Device and process for preparation of melamine formaldehyde foam

A technology of melamine formaldehyde and melamine, which is used in household components, household appliances, other household appliances, etc., can solve the problems of large reaction heat, difficult to realize industrialized continuous reaction, and high viscosity of melamine formaldehyde reaction system, and can control the reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

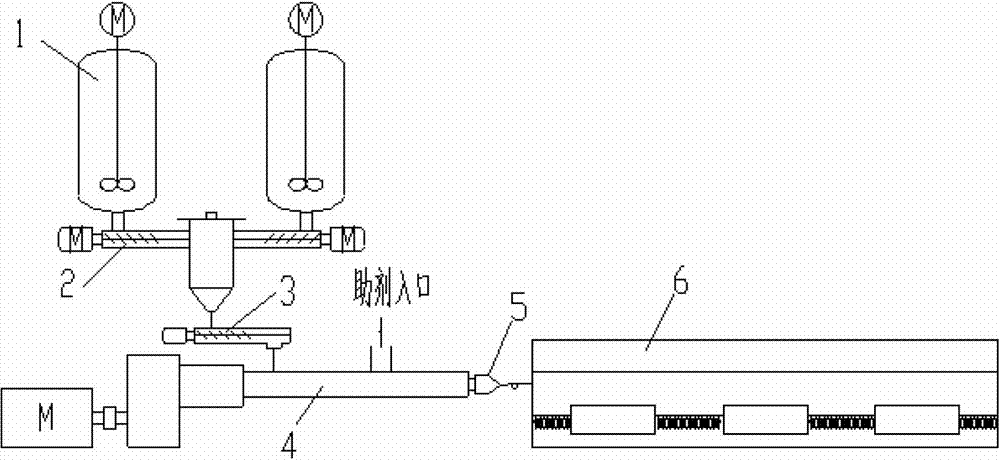

[0017] like figure 1 The shown device for preparing melamine formaldehyde foam includes two melamine reaction kettles 1, a single-screw extruder 2, a metering feeder 3, a reactive twin-screw extruder 4, a sheet head 5, a microwave generator Bubble device 6, melamine reactor 1 effective volume 1 m 3 ; single screw extruder 2 screw diameter 120mm; melamine reaction kettle (2 units) 1 connected in parallel with single screw extruder 2, and connected with metering feeder 3 through a hopper, the screw diameter of metering feeder 3 is 65 mm; the metering feeder 3 is connected to the reactive twin-screw extruder 4 with the motor, gear box, frame and body as a whole. Reaction type twin-screw extruder 4 has a screw diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com