Smog-free ultrasound knife

An ultrasonic knife and smoke technology, applied in the field of medical devices, can solve the problems of unfavorable surgical safety and efficiency, poor use effect, inconvenient use, etc., to improve surgical safety and fluency, avoid frequent replacement, and improve safety. Effects of Sex and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

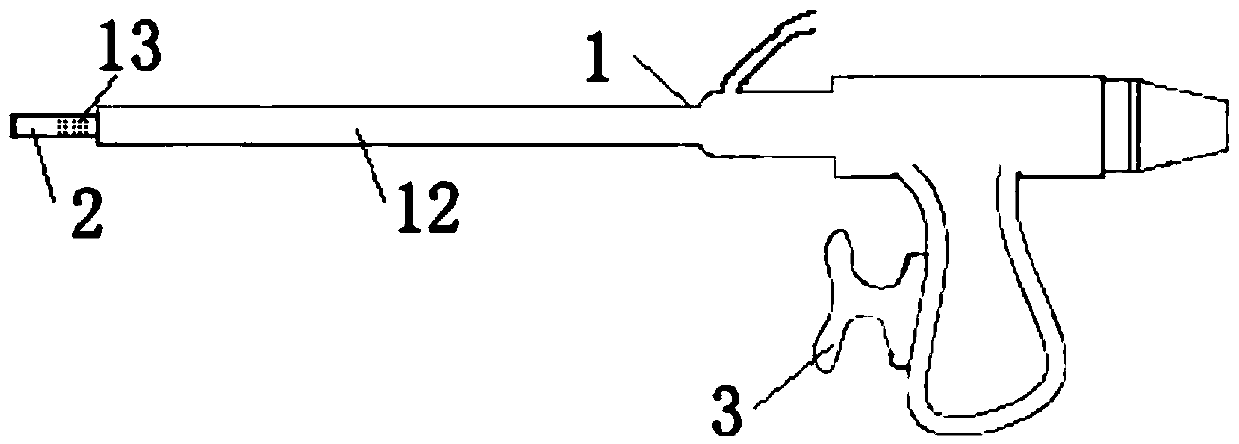

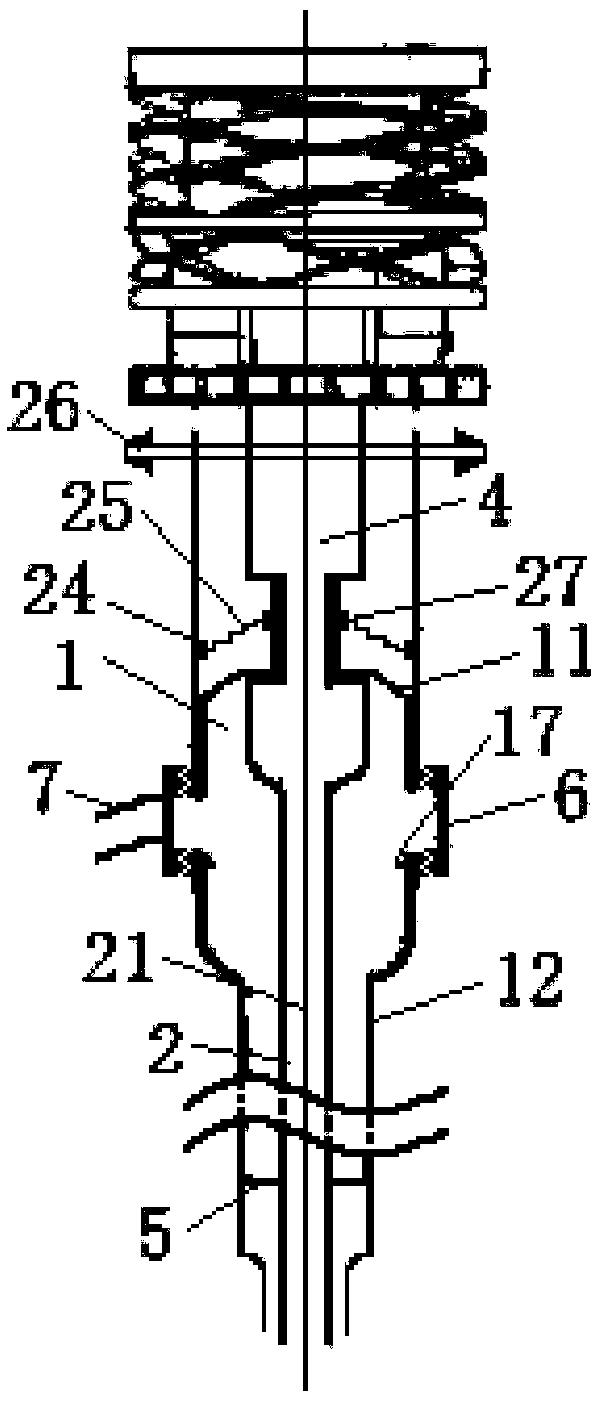

[0040] Such as Figure 1 to 3 As shown, a smoke-free ultrasonic knife includes a control device, a suction device 1 and an ultrasonic knife 2. The control device includes a switch 3, a power device, and a transmission device 4. The power device is connected to the transmission device 4, so The switch 3 is electrically connected to the power device and the negative pressure generator. The suction device 1 includes a negative pressure generator and a suction component 11. The negative pressure generator is electrically connected to the control device. The suction component 11 coincides with the shaft center of the ultrasonic knife 2, the inner diameter of the tube of the suction component 11 is greater than the maximum diameter of the outer tube of the ultrasonic knife 2, and the suction component 11 is in sealed communication with the negative pressure generator; One end of the suction component 11 is in transmission connection with the transmission device 4 and forms a seal, and...

Embodiment 2

[0050] Smoke-free ultrasonic knife as described above, such as Figure 5 As shown in the schematic structural diagram of the cross section of the suction part and the housing of the smoke-free ultrasonic knife provided by the present invention, the suction part 11 is provided with a first protrusion 16 at