A directional flow electrolysis process

A directional flow and process technology, applied in the field of electrolysis process, can solve the problems of inability to effectively remove electrochemical reaction products in time, complex structure of the electrolysis device, slow electrochemical reaction speed, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

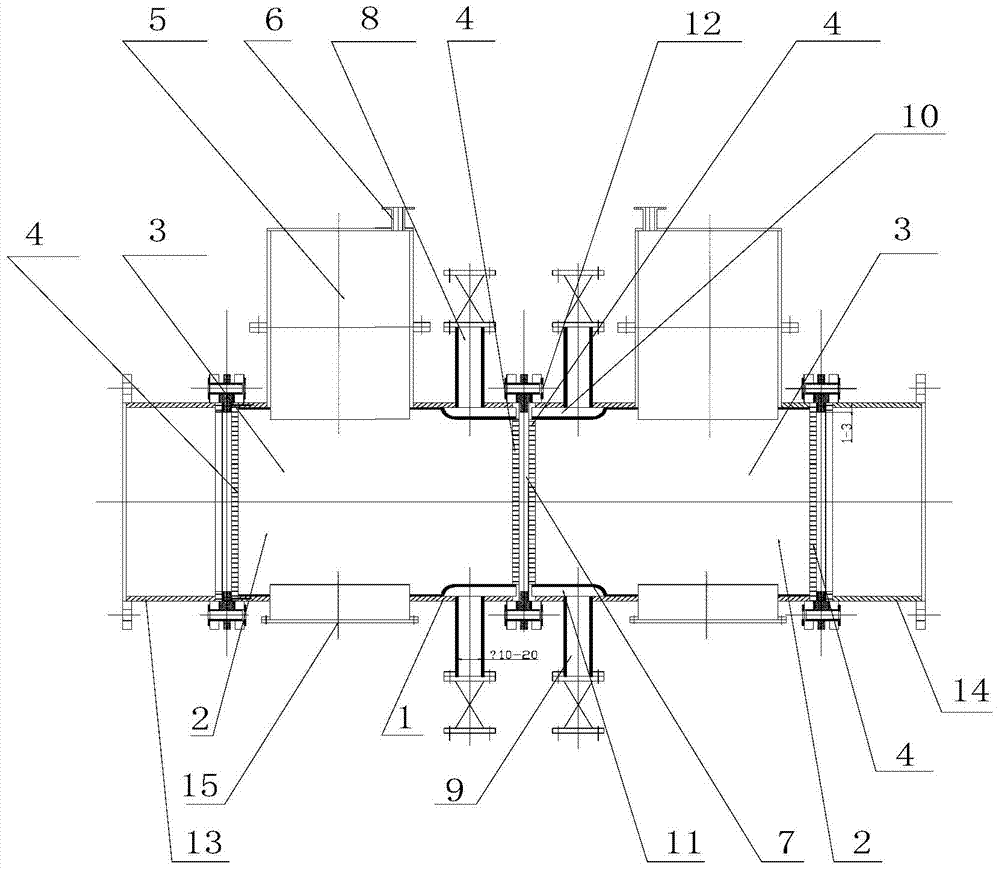

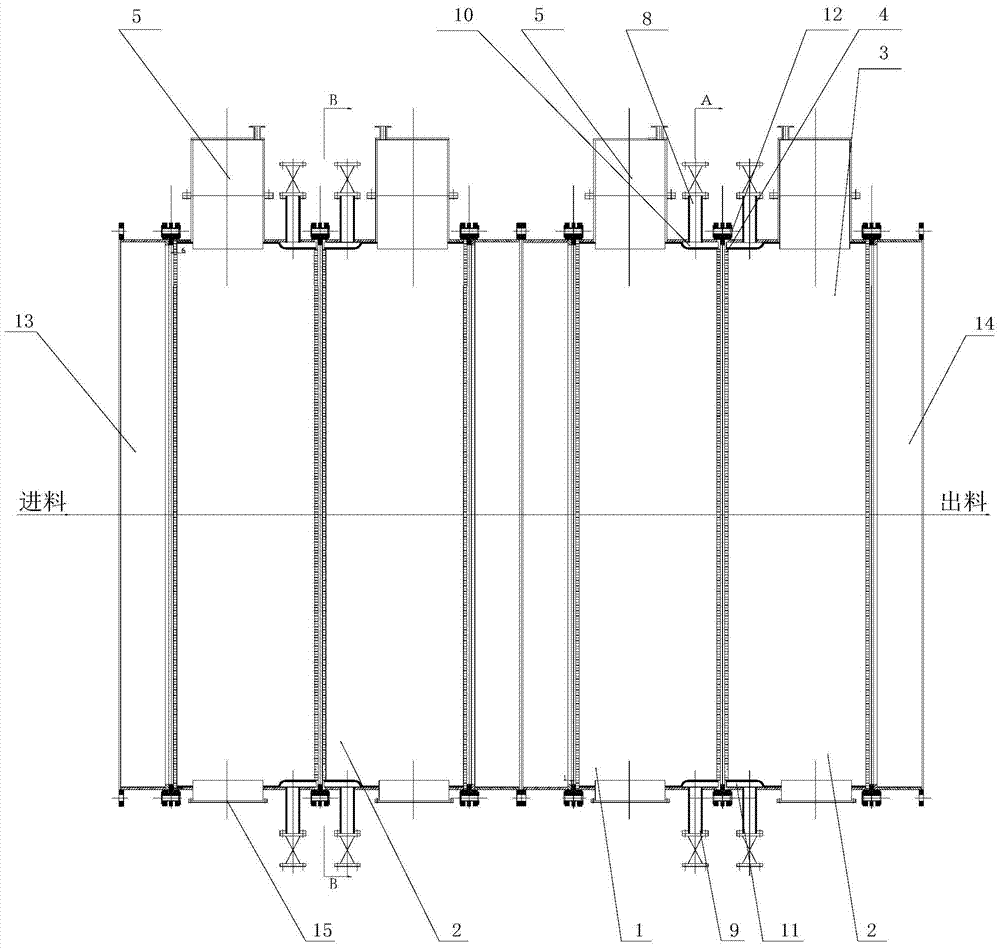

[0048] see figure 2 , the reactor in this embodiment is horizontal, one end of the cylinder 1 is provided with an inlet connection short pipe 13, and the other end is provided with an outlet connection short pipe 14, and a reaction unit is arranged in the cylinder body, which consists of two mutually insulated electrode chambers 2 It consists of a cathode chamber and an anode chamber respectively. The electrode chamber 2 is composed of the area surrounded by the porous plate electrodes 4 at both ends and the corresponding cylinder 1. The electrode chamber 2 is filled with a conductive electrode material 3. The electrode material 3 filled in the electrode chamber is granular activated carbon, coal coke, petroleum coke or corrosion-resistant metal shavings or metal pellets modified by noble metal salts, with a particle size of 8-20mm (the particle size of the electrode material should be larger than that of the porous plate electrode aperture). Both ends of the electrode chamb...

Embodiment 2

[0057] see Figure 5 , the electrode chamber 2 is made up of a mesh structure 16 made of conductive material, the conductive material can be made of lead, platinum, titanium, graphite and other materials with good conductivity and strong corrosion resistance, and its porosity is controlled at 0.7-0.9. There is no porous plate electrode 4 and the filled electrode material 3, and the rest of the structure is the same as in Example 1. The electrolyte is the concentrated solution of the concentration tower in the flue gas wet ammonia-complex absorption synchronous desulfurization and denitrification system.

