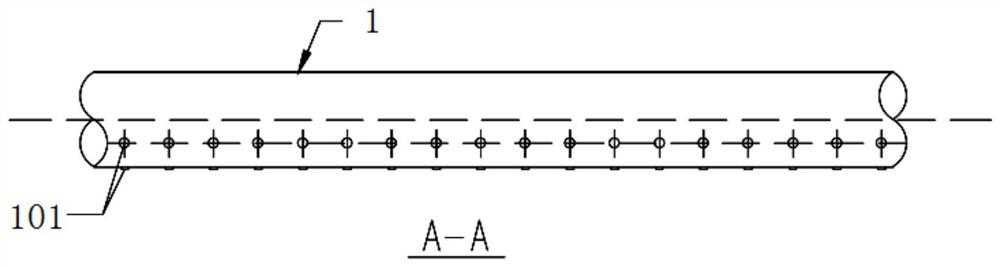

Direct cooling type circulating water drainage open channel defoaming device

PendingCN112456595AEfficient removalTimely and effective removalWater/sewage treatment by degassingNon-contaminated water treatmentWater flowEnvironmental engineering

The invention discloses a direct cooling type circulating water drainage open channel defoaming device which comprises a water spraying pipeline and a supporting plate, the water spraying pipeline isarranged on the supporting plate, small water spraying holes with set angles are evenly distributed in the lower side of the center line of the water spraying pipeline, and small columnar water flow can be generated and sprayed to the water surface. Original foam can be effectively removed, and new foam cannot be generated; and the supporting plate floats on the water surface and can intercept foam on the water surface, so that the foam on the water surface close to the wood plate can be timely and effectively removed under the water spraying condition. The direct cooling type circulating water drainage open channel defoaming device is simple in structure, low in manufacturing cost, economical, practical, free of personnel on duty, capable of effectively removing foam on the water surfaceand capable of reducing negative effects on the environment and ecology, and only whether abnormity exists or not is inspected, and operation is not needed.

Owner:CHINA CHENGDA ENG

A flue gas ammonia desulfurization and denitrification process with complexation absorption and synchronous electrolysis regeneration

ActiveCN105413422BEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationElectrolysisAmmonium sulfate

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

Novel efficient fruit juicing device

The invention discloses a novel efficient fruit juicing device which structurally comprises a feeding cover hole, a connection protective outer frame, a juicing separation device, a pollution discharge platform, a supporting buffer base, a placement cup groove, a juice outlet pipe orifice, a safety handle grip, an isolation buffer layer, a fruit placement bottle and a safety pressure grip; the front side of the outer surface of the supporting buffer base is welded to the back end of the placement cup groove; the upper end of the supporting buffer base is installed at the lower end of the juicing separation device; and the lower side of the front end of the juicing separation device is mechanically connected to the back end of the juice outlet pipe orifice. The novel efficient fruit juicingdevice has the beneficial effects that by adding the juicing separation device on the equipment, when the equipment performs fruit juicing operation, fruit dregs and residues in a fruit juice can betimely and effectively eliminated, so that the efficiency of the novel efficient fruit juicing device in juicing the fruit juice is improved, the workload of a worker is lightened, the working efficiency of the equipment is greatly improved, and the novel efficient fruit juicing device is more practical.

Owner:江苏速冰洋饮料有限公司

Slurry bed reaction system and method for Fischer-Tropsch synthesis reaction

ActiveCN108067167BImprove heat transfer efficiencyHigh yieldLiquid hydrocarbon mixture productionChemical/physical processesPtru catalystProcess engineering

The invention relates to the field of Fischer-Tropsch synthesis, and particularly provides a slurry bed reaction system and a method. The slurry bed reaction system comprises a slurry bed reactor, aninternal heat exchange unit and an external heat exchange unit, wherein the external heat exchange unit comprises a steam drum and a heater, the steam drum and the heater are sequentially connected inseries, the heater is communicated to the lower-portion water inlet of the internal heat exchange unit, the steam drum is communicated to the upper-portion water outlet of the internal heat exchangeunit, the internal heat exchange unit comprises heat exchange pipes, and baffles are arranged inside the part of or all of the heat exchange pipes, and are used for prolonging the residence time of aheat exchange medium in the internal heat exchange unit. With system of the present invention, the heat exchange efficiency of the heat exchange unit in the reactor can be improved, the uniform and stable temperature inside the slurry bed reactor can be ensured, and the excess heat caused by the temperature runaway can be effectively removed when the catalyst is subjected to local temperature runaway so as to ensure the yield of the target product and improve the operation safety of the device.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com