Device and method for preparing ethylene glycol through dimethyl oxalate hydrogenation

A technology of dimethyl oxalate and ethylene glycol, which is applied in chemical instruments and methods, bulk chemical production, hydroxyl compound preparation, etc., can solve the problems of catalyst fragmentation, large catalyst loss, shortened catalyst regeneration cycle, etc., and achieve improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

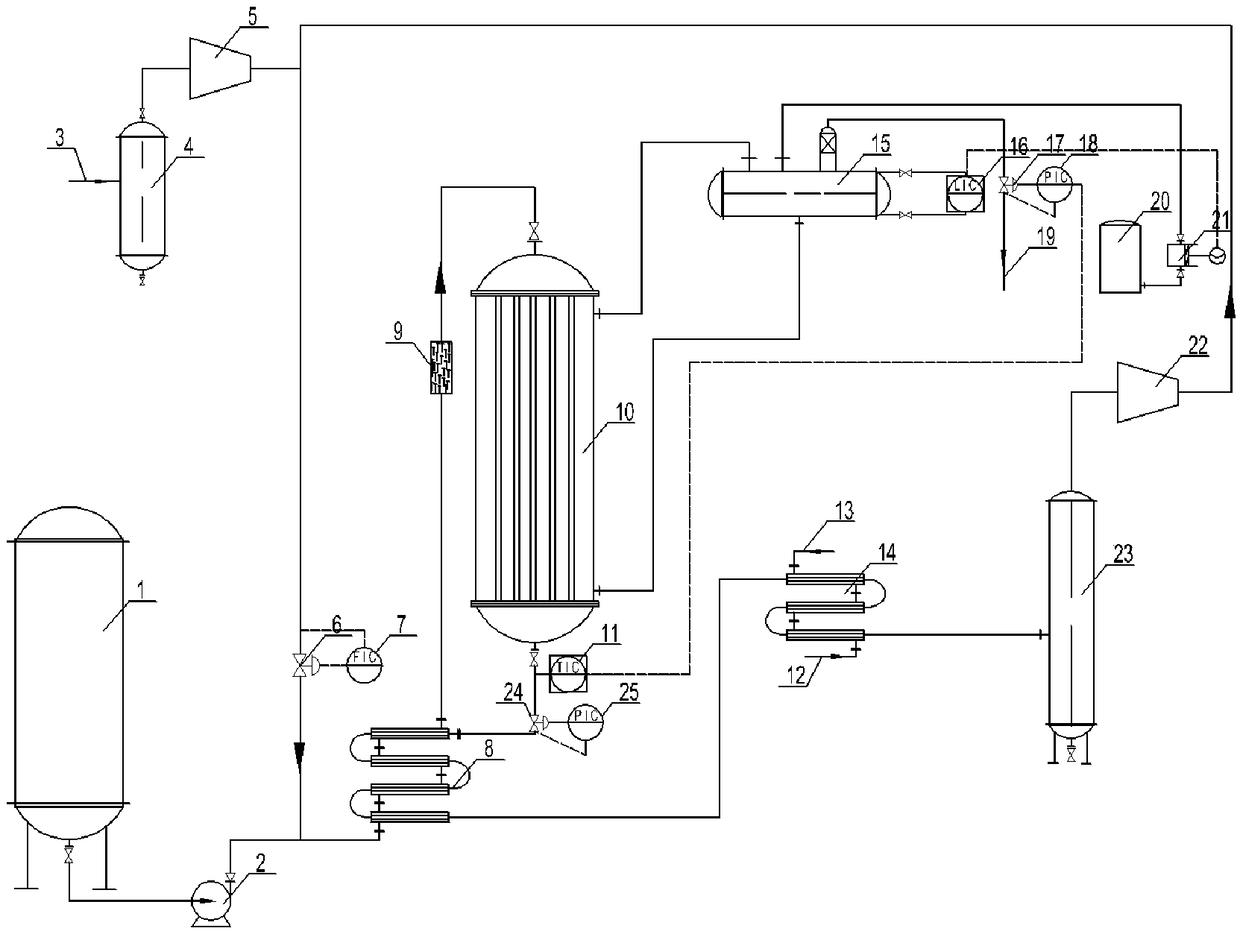

[0038] A device for hydrogenating dimethyl oxalate to ethylene glycol, comprising a gas feeding system, a liquid feeding system, a preheating filtration system, a reaction system, and a condensation separation system;

[0039]The gas feeding system includes a fresh hydrogen circuit and a circulating hydrogen circuit, the fresh hydrogen inlet pipeline 3 is connected to a fresh hydrogen buffer tank 4, and the fresh hydrogen buffer tank 4 is connected to a fresh hydrogen compressor 5;

[0040] The upper end of the gas-liquid separation tank 23 is provided with a circulating outlet, and the circulating outlet is connected to the circulating hydrogen compressor 22;

[0041] The outlet pipeline of the fresh hydrogen compressor 5 and the outlet pipeline of the circulating hydrogen compressor 22 are merged in the main gas line, and the main gas line is provided with a flow transmitter 7 and a flow regulating valve 6 in turn;

[0042] The liquid feeding system includes a dimethyl oxala...

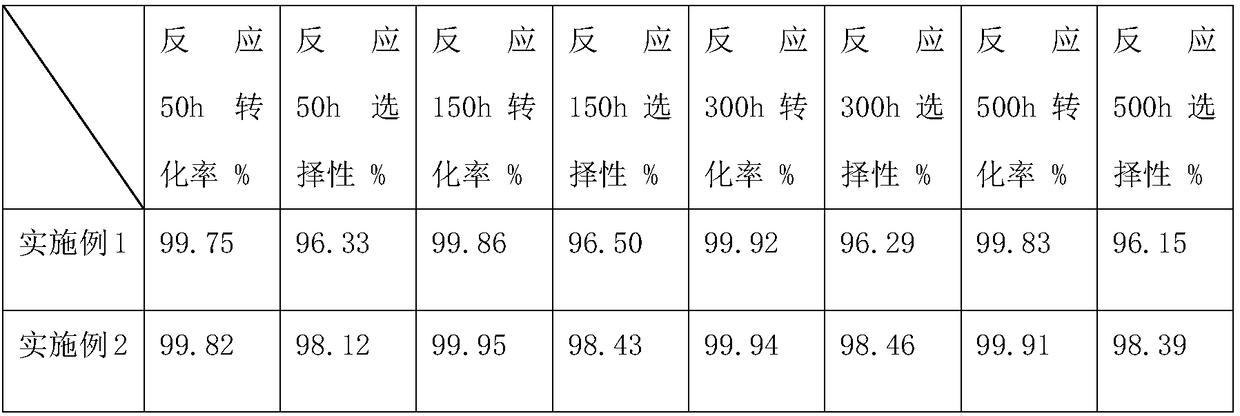

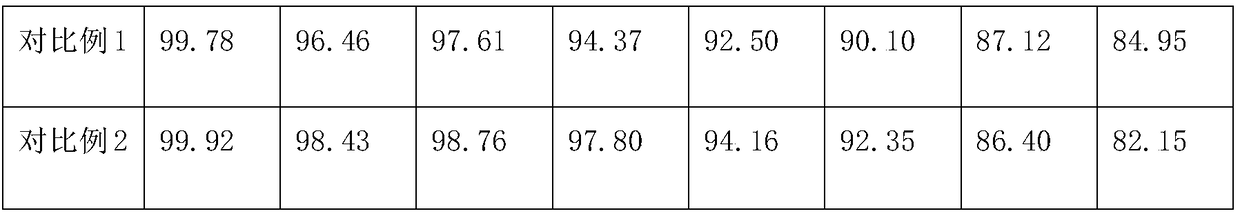

Embodiment 2

[0056] The operation steps are the same as in Example 1, except that catalyst 1 is replaced with catalyst 2, and the specific reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com