[0058] work process:

[0059] The physical parameters and related composition of the concentrated liquid from the concentration tower in the flue gas wet ammonia-complex absorption synchronous desulfurization and denitrification system are as follows:

[0060] pH value: 4.0~5.0;

[0061] Ammonium sulfate concentration: 30-45%;

[0062] EDTA-Fe(Ⅱ)+EDTA-Fe(Ⅲ)concentration: ...

Embodiment 3

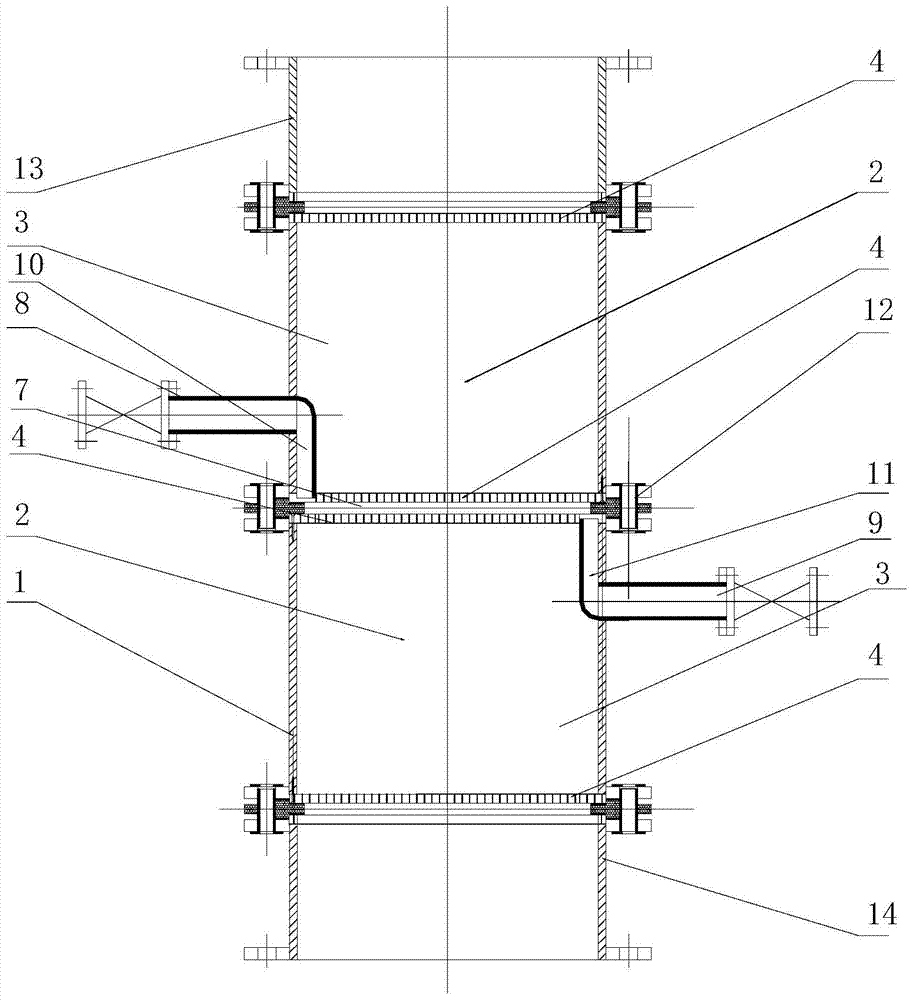

[0084] see figure 1 , the reactor in this embodiment is vertical, and its basic structure is the same as that of the horizontal type in Example 1. The upper layer is the cathode chamber, and the lower layer is the anode chamber. Export 15, all the other are with embodiment 1.

[0085] crafting process:

[0086] The source of the electrolyte is the same as in Example 1, and the reaction process is the same as in Example 1. The electrolyte enters the reactor from the inlet connection short pipe 13 at the bottom of the reactor, flows directionally from bottom to top, and passes through the anode chamber and the cathode chamber successively from the top of the reactor. Outlet connects short pipe 14 to flow out, and all the other are with embodiment 1. Iron removal efficiency is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com