one end close to the housing 12, and the housing 12 is close to the housing 12. A second protrusion 19 is provided inside one end of the attracting member 11. When the attracting member 11 and the housing 12 are close to each other, the first protrusion 16 and the second protrusion 19 form a transmission connection, and A sealing member 14 is provided at the contact between the attracting member 11 and the housing 12. The transmission connection here is specifically a gear transmission connection. The first protrusion 16 and the second protrusion 19 are complementary nested, and when the attraction member 11 rotates, the housing 12 is driven to rotate synchronously. The sealin...

Embodiment 3

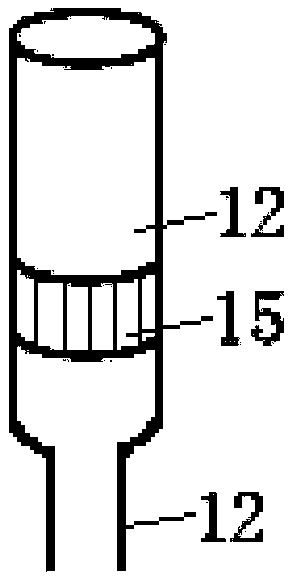

[0052] Such as Figure 3 to 7 As shown, a tubular sealed connection device 6 is provided between the housing 12 and the negative pressure generator, the housing 12 is provided with a fence-shaped second communication member 15, and the sealed connection device 6 is provided on the first Outside the two communicating parts 15, the inner wall of the sealing connection device 6 is provided with a soft material, and the inner diameter of the sealing connection device 6 is equal to the outer wall diameter of the housing 12. The soft material is preferably rubber. The second connecting member 15 is a fence-shaped gap and is arranged on the housing 12. The sealed connection device 6 includes a first member 61 and a second member 62, and the first member 61 and the second member 62 pass through The detachable fixed connection forms the sealed connection device 6, the sealed connection device 6 completely covers the second communication member 15, so that the entire suction device 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com