Novel automatic bar replacing device of cotton lapping machine

A lapping machine, automatic technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of heavy workload and high labor intensity, and achieve the effect of accurate movement and automatic bar change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

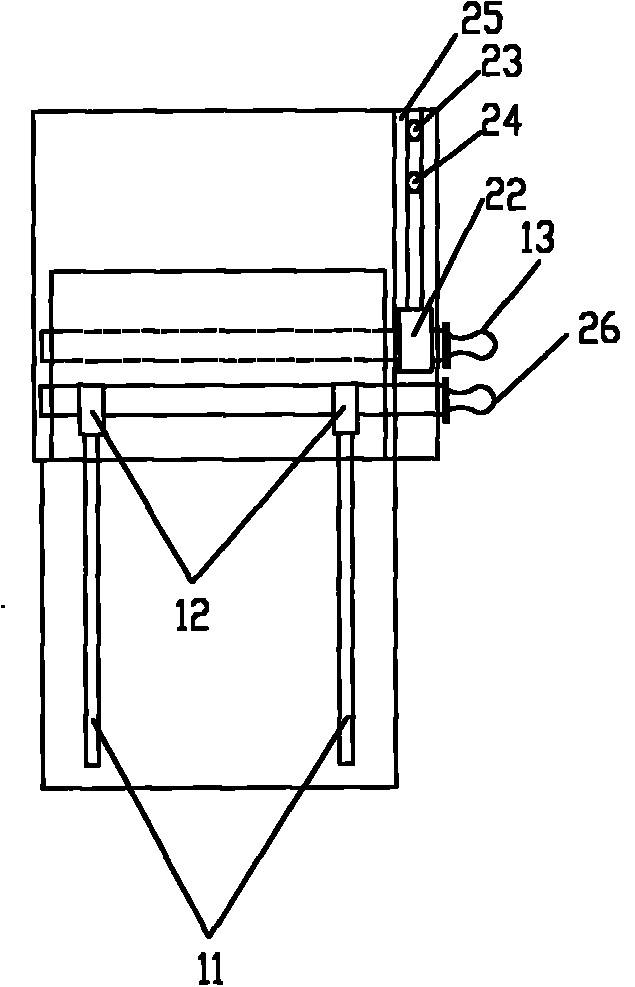

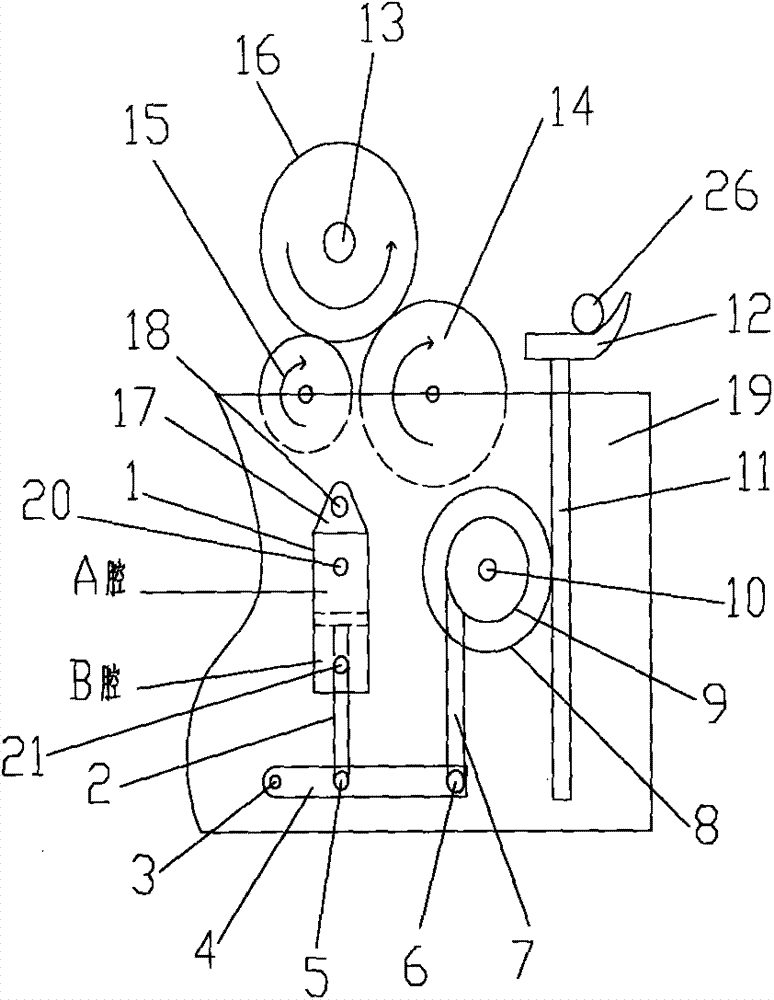

[0007] like figure 1 , 2 As shown, the cylinder body of the cylinder 1 is installed and fixed on the wallboard 19 of the coiler through the mounting seat 17 and the bolt 18; the telescopic shaft 2 of the cylinder is connected with the connecting rod 4 through the pin 5; one end of the connecting rod 4 is installed on the On the wallboard 19, the other end is connected with one end of the chain 7 through the pin shaft 6; the other end of the chain 7 is connected with the sprocket 9, which has a meshing function; The bars are installed side by side in the axial direction, and the sprocket 9 is close to the side of the wallboard 19; the gear 8 is meshed with the rack 11; the rack 11 is connected with the standoff 12; The lap bar 13 is placed between the transmission rollers 14 and 15, and the lap pressing hook 22 presses on one end of the lap bar 13, which has the function of stabilizing the lap bar. The previous process outputs a continuous cotton fiber layer, which passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com