Slurry bed reaction system and method for Fischer-Tropsch synthesis reaction

A reaction system, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, chemical/physical processes, etc., can solve problems such as increased proportion, test failure, complex manufacturing, etc., to improve heat exchange efficiency , improve safety and ensure the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

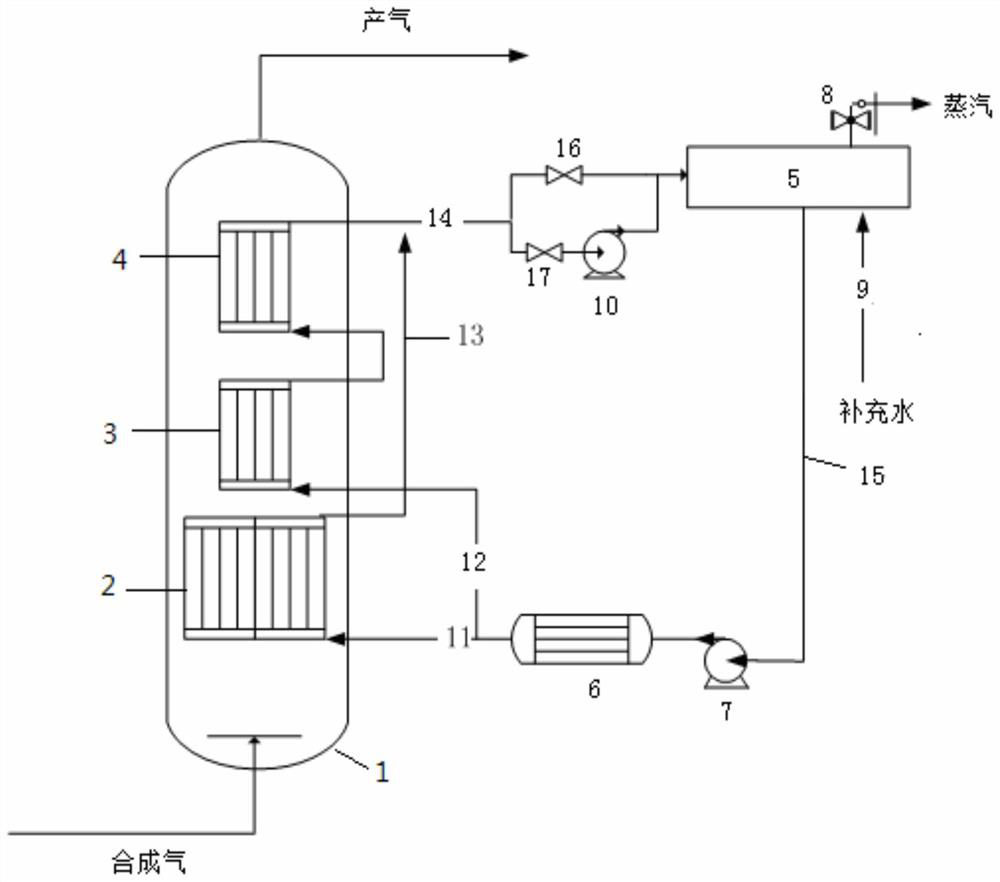

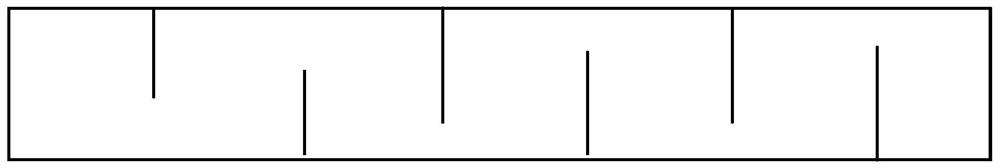

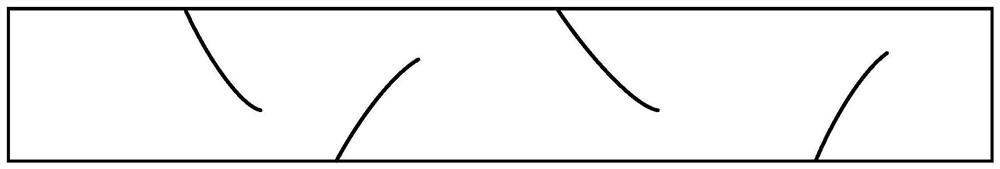

[0039] According to a preferred embodiment of the present invention, 20-70% of the heat exchange tubes of the internal heat exchange unit are provided with baffles.

[0040] According to a preferred embodiment of the present invention, the internal heat exchange unit includes a lower heat exchange unit 2, a middle heat exchange unit 3 and an upper heat exchange unit 4 arranged inside the slurry bed reactor 1;

[0041] The lower heat exchange unit 2, the middle heat exchange unit 3 and the upper heat exchange unit 4 each include a plurality of parallel heat exchange tubes, and part or all of the lower heat exchange unit 2 and the middle heat exchange unit 3 Baffles are respectively arranged in the heat exchange tubes, and the baffles are used to prolong the residence time of the heat exchange medium in the internal heat exchange unit;

[0042] Relative to the heater (6), the lower heat exchange unit 2, the middle heat exchange unit 3 and the upper heat exchange unit 4 are conne...

Embodiment 1

[0098] This example is used to illustrate the slurry bed reaction system and the Fischer-Tropsch synthesis reaction method of the present invention.

[0099] use figure 1 In the slurry bed reaction system shown, the Fischer-Tropsch synthesis feed gas (synthesis gas) is introduced from the lower part of the slurry bed reactor 1, and then reacts on the surface of the catalyst in the environment of liquid wax, and the gas produced after the reaction is released from the reactor The top flows out to the downstream for separation, and the heater 6 makes the temperature rise rate of the flowing water 20°C / h; when the temperature in the slurry bed reactor 1 reaches 120°C, the heater 6 is set so that the temperature rise rate of the flowing water 10°C / h; when the temperature in the slurry bed reactor 1 reaches 200°C, set the heater 6 so that the temperature rise rate of the water flowing through it is 5°C / h; when the temperature in the slurry bed reactor 1 reaches 250°C , it is consi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com