Iron core reactor batch simulation method

A technology of iron core reactor and simulation method, which is applied in the direction of design optimization/simulation, special data processing application, etc., can solve the problems of increasing the risk of simulation error and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

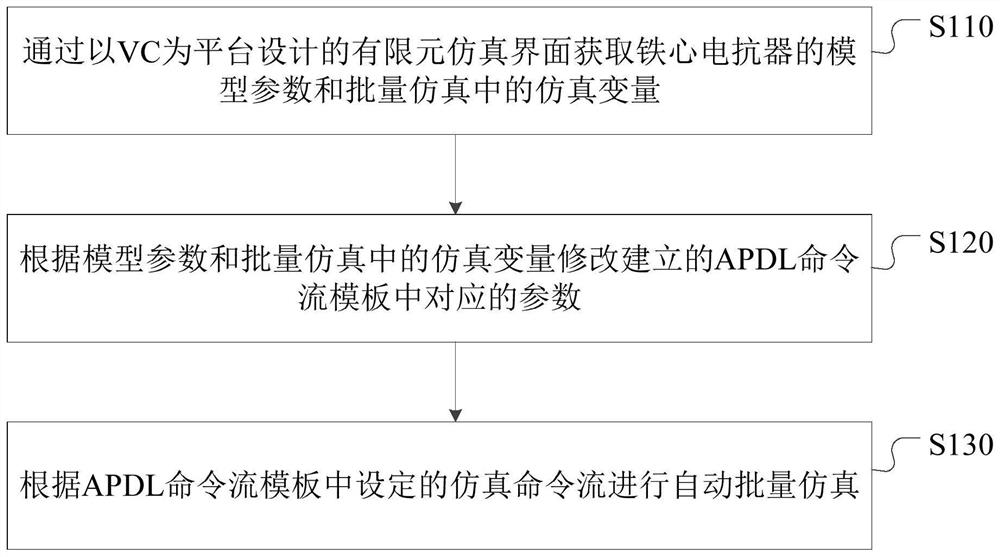

[0057] The embodiment of the present invention provides a method for batch simulation of core reactors, figure 1 It is a flow chart of a batch simulation method for core reactors provided by Embodiment 1 of the present invention, refer to figure 1 , methods include:

[0058] S110. Obtain model parameters of the core reactor and simulation variables in batch simulation through the finite element simulation interface designed on the VC platform.

[0059] Specifically, APDL (ANSYS Parametric Design Language, ANSYS Parametric Design Language) is an embedded development tool of ANSYS. It can realize parametric modeling, parametric loading, parametric solution, and parametric post-processing, so as to realize the whole process of parametric finite element analysis. Based on APDL, various operations such as loops, conditions, and variable definitions can be realized, which is convenient for users to develop special finite element analysis processes, or write small programs for repe...

Embodiment 2

[0066] The embodiment of the present invention provides a method for batch simulation of core reactors. On the basis of the first embodiment above, the embodiment of the present invention provides a method for obtaining model parameters and batches of core reactors through a finite element simulation interface designed on the platform of VC. The simulation variables in the simulation are supplemented and refined.

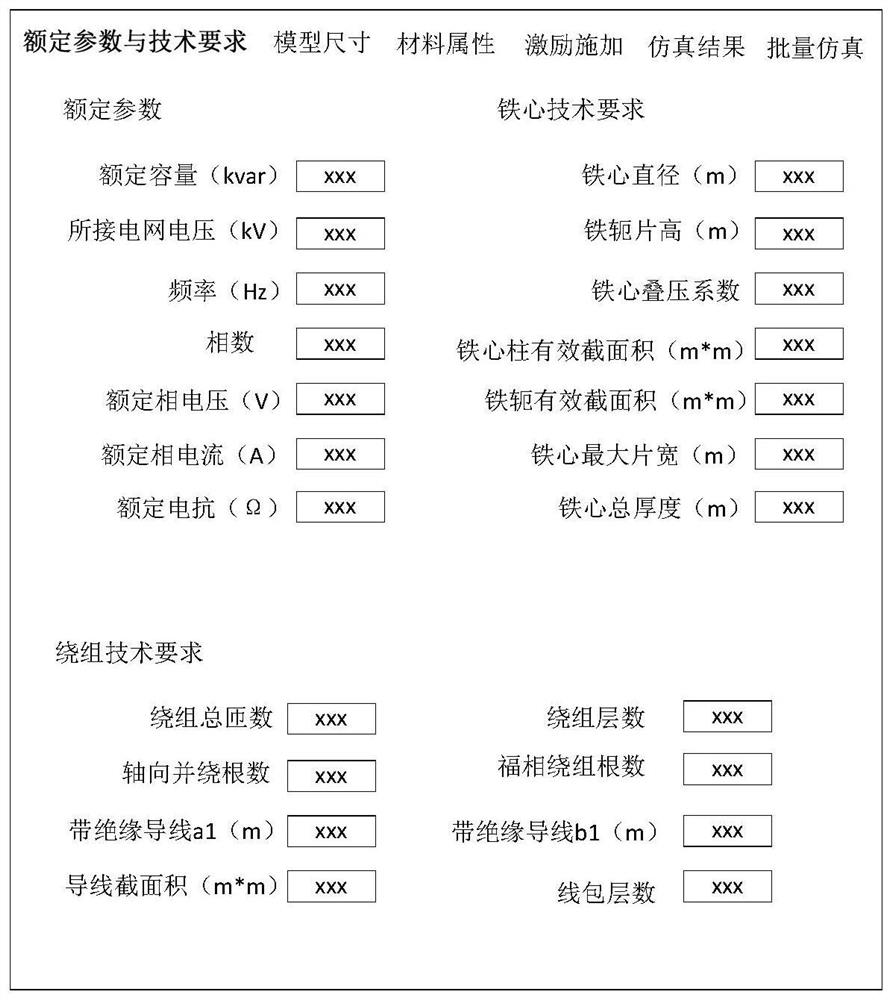

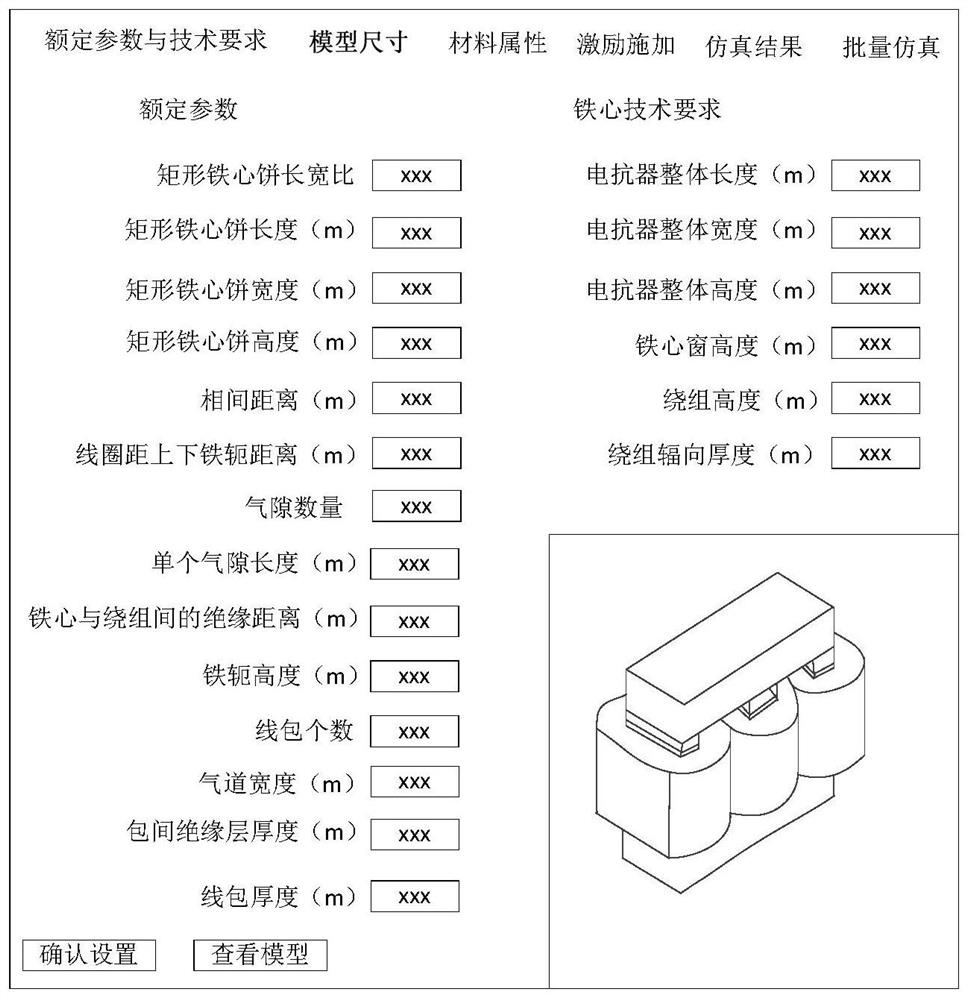

[0067] Optionally, the finite element simulation interface includes the interface of rated parameters and technical requirements, the interface of model size, the interface of material properties, the interface of excitation application, the interface of simulation results and the interface of batch simulation; the core reactance can be obtained through the finite element simulation interface designed on the platform of VC Model parameters of the controller and simulation variables in batch simulation, including:

[0068] Obtain the parameter value corresponding to ...

Embodiment 3

[0089] The embodiment of the present invention provides a method for batch simulation of core reactors. On the basis of the above-mentioned embodiments, the embodiment of the present invention provides an automatic batch simulation of the steps according to the simulation command flow set in the APDL command flow template. complement and refine.

[0090] Optionally, perform automatic batch simulation according to the simulation command flow set in the APDL command flow template, including:

[0091] Establish a parameterized iron core reactor model and determine the body number, and perform body lap according to the body number;

[0092] Add material properties to each component of the core reactor model and divide the grid;

[0093] Set the boundary conditions of the core reactor model solution domain and parameterize the current excitation;

[0094] Perform three-dimensional nonlinear transient magnetic field analysis on the core reactor model and perform post-processing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com