Automatic hardware test system

A technology for hardware testing and testing of motherboards, applied in automated testing systems, electronic circuit testing, etc., can solve problems such as multiple discrete instruments and equipment, high testers' dependence, manual judgment, etc., to avoid risks, save manpower, and simplify test models. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

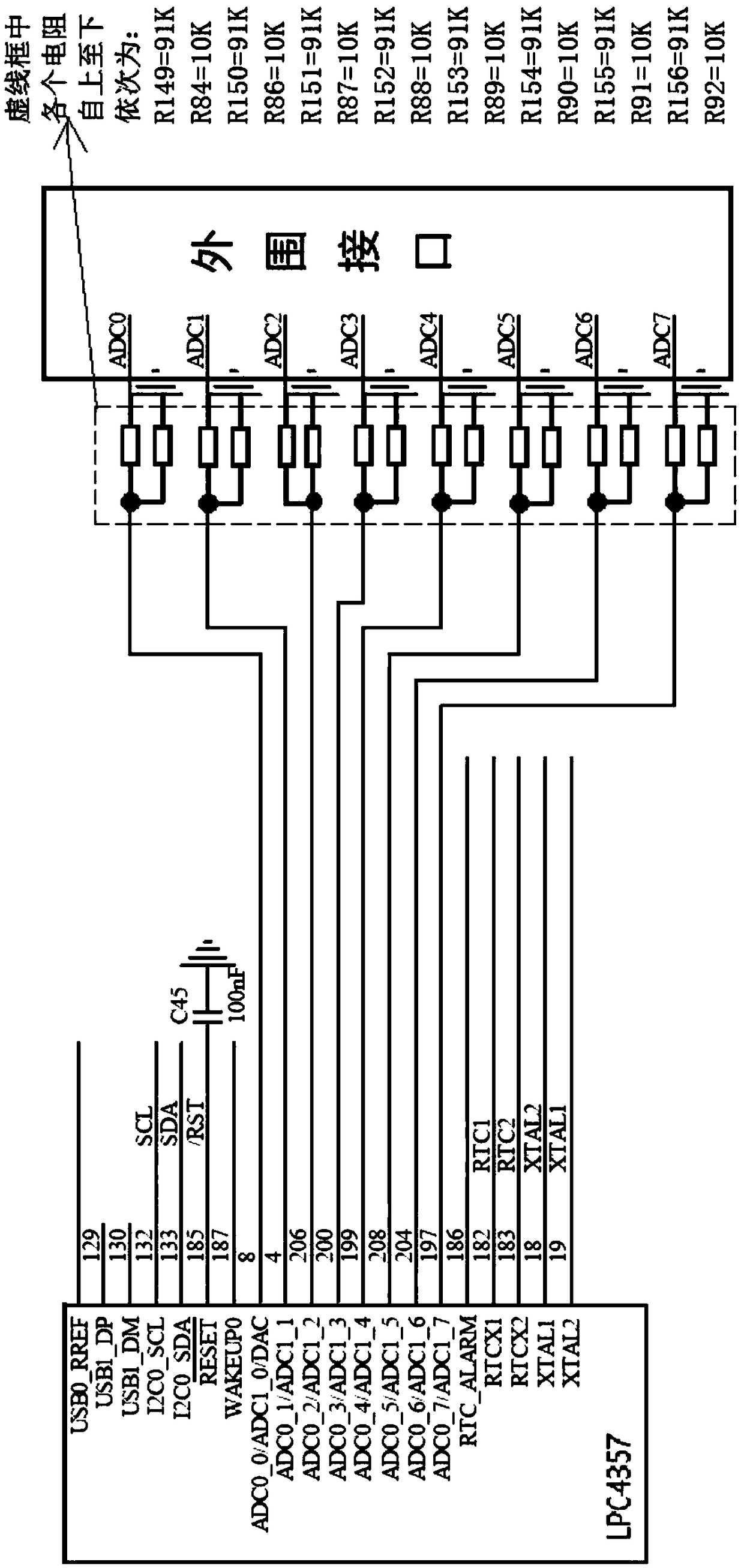

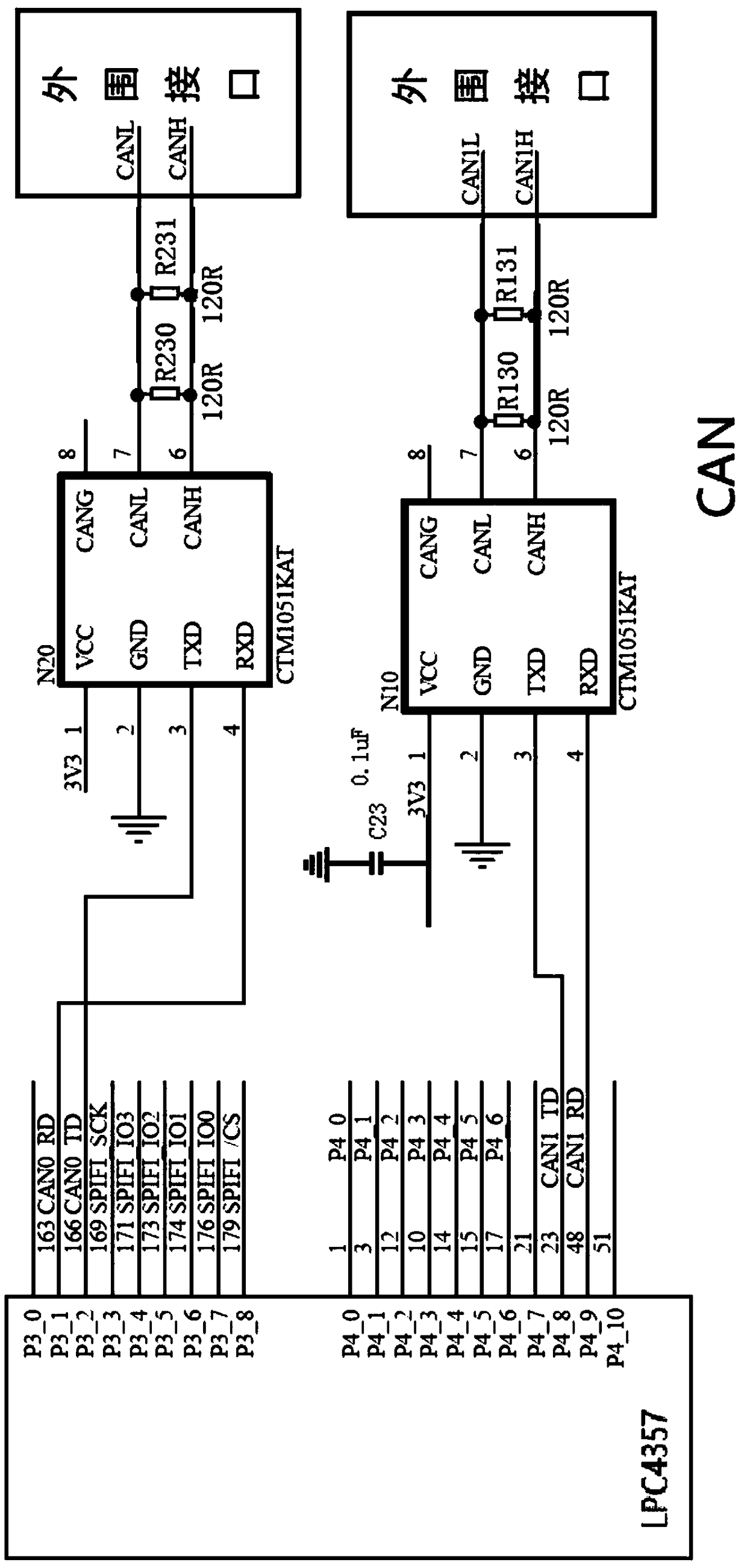

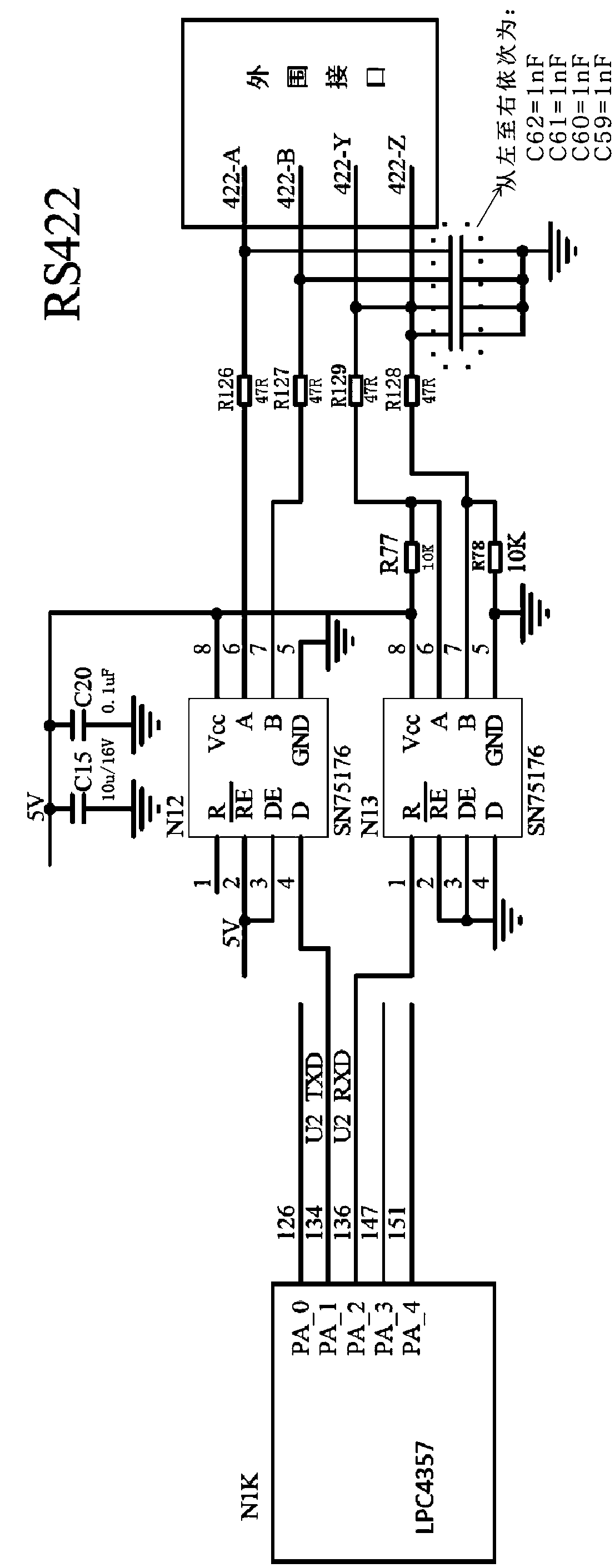

[0034] It mainly includes five parts: computer, power supply, test fixture, test motherboard, and the motherboard to be tested. The power supply is 220V AC input, the highest 30V / 3A DC output adjustable power supply, and the typical output voltage is set to 12V. It can be adjusted according to the power supply voltage of the motherboard under test. The computer configuration requirements are: the main frequency of the processor is above 2GHz, the memory is above 1GB, and the hardware capacity is above 80GB. The typical loading system is Microsoft Windows XP / Windows 7. The interior of the test motherboard is designed around the core processor NXP LPC4357, supplemented by several integrated circuits. The test fixture is a structural fixture specially made for different motherboards to be tested. Its function is to connect the test resources that can be provided on the motherboard to the functional modules that need to be tested on the motherboard to be tested through wiring + p